PFERD Tools for Use on Aluminium

PFERD Tools for Use on Aluminium

PFERD Tools for Use on Aluminium

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

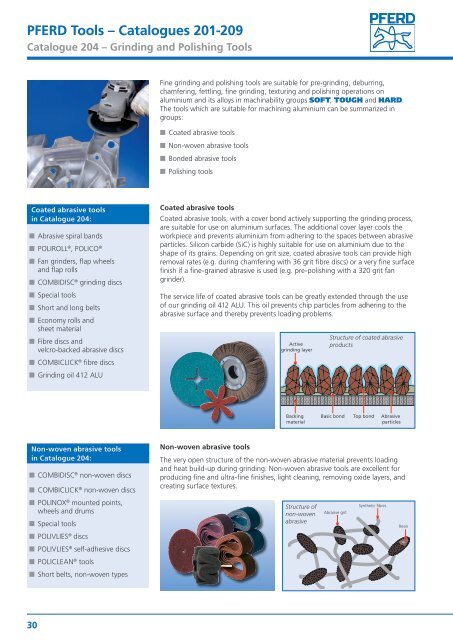

<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> <str<strong>on</strong>g>Tools</str<strong>on</strong>g> – Catalogues 201-209Catalogue 204 – Grinding and Polishing <str<strong>on</strong>g>Tools</str<strong>on</strong>g>Fine grinding and polishing tools are suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> pre-grinding, deburring,chamfering, fettling, fine grinding, texturing and polishing operati<strong>on</strong>s <strong>on</strong>aluminium and its alloys in machinability groups SOFT, TOUGH and harD.The tools which are suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> machining aluminium can be summarized ingroups:■■Coated abrasive tools■■N<strong>on</strong>-woven abrasive tools■■B<strong>on</strong>ded abrasive tools■■Polishing toolsCoated abrasive toolsin Catalogue 204:■■Abrasive spiral bands■■POLIROLL ® , POLICO ®■■Fan grinders, flap wheelsand flap rolls■■COMBIDISC ® grinding discs■■Special tools■■Short and l<strong>on</strong>g belts■■Ec<strong>on</strong>omy rolls andsheet material■■Fibre discs andvelcro-backed abrasive discs■■COMBICLICK ® fibre discs■■Grinding oil 412 ALUCoated abrasive toolsCoated abrasive tools, with a cover b<strong>on</strong>d actively supporting the grinding process,are suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> use <strong>on</strong> aluminium surfaces. The additi<strong>on</strong>al cover layer cools theworkpiece and prevents aluminium from adhering to the spaces between abrasiveparticles. Silic<strong>on</strong> carbide (SiC) is highly suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> use <strong>on</strong> aluminium due to theshape of its grains. Depending <strong>on</strong> grit size, coated abrasive tools can provide highremoval rates (e.g. during chamfering with 36 grit fibre discs) or a very fine surfacefinish if a fine-grained abrasive is used (e.g. pre-polishing with a 320 grit fangrinder).The service life of coated abrasive tools can be greatly extended through the useof our grinding oil 412 ALU. This oil prevents chip particles from adhering to theabrasive surface and thereby prevents loading problems.Activegrinding layerStructure of coated abrasiveproductsBackingmaterialBasic b<strong>on</strong>d Top b<strong>on</strong>d AbrasiveparticlesN<strong>on</strong>-woven abrasive toolsin Catalogue 204:■■COMBIDISC ® n<strong>on</strong>-woven discs■■COMBICLICK ® n<strong>on</strong>-woven discs■■POLINOX ® mounted points,wheels and drums■■Special tools■■POLIVLIES ® discs■■POLIVLIES ® self-adhesive discs■■POLICLEAN ® tools■■Short belts, n<strong>on</strong>-woven typesN<strong>on</strong>-woven abrasive toolsThe very open structure of the n<strong>on</strong>-woven abrasive material prevents loadingand heat build-up during grinding. N<strong>on</strong>-woven abrasive tools are excellent <str<strong>on</strong>g>for</str<strong>on</strong>g>producing fine and ultra-fine finishes, light cleaning, removing oxide layers, andcreating surface textures.Structure ofn<strong>on</strong>-wovenabrasiveAbrasive gritSynthetic fibresResin30