PFERD Tools for Use on Aluminium

PFERD Tools for Use on Aluminium

PFERD Tools for Use on Aluminium

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

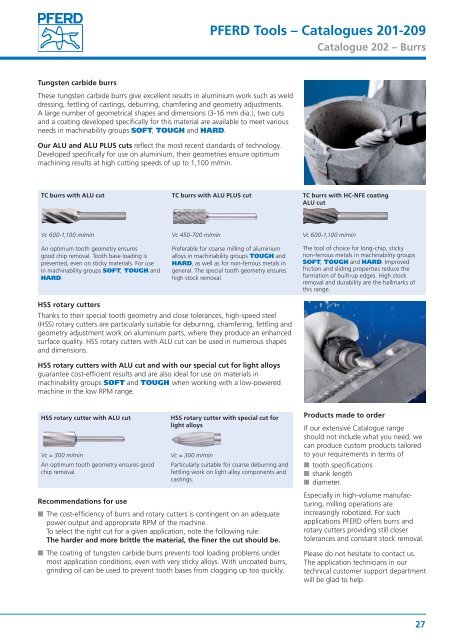

<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> <str<strong>on</strong>g>Tools</str<strong>on</strong>g> – Catalogues 201-209Catalogue 202 – BurrsTungsten carbide burrsThese tungsten carbide burrs give excellent results in aluminium work such as welddressing, fettling of castings, deburring, chamfering and geometry adjustments.A large number of geometrical shapes and dimensi<strong>on</strong>s (3-16 mm dia.), two cutsand a coating developed specifically <str<strong>on</strong>g>for</str<strong>on</strong>g> this material are available to meet variousneeds in machinability groups SOFT, TOUGH and harD.Our ALU and ALU PLUS cuts reflect the most recent standards of technology.Developed specifically <str<strong>on</strong>g>for</str<strong>on</strong>g> use <strong>on</strong> aluminium, their geometries ensure optimummachining results at high cutting speeds of up to 1,100 m/min.TC burrs with ALU cutTC burrs with ALU PLUS cutTC burrs with HC-NFE coatingALU cutVc 600-1,100 m/minAn optimum tooth geometry ensuresgood chip removal. Tooth base loading isprevented, even <strong>on</strong> sticky materials. For usein machinability groups SOFT, TOUGH andharD.Vc 450-700 m/minPreferable <str<strong>on</strong>g>for</str<strong>on</strong>g> coarse milling of aluminiumalloys in machinability groups TOUGH andharD, as well as <str<strong>on</strong>g>for</str<strong>on</strong>g> n<strong>on</strong>-ferrous metals ingeneral. The special tooth geometry ensureshigh stock removal.Vc 600-1,100 m/minThe tool of choice <str<strong>on</strong>g>for</str<strong>on</strong>g> l<strong>on</strong>g-chip, stickyn<strong>on</strong>-ferrous metals in machinability groupsSOFT, TOUGH and harD. Improvedfricti<strong>on</strong> and sliding properties reduce the<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> of built-up edges. High stockremoval and durability are the hallmarks ofthis range.HSS rotary cuttersThanks to their special tooth geometry and close tolerances, high-speed steel(HSS) rotary cutters are particularly suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> deburring, chamfering, fettling andgeometry adjustment work <strong>on</strong> aluminium parts, where they produce an enhancedsurface quality. HSS rotary cutters with ALU cut can be used in numerous shapesand dimensi<strong>on</strong>s.HSS rotary cutters with ALU cut and with our special cut <str<strong>on</strong>g>for</str<strong>on</strong>g> light alloysguarantee cost-efficient results and are also ideal <str<strong>on</strong>g>for</str<strong>on</strong>g> use <strong>on</strong> materials inmachinability groups SOFT and TOUGH when working with a low-poweredmachine in the low RPM range.HSS rotary cutter with ALU cutVc = 300 m/minAn optimum tooth geometry ensures goodchip removal.Recommendati<strong>on</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g> useHSS rotary cutter with special cut <str<strong>on</strong>g>for</str<strong>on</strong>g>light alloysVc = 300 m/minParticularly suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> coarse deburring andfettling work <strong>on</strong> light alloy comp<strong>on</strong>ents andcastings.■■The cost-efficiency of burrs and rotary cutters is c<strong>on</strong>tingent <strong>on</strong> an adequatepower output and appropriate RPM of the machine.To select the right cut <str<strong>on</strong>g>for</str<strong>on</strong>g> a given applicati<strong>on</strong>, note the following rule:The harder and more brittle the material, the finer the cut should be.■■The coating of tungsten carbide burrs prevents tool loading problems undermost applicati<strong>on</strong> c<strong>on</strong>diti<strong>on</strong>s, even with very sticky alloys. With uncoated burrs,grinding oil can be used to prevent tooth bases from clogging up too quickly.Products made to orderIf our extensive Catalogue rangeshould not include what you need, wecan produce custom products tailoredto your requirements in terms of■■tooth specificati<strong>on</strong>s■■shank length■■diameter.Especially in high-volume manufacturing,milling operati<strong>on</strong>s areincreasingly robotized. For suchapplicati<strong>on</strong>s <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> offers burrs androtary cutters providing still closertolerances and c<strong>on</strong>stant stock removal.Please do not hesitate to c<strong>on</strong>tact us.The applicati<strong>on</strong> technicians in ourtechnical customer support departmentwill be glad to help.27