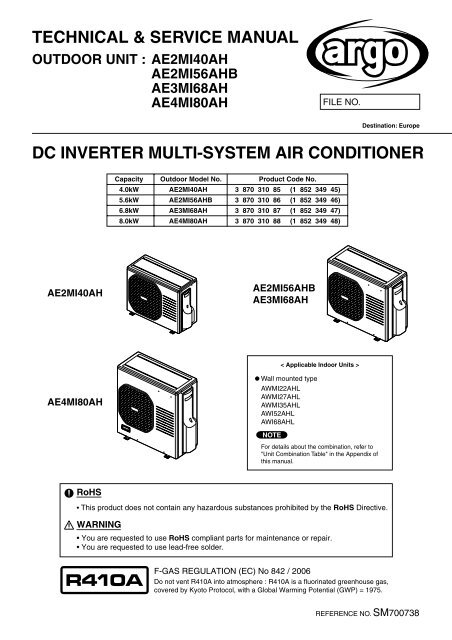

TECHNICAL & SERVICE MANUAL DC INVERTER MULTI-SYSTEM ...

TECHNICAL & SERVICE MANUAL DC INVERTER MULTI-SYSTEM ...

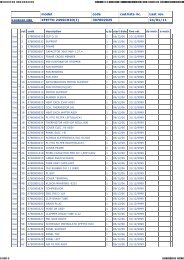

TECHNICAL & SERVICE MANUAL DC INVERTER MULTI-SYSTEM ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1. OPERATING RANGECoolingHeatingTemperature Indoor Air Intake Temp. Outdoor Air Intake Temp.MaximumMinimumMaximumMinimum32 °C D.B. / 23 °C W.B.19 °C D.B. / 14 °C W.B.27 °C D.B.16 °C D.B.43 °C D.B.19 °C D.B.24 °C D.B. / 18 °C W.B._ D.B. / -15 °C W.B.6

Outdoor Unit AE3MI68AHIndoor Unit AWMI27AHL × 3TypeNumber of Connectable Indoor UnitsNumber of Operatable Indoor UnitsMax. Capacity of Operating Indoor UnitsPower SourceVoltage RatingkW4-Room Multi Outdoor Unit4312.2220 to 240V Single-Phase 50Hz230VPerformanceCapacityAir Circulation (High)kWBTU/hm 3 /h6.823,200Cooling( 2.9 to 8.1 )( 9,900 to 27,600 )2,9008.629,300Heating( 3.4 to 9.0 )( 11,600 to 30,700 )2,900Electrical RatingCoolingAvailable Voltage RangeV198 to 264Running AmperesPower InputAW8.872,000Power Factor %98E.E.R. W/W 3.40C.O.P.W/W -Compressor Locked Rotor Amperes A 14.5Heating8.872,00098-4.30Features (Outdoor Unit)ControlMicroprocessorFan SpeedsAuto (Hi, Me, Lo)CompressorRefrigerant / Amount charged at shipmentkg<strong>DC</strong> Twin Rotary (Inverter)R410A / 2.8Refrigerant ControlElectric Expansion ValveOperation Sound Hi dB-A50 52Refrigerant Tubing ConnectionsFlare TypeMax. allowable tubing length per unitm25RefrigerantNarrow tubemm (in.)6.35 (1/4") × 4Tube Diameter Wide tubemm (in.)9.52 (3/8") × 3 + 12.7 (1/2") × 1Dimensions & Weight (Outdoor Unit)Unit DimensionsPackage DimensionsWeightHeight × Width × DepthHeight × Width × DepthShipping VolumeNetShippingmmmmkgkgm 3740 × 900 × 320868 × 1,050 × 42365.069.00.38DATA SUBJECT TO CHANGE WITHOUT NOTICE.Remarks:1. The Values shown in performance section and electrical rating section above are based on the following unit combination.For other combination unit, please refer to the "Unit Combination Tables" in this manual.Indoor Unit : AWMI27AHL 3units Outdoor Unit : AE3MI68AH 1unit2. Rating conditions are: Cooling : Indoor air temp. 27°C D.B. / 19°C W.B. Heating : Indoor air temp. 20°C D.B.Outdoor air temp. 35°C D.B. / 24°C W.B.Outdoor air temp. 7°C D.B. / 6°C W.B.9

Outdoor Unit AE4MI80AHIndoor Unit AWMI27AHL × 4TypeNumber of Connectable Indoor UnitsNumber of Operatable Indoor UnitsMax. Capacity of Operating Indoor UnitsPower SourceVoltage RatingkW4-Room Multi Outdoor Unit4414.7220 to 240V Single-Phase 50Hz230VPerformanceCapacityAir Circulation (High)kWBTU/hm 3 /h8.027,300Cooling( 2.9 to 9.2 )( 9,900 to 31,400 )3,0709.432,100Heating( 3.4 to 9.8 )( 11,600 to 33,400 )3,070Electrical RatingCoolingAvailable Voltage RangeV198 to 264Running AmperesPower InputAW7.581,725Power Factor %99E.E.R. W/W 4.64C.O.P.W/W -Compressor Locked Rotor Amperes A 17.0Heating8.962,04099-4.61Features (Outdoor Unit)ControlMicroprocessorFan SpeedsAuto (Hi, Me, Lo)CompressorRefrigerant / Amount charged at shipmentkg<strong>DC</strong> Twin Rotary (Inverter)R410A / 3.8Refrigerant ControlElectric Expansion ValveOperation Sound Hi dB-A50 52Refrigerant Tubing ConnectionsFlare TypeMax. allowable tubing length per unitm30RefrigerantNarrow tubemm (in.)6.35 (1/4") × 4Tube Diameter Wide tubemm (in.)9.52 (3/8") × 2 + 12.7 (1/2") × 2Dimensions & Weight (Outdoor Unit)Unit DimensionsPackage DimensionsWeightHeight × Width × DepthHeight × Width × DepthShipping VolumeNetShippingmmmmkgkgm 3890 × 900 × 3201,019 × 1,050 × 42382.086.00.45DATA SUBJECT TO CHANGE WITHOUT NOTICE.Remarks:1. The Values shown in performance section and electrical rating section above are based on the following unit combination.For other combination unit, please refer to the "Unit Combination Tables" in this manual.Indoor Unit : AWMI27AHL 4units Outdoor Unit : AE4MI80AH 1unit2. Rating conditions are: Cooling : Indoor air temp. 27°C D.B. / 19°C W.B. Heating : Indoor air temp. 20°C D.B.Outdoor air temp. 35°C D.B. / 24°C W.B.Outdoor air temp. 7°C D.B. / 6°C W.B.10

2-2. Major Component Specifications2-2-1. Outdoor UnitOutdoor UnitAE2MI40AHControl PCBPart No.ControlsControl Circuit FuseCB-CMRV1424EHMicroprocessor250V 25ACompressorTypeCompressor Model / Nominal OutputCompressor Oil ... AmountCoil Resistance (Ambient Temp. 20 °C)ccOhmSafety DeviceCT (Peak current cut-off control)Compressor Discharge Temp. ControlOperation cut-off control in abnormal ambient Temp.Overload RelayModelRun CapacitorCrankcase Heater<strong>DC</strong> Twin Rotary (Hermetic)C-6RVN93H0M / 1,000WFV50S ... 350R - S : 0.482S - T : 0.482T - R : 0.482YesYesYesCS-7L115Operation Temp. Open : 115 °C, Close : 95 °CMicro F-VAC--FanTypeQ'ty ... Dia.mmPropeller1 ... D420Fan MotorTypeModel ... Q'tyNo. of PolesRough Measure RPM (Cool:Hi / Heat:Hi)Nominal OutputCoil Resistance(Ambient Temp. 20 °C)Safety DeviceTypeOver-Current ProtectionRun CapacitorWOhmMicro FVAC<strong>DC</strong> MotorDAJ12-55J71-CR ... 18750 / 75050RED - WHT : 77.5WHT - BLU : 77.5BLU - RED : 77.5Internal ControllerYes--Heat Exchanger CoilCoilRowsFin PitchmmFace Area m 2External FinishAluminum Plate Fin / Copper Tube2130.452Acrylic baked-on enamel finishDATA SUBJECT TO CHANGE WITHOUT NOTICE.11

Outdoor UnitAE2MI56AHBControl PCBPart No.ControlsControl Circuit FuseCB-CMRV1924EHMicroprocessor250V 25ACompressorTypeCompressor Model / Nominal OutputCompressor Oil ... AmountCoil Resistance (Ambient Temp. 20 °C)Safety DeviceCT (Peak current cut-off control)Compressor Discharge Temp. ControlOperation cut-off control in abnormal ambient Temp.Overload RelayModelRun CapacitorCrankcase Heater<strong>DC</strong> Twin Rotary (Hermetic)5KD240XAB21 / 1,700Wcc FV50S ... 900OhmU - V : 0.720V - W : 0.708W - U : 0.726YesYesYesCS-7LN115Operation Temp. Open : 115 °C, Close : 100 °CMicro F-VAC-230V 25WFanTypeQ'ty ... Dia.mmPropeller1 ... D460Fan MotorTypeModel ... Q'tyNo. of PolesRough Measure RPM (Cool:Hi / Heat:Hi)Nominal OutputCoil Resistance(Ambient Temp. 20 °C)Safety DeviceTypeOver-Current ProtectionOver-Heat ProtectionRun CapacitorWOhmMicro FVAC<strong>DC</strong> MotorSIC-71FW-D490-1 ... 18750 / 75090-Internal ControllerYesYes--Heat Exchanger CoilCoilRowsFin PitchmmAluminum Plate Fin / Copper Tube21.4Face Area 0.595m 2External FinishAcrylic baked-on enamel finishDATA SUBJECT TO CHANGE WITHOUT NOTICE.12

Outdoor UnitAE3MI68AHControl PCBPart No.ControlsControl Circuit FuseCB-CMRV2444EHMicroprocessor250V 25ACompressorTypeCompressor Model / Nominal OutputCompressor Oil ... AmountCoil Resistance (Ambient Temp. 20 °C)Safety DeviceCT (Peak current cut-off control)Compressor Discharge Temp. ControlOperation cut-off control in abnormal ambient Temp.Overload RelayModelRun CapacitorCrankcase Heater<strong>DC</strong> Twin Rotary (Hermetic)5KD240XAB21 / 1,700Wcc FV50S ... 900OhmU - V : 0.720V - W : 0.708W - U : 0.726YesYesYesCS-7LN115Operation Temp. Open : 115 °C, Close : 100 °CMicro F-VAC-230V 25WFanTypeQ'ty ... Dia.mmPropeller1 ... D460Fan MotorTypeModel ... Q'tyNo. of PolesRough Measure RPM (Cool:Hi / Heat:Hi)Nominal OutputCoil Resistance(Ambient Temp. 20 °C)Safety DeviceTypeOver-Current ProtectionOver-Heat ProtectionRun CapacitorWOhmMicro FVAC<strong>DC</strong> MotorSIC-71FW-D490-1 ... 18750 / 75090-Internal ControllerYesYes--Heat Exchanger CoilCoilRowsFin PitchmmAluminum Plate Fin / Copper Tube21.4Face Area 0.595m 2External FinishAcrylic baked-on enamel finishDATA SUBJECT TO CHANGE WITHOUT NOTICE.13

Outdoor UnitAE4MI80AHControl PCBPart No.ControlsControl Circuit FuseCB-CMRV3144EHMicroprocessor250V 25ACompressorTypeCompressor Model / Nominal OutputCompressor Oil ... AmountCoil Resistance (Ambient Temp. 20 °C)Safety DeviceCT (Peak current cut-off control)Compressor Discharge Temp. ControlOperation cut-off control in abnormal ambient Temp.Overload RelayModelRun CapacitorCrankcase Heater<strong>DC</strong> Twin Rotary (Hermetic)5JD420XAB22 / 3,000Wcc FV50S ... 1,200OhmU - V : 0.435V - W : 0.441W - U : 0.452YesYesYesCS-7LN115Operation Temp. Open : 115 °C, Close : 100 °CMicro F-VAC-230V 25WFanTypeQ'ty ... Dia.mmPropeller1 ... D460Fan MotorTypeModel ... Q'tyNo. of PolesRough Measure RPM (Cool:Hi / Heat:Hi)Nominal OutputCoil Resistance(Ambient Temp. 20 °C)Safety DeviceTypeOver-Current ProtectionOver-Heat ProtectionRun CapacitorWOhmMicro FVAC<strong>DC</strong> MotorSIC-71FW-D490-1 ... 18750 / 75090-Internal ControllerYesYes--Heat Exchanger CoilCoilRowsFin PitchmmAluminum Plate Fin / Copper Tube21.4Face Area 0.723m 2External FinishAcrylic baked-on enamel finishDATA SUBJECT TO CHANGE WITHOUT NOTICE.14

2-3. Other Component SpecificationsSensor NameModel No.of sensorQuantity of SensorAE2MI40AH AE2MI56AHB AE3MI68AH AE4MI80AHOutdoor air temp sensorTKS295B1111Outdoor heat exchanger sensorTKS292B1111AW / AN sensorTKS292B1/11/11/11/1BW / BN sensorTKS292B1/11/11/11/1CW / CN sensorTKS292B001/11/1DW / DN sensorTKS292B001/11/140Resistance (k ohm)35302520151050-20 -15 -10 -5 0 5 10 15 20Temperature (°C)Sensor NameModel No.of sensorQuantity of SensorAE2MI40AH AE2MI56AHB AE3MI68AH AE4MI80AHCompressor temp sensorTKS293B1 11 1Resistance (k ohm)2001801601401201008060402000 10 20 30 40 50 60 70 80 90Temperature (°C)15

3. DIMENSIONAL DATAOutdoor Unit AE2MI40AH608 852-ID:124-ID:23.629528531033646ID:18Narrow tube service valvedia.6.35 (1/4") × 2790 70Wide tube service valvedia.9.52 (3/8") × 2158 70151227056946142Unit: mm16

Outdoor Unit AE2MI56AHB608 13635293ID:185-ID:23.612320345369Narrow tube service valvedia.6.35 (1/4") × 2900 85Wide tube service valvedia.9.52 (3/8") × 218150 721137574051114Unit: mm17

Outdoor Unit AE3MI68AH608 13635293ID:185-ID:23.612320345369Wide tube service valvedia.12.70 (1/2") × 1Narrow tube service valvedia.6.35 (1/4") × 4900 85Wide tube service valvedia.9.52 (3/8") × 318740150 72 707011375 707051114Unit: mm18

Outdoor Unit AE4MI80AH608 13635293ID:185-ID:23.612320345369Wide tube service valvedia.12.70 (1/2") × 2Narrow tube service valvedia.6.35 (1/4") × 4900 85Wide tube service valvedia.9.52 (3/8") × 218150 73 707011375 707089051114Unit: mm19

4. REFRIGERANT FLOW DIAGRAM4-1. Refrigerant Flow DiagramOutdoor Unit AE2MI40AHIndoor unitOutdoor unitWide tubeO.D.9.52mmO.D.9.52mmService valve onwide tubeBWAWMufflerSubaccumulatorMainaccumulatorCompressor4-wayvalveDefrost valvefor hot gas bypassSHeat exchangerNarrow tubeO.D.6.35mmO.D.6.35mmService valve onnarrow tubeBNANStrainerElectricexpansionvalveMMCapillarytube forsplit flowCooling cycleHeating cycleDefrosting cycleInsulation of Refrigerant TubingIMPORTANTBecause capillary tubing is used in the outdoor unit, both thewide and narrow tubes of this air conditioner become cold. Toprevent heat loss and wet floors due to dripping ofcondensation, both tubes must be well insulated with aproper insulation material. The thickness of the insulationshould be a min. 8 mm.Thickness:Min. 8 mmInsulationThickness:Min. 8 mmCAUTIONAfter a tube has been insulated,never try to bend it into a narrowcurve because it can cause the tubeto break or crack.Wide tubeNarrow tube20

Outdoor UnitAE2MI56AHBIndoor unitOutdoor unitWide tubeO.D.9.52mmO.D.9.52mmService valve onwide tubeBWAWHeaderSubaccumulatorMainaccumulatorCompressor4-wayvalveDefrost valvefor hot gas bypassSHeat exchangerNarrow tubeO.D.6.35mmO.D.6.35mmService valve onnarrow tubeBNANStrainerElectricexpansionvalveMMHeaderCooling cycleHeating cycleDefrosting cycleInsulation of Refrigerant TubingIMPORTANTBecause capillary tubing is used in the outdoor unit, both thewide and narrow tubes of this air conditioner become cold. Toprevent heat loss and wet floors due to dripping ofcondensation, both tubes must be well insulated with aproper insulation material. The thickness of the insulationshould be a min. 8 mm.Thickness:Min. 8 mmInsulationThickness:Min. 8 mmCAUTIONAfter a tube has been insulated,never try to bend it into a narrowcurve because it can cause the tubeto break or crack.Wide tubeNarrow tube21

Outdoor UnitAE3MI68AHIndoor unitOutdoor unitWide tubeO.D.9.52mmO.D.9.52mmO.D.9.52mmO.D.12.7mmService valve onwide tubeDWCWBWAWHeader4-wayvalveSubaccumulatorMainaccumulatorCompressorNarrow tubeO.D.6.35mmO.D.6.35mmO.D.6.35mmO.D.6.35mmService valve onnarrow tubeDNCNBNANStrainerElectricexpansionvalveMMMMHeaderDefrost valvefor hot gas bypassSHeat exchangerCooling cycleHeating cycleDefrosting cycleInsulation of Refrigerant TubingIMPORTANTBecause capillary tubing is used in the outdoor unit, both thewide and narrow tubes of this air conditioner become cold. Toprevent heat loss and wet floors due to dripping ofcondensation, both tubes must be well insulated with aproper insulation material. The thickness of the insulationshould be a min. 8 mm.Thickness:Min. 8 mmInsulationThickness:Min. 8 mmCAUTIONAfter a tube has been insulated,never try to bend it into a narrowcurve because it can cause the tubeto break or crack.Wide tubeNarrow tube22

Outdoor UnitAE4MI80AHIndoor unitOutdoor unitWide tubeO.D.9.52mmO.D.9.52mmO.D.12.7mmO.D.12.7mmService valve onwide tubeDWCWBWAWHeader4-wayvalveSubaccumulatorMainaccumulatorCompressorNarrow tubeO.D.6.35mmO.D.6.35mmO.D.6.35mmO.D.6.35mmService valve onnarrow tubeDNCNBNANStrainerElectricexpansionvalveMMMMHeaderDefrost valvefor hot gas bypassSHeat exchangerCooling cycleHeating cycleDefrosting cycleInsulation of Refrigerant TubingIMPORTANTBecause capillary tubing is used in the outdoor unit, both thewide and narrow tubes of this air conditioner become cold. Toprevent heat loss and wet floors due to dripping ofcondensation, both tubes must be well insulated with aproper insulation material. The thickness of the insulationshould be a min. 8 mm.Thickness:Min. 8 mmInsulationThickness:Min. 8 mmCAUTIONAfter a tube has been insulated,never try to bend it into a narrowcurve because it can cause the tubeto break or crack.Wide tubeNarrow tube23

5. PERFORMANCE DATA5-1. Temperature Charts5-1-1. Temperature Charts (AE2MI40AH)Outdoor Unit AE2MI40AH Indoor Unit AWMI22AHL × 1Cooling Characteristics(RH : 46%, Indoor fan speed : High fan)(230V, 50Hz)Heating Characteristics(RH : 85%, Indoor fan speed : High fan)(230V, 50Hz)(1) Low pressure performance chart (1) High pressure performance chartLow pressure at wide tube service valveMPaG (kgf/cm 2 G)1.6(16.2)1.4(14.2)1.2(12.2)Lo fanHi fanIndoor air temp.30°C27°C24°C1.0(10.2) 1.525 30 35 40(15.3) -5 0 5 10 15 20 25Outdoor air temperature (°C)(2) Operating current performance chart (2) Operating current performance chartHigh pressure at wide tube service valveMPaG (kgf/cm 2 G)3.5(35.7)3.0(30.6)2.5(25.5)2.0(20.4)Indoor air temp.23°C20°C17°COutdoor air temperature (°C)4Lo fanHi fan4Operating current (A)32Indoor air temp.30°C27°C24°COperating current (A)32Indoor air temp.23°C20°C17°C1 125 30 35 40-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(3) Indoor discharge air performance chart (3) Indoor discharge air performance chart2555Indoor discharge air temperature (°C)201510Lo fanHi fanIndoor air temp.30°C27°C24°CIndoor discharge air temperature (°C)504540353025Indoor air temp.23°C20°C17°C52530 35 4020-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)NOTE• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending onthe indoor unit type.• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.(In this case, be sure to stop all the indoor units where performance is not being checked.)• The performance is for a tubing length of 7.5 m. If the tubing length is different, the performance chart will vary.24

Outdoor Unit AE2MI40AH Indoor Unit AWMI27AHL × 1Cooling Characteristics(RH : 46%, Indoor fan speed : High fan)(230V, 50Hz)Heating Characteristics(RH : 85%, Indoor fan speed : High fan)(230V, 50Hz)(1) Low pressure performance chart (1) High pressure performance chartLow pressure at wide tube service valveMPaG (kgf/cm 2 G)1.6(16.2)1.4(14.2)1.2(12.2)1.0(10.2)25Lo fanHi fanIndoor air temp.30°C27°C24°C30 35 40High pressure at wide tube service valveMPaG (kgf/cm 2 G)3.5(35.7)3.0(30.6)2.5(25.5)Indoor air temp.23°C20°C17°C2.0(20.4)-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(2) Operating current performance chart (2) Operating current performance chartOperating current (A)4Lo fan Hi fan32Indoor air temp.30°C27°C24°C30 35 40Outdoor air temperature (°C)Operating current (A)7654Indoor air temp.23°C20°C17°C3-5 0 5 10 15 20 25Outdoor air temperature (°C)(3) Indoor discharge air performance chart (3) Indoor discharge air performance chart2560Indoor discharge air temperature (°C)201510Lo fanHi fanIndoor air temp.30°C27°C24°CIndoor discharge air temperature (°C)555045403530Indoor air temp.23°C20°C17°C52530 35 4025-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)NOTE• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending onthe indoor unit type.• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.(In this case, be sure to stop all the indoor units where performance is not being checked.)• The performance is for a tubing length of 7.5 m. If the tubing length is different, the performance chart will vary.25

Outdoor Unit AE2MI40AH Indoor Unit AWMI35AHL × 1Cooling Characteristics(RH : 46%, Indoor fan speed : High fan)(230V, 50Hz)Heating Characteristics(RH : 85%, Indoor fan speed : High fan)(230V, 50Hz)(1) Low pressure performance chart (1) High pressure performance chartLow pressure at wide tube service valveMPaG (kgf/cm 2 G)1.4(14.2)1.2(12.2)1.0(10.2)0.8(8.2)25Lo fanHi fanIndoor air temp.30°C27°C24°C30 35 40High pressure at wide tube service valveMPaG (kgf/cm 2 G)4.0(40.8)3.5(35.7)3.0(30.6)Indoor air temp.23°C20°C17°C2.5(25.5)-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(2) Operating current performance chart (2) Operating current performance chartOperating current (A)6Lo fan Hi fan54Indoor air temp.30°C27°C24°C30 35 40Outdoor air temperature (°C)Operating current (A)8765Indoor air temp.23°C20°C17°C4-5 0 5 10 15 20 25Outdoor air temperature (°C)(3) Indoor discharge air performance chart (3) Indoor discharge air performance chart2565Indoor discharge air temperature (°C)201510Lo fanHi fanIndoor air temp.30°C27°C24°CIndoor discharge air temperature (°C)605550454035Indoor air temp.23°C20°C17°C52530 35 4030-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)NOTE• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending onthe indoor unit type.• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.(In this case, be sure to stop all the indoor units where performance is not being checked.)• The performance is for a tubing length of 7.5 m. If the tubing length is different, the performance chart will vary.26

5-1-2. Temperature Charts (AE2MI56AHB)Outdoor Unit AE2MI56AHB Indoor Unit AWMI22AHL × 1Cooling Characteristics(RH : 46%, Indoor fan speed : High fan)(230V, 50Hz)Heating Characteristics(RH : 85%, Indoor fan speed : High fan)(230V, 50Hz)(1) Low pressure performance chart (1) High pressure performance chartLow pressure at wide tube service valveMPaG (kgf/cm 2 G)1.3(13.2)1.2(12.2)1.1(11.2)1.0(10.2)25Lo fan Hi fan HH fanIndoor air temp.30°C27°C24°C30 35 40High pressure at wide tube service valveMPaG (kgf/cm 2 G)3.5(35.7)3.0(30.6)2.5(25.5)Indoor air temp.23°C20°C17°C2.0(20.4) -5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(2) Operating current performance chart (2) Operating current performance chartOperating current (A)Lo fan Hi fan HH fan543Indoor air temp.30°C27°C24°C30 35 40Outdoor air temperature (°C)Operating current (A)8765Indoor air temp.23°C20°C17°C-5 0 5 10 15 20 25Outdoor air temperature (°C)(3) Indoor discharge air performance chart (3) Indoor discharge air performance chart60Indoor discharge air temperature (°C)201816141210Lo fan Hi fan HH fanIndoor air temp.30°C27°C24°CIndoor discharge air temperature (°C)555045403530Indoor air temp.23°C20°C17°C82530 35 4025-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)NOTE• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending onthe indoor unit type.• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.(In this case, be sure to stop all the indoor units where performance is not being checked.)• The performance is for a tubing length of 7.5 m. If the tubing length is different, the performance chart will vary.27

Outdoor Unit AE2MI56AHB Indoor Unit AWMI27AHL × 1Cooling Characteristics(RH : 46%, Indoor fan speed : High fan)(230V, 50Hz)Heating Characteristics(RH : 85%, Indoor fan speed : High fan)(230V, 50Hz)(1) Low pressure performance chart (1) High pressure performance chartLow pressure at wide tube service valveMPaG (kgf/cm 2 G)1.3(13.2)1.2(12.2)1.1(11.2)1.0(10.2)25Lo fanHi fanIndoor air temp.30°C27°C24°CHH fan30 35 40High pressure at wide tube service valveMPaG (kgf/cm 2 G)3.5(35.7)3.0(30.6)2.5(25.5)Indoor air temp.23°C20°C17°C2.0(20.4)-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(2) Operating current performance chart (2) Operating current performance chartOperating current (A)Lo fan Hi fan654Indoor air temp.30°C27°C24°C30 35 40Outdoor air temperature (°C)HH fanOperating current (A)8765Indoor air temp.23°C20°C17°C-5 0 5 10 15 20 25Outdoor air temperature (°C)(3) Indoor discharge air performance chart (3) Indoor discharge air performance chart60Indoor discharge air temperature (°C)2018161412Lo fanHi fanIndoor air temp.30°C27°C24°CHH fanIndoor discharge air temperature (°C)555045403530Indoor air temp.23°C20°C17°C102530 35 4025-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)NOTE• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending onthe indoor unit type.• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.(In this case, be sure to stop all the indoor units where performance is not being checked.)• The performance is for a tubing length of 7.5 m. If the tubing length is different, the performance chart will vary.28

Outdoor Unit AE2MI56AHB Indoor Unit AWMI35AHL × 1Cooling Characteristics(RH : 46%, Indoor fan speed : High fan)(230V, 50Hz)Heating Characteristics(RH : 85%, Indoor fan speed : High fan)(230V, 50Hz)(1) Low pressure performance chart (1) High pressure performance chartLow pressure at wide tube service valveMPaG (kgf/cm 2 G)1.2(12.2)1.1(11.2)1.0(10.2)0.9(9.2)25Lo fanHi fanIndoor air temp.30°C27°C24°C30 35 40Outdoor air temperature (°C)HH fan-5 0 5 10 15 20 25Outdoor air temperature (°C)(2) Operating current performance chart (2) Operating current performance chartHigh pressure at wide tube service valveMPaG (kgf/cm 2 G)4.0(40.8)3.5(35.7)3.0(30.6)2.5(25.5)Indoor air temp.23°C20°C17°COperating current (A)Lo fan Hi fan654Indoor air temp.30°C27°C24°C30 35 40Outdoor air temperature (°C)HH fanOperating current (A)10987654Indoor air temp.23°C20°C17°C3-5 0 5 10 15 20 25Outdoor air temperature (°C)(3) Indoor discharge air performance chart (3) Indoor discharge air performance chart60Indoor discharge air temperature (°C)201816141210Lo fanHi fanIndoor air temp.30°C27°C24°CHH fanIndoor discharge air temperature (°C)55504540353020°CIndoor air temp.23°C17°C82530 35 4025-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)NOTE• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending onthe indoor unit type.• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.(In this case, be sure to stop all the indoor units where performance is not being checked.)• The performance is for a tubing length of 7.5 m. If the tubing length is different, the performance chart will vary.29

Outdoor Unit AE2MI56AHB Indoor Unit AWI52AHL × 1Cooling Characteristics(RH : 46%, Indoor fan speed : High fan)(230V, 50Hz)Heating Characteristics(RH : 85%, Indoor fan speed : High fan)(230V, 50Hz)(1) Low pressure performance chart (1) High pressure performance chartLow pressure at wide tube service valveMPaG (kgf/cm 2 G)1.2(12.2)1.1(11.2)1.0(10.2)0.9(9.2)25Lo fanHi fanIndoor air temp.30°C27°C24°CHH fan30 35 40High pressure at wide tube service valveMPaG (kgf/cm 2 G)4.0(40.8)3.5(35.7)3.0(30.6)Indoor air temp.23°C20°C17°C2.5(25.5) -5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(2) Operating current performance chart (2) Operating current performance chart8Lo fanHi fanHH fan12Operating current (A)76Indoor air temp.30°C27°C24°COperating current (A)111098Indoor air temp.23°C20°C17°C572530 35 40Outdoor air temperature (°C)6-5 0 5 10 15 20 25Outdoor air temperature (°C)(3) Indoor discharge air performance chart (3) Indoor discharge air performance chartIndoor discharge air temperature (°C)201816141210Lo fanHi fanIndoor air temp.30°C27°C24°CHH fanIndoor discharge air temperature (°C)605550454035Indoor air temp.23°C20°C17°C82530 35 4030-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)NOTE• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending onthe indoor unit type.• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.(In this case, be sure to stop all the indoor units where performance is not being checked.)• The performance is for a tubing length of 7.5 m. If the tubing length is different, the performance chart will vary.30

5-1-3. Temperature Charts (AE3MI68AH)Outdoor Unit AE3MI68AH Indoor Unit AWMI22AHL × 1Cooling Characteristics(RH : 46%, Indoor fan speed : High fan)(230V, 50Hz)Heating Characteristics(RH : 85%, Indoor fan speed : High fan)(230V, 50Hz)(1) Low pressure performance chart (1) High pressure performance chartLow pressure at wide tube service valveMPaG (kgf/cm 2 G)1.3(13.2)1.2(12.2)1.1(11.2)1.0(10.2)25Lo fan Hi fan HH fanIndoor air temp.30°C27°C24°C30 35 40High pressure at wide tube service valveMPaG (kgf/cm 2 G)3.5(35.7)3.0(30.6)2.5(25.5)Indoor air temp.23°C20°C17°C2.0(20.4) -5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(2) Operating current performance chart (2) Operating current performance chartOperating current (A)Lo fan Hi fan HH fan543Indoor air temp.30°C27°C24°C30 35 40Outdoor air temperature (°C)Operating current (A)8765Indoor air temp.23°C20°C17°C-5 0 5 10 15 20 25Outdoor air temperature (°C)(3) Indoor discharge air performance chart (3) Indoor discharge air performance chart60Indoor discharge air temperature (°C)201816141210Lo fan Hi fan HH fanIndoor air temp.30°C27°C24°CIndoor discharge air temperature (°C)555045403530Indoor air temp.23°C20°C17°C82530 35 4025-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)NOTE• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending onthe indoor unit type.• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.(In this case, be sure to stop all the indoor units where performance is not being checked.)• The performance is for a tubing length of 7.5 m. If the tubing length is different, the performance chart will vary.31

Outdoor Unit AE3MI68AH Indoor Unit AWMI27AHL × 1Cooling Characteristics(RH : 46%, Indoor fan speed : High fan)(230V, 50Hz)Heating Characteristics(RH : 85%, Indoor fan speed : High fan)(230V, 50Hz)(1) Low pressure performance chart (1) High pressure performance chartLow pressure at wide tube service valveMPaG (kgf/cm 2 G)1.3(13.2)1.2(12.2)1.1(11.2)1.0(10.2)25Lo fanHi fanIndoor air temp.30°C27°C24°CHH fan30 35 40High pressure at wide tube service valveMPaG (kgf/cm 2 G)3.5(35.7)3.0(30.6)2.5(25.5)Indoor air temp.23°C20°C17°C2.0(20.4)-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(2) Operating current performance chart (2) Operating current performance chartOperating current (A)Lo fan Hi fan654Indoor air temp.30°C27°C24°C30 35 40Outdoor air temperature (°C)HH fanOperating current (A)8765Indoor air temp.23°C20°C17°C-5 0 5 10 15 20 25Outdoor air temperature (°C)(3) Indoor discharge air performance chart (3) Indoor discharge air performance chart60Indoor discharge air temperature (°C)2018161412Lo fanHi fanIndoor air temp.30°C27°C24°CHH fanIndoor discharge air temperature (°C)555045403530Indoor air temp.23°C20°C17°C102530 35 4025-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)NOTE• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending onthe indoor unit type.• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.(In this case, be sure to stop all the indoor units where performance is not being checked.)• The performance is for a tubing length of 7.5 m. If the tubing length is different, the performance chart will vary.32

Outdoor Unit AE3MI68AH Indoor Unit AWMI35AHL × 1Cooling Characteristics(RH : 46%, Indoor fan speed : High fan)(230V, 50Hz)Heating Characteristics(RH : 85%, Indoor fan speed : High fan)(230V, 50Hz)(1) Low pressure performance chart (1) High pressure performance chartLow pressure at wide tube service valveMPaG (kgf/cm 2 G)1.2(12.2)1.1(11.2)1.0(10.2)0.9(9.2)25Lo fanHi fanIndoor air temp.30°C27°C24°C30 35 40Outdoor air temperature (°C)HH fan-5 0 5 10 15 20 25Outdoor air temperature (°C)(2) Operating current performance chart (2) Operating current performance chartHigh pressure at wide tube service valveMPaG (kgf/cm 2 G)4.0(40.8)3.5(35.7)3.0(30.6)2.5(25.5)Indoor air temp.23°C20°C17°COperating current (A)Lo fan Hi fan654Indoor air temp.30°C27°C24°C30 35 40Outdoor air temperature (°C)HH fanOperating current (A)10987654Indoor air temp.23°C20°C17°C3-5 0 5 10 15 20 25Outdoor air temperature (°C)(3) Indoor discharge air performance chart (3) Indoor discharge air performance chart60Indoor discharge air temperature (°C)201816141210Lo fanHi fanIndoor air temp.30°C27°C24°CHH fanIndoor discharge air temperature (°C)55504540353020°CIndoor air temp.23°C17°C82530 35 4025-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)NOTE• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending onthe indoor unit type.• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.(In this case, be sure to stop all the indoor units where performance is not being checked.)• The performance is for a tubing length of 7.5 m. If the tubing length is different, the performance chart will vary.33

Outdoor Unit AE3MI68AH Indoor Unit AWI52AHL × 1Cooling Characteristics(RH : 46%, Indoor fan speed : High fan)(230V, 50Hz)Heating Characteristics(RH : 85%, Indoor fan speed : High fan)(230V, 50Hz)(1) Low pressure performance chart (1) High pressure performance chartLow pressure at wide tube service valveMPaG (kgf/cm 2 G)1.2(12.2)1.1(11.2)1.0(10.2)0.9(9.2)25Lo fanHi fanIndoor air temp.30°C27°C24°CHH fan30 35 40High pressure at wide tube service valveMPaG (kgf/cm 2 G)4.0(40.8)3.5(35.7)3.0(30.6)Indoor air temp.23°C20°C17°C2.5(25.5) -5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(2) Operating current performance chart (2) Operating current performance chart8Lo fanHi fanHH fan12Operating current (A)76Indoor air temp.30°C27°C24°COperating current (A)111098Indoor air temp.23°C20°C17°C572530 35 40Outdoor air temperature (°C)6-5 0 5 10 15 20 25Outdoor air temperature (°C)(3) Indoor discharge air performance chart (3) Indoor discharge air performance chartIndoor discharge air temperature (°C)201816141210Lo fanHi fanIndoor air temp.30°C27°C24°CHH fanIndoor discharge air temperature (°C)605550454035Indoor air temp.23°C20°C17°C82530 35 4030-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)NOTE• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending onthe indoor unit type.• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.(In this case, be sure to stop all the indoor units where performance is not being checked.)• The performance is for a tubing length of 7.5 m. If the tubing length is different, the performance chart will vary.34

5-1-4. Temperature Charts (AE4MI80AH)Outdoor Unit AE4MI80AH Indoor Unit AWMI22AHL × 1Cooling Characteristics(RH : 46%, Indoor fan speed : High fan)(230V, 50Hz)Heating Characteristics(RH : 85%, Indoor fan speed : High fan)(230V, 50Hz)(1) Low pressure performance chart (1) High pressure performance chartLow pressure at wide tube service valveMPaG (kgf/cm 2 G)1.2(12.2)1.0(10.2)0.8(8.2)0.6(6.2)25Lo fan Hi fan Hi fan HH fanIndoor air temp.30°C27°C24°C30 35 40High pressure at wide tube service valveMPaG (kgf/cm 2 G)3.5(35.7)3.0(30.6)2.5(25.5)2.0(20.4)20°CIndoor air temp.23°C17°C1.5(15.3) -5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(2) Operating current performance chart (2) Operating current performance chart5Lo fan Hi fan Hi fan HH fan9Operating current (A)4Indoor air temp.30°C27°C24°COperating current (A)87620°CIndoor air temp.23°C17°C53 425 30 35 40-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(3) Indoor discharge air performance chart (3) Indoor discharge air performance chartIndoor discharge air temperature (°C)25201510525Lo fan Hi fan Hi fan HH fanIndoor air temp.30°C27°C24°C30 35 40Outdoor air temperature (°C)Indoor discharge air temperature (°C)55504540353025Indoor air temp.23°C20°C17°C20-5 0 5 10 15 20 25Outdoor air temperature (°C)NOTE• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending onthe indoor unit type.• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.(In this case, be sure to stop all the indoor units where performance is not being checked.)• The performance is for a tubing length of 7.5 m. If the tubing length is different, the performance chart will vary.36

Outdoor Unit AE4MI80AH Indoor Unit AWMI27AHL × 1Cooling Characteristics(RH : 46%, Indoor fan speed : High fan)(230V, 50Hz)Heating Characteristics(RH : 85%, Indoor fan speed : High fan)(230V, 50Hz)(1) Low pressure performance chart (1) High pressure performance chartLow pressure at wide tube service valveMPaG (kgf/cm 2 G)1.2(12.2)1.0(10.2)0.8(8.2)0.6(6.2)25Lo fan Hi fan Hi fan HH fanIndoor air temp.30°C27°C24°C30 35 40High pressure at wide tube service valveMPaG (kgf/cm 2 G)3.5(35.7)3.0(30.6)2.5(25.5)2.0(20.4)20°CIndoor air temp.23°C17°C1.5(15.3) -5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(2) Operating current performance chart (2) Operating current performance chartOperating current (A)54Lo fan Hi fan Hi fan HH fanIndoor air temp.30°C27°C24°COperating current (A)876520°CIndoor air temp.23°C17°C3 425 30 35 40-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(3) Indoor discharge air performance chart (3) Indoor discharge air performance chartIndoor discharge air temperature (°C)25201510525Lo fan Hi fan Hi fan HH fanIndoor air temp.30°C27°C24°C30 35 40Outdoor air temperature (°C)Indoor discharge air temperature (°C)55504520°CIndoor air temp.23°C17°C4035302520-5 0 5 10 15 20 25Outdoor air temperature (°C)NOTE• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending onthe indoor unit type.• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.(In this case, be sure to stop all the indoor units where performance is not being checked.)• The performance is for a tubing length of 7.5 m. If the tubing length is different, the performance chart will vary.37

Outdoor Unit AE4MI80AH Indoor Unit AWMI35AHL × 1Cooling Characteristics(RH : 46%, Indoor fan speed : High fan)(230V, 50Hz)Heating Characteristics(RH : 85%, Indoor fan speed : High fan)(230V, 50Hz)(1) Low pressure performance chart (1) High pressure performance chartLow pressure at wide tube service valveMPaG (kgf/cm 2 G)1.2(12.2)1.0(10.2)0.8(8.2)0.6(6.2)25Lo fan Hi fan Hi fan HH fanIndoor air temp.30°C27°C24°C30 35 40High pressure at wide tube service valveMPaG (kgf/cm 2 G)3.5(35.7)3.0(30.6)2.5(25.5)2.0(20.4)Indoor air temp.23°C20°C17°C1.5(15.3) -5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(2) Operating current performance chart (2) Operating current performance chartOperating current (A)654Lo fan Hi fan Hi fan HH fan27°CIndoor air temp.30°C24°COperating current (A)13121110920°C 20°CIndoor air air temp.23°C temp.23°C17°C83 725 30 35 40-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(3) Indoor discharge air performance chart (3) Indoor discharge air performance chartIndoor discharge air temperature (°C)25201510525Lo fan Hi fan Hi fan HH fanIndoor air temp.30°C27°C24°C30 35 40Outdoor air temperature (°C)Indoor discharge air temperature (°C)55504540353025Indoor air temp.23°C20°C17°C20-5 0 5 10 15 20 25Outdoor air temperature (°C)NOTE• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending onthe indoor unit type.• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.(In this case, be sure to stop all the indoor units where performance is not being checked.)• The performance is for a tubing length of 7.5 m. If the tubing length is different, the performance chart will vary.38

Outdoor Unit AE4MI80AH Indoor Unit AWI52AHL × 1Cooling Characteristics(RH : 46%, Indoor fan speed : High fan)(230V, 50Hz)Heating Characteristics(RH : 85%, Indoor fan speed : High fan)(230V, 50Hz)(1) Low pressure performance chart (1) High pressure performance chartLow pressure at wide tube service valveMPaG (kgf/cm 2 G)1.2(12.2)1.0(10.2)0.8(8.2)0.6(6.2)25Lo fanIndoor air temp.30°C27°C24°CHi fan30 35 40High pressure at wide tube service valveMPaG (kgf/cm 2 G)3.5(35.7)3.0(30.6)2.5(25.5)2.0(20.4)Indoor air temp.23°C20°C17°C1.5(15.3) -5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(2) Operating current performance chart (2) Operating current performance chartOperating current (A)98765Lo fan27°CIndoor air temp.30°C24°CHi fanOperating current (A)14131220°C 20°CIndoor Indoor air temp.23°C temp.23°C17°C4 1125 30 35 40-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(3) Indoor discharge air performance chart (3) Indoor discharge air performance chartIndoor discharge air temperature (°C)25201510525Lo fanIndoor air temp.30°C27°C24°C30 35 40Outdoor air temperature (°C)Hi fanIndoor discharge air temperature (°C)60555045403530Indoor air temp.23°C20°C17°C25-5 0 5 10 15 20 25Outdoor air temperature (°C)NOTE• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending onthe indoor unit type.• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.(In this case, be sure to stop all the indoor units where performance is not being checked.)• The performance is for a tubing length of 7.5 m. If the tubing length is different, the performance chart will vary.39

Outdoor Unit AE4MI80AH Indoor Unit AWI68AHL × 1Cooling Characteristics(RH : 46%, Indoor fan speed : High fan)(230V, 50Hz)Heating Characteristics(RH : 85%, Indoor fan speed : High fan)(230V, 50Hz)(1) Low pressure performance chart (1) High pressure performance chartLow pressure at wide tube service valveMPaG (kgf/cm 2 G)1.2(12.2)1.0(10.2)0.8(8.2)0.6(6.2)25Lo fanIndoor air temp.30°C27°C24°CHi fan30 35 40High pressure at wide tube service valveMPaG (kgf/cm 2 G)3.5(35.7)3.0(30.6)2.5(25.5)2.0(20.4)Indoor air temp.23°C20°C17°C1.5(15.3) -5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(2) Operating current performance chart (2) Operating current performance chartOperating current (A)1211109Lo fan27°CIndoor air temp.30°C24°CHi fanOperating current (A)14131220°C 20°CIndoor Indoor air temp.23°C temp.23°C17°C81125 30 35 40-5 0 5 10 15 20 25Outdoor air temperature (°C)Outdoor air temperature (°C)(3) Indoor discharge air performance chart (3) Indoor discharge air performance chartIndoor discharge air temperature (°C)25201510525Lo fanIndoor air temp.30°C27°C24°C30 35 40Outdoor air temperature (°C)Hi fanIndoor discharge air temperature (°C)60555045403530Indoor air temp.23°C20°C17°C25-5 0 5 10 15 20 25Outdoor air temperature (°C)NOTE• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending onthe indoor unit type.• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.(In this case, be sure to stop all the indoor units where performance is not being checked.)• The performance is for a tubing length of 7.5 m. If the tubing length is different, the performance chart will vary.40

6. ELECTRICAL DATA6-1. Electric Wiring DiagramsOutdoor Unit AE2MI40AHWARNINGTo avoid electrical shock hazard, be sure todisconnect power before checking, servicingand/or cleaning any electrical parts.CONTROLLERREACTANCECOMPRESSORTHERMISTORBLKBLK(4P) CONNECTORWHTCOILTHERMISTOROUTDOORTHERMISTOR(7P) CONNECTORWHT WHTYELBLUREDBLK(5P) CONNECTORORG ORGRED REDYEL YELBLK BLKGRY GRYREDN LPOWERSUPPLYB INDDORUNITA INDDORUNITTO INDDOR UNITWHT12(2P) CONNECTORRED(2P) CONNECTOR12BLKBLKWHTWHT121 2 3 4COIL/OUTDOORCOMPMV0MAGNETIC COILBLKWHTBLKTERMINALPLATE12345678GNDYELYELBLKBLKYELYELBLKBLK112233441 2 3 4A-TH(4P) CONNECTORREDAW THERMISTORYELYELYELYELYELYELYELYELAN THERMISTOR(4P) CONNECTORBLUYELYELYELYELBW THERMISTORYELYELYELYELBN THERMISTOR11223344COILDEFROST VALVEDEF112233441 2 3 4 W WB-THDEF1 DEF0MV01 2 3 4 511223344551122334455BLKBLK(2P) CONNECTORBLKBLUBLUBLKBLK(2P) CONNECTORWHTBLUBLU2211COIL4WAY VALVERV2211W WRV1 RV0MAGNETIC COILW W W WL2 L1 E-2 E-1(5P) CONNECTORORG ORGRED REDYEL YELBLK BLKGRY GRYBLUCN04 <strong>DC</strong>FM1 2 3 4 5 6 71 2 3 4 5 6 7FAN MOTORMV11 2 3 4 511223344551122334455MV1WHTBLKREDBLUYELWHTWHT(2P) CONNECTORWHTGRN/YELGRN/YELWHTWHTGRN/YEL(OLR)OVERLOAD RELAYWHTWHT1 12 2WWOLR0OLR1UWVWWWCOMPRESSORMOTORCMCSRGRN/YELRED (PNK)WHTBLUFERRITECORE(3P)CONNECTOR1 12 23 3WHTRED (PNK)WHTBLU1234567FM2211W WE ACIN1W25AACIN2BLKWHTSI-A W REDSI-B W BLUREACTANCE BLKWHT418FA2-5257-56900-2

Outdoor UnitAE2MI56AHBWARNINGTo avoid electrical shock hazard, be sure todisconnect power before checking, servicingand/or cleaning any electrical parts.1 2 3 4 5 1 2 3 4 5ORGREDYELBLKGRYN LPOWERSUPPLYB INDDORUNITA INDDORUNITTO INDDOR UNITREACTANCECONTROLLERHEATERCRANKCASEWHT(2P) CONNECTOR1122MV0MAGNETIC COIL334455REACTANCEBLKWHTREDBLUBLKBLKBLKWHTWHTTERMINALPLATE12345678GNDREDORGWHTBRNBLUREDORGWHTBRNBLU12345671 2 3 4 5 6 7(3P) CONNECTORFERRITECORES/UC/WFMR/VWHTCMFAN MOTORCOMPRESSORMOTORFERRITECORECOMPRESSORTHERMISTORBLKBLKRED (PNK)WHTBLUWHTWHTWHTWHTBLUWHTRED (PNK)WHTWHT1 2 3 41 2 3 4COIL/OUTDOORCOMPCOILTHERMISTORBLKBLKYELYELBLKBLKOUTDOORTHERMISTORAW THERMISTORYELYELYELYELAN THERMISTORBW THERMISTORYELYELYELYELBN THERMISTOR(2P) CONNECTORBLKBLUBLURED(2P) CONNECTOR12COILDEFROST VALVECOIL4WAY VALVEDEFRV(2P) CONNECTORWHT2211BLKBLKBLUBLU22111 2 3 41 2 3 4A-TH1 2 3 41 2 3 4 W WW WB-THDEF1 DEF0RV1 RV0W W W WL2 L1 E-2 E-112CN04 <strong>DC</strong>FM1 2 3 4 5MV16 7 1 2 3MV04 5 1 2 3 4 5ORGREDYELBLKGRYWHTWHT(2P) CONNECTORWHTGRN/YELGRN/YELWHTWHTGRN/YEL(OLR)OVERLOAD RELAYWHTWHT1 12 2WW2211OLR0OLR1U W V W WWHEATER1WHEATER0W1231 2 3GRN/YEL1122MV1MAGNETIC COIL3344552121W WACIN1E25AWACIN2SI-AWSI-BW8FA2-5257-84200-042

Outdoor UnitAE3MI68AHWARNINGTo avoid electrical shock hazard, be sure todisconnect power before checking, servicingand/or cleaning any electrical parts.RED21(2P) CONNECTOR21OVERLOAD RELAY(OLR)CONTROLLERREACTANCECOMPRESSORTHERMISTORBLKBLKCOILTHERMISTOROUTDOORTHERMISTOR1 2 3 41 2 3 4COIL/OUTDOORCOMPYELYELBLKBLK12121 2 3 41 2 3 4A-THCOILDEFROST VALVEDEFAW THERMISTORYELYELYELBLKBLKYELAN THERMISTORBW THERMISTORYELYELYELYELBN THERMISTOR(2P) CONNECTORBLKBLUBLUBLKBLK(2P) CONNECTORWHTBLUBLU22111 2 3 41 2 3 4 W WB-THDEF1 DEF0COIL4WAY VALVERV(2P) CONNECTORWHT2211WHTWHTGRN/YELGRN/YELWHTWHTGRN/YELW OLR0W OLR1W UW VWW2211WE25AGND1A INDDORUNIT234B INDDORUNIT56C INDDORUNIT789D INDDORUNITN LPOWERSUPPLYTO INDDOR UNITBRNGRYWACIN1WACIN2SI-AWSI-BWREACTANCEBLKWHTREDBLUBLKFERRITECOREBLKBLKWHTBLKWHT101112GNDR/VBLUWHTRED (PNK)(3P) CONNECTORWHTFERRITECOREBLUWHTRED (PNK)1231 2 3S/UCMC/WGRN/YELCOMPRESSORMOTOR(2P) CONNECTORWHT1212WHTWHTWHTWHTCRANKCASEHEATERW WW WW W W WRV1 RV0HEATER1 HEATER0 L2 L1 E-2 E-1SICOM2MV1MV0W41 2 3 4 5 1 2 3 4 51 2 3 4 5 1 2 3 4 5ORGREDYELBLKGRYORGREDYELBLKGRYORGREDYELBLKGRYC-THMV31 2 3 4 1 2 3 4 51 2 3 4 1 2 3 4 5MV355MAGNETIC COILMV21 2 31 2 3 4SI-D SI-CW W MAGNETIC COIL MAGNETIC COIL4 551122334455MV2MAGNETIC COILORGREDYELBLKGRY11223344REDORGWHTBRNBLUREDORGWHTBRNBLUBLKWHTREDBLUBLKWHTREDBLU1122CN04 <strong>DC</strong>FM33445566771 2 3 4 5 6 7FMFAN MOTOR1 21 21 2 3 4 5 6 7KS233 4 5 6 7 8 1 2KS223 4 5 6BLKWHTREDBLUBLKWHTBLKWHTREDBLUWHT3 4 5 6 7 8 1 2 3 4 5 68 1 2 3 4 5 6CN03CN02D-THKS101 2 31 2 31 2 3 4CN0141 2 3 4 5 1 2 3 4 51 2 3 4 5 1 2 3 4 5WSICOM2MV1MV0DW THERMISTORYELYELYELYELDN THERMISTORCW THERMISTORYELYELYELYELCN THERMISTORWHTWHTWHTWHT1 2 3 41 2 3 4BLKWHTWHTTERMINALPLATE1238FA2-5257-57100-043

Outdoor UnitAE4MI80AHWARNINGTo avoid electrical shock hazard, be sure todisconnect power before checking, servicingand/or cleaning any electrical parts.COILDEFROST VALVEDEFCONTROLLERRED21(2P) CONNECTOR21OVERLOAD RELAY(OLR)REACTANCECOMPRESSORTHERMISTORBLKBLKCOILTHERMISTOROUTDOORTHERMISTOR1 2 3 41 2 3 4COIL/OUTDOORCOMPBLKBLKYELYELBLKBLKAW THERMISTORYELYELYELYELAN THERMISTORBW THERMISTORYELYELYELYELBN THERMISTOR(2P) CONNECTORBLKBLUBLUBLKBLK(2P) CONNECTORWHTBLUBLU12121 2 3 41 2 3 4A-TH1 2 3 41 2 3 4 W WB-THDEF1 DEF02211COIL4WAY VALVERV(2P) CONNECTORWHT2211WHTWHTGRN/YELGRN/YELWHTWHTFERRITECOREGRN/YELW OLR0W OLR1W UW VWW2211WE25AGND1A INDDORUNIT234B INDDORUNIT56C INDDORUNIT789D INDDORUNITN LPOWERSUPPLYTO INDDOR UNITBRNGRY55WACIN1WACIN2SI-AWSI-BWREACTANCEBLKWHTREDBLUBLKFERRITECOREBLKBLKWHTBLKWHT101112GNDR/VBLUWHTRED (PNK)(3P) CONNECTORWHT(7P) CONNECTORWHTFERRITECOREBLUWHTRED (PNK)S/U121 2 3CM3C/WGRN/YELCOMPRESSORMOTOR(2P) CONNECTORWHT1212WHTWHTWHTWHTCRANKCASEHEATERW WW WW W W WRV1 RV0HEATER1 HEATER0 L2 L1 E-2 E-1SICOM2MV1MV041 2 3 4 5 1 2 3 4 5W1 2 3 4 5 1 2 3 4 5ORGREDYELBLKGRYORGREDYELBLKGRY1 2 3 4CN01MV21 2 3 41 2 3 4W1 2 3 4 5 1 2 3 4 5SICOM2MV1MV0SI-D SI-CW W MAGNETIC COIL MAGNETIC COIL55ORGREDYELBLKGRY1C-TH1 2 3 41 2 3 41122MV3334455MV3MAGNETIC COIL5511223344MV2MAGNETIC COILORGREDYELBLKGRYREDORGWHTBRNBLUREDORGWHTBRNBLUBLKWHTREDBLUBLKWHTREDBLU122CN04 <strong>DC</strong>FM33445566771 2 3 4 5 6 7112233KS234455661 2 3 4 5 6 7CN03778BLKWHTREDBLUBLKWHTBLKWHTREDBLUWHTD-TH1 2 3 41 2 3 4881122KS223344551 2 3 4 5 6CN0266FMFAN MOTOR11223344KS101 2 31 2 341 2 3 4 5 1 2 3 4 5DW THERMISTORYELYELYELYELDN THERMISTORCW THERMISTORYELYELYELYELCN THERMISTORWHTWHTWHTWHTBLKWHTWHTTERMINALPLATE1238FA2-5257-89000-044

7. FUNCTIONS7-1. Explanation of FunctionsNOTEThe numerical values such as temperature, frequency, time and current in parentheses are an exampleof AE4MI80AH and the values are different from the other models.Control/conditionsUnit operationExplanationINITIAL Breaker is ON. Power is supplied to the indoor and outdoor unitcontrol circuits, however the unit remains stopped.Positioning of the outdoor unit electric expansionvalve is performed.The ON/OFF operationbutton on the remotecontroller is pressed.If automatic operation mode has been selectedwith the remote controller, operation begins inHEAT, SENSOR DRY, or COOL modedepending on the room temperature andoutdoor temperature at the time operation starts.This applies in the case of automaticHEAT/COOL operation.Depending on the operational mode, refer to the HEAT, SENSOR DRY, or COOL item.HEATThe ON/OFF operationbutton on the remotecontroller is pressed.Operation lamp illuminates.Indoor fan is stopped to prevent cold air frombeing emitted.Outdoor unit begins operating afterforced-stop is canceled.The unit is forced to stop for 3 minutes afterthe power is turned ON, or 3 minutes after thecompressor stops, in order to protect thecompressor.The frequency is increased at the rate of 1 Hzevery 0.5 seconds.When the indoor coil temperature rises,the compressor starts,the outdoor fan starts,and the indoor fan changes from "LL"to the set fan speed.Depending on the relationship between theremote controller temperature setting and theroom temperature, the compressor may stoptemporarily (in other words, the thermostatmay turn OFF).When the frequency reaches Hz,frequencyincreases are stopped for a period of seconds.(Refor to Table 2 "Freguency control".)This is in order to stabilize the return of oil to thecompressor.The frequency then increases.If the indoor and outdoor temperatures are high,the current peak cut-off activates, stopping anyincreases in frequency.The room temperaturehas reached the desiredtemperature.The indoor temperature and the remotecontroller temperature setting areapproximately equal.Operating frequency is stabilized in order tomaintain a comfortable environment.The thermostat turnsOFF.The indoor fan is stopped.The outdoor unit stops. (It does not stop if thethermostat for another indoor unit is ON.)Approximately 30 seconds after thethermostat turns OFF, the indoor fan isstopped.The indoor and outdoortemperatures are high.In order to protect the compressor, the outdoorunit will not operate for 3 minutes after thethermostat turns OFF, even if the roomtemperature drops below the desiredtemperature.The outdoor unit starts automatically after 3minutes.During these 3 minutes, a low-pressurepressure balance is achieved, allowing thecompressor to start more easily.The frequency is not increased, even ifthere is a difference between the roomtemperature and the desired temperature.In some cases, the frequency may bedecreased.The amount of heat pump exceeds the amountof heat radiation from the room.Therefore, there is no need to further increasethe compressor capacity, and the frequency isstabilized or lowered.The thermostat turns ON.The indoor unit is stopped.The unit operated before, and the temperature ofthe indoor heat exchanger is relatively warm.Therefore,the fan speed may start at the set fanspeed at the same time that the thermostat turnsON.45

Control/conditionsUnit operationExplanationHEATWhen defrost operationbegins, frost has formedon the outdoor unit(when the ambient airtemperature is low).Non-stop defrostIndoor fan : StoppedOutdoor fan : StoppedCompressor : 80 HzSolenoid valve (for hot gas bypass): ON4-way valve : Remains ONOperation lamp : Red and orange ONalternatelyDefrost operation begins based on outdoor heatexchanger temperature and outdoor airtemperature conditions.Non-stop defrost (Refer to Fig. 1)1. After HEAT operation begins, the temperatureof the outdoor heat exchanger is at or below theL1 line for 35 minutes.(If outdoor air temperature is less than –3 °C,the time is 48 minutes)2. After HEAT operation begins, the temperatureof the outdoor heat exchanger is at or below theL2 line for 120 minutes.The 4-way valve remains ON during defrost.The outdoor fan stops and the solenoidvalve turns ON, allowing the refrigerant tobypass the indoor unit.The operating frequency during defrost is80 Hz. (Frequency is lowered if the currentpeak cut-off function is activated.)The maximum length of a single defrostoperation is 12 minutes.For the outdoor heat exchanger temperatureconditions for ending defrost, refer to Table 1.Defrost releaseIndoor fan turns ON.After 10 seconds, the solenoid valve(for hot gas bypass) turns OFF.When the cold air feel has disappeared,the indoor fan starts and gradually increasesspeed until it reaches the set speed.STOP[Clean defrost]Defrost is performedwhen the outdoor unit isstopped, and thetemperature of theoutdoor unit coil is at orbelow the L1 line.(Refer to Fig. 1.)All indicator lamps turn OFF. The indoor andoutdoor units stop.Operation is restartedwithin 4 hours (only whenAUTO mode is selectedwith the remotecontroller).Starts operating in the same operating mode(HEAT) and with the same temperaturesettings as before operation was stopped.Within 4 hours after operation was stopped, it isassumed that there has been no significantchange in the indoor and outdoor temperatures,and the previous conditions (HEAT) are stored.Operation starts after 4hours or more havepassed.New operation begins based on thetemperature conditions at the time theON/OFF button is pressed.Outdoor heatexchanger temperatureL2L1(–20) 0Fig. 1Outdoor airtemperature(– 6)(– 7)(– 24)(– 25)Temperature of releasingDefrost operation timeHeat exchangertemperature forreleasing defrostingLess than 2 minutes*1 The temperature for releasing of defrosting is (20 °C) or higher when theoutdoor air temperature is less than 0 °C.Table 12 minutes or moreNo releasing 14 °C or higher (*1)46

Control/conditionsUnit operationExplanationCOOLThe ON/OFF operationbutton on the remotecontroller is pressed.The operation lamp illuminates.The indoor fan operates at the set fan speed.The outdoor unit stops.The outdoor unit does not operate for 3 minuteseven after the breaker is turned ON.The outdoor unit starts.The frequency is increased at the rate of 0.5Hz every 1 seconds.(Compressor and the outdoor fan start.)When the frequency reaches Hz,frequency increases are stopped for a periodof seconds. (Refer to Table 2.)This is in order to stabilize the return of oil to thecompressor.The frequency then increases.If the indoor and outdoor temperatures are high,the current peak cut-off activates, stoppingany increases in frequency.The room temperaturehas reached thedesired temperature.The indoor temperature and the desiredtemperature are approximately equal.Operating frequency is stabilized in order tomaintain a comfortable environment.The thermostat turnsOFF.The outdoor unit stops. (It does not stop if thethermostart for another indoor unit is ON.)The thermostat turnsON again.After the thermostat turns ON again, theoutdoor unit will not operate for 3 minutes,even if the room temperature increasesabove the desired temperature.After 3 minutes, the outdoor unit begins operatingautomatically.During these 3 minutes, a pressure balance isachieved, allowing the compressor to startmore easily.Freeze preventionWhen the temperature of the indoor heatexchanger drops to approximately 2 °Cor below, the compressor turns OFF, theoutdoor fan turns OFF, and the indoor fancontinues operating with no changes.In order to protect against freezing, thecompressor stops temporarily, until thetemperature of the indoor heat exchanger hasrisen.Approximately 3 minutes later, if thetemperature of the indoor heat exchangeris adove 8 °C, the system returns to itsoriginal conditions.StopAll indicator lamps turn OFF. The indoor andoutdoor units stop.Operation is restartedwithin 4 hours (only whenAUTO mode is selectedwith the remotecontroller).Starts operating in the same operating mode(COOL) and with the same temperaturesettings as before operation was stopped.Within 4 hours after operation was stopped, it isassumed that there has been no significantchange in the indoor and outdoor temperatures,and the previous conditions (COOL) are stored.Operation starts after 4hours or more havepassed.New operating mode is determined based onthe temperature conditions at the time theON/OFF operation button is pressed.Frequency control(Hz)Outdoor air temperature is below 0 °C.(senconds)Outdoor air temperature is 0 °C or higher.(25) Hz(35) Hz(45) Hz(55) Hz(120) seconds(60) seconds(60) seconds(180) secondsTable 2(60) seconds(30) seconds(30) seconds(90) seconds47

(1/f fluctuation fan)Control/conditionsUnit operationExplanationSENSORDRYThe ON/OFF operationbutton on the remotecontroller is pressed.The operation lamp illuminates.The indoor fan operates at the set fan speed.The outdoor unit stops.The outdoor unit does not operate for 3 minuteseven after the breaker is turned ON.The outdoor unit starts.The frequency is increased at the rate of 0.5Hz every 1 seconds.(Compressor and the outdoor fan start.)When the frequency reaches Hz,frequency increases are stopped for a periodof seconds. (Refer to Table 2.)This is in order to stabilize the return of oil to thecompressor.The frequency then increases.If the indoor and outdoor temperatures are high,the current peak cut-off activates, stoppingany increases in frequency.The room temperaturereaches the desiredtemperature, and thereis no need for furthercooling.DRY operation startsDRY A operationThe indoor fan changes between "Low"and "LL" (very low) over a 6-minute cycle.This is 1/f fluctuation fan operation.(Refer to Fig. 2.)Operating frequency is stabilized in order tomaintain a comfortable environment.Operates to effectively dehumidify the air whilenot excessively reducing the indoortemperature.The indoor unit operates at 1/f fluctuation fanoperation, at a fan speed that does not causea chilly feeling.The room temperature is15 °C or higher, and isslightly too cold.DRY B operation(1)The indoor fan changes between "Low"and "LL" (very low) over a 6-minute cycle.This is 1/f fluctuation fan operation.The compressor operates on a 3-minutes ON,6-minutes OFF cycle, to prevent the roomtemperature from dropping too much.(2)After appoximately 3 minutes, thecompressor turns OFF, the outdoor fanturns OFF, and the indoor fan turns OFF.(3)After approximately 6 minutes, theconditions return to (1).The room temperature isbelow 15 °C.Monitoring operation begins.When monitoring operation begins, thecompressor stops, and the indoor fan operates at"LL" (very low) speed.1/f fluctuation fan250200(Step)1501005006-minute cycleFig. 248

7-2. Protective FunctionsNOTEThe numerical values such as temperature, frequency, time and current in parentheses are an exampleof AE4MI80AH and the values are different from the other models.7-2-1. Defrost Detection and Release(1) Non-stop defrostingDefrosting sequence4-way valve ONHeating operationFrost detectionDefrost detection occurs in either of the following cases:• The temperature of the heat exchanger remains at or belowthe L1 line for 35 minutes after the start of HEAT operation.• The temperature of the heat exchanger remains at or belowthe L2 line for 120 minutes after the start of HEAT operation.Outdoor heatexchanger temperatureL2L1(–20) 0Outdoor air(– 6) temperature(– 7)(– 24)(– 25)Non-stop defrosting•••CompressorOutdoor fanSolenoid valve(for hot gas bypass)• Indoor fan(80 Hz) operation (4-way valve ON)OFFONOFFReleasing of defrosting• Temperature of the outdoor heat exchanger is at or above thetemperature shown in the table below.• Defrost operation has continued for 12 minutes (max. length).Temperature of releasingDefrost operation timeLess than 2 minutes2 minutes or moreHeat exchangertemperature forreleasing defrostingNo releasing 14 °C or higher (*1)*1 The temperature for releasing of defrosting is (20 °C) or higher when theoutdoor air temperature is less than 0 °C.NOTEDefrost does not occur during HIGH POWER operation.If other stopped indoor units are started during defrost operation, they begin operating indefrost mode.(2) Clean defrostIf all indoor units are stopped during HEAT operation, and frost is detected at the L1 line, and theconditions for defrost are met, then defrost operation occurs, and the unit stops after defrost is completed.49

7-2-2. Current ControlThe operating current may rise as a result of causes including increasing heating or cooling loads or decreases in powervoltage. In these cases, the operating frequency is automatically reduced, or operation is stopped, in order to controlthe operating current so that it is (20 A) or less.As a result:• Power breakers and fuses will not be tripped.• Operation can continue during this period with somewhat reduced heating or cooling capacity.• Operation at normal capacity is restored when the cause of the current rise is eliminated.Description of functionExample of operation for heating(20A)(17A)(16.6A)TargetfrequencyFrequency CurrentFrequencyStops operationApprox.3 minutesPower Point CPoint BPoint A• Operates at the target frequency at Point A and below.• Stops increases to the frequency between Points A and B.• Reduces the frequency by 1 Hz per 0.5 seconds when Point B is exceeded.• Stops operation, and restarts it appoximately 3 minutes later, if Point C is exceeded.(May operate when sudden voltage fluctuations occur. Indicates trouble.)(1) Automatic frequency controlThe operating frequency is reduced automatically, or operation is stopped, in order to control the operatingcurrent so that it is at or below the values shown in the table below.(20A)HEAT COOLPoint C (peak cut trip)(20.0) (20.0)Point B (Hz reduction)(17.0) (17.0)Point A (Hz increase prohibit) (16.6) (16.6)NOTEDuring defrost operation, the COOL current setting value is used.(2) Current controlThe operating frequency upper limits shown in the figure below are established for frequency reduction andincrease-prohibit.Current(A)TripHz reductionHz increaseprohibitExample of operation during coolingHz reductionHz increase prohibit(16)(15.6)0(30)Hz reductionHz increase prohibitFrequency (Hz)50

7-2-3. Low Start CurrentOperation starts at (8 Hz), and the start current is less than the normal operating current. This prevents the flickeringof fluorescent lights or television screens that occurs when ordinary A/C units start.7-2-4. Compressor Temperature ControlTo protect the compressor coil from overheating, the operating frequency is controlled based on the compressordischarge temperature.(°C)Compressor discharge temperature(110)(106)(100)(90)Trip5Hz every 30 sec. reduction2Hz every 30 sec. reductionNo controlIncreaseprohibit range(Hz reduction)*Within the increase-prohibit range, the range changesto the Hz reduction range (2 Hz every 30 seconds) ifthe compressor temperature rises by 2 °C.7-2-5. Control at HEAT Start-upIf HEAT operation is started when the outdoor air temperature is 15 °C or below, the unit operates at the HEAT start-upfrequency (70 Hz or above).Reset conditions(1)(2)(3)(4)(5)The compressor frequency exceeds the start-up frequency of (70 Hz).The compressor thermostat is OFF.Frequency reduction for indoor high-load control has occurred.The outdoor air temperature is above 15 °C.The main-unit switch on one or more indoor units is set to TEST run.51

8. TROUBLESHOOTING8-1. Precautions before Performing Inspection or RepairBoth the indoor unit and outdoor unit include electronic control circuits.Be sure to pay attention to the following before inspecting or repairing the outdoorsideelectronic circuits.High-capacity electrolytic capacitors are used inside the outdoor unit controller (inverter). They retain anelectrical charge (charging voltage <strong>DC</strong> 311 V) even after the power is turned OFF, and some time is requiredfor the charge to dissipate.Be careful not to touch any electrified parts before the control circuit board Power Lamp (red) turns OFF.If the outdoor control circuit board is normal, approximately 180 seconds will be required for the charge todissipate. However, allow at least 30 minutes for the charge to dissipate if it is thought there might be troublewith the outdoor control circuit board.For example, if the outdoor control circuit board fuse has blown, approximately 30 minutes will be required todischarge the high-capacity electrolytic capacitors.52

8-2. Trouble Diagnosis by Error Monitor LampsWARNINGTo prevent electric shock, do not inspect or repair untilthe Power Lamp on the P.C.Board is turned off.8-2-1. Location of the Error Monitor LampsRemove the top plate of outdoor unit and the cover of Electrical Component Box.The Power Lamp and Error Monitor Lamps are located on the P.C.Board of Electrical Component Box. (Fig.1)Heat Exchanger Rear side P.C.Board of Electrical Component Box.Error Monitor LampsPower LampFront sideERR0ERR1ERR2ERR3Fig.1 View from top8-2-2. Display of the Error Monitor LampsIf a protective device has activated or there is a sensor failure in the outdoor unit, the 4 error monitor lamps on theoutdoor control circuit board will indicate the nature of the trouble.: ON : OFFError Monitor LampError ContentsERR0 ERR1 ERR2 ERR3Sensor for compressor discharge tempSensor for heat excharge tempSensor for branch pipe A (Narrow tube)Sensor for branch pipe B (Narrow tube)Sensor for branch pipe C (Narrow tube)Sensor for branch pipe D (Narrow tube)Outdoor temp sensorSensor for branch pipe A (Wide tube)Sensor for branch pipe B (Wide tube)Sensor for branch pipe C (Wide tube)Sensor for branch pipe D (Wide tube)HIC circuit trouble (current, temp)Actuation of comp over load relayActuation of freeze protection functionOutdoor unit error. Detail of error message indicate on indoor LED53

8-3. Checking the Outdoor System8-3-1. Checking the outdoor unitNo.Work procedureCheck items (unit operation)1• Apply 220 V AC between terminals L and N on theoutdoor unit terminal plate.• The LED (red) on the control board must illuminate.2• Short-circuit the T-RUN terminal to the COM terminalof TEST/T-RUN terminals.• The compressor, fan motor, 4-way valve, and solenoidvalve (for the hot gas bypass) must turn ON.(They turn ON about (70) seconds later after the poweris turned ON.)NOTEIf the above check items are okay, but the outdoor unit does not operate, there may be a faultyconnection between the indoor unit and the outdoor unit.8-3-2. Checking the defrost operationUsing forced defrost operation to check this function.No.Work procedureCheck items (unit operation)1• Connect a dummy resistor of 39 k ohm to the outdoor Non-stop defrostcoil temperature sensor connector.Indoor fanCMSetting30 sec.LL Stop(80 Hz)ONSettingSolenoid valve(for hot gasbypass)OFF5 sec.ONOFF10 sec.Outdoor fanONOFFONDefrost startRelease• The maximum length of defrost operation is 12minutes.Defrost can also be released based on the belowconditions for the outdoor heat exchanger sensor.Less than 2 minutes Not released2 minutes or more 14 °C or higher(*1)*1 However, the condition is (20 °C) or higher when theoutdoor air temperature is below 0 °C.54

8-4. Trouble Diagnosis of Each Part8-4-1. Problems of Each Part and Inspection PointsFor details about the inspection points, refer to the Inspection Points for Each Part.Indoor unitOutdoor unitOthersInspectionpointsProblemsIndoor unit does not operate.Operation lamp blinking.Operation lamp does not illuminate.Indoor fan dose not turn.Outdoor unit does not operate.Outdoor fan dose not turn.4-way valve does not operate.The compressor (only) does notoperate.The compressor stops on occasion.The compressor speed does notincrease.The outdoor air temperature is high,however defrost operation occurs.Defrost operation does not occur.The electric expansion valve doesnot operate.Does not cool or coolingperformance is inadequate.Does not heat or heatingperformance is inadequate.No. ofInspectionPoints forEach partSelf-Diagnostics checkIndoor controller(control unit)Indoor fan motorIndoor unitRoom temperaturesensorHeat exchangertemperature sensorInter-unit cableSwitch circuit boardOutdoor control circuitboard(1)Diode moduleHICElectrolytic capacitorOutdoor unitFuseCompressorCompressor protectivesensorOutdoor fan motor(2)(3)(4)Others4-way valveCoil thermistorElectric expansion valveBranch tubingtemperature sensorBreakerRefrigerant gas pressure(5)(6)(7)(8)(9)(10)55

8-4-2. Inspection Points for Each Part(1) Outdoor control circuit boardRefer to 8-3-1. Checking the outdoor unit.NOTEDo not remove or insert the outdoor control circuit board connector when power is being supplied to it.(The controller will be damaged.)(2) FuseCheck it visually or the continuity with a tester.(3) CompressorCheck for an open circuit in the compressor coil winding.(4) Compressor protective sensor (compressor discharge temperature thermistor)Check that the senseor is securely contained in the thermostart holder.(5) 4-way valveShort-circuit the T-RUN terminal to the COM terminal of TEST/T-RUN terminals. Perfrom a test run of the unitalone, and check whether the 4-way valve inside the outdoor unit produces a click sound.(6) Coil thermistorCheck that the sensor is securely contained in the thermostat holder.(7) Electric expansion valveWhen replacing the electric expansion valve and coil, be sure to attach the connectors in the correct positions.Labels are applied to the valve body and coil, corresponding to the connector colors, to identify them.No voltage on circuit boardController checkVoltage variesUse a multi-meter to measure the voltage (12 V).When the power is turned ON, the needle will move in thefollowing seguence in approximately 10 to 20 seconds foreach point.Model No.AE2MI40AHAE2MI56AHBAE3MI68AHAE4MI80AHSequenceMV0 MV1MV0 MV1 MV2 MV3Check the illuminationof the red Power Lamp.Replace the controller.Check the coil resistance.0 ohmApprox. 46 +/– 4 ohmCheck the resistance between the gray leadwire and the other wires.Resistance is OK if it is 46 +/– 4ohm at 20 °CNOTECool the main unit witha damp cloth or othermeans while welding.When applyingvacuum, use thespecial service magnetand rotate at least 5revolutionscounterclockwise tofully open the electricexpansion valve.Replace the coil.No temperature changeReplace the electricexpansion valve.Open and close theelectric expansion valveby hand to check it.*1Temperature changesThis part is normal.Check elsewhere.Use the special service magnet androtate 5 revolutions clockwise to fullyclose the valve.Then start the unit and measure thetemperature at the inlet and outlettubes of the electric expansion valve.If the temperature difference is large,the valve is closed.Then rotate 5 revolutionscounterclockwise to open the valve.Operation is normal if the temperaturedifference between the 2 tubes drops.*1If you have manually checked the electric expansion valve, be sure to reapply the outdoor power after you havereplaced the wiring. (The position of the elecric expansion valve will changed.)56

(8) Branch tubing temperature sensorCheck that the sensor is securely contained in the thermostat holder.(9) BreakerCheck whether or not the breaker has been tripped.Check that the breakers and fuses used are of the specified capacity.Check that the breaker and its line are exclusive for A/C use.(10) Refrigerant gas pressureStart a COOL test run, and messure the temperatures of the A/C intake air and discharge air. Compare the valueswith the performance charts.If the values are higher than the performance charts:Check for refrigerant shortage or blockage of the refrigerant circuit.< Assessment of refrigerant shortage >1. The pressure in the low-pressure section is 5 MPa or more below the value in the performance charts.2. There is little condensation on the indoor heat exchanger, which overall appears dry.< Distinguishing between refrigerant shortage and refrigerant circuit blockage >If the pressure in the low-pressure section does not change when the circuit is charged 2 to 3 times withrefrigerant gas (0.44 lbs each time), or if the change is small, then the problem may not be refrigerantshortage.The problem may be a blockage of the refrigerant circuit.1. Check that there is no internal leakage inside the 4-way valve:At the low-pressure side tubing, check that there is no temperature difference between the intake anddischarge of the 4-way valve.2. Check that the electric expansion valve is not blocked. Check as described on the preceding page.57

8-5. Trouble Diagnosis of Fan MotorThis outdoor <strong>DC</strong> fan motor contains an internal control PCB. Therefore, it is not possible to measure the coilresistance, and the following procedure should be used to check the motor.Perform the trouble diagnosis by Test Run mode described on Installation Instructions of indoor unit.Important: (A) Turn OFF the power before connecting or disconnecting the motor connectors.(B) When performing voltage measurement at the outdoor controller connector for (3) in the tablebelow, the <strong>DC</strong> motor will trip and voltage output will stop approximately 10 seconds afteroperation is started. For this reason, to measure the voltage again, first turn OFF the outdoorunit power, then, measure the voltage in Test Run mode.[Trouble symptom 1] The fan does not stop when the outdoor unit stops. Outdoor unit controller trouble[Trouble symptom 2] The fan motor does not rotate when the outdoor unit is operating.(Diagnostic procedure)* Disconnect the motor connectors and measure the voltage at the <strong>DC</strong> motor connectors on the outdoorunit controller (3 locations).Measurement location(1) Vs-Gnd : Between pin 1 and pin 4orVm-Gnd : Between pin 1 and pin 4(2) Vcc-Gnd : Between pin 5 and pin 4(3) Vsp-Gnd : Between pin 7 and pin 4Normal value<strong>DC</strong> 230V or more<strong>DC</strong> 14V or moreAfter fluctuating 4 times between <strong>DC</strong> 1.7 to 6.1V(1 sec. ON) and <strong>DC</strong> 0 V (1 sec. OFF), the <strong>DC</strong>motor trips.(Diagnostic results)All of the above measured values are normal. Fan motor trouble (Replace the motor.)Any one of the above measured values is not normal. Outdoor unit controller trouble(Replace the controller .)(Reference) <strong>DC</strong> motor connector pin arrangementAE2MI40AHPin 1: Vs (white)Pin 2: Not usedPin 3: Not usedPin 4: Gnd (black)Pin 5: Vcc (red)Pin 6: FG (blue)Pin 7: Vsp (yellow)AE2MI56AHBAE3MI68AH / AE4MI80AHPin 1: Vm (red)Pin 2: Not usedPin 3: Not usedPin 4: Gnd (blue)Pin 5: Vcc (brown)Pin 6: PG (white)Pin 7: Vsp (orange)[Trouble symptom 3][Trouble symptom 4][Trouble symptom 5]Motor rotates for some time (several seconds), but then quickly stops, when the outdoorunit operates.(There is trouble in the system that provides feedback of motor rotation speed from themotor to the outdoor unit controller.)Fan motor rotation speed does not change during outdoor unit operation.Fan motor rotation speed varies excessively during outdoor unit operation.(Remedy for symptom 3 to 5)It is not possible to identify whether the trouble is outdoor unit controller trouble or motor trouble.Therefore, first replace the outdoor unit controller, then (if necessary) replace the <strong>DC</strong> motor.58

9. REFRIGERANT R410A:SPECIAL PRECAUTIONS WHEN SERVICING UNIT9-1. Characteristics of New Refrigerant R410A9-1-1. What is New Refrigerant R410A?R410A is a new refrigerant that contains two types of pseudo-non-azeotropic refrigerant mixture. Itsrefrigeration capacity and energy efficiency are about the same level as the conventional refrigerant, R22.9-1-2. Components (mixing proportions)HFC32 (50%) / HFC125 (50%)9-1-3. CharacteristicsLess toxic, more chemically stable refrigerantThe composition of refrigerant R410A changes whether it is in a gaseous phase or liquid phase. Thus, whenthere is a refrigerant leak the basic performance of the air conditioner may be degraded because of a change incomposition of the remaining refrigerant. Therefore, do not add new refrigerant. Instead, recover theremaining refrigerant with the refrigerant recovery unit. Then, after evacuation, totally recharge the specifiedamount of refrigerant with the new refrigerant at its normal mixed composition state (in liquid phase).When refrigerant R410A is used, the composition will differ depending on whether it is in gaseous or liquidphase, and the basic performance of the air conditioner will be degraded if it is charged while the refrigerant is ingaseous state. Thus, always charge the refrigerant while it is in liquid phase.CAUTIONEther-type oil is used for compressor oil for R410A-type units, which is differentfrom the mineral oil used for R22. Thus more attention to moisture prevention andfaster replacement work compared with conventional models are required.9-2. Checklist before ServicingUse a clutch-type flare tool for R410A or the conventional flare tool. Note that sizes of the resultant flares differbetween these two tools. Where a conventional flare tool is used, make sure to observe A Specification (amount ofextrusion) by using the flare spacer.Diameter of tube DDia.6.35 mm (1/4")Dia.9.52 mm (3/8")Dia.12.7 mm (1/2")Dia.15.88 mm (5/8")Specification AFlare tool for R410A Conventional flare tool (for R22)0 to 0.5 mm 1.2 mmSize of flareDDSpacerAAFlare tool for R410AConventional flare tool (R22)59

Tubing precautionsRefrigerant R410A is more easily affected by dust or moisture compared with R22, thus be sure to temporarilycover the ends of the tubing with caps or tape prior to installation.Never use 0.7mm-thick copper tubing or tubing which is less than 0.8mm in thickness, since air conditioners withR410A are subject to higher pressure than those using R22 and R407C.No addition of compressor oil for R410ANo additional charge of compressor oil is permitted.No use of refrigerant other than R410ANever use a refrigerant other than R410A.If refrigerant R410A is exposed to fireThrough welding, etc., toxic gas may be released when R410A refrigerant is exposed to fire. Therefore, be sureto provide ample ventilation during installation work.Caution in case of R410A leakCheck for possible leak points with the special leak detector for R410A. If a leak occurs inside the room,immediately provide thorough ventilation.60

9-3. Tools Specifically for R410AFor servicing, use the following tools for R410ATool DistinctionTools specifically for R410ATools which can be commonlyused for R22,R407C, and R410ATool NameGauge manifoldCharging hoseGas leak detectorRefrigerant cylinderCharging cylinderRefrigerant recovery unitVacuum pump with anti-reverse flow (*1)(Solenoid valve-installed type, which prevents oil from flowing back into theunit when the power is off, is recommended.)Vacuum pump (*2)...can be used if the following adapter is attached.Vacuum pump adapter (reverse-flow prevention adapter) (*3).(Solenoid valve-installed adapter attached to a conventional vacuum pump.)Electronic scale for charging refrigerantFlare toolBenderTorque wrenchCutter, reamerWelding tool, nitrogen gas cylinderCAUTIONThe above tools specifically for R410A must not be used for R22 and R407C.Doing so will cause malfunction of the unit.For the above vacuum pump (*1, *2) and vacuum pump adapter (*3), those forR22-type units can be used for R410A-type. However, they must be usedexclusively for R410A and never alternately with R22 and R407C.To prevent other refrigerants (R22, R407C) from being mistakenly charged to this unit, shape and externaldiameter of the service port screw has been altered. R410A : 7.94 mm (5/16")R22, R407C : 6.35 mm (1/4")9-4. Tubing Installation ProceduresWhen the tubes are connected, always apply HAB oil on the flare portions to improve the sealing of tubing.The following is the HAB oil generally used:Esso: ZERICE S32NOTEFor details on tubing installation procedures, refer to the installation manuals attached to the indoorunit and outdoor unit.61