TFDU4203 Integrated Low Profile Transceiver Module for Telecom ...

TFDU4203 Integrated Low Profile Transceiver Module for Telecom ...

TFDU4203 Integrated Low Profile Transceiver Module for Telecom ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

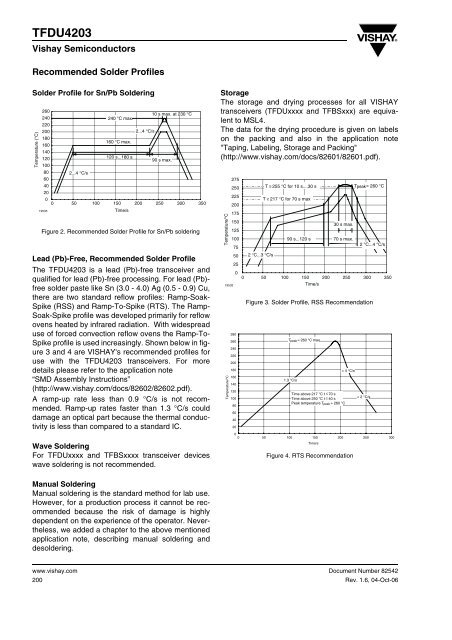

<strong>TFDU4203</strong>Vishay SemiconductorsRecommended Solder <strong>Profile</strong>sSolder <strong>Profile</strong> <strong>for</strong> Sn/Pb SolderingTemperature (°C)260240220200180160140120100806040200195352...4 °C/s240 °C max.160 °C max.120 s...180 s2...4 °C/s10 s max. at 230 °C90 s max.0 50 100 150 200 250 300 350Time/sFigure 2. Recommended Solder <strong>Profile</strong> <strong>for</strong> Sn/Pb solderingLead (Pb)-Free, Recommended Solder <strong>Profile</strong>The <strong>TFDU4203</strong> is a lead (Pb)-free transceiver andqualified <strong>for</strong> lead (Pb)-free processing. For lead (Pb)-free solder paste like Sn (3.0 - 4.0) Ag (0.5 - 0.9) Cu,there are two standard reflow profiles: Ramp-Soak-Spike (RSS) and Ramp-To-Spike (RTS). The Ramp-Soak-Spike profile was developed primarily <strong>for</strong> reflowovens heated by infrared radiation. With widespreaduse of <strong>for</strong>ced convection reflow ovens the Ramp-To-Spike profile is used increasingly. Shown below in figure3 and 4 are VISHAY's recommended profiles <strong>for</strong>use with the <strong>TFDU4203</strong> transceivers. For moredetails please refer to the application note“SMD Assembly Instructions”(http://www.vishay.com/docs/82602/82602.pdf).A ramp-up rate less than 0.9 °C/s is not recommended.Ramp-up rates faster than 1.3 °C/s coulddamage an optical part because the thermal conductivityis less than compared to a standard IC.Wave SolderingFor TFDUxxxx and TFBSxxxx transceiver deviceswave soldering is not recommended.StorageThe storage and drying processes <strong>for</strong> all VISHAYtransceivers (TFDUxxxx and TFBSxxx) are equivalentto MSL4.The data <strong>for</strong> the drying procedure is given on labelson the packing and also in the application note"Taping, Labeling, Storage and Packing"(http://www.vishay.com/docs/82601/82601.pdf).Temperature/°C19532Temperature/°C2752502252001751501251007550252802602402202001801601401201008060402002 °C...3 °C/sT ≥ 255 °C <strong>for</strong> 10 s....30 sT ≥ 217 °C <strong>for</strong> 70 s max90 s...120 s30 s max.70 s max.0 50 100 150 200 250 300 350Time/sFigure 3. Solder <strong>Profile</strong>, RSS RecommendationT peak = 260 °C max1.3 °C/sTime above 217 °C t ≤ 70 sTime above 250 °C t ≤ 40 sPeak temperature T peak = 260 °C< 4 °C/sFigure 4. RTS RecommendationT peak = 260 °C2 °C...4 °C/s< 2 °C/s00 50 100 150 200 250 300Time/sManual SolderingManual soldering is the standard method <strong>for</strong> lab use.However, <strong>for</strong> a production process it cannot be recommendedbecause the risk of damage is highlydependent on the experience of the operator. Nevertheless,we added a chapter to the above mentionedapplication note, describing manual soldering anddesoldering.www.vishay.com200Document Number 82542Rev. 1.6, 04-Oct-06