Product manual 28ST v1.2 Standard Self Tailing Winch

Product manual 28ST v1.2 Standard Self Tailing Winch

Product manual 28ST v1.2 Standard Self Tailing Winch

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

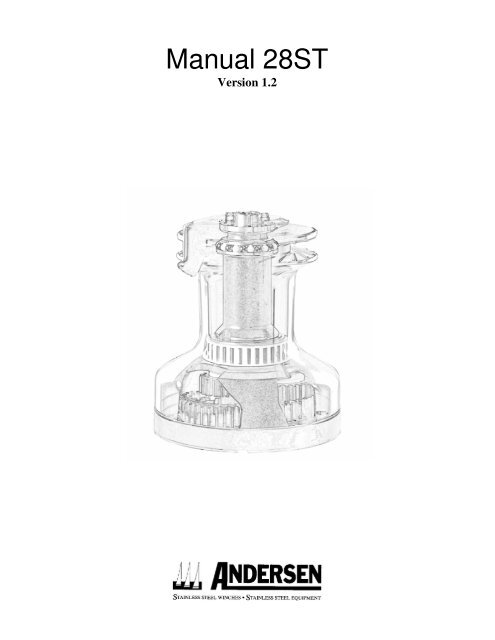

Manual <strong>28ST</strong>Version 1.2

CONGRATULATIONSYou have purchased an ANDERSEN premium quality winch. This product is a result of many years of developmentand experience in producing sailing winches. This winch gives you a high degree of functionality and many years ofsafe and trouble free sail handling.TILLYKKEDe har købt et ANDERSEN spil af høj kvalitet. Dette produkt er et resultat af mange års udviklingsarbejde samterfaring indenfor produktion af spil til sejlbåde.Med dette spil får De funktionalisme på højt plan med henblik på at yde Dem enbehagelig samt sikker sejlads.Sehr geehrter ANDERSEN kunde,Wir beglückwünschen Sie zu dem kauf einer ANDERSEN Winde, ein Produkt höchster Qualität, daß ein Resultatjahrelanger Entwicklungsarbeit und Erfahrung in der Produktion von Winden für Segelboote ist. Die funktionalitätdieser Winde ermöglicht Ihnen viele Jahre lang eine handliche und sichere Segelführung.FÉLICITATIONSVous venez d`acheter un winch ANDERSEN de grande qualité. Ce produit est le résultat de longues annéesd’expérience et de développement dans la production des winches pour voilier. Ce winch vous apportera denombreuses années de fonctionnement sécurisant, pour une voile facile.Frode AndersenManaging Director

GENERAL INFORMATIONDue to the best choice of materials and high precision in manufacturing, we recommend,dismantling, cleaning and lubricating the winch only every second year. Under intensive use,such as racing, charter or blue water sailing this should be carried out every year.We strongly recommend always using ANDERSEN WINCH GREASE, when lubricating yourwinch. ANDERSEN WINCH GREASE is a high quality silicone/Teflon grease product.Most other types of grease, including “marine grease” are not suitable for lubrication of winches.Non-suitable grease products can cause malfunction, which could result in fatal injuries for theuser and others.Pawl arm springs should be replaced every second year. Spare arm springs and other parts thatmay be required are included in the ANDERSEN Service Kit. Please refer to the serviceinstruction for the Service Kit suitable for the specific winch.When the winch is loaded but the handle is not in use we recommend, from a safety point ofview, to remove the winch handle from the winch.To ensure correct function of the self-tailing unit, only use recommended line sizes. When usingthe winch with mooring lines DO NOT use the self-tailing function and be sure that the mooringline is not in contact with the self-tailing arm.To ensure the best possible functioning of the winch, we recommend that the winch be placed inaccordance with the line entry shown below.Be also aware that the self-tailing arm is positioned correctly. We recommend having the selftailingarm positioned within the shaded area. On 12ST and <strong>28ST</strong> the position of the self-tailingarm is fixed, making it very important to establish the proper location of the holes prior to drilling.On all other models, the self-tailing arm can be placed in several different positions after havinginstalled the winch.

INSTALLATIONInstalling the winch is easy, if you follow these instructions. The numbers in ( ) refer to theposition numbers in the parts list.What’s required for the installation?Screwdriver (large).Ø6.5 mm. (1/4”) drill.Ring spanner to match nuts.5 x M6 (1/4”) countersunk head screws and corresponding nuts.5 x large washers or backing plate.Bedding compound1. Remove screw (1).2. Remove self-tailing arm (2) and drum (6).3. Mark location of boltholes using the base (22) as a template.IMPORTANT: On the <strong>28ST</strong> the self-tailing arm (2) is fixed in one position.Ensure correct positioning of the self-tailing arm, before marking and drilling the boltholes.4. Remove base (22). Be sure that no dust comes into contact with the winch while drilling.5. Drill bolt holes Ø6.5mm (1/4”).6. Apply a light coat of bedding compound, ensuring that each bolthole is bedded.Keep drain grooves clear.7. Fasten base (22) into place using 5 pieces. M6 (1/4”) countersunk head screws. Use largewashers or a backing plate.8. Assemble in reverse order.9. Check that the winch is functioning correctly:The drum should operate smoothly, by turning the drum clockwise by hand.The drum must not turn when trying to turn the drum anti clockwise.While turning the winch handle clockwise the drum should turn fast.While turning the winch handle anti clockwise the drum should turn slowly.

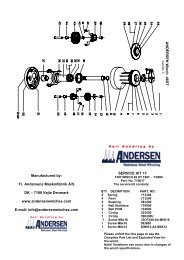

SERVICE INSTRUCTIONWhat’s required for service?Screwdriver (large).Screwdriver (small).<strong>Winch</strong> handle.Service Kit No: 1 (art. no. 710001) contains spare parts <strong>28ST</strong>ANDERSEN winch grease1. Remove screw (1).2. Remove self-tailing arm (2) and drum (6).3. Insert a winch handle. Pull up the drive shaft (7) gently, while turning gear wheel (14) andratchet gear (23) carefully. Remove drive shaft (7).4. Remove lower pawls (9) arm springs (10) and springs (8). The upper pawls are notremovable.5. Remove ratchet gear (23).6. Remove shaft ring (11). It can be difficult to get the shaft over the top of the base (22). Byturning and tilting the shaft, it will come off. DO NOT use violence.7. Remove gear wheel (14).8. To release the roller bearing (12), gently insert a small screwdriver between roller bearingand base (22). Remove roller bearing.9. Clean the balls (20, 21) with a rag. DO NOT remove the balls and the small retaining ring(19) above the balls.10. The ratchet gear (17) should be cleaned without being removed from the base (22).11. Clean all parts in petrol. Remember to clean the gear teeth, roller bearing track and balltrack inside the drum (6).12. Assemble in reverse order. During assembly, lightly grease all gear teeth, drive shaft,roller bearing, shafts, balls, pawls, springs and bushings. Use a small, soft brush. Pawlsmay be lubricated with either a very thin film of ANDERSEN WINCH GREASE. It is veryimportant that pawls can move freely.IMPORTANT: When assembling the winch, check the function of each pawl by pushing the pawlagainst the spring. The pawls should smoothly and automatically return to their normal outerposition. If the pawls do not function correctly, clean and lightly lubricate the pawls and gearsagain replacing the springs where necessary.Malfunctioning pawls may lead to unexpected failure of a loaded winch resulting in materialdamage or serious personal injury.

NOTES:__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

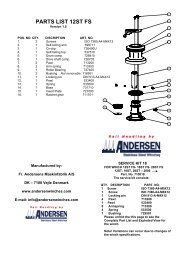

_______________________________________________________________________________PARTS LISTVer.1.2POS. QTY. DESCRIPTION ART. NO.1. 1 Screw ISO 7380-A4-M6×122. 1 <strong>Self</strong>-tailing arm 7478023 1 Cir clip 726400U4. 1 Disc spring 7263005. 1 Driving plate 7265006. 1 Drum complete. 7291047. 1 Drive shaft complete. 7290008. 2 Spring 5335009. 2 Pawl 71320010. 2 Arm spring 71330011. 1 Shaft ring 72970012. 1 Roller bearing complete. 72740013. 2 Bushing Not removable 71650114. 1 Gear wheel complete. 72960015. 1 Bushing 72950116. 1 Insert plate 72950317. 1 Ratchet gear 72940018. 1 Cir clip 729502U19. 1 Retaining ring Not removable 72660020. 14 Ball bearing, stainless steel 72490021. 15 Ball bearing, POM 72490222. 1 Base 73180023. 1 Ratchet gear 7117011 Service kit, consist of pos. 1+8+9+10+20+21 710001

EXPLODED VIEW

LIMITED WARRANTY1.1 Andersen issue a three-year warranty on all their products covering manufacturing and material defects oncondition that the products are used in normal fashion. The warranty shall apply for three years from themoment ANDERSEN sell the product concerned (to the first buyer).1.2 Within the period of the warranty, and in accordance with the terms of the warranty, ANDERSEN undertaketo replace or repair all defective components, which have been used in normal fashion.1.3 The warranty is however subject to the limitations and exceptions outlined below.Conditions and limitations:2.1 ANDERSEN´s liability shall be limited to repair or replacement of components, which are defective owing tomanufacturing or material defects.2.2 ANDERSEN assume no other liability than this, not even liability for indirect losses caused by defectconcerned, including operating losses, loss of profits, or damage caused to real property or moveable propertyoccurring while the product concerned is in the possession of the Buyer.2.3 The Buyer alone shall bear the responsibility and risk involved as to whether the products are suitable for theapplication intended. ANDERSEN assume no liability in this connection.2.4 ANDERSEN assume no liability for defects which occur due to use of their products for purposes for whichthey are not intended, or for defects which occur owing to incorrect installation, corrosion, ultravioletdegradation, lack of maintenance, or any alteration or repair of the product carried out incorrectly by theBuyer. Finally, ANDERSEN assume no liability for normal wear and tear, or for depreciation in value.2.5 ANDERSEN do not assume any liability for service carried out by anyone other than authorised ANDERSENrepresentatives, unless such service is carried out pursuant to guidelines laid down by ANDERSEN and inaccordance with good craftsmanship.2.6 The buyer shall inform ANDERSEN in writing of any defects with no undue delay once defects have beenregistered. <strong>Product</strong>s being dealt with under the warranty shall be returned to ANDERSEN for repair unlessany other agreement has been reached in writing.2.7 ANDERSEN shall not cover costs incurred by the Buyer in connection with the transport or wages involvedin a warranty case. The Buyer in full shall meet such costs.Exceptions:3.1 The warranty is only valid for one year in respect of components bought for the products concerned, such aselectric motors, electric equipment, hydraulic pumps, motors and valves.3.2 ANDERSEN assume no liability for consequential damage of ships, equipment, property or people caused bydefects in ANDERSEN products.3.3 The company’s products are subject to continuous development, and consequently ANDERSEN reserve theright to change designs and specifications without prior notice.

WORLDWIDE DISTRIBUTION & SERVICEANDERSEN ArgentinaArgen Mast & Systems s.r.l.Tel.: 11 4742 44 62Fax: 11 4742 44 62E-mail: info@argenmast.com.arANDERSEN AustraliaAllyacht Spars AustraliaTel.: 07 3893 2233Fax: 07 3893 2478E-mail: info@allyachtspars.com.auWeb: www.allyachtspars.com.auANDERSEN AustriaRobert Lindemann KGTel.: 040 21 11 970Fax: 040 21 11 97 30E-mail: info@lindemann-kg.deWeb: www.lindemann-kg.deANDERSEN BelgiumJachten JupiterTel.: 03 457 43 81Fax: 03 457 68 21E-mail: jup@village.uunet.beANDERSEN CanadaRekord Marine Enterprises LtdTel.: 604 325 5233Fax: 604 325 0326Toll free fax: 1-800-663-6424E-mail: steve@rekord-marine.comWeb: www.seatosky.com/rekordANDERSEN ChilePro NauticaTel.: 246 3456Fax: 229 7109ANDERSEN CroatiaSas-Vector D.D.Tel.: 023 316 344Fax.: 023 319 103ANDERSEN Czech RepublicNereide Yachting Ltd.Tel.: 420 02 579 416 12Fax.: 420 02 579 417 46E-mail: perlange@nereide-yachting.comANDERSEN DenmarkHerman Gotthardt A/STel.: 45 76 40 11Fax: 45 76 40 12E-mail: a.jessen@gotthardt.orgWeb: www.watski.comANDERSEN FinlandKy Jotiko-Marine KbTel.: 09 135 1344Fax: 09 135 1404E-mail: info@jotiko-marine.comWeb: www.jotiko-marine.comANDERSEN FranceGreement Import - Head office:Tel.: 02 28 03 01 01Fax: 02 28 03 19 91E-mail: infoGi@greementimport.frWeb: www.greementimport.frANDERSEN GermanyHerman Gotthardt GmbhTel.: 040 851 50 50Fax: 040 850 91 33E-mail: info@gotthardt-yacht.deWeb: www.gotthardt-yacht.deANDERSEN Great BritainNauquipTel.: 01489 885336Fax: 01489 885337E-mail: sales@nauquip.comWeb: www.nauquip.comANDERSEN GreeceMeltemi Yacht ServiceTel.: 210 9849983Fax: 210 9844356E-mail: meltemi@biznet.com.grANDERSEN HungaryMarina Yacht SportTel.: 322 86 55Fax: 322 98 34E-mail: info@marina.huWeb: www.marina.huANDERSEN ItalyG & G RiggingTel.: 02 240 09 80Fax: 02 26 22 14 22E-mail: gegrigging@tiscalinet.itWeb: www.gegrigging.comANDERSEN NetherlandNautec Engineering B.V.Tel.: 04 755 377 60Fax: 04 755 377 59E-mail: info@nautec.nlWeb: www.nautec.nlANDERSEN New ZealandNordic Marketing Ltd.Tel.: 09 368 4740Fax: 09 368 4740E-mail: nordic@xtra.co.nzWeb: www.nordic.co.nzANDERSEN NorwayHovdan-Poly A/STel.: 23 14 12 60Fax: 23 14 12 61E-mail: hovdan@hovdan.noANDERSEN PolenMarco MarineTel.: 42 30 225Fax: 42 22 427E-mail: leslaw@marco-marine.com.plANDERSEN PortugalJ.P. VelasTel.: 289 321 155Fax: 289 321 159E-mail: j.p.velas@mail.telepac.ptANDERSEN SingaporeAlquest MarketingTel.: 749 9359Fax: 749 9360E-mail: alquest@singnet.com.sgANDERSEN SloveniaMetalcheramica d.o.o.Tel.: 67 22 412Fax: 67 22 411E-mail: mladen.lazar@siol.netANDERSEN South AfricaManex & Power MarineTel.: 021 511 7292Fax: 021 510 1487E-mail: manex@manex.co.zaWeb: www.manex.co.zaANDERSEN SpainYacht Riggers Mallorca, s.l.Tel.: 971 58 41 30Fax: 971 58 41 31E-mail: info@yachtriggers.comWeb: www.yachtriggers.comANDERSEN SwedenPlastimo Nordic ABTel.: 0304 360 60Fax: 0304 307 43E-mail: info@plastimo.seWeb: www.plastimo.seANDERSEN SchweizRobert Lindemann KGTel.: 040 211 19 70Fax: 040 211 19 730E-mail: info@lindemann-kg.deWeb: www.lindemann-kg.deANDERSEN Trinidad & TobagoSoca SailsTel.: 868 634 4178Fax: 868 634 1044E-mail: info@socasails.comANDERSEN TurkeyTursan A.S / North SailsTel.: 90 212 696 9915Fax: 90 212 696 9919E-mail: fr@tursan.trANDERSEN U.S.AScandvik Inc.Tel.: 772 567 2877Fax: 772 567 9113Toll free 1-800-535-6009E-mail: sebastian@scandvik.comWeb: www.scandvik.com