Special-Uses-Alkali - Expanded Shale & Clay

Special-Uses-Alkali - Expanded Shale & Clay

Special-Uses-Alkali - Expanded Shale & Clay

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

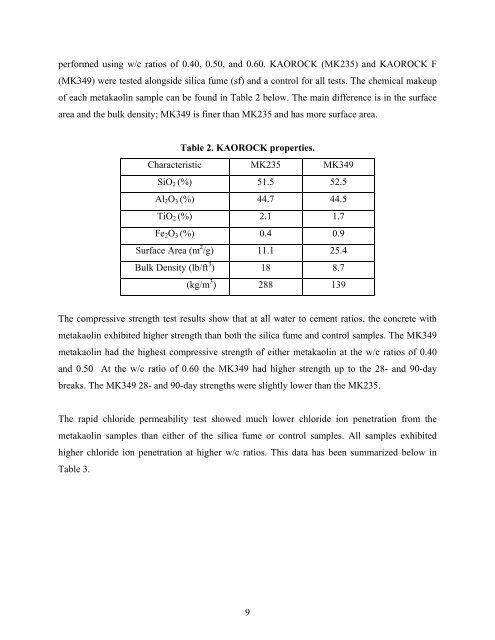

performed using w/c ratios of 0.40, 0.50, and 0.60. KAOROCK (MK235) and KAOROCK F(MK349) were tested alongside silica fume (sf) and a control for all tests. The chemical makeupof each metakaolin sample can be found in Table 2 below. The main difference is in the surfacearea and the bulk density; MK349 is finer than MK235 and has more surface area.Table 2. KAOROCK properties.Characteristic MK235 MK349SiO 2 (%) 51.5 52.5Al 2 O 3 (%) 44.7 44.5TiO 2 (%) 2.1 1.7Fe 2 O 3 (%) 0.4 0.9Surface Area (m 2 /g) 11.1 25.4Bulk Density (lb/ft 3 ) 18 8.7(kg/m 3 ) 288 139The compressive strength test results show that at all water to cement ratios, the concrete withmetakaolin exhibited higher strength than both the silica fume and control samples. The MK349metakaolin had the highest compressive strength of either metakaolin at the w/c ratios of 0.40and 0.50 At the w/c ratio of 0.60 the MK349 had higher strength up to the 28- and 90-daybreaks. The MK349 28- and 90-day strengths were slightly lower than the MK235.The rapid chloride permeability test showed much lower chloride ion penetration from themetakaolin samples than either of the silica fume or control samples. All samples exhibitedhigher chloride ion penetration at higher w/c ratios. This data has been summarized below inTable 3.9