Snapper Lawn Tractor Hydrostatic Drive Electric Clutch Series G ...

Snapper Lawn Tractor Hydrostatic Drive Electric Clutch Series G ...

Snapper Lawn Tractor Hydrostatic Drive Electric Clutch Series G ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

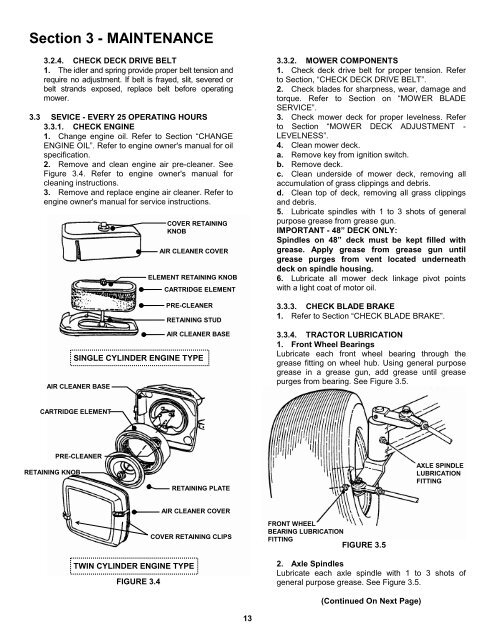

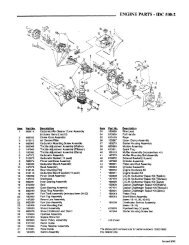

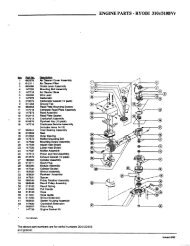

Section 3 - MAINTENANCE3.2.4. CHECK DECK DRIVE BELT1. The idler and spring provide proper belt tension andrequire no adjustment. If belt is frayed, slit, severed orbelt strands exposed, replace belt before operatingmower.3.3 SEVICE - EVERY 25 OPERATING HOURS3.3.1. CHECK ENGINE1. Change engine oil. Refer to Section “CHANGEENGINE OIL”. Refer to engine owner's manual for oilspecification.2. Remove and clean engine air pre-cleaner. SeeFigure 3.4. Refer to engine owner's manual forcleaning instructions.3. Remove and replace engine air cleaner. Refer toengine owner's manual for service instructions.SINGLE CYLINDER ENGINE TYPEAIR CLEANER BASECOVER RETAININGKNOBAIR CLEANER COVERELEMENT RETAINING KNOBCARTRIDGE ELEMENTPRE-CLEANERRETAINING STUDAIR CLEANER BASE3.3.2. MOWER COMPONENTS1. Check deck drive belt for proper tension. Referto Section, “CHECK DECK DRIVE BELT”.2. Check blades for sharpness, wear, damage andtorque. Refer to Section on “MOWER BLADESERVICE”.3. Check mower deck for proper levelness. Referto Section “MOWER DECK ADJUSTMENT -LEVELNESS”.4. Clean mower deck.a. Remove key from ignition switch.b. Remove deck.c. Clean underside of mower deck, removing allaccumulation of grass clippings and debris.d. Clean top of deck, removing all grass clippingsand debris.5. Lubricate spindles with 1 to 3 shots of generalpurpose grease from grease gun.IMPORTANT - 48” DECK ONLY:Spindles on 48” deck must be kept filled withgrease. Apply grease from grease gun untilgrease purges from vent located underneathdeck on spindle housing.6. Lubricate all mower deck linkage pivot pointswith a light coat of motor oil.3.3.3. CHECK BLADE BRAKE1. Refer to Section “CHECK BLADE BRAKE”.3.3.4. TRACTOR LUBRICATION1. Front Wheel BearingsLubricate each front wheel bearing through thegrease fitting on wheel hub. Using general purposegrease in a grease gun, add grease until greasepurges from bearing. See Figure 3.5.CARTRIDGE ELEMENTPRE-CLEANERRETAINING KNOBRETAINING PLATEAXLE SPINDLELUBRICATIONFITTINGAIR CLEANER COVERTWIN CYLINDER ENGINE TYPEFIGURE 3.4COVER RETAINING CLIPSFRONT WHEELBEARING LUBRICATIONFITTINGFIGURE 3.52. Axle SpindlesLubricate each axle spindle with 1 to 3 shots ofgeneral purpose grease. See Figure 3.5.(Continued On Next Page)13