tender notice extension of tender submission date tender for design ...

tender notice extension of tender submission date tender for design ...

tender notice extension of tender submission date tender for design ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

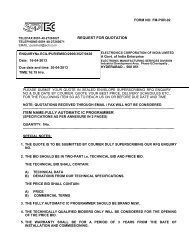

provided by vendors only. In case <strong>of</strong> non availability <strong>of</strong> any item mentioned above asagainst point No. 9 & items <strong>of</strong> Cables, prior approval from ECIL to be taken & thedata sheet <strong>for</strong> alternative components should be provided.11. The system shall be provided with suitable integrated thermal management todissipate the heat. Air intake shall be from side and exhaust through rear.12. Only stainless steel hardware as per AISI 304, 18-8 grade to be used to withstandharsh environment applications. All the tapped holes in the unit shall be providedwith SS-304 helicoils.13. In case <strong>of</strong> non availability <strong>of</strong> any component, alternate component can be suggestedif it meets specifications, prior approval from EC project team should be taken.14. Any modification/Engineering change <strong>for</strong> the betterment <strong>of</strong> unit projected by ECILshall be incorporated and absorbed in the quoted price.15. All Fabrication drawings, Mechanical assembly Bill <strong>of</strong> Materials including boughtoutmaterials, fasteners Drg. Part No. Specification <strong>of</strong> material, make and remarks are tobe provided in structured ECIL <strong>for</strong>mat <strong>for</strong> <strong>of</strong>fering it to Defence customer along withthe unit.16. 3D mechanical drawings with all the views and assembly presentation shall besubmitted along with the quotation17. Engraving details, EC logo, product title and component layout details shall beprovided by ECIL and vendor should do the engraving accordingly.18. One set <strong>of</strong> engineering, Fabrication Assembly documents hard and s<strong>of</strong>t copy shall beprovided by the vendor. This document shall become the property <strong>of</strong> ECIL .. Thecomplete enclosure fabrication details are to be provided in the ECIL Drg. <strong>for</strong>mat.19. All the cables material like Connectors, wires, sleeve, crimp terminals etc. <strong>for</strong> makingsignal and power cables are to be procured by Vendor only. The vendor has to supplyassembled cables as per BOM, Wiring Details, Wiring Diagram , signal list & are tobe integrated into the Unit as per Source Drg. No. 25661799000020. The unit has to withstand against shock, vibration, drop and bump tests .All 8 corners<strong>of</strong> unit should be strengthened with the help <strong>of</strong> using corner blocks inside the unit.For testing the equipment <strong>for</strong> bump, shock & vibration, ECIL will provide the facilityconducting <strong>for</strong> the above tests.21. COC <strong>for</strong> EMI / EMC filter, gasket, fans etc. shall be provided with Data sheet by thevendorMeeting MIL std 461E is sole responsibility <strong>of</strong> Vendor. Vendor is free to selectPower Line Filter or <strong>design</strong> Inductor PCB to meet this.22. The vendor should co-ordinate with ECIL representative during environmentaltesting in presence <strong>of</strong> inspection agency i.e. MSQA/DGAQA. The environmentaltests will be conducted either at ECIL or at any Govt. approved testing Laboratorylike RCI, SAMEER etc. Any modification /engineering changes <strong>for</strong> betterment <strong>of</strong>unit as suggested by MSQA/DGAQA/ECIL is to absorbed by the Vendor withquoted Price. Testing charges <strong>for</strong> EMI / EMC should be born by ECIL.