The First Solar Water Heater with an integrated - Thermal Products Inc

The First Solar Water Heater with an integrated - Thermal Products Inc

The First Solar Water Heater with an integrated - Thermal Products Inc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

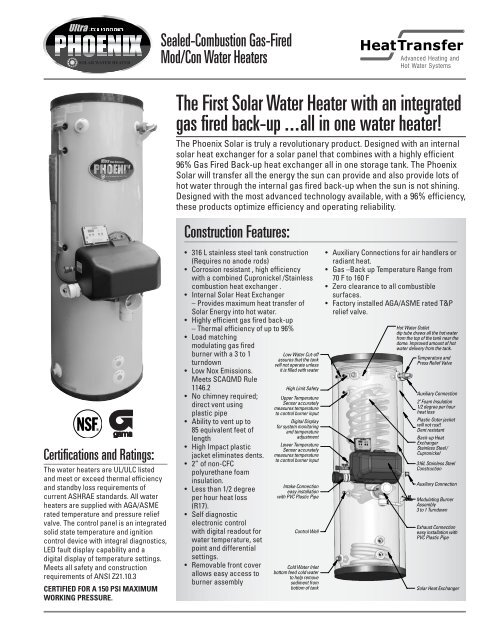

Sealed-Combustion Gas-FiredMod/Con <strong>Water</strong> <strong>Heater</strong>sCertifications <strong>an</strong>d Ratings:<strong>The</strong> water heaters are UL/ULC listed<strong>an</strong>d meet or exceed thermal efficiency<strong>an</strong>d st<strong>an</strong>dby loss requirements ofcurrent ASHRAE st<strong>an</strong>dards. All waterheaters are supplied <strong>with</strong> AGA/ASMErated temperature <strong>an</strong>d pressure reliefvalve. <strong>The</strong> control p<strong>an</strong>el is <strong>an</strong> <strong>integrated</strong>solid state temperature <strong>an</strong>d ignitioncontrol device <strong>with</strong> integral diagnostics,LED fault display capability <strong>an</strong>d adigital display of temperature settings.Meets all safety <strong>an</strong>d constructionrequirements of ANSI Z21.10.3CERTIFIED FOR A 150 PSI MAXIMUMWORKING PRESSURE.<strong>The</strong> <strong>First</strong> <strong>Solar</strong> <strong>Water</strong> <strong>Heater</strong> <strong>with</strong> <strong>an</strong> <strong>integrated</strong>gas fired back-up ...all in one water heater!<strong>The</strong> Phoenix <strong>Solar</strong> is truly a revolutionary product. Designed <strong>with</strong> <strong>an</strong> internalsolar heat exch<strong>an</strong>ger for a solar p<strong>an</strong>el that combines <strong>with</strong> a highly efficient96% Gas Fired Back-up heat exch<strong>an</strong>ger all in one storage t<strong>an</strong>k. <strong>The</strong> Phoenix<strong>Solar</strong> will tr<strong>an</strong>sfer all the energy the sun c<strong>an</strong> provide <strong>an</strong>d also provide lots ofhot water through the internal gas fired back-up when the sun is not shining.Designed <strong>with</strong> the most adv<strong>an</strong>ced technology available, <strong>with</strong> a 96% efficiency,these products optimize efficiency <strong>an</strong>d operating reliability.Construction Features:• 316 L stainless steel t<strong>an</strong>k construction(Requires no <strong>an</strong>ode rods)• Corrosion resist<strong>an</strong>t , high efficiency<strong>with</strong> a combined Cupronickel /Stainlesscombustion heat exch<strong>an</strong>ger .• Internal <strong>Solar</strong> Heat Exch<strong>an</strong>ger– Provides maximum heat tr<strong>an</strong>sfer of<strong>Solar</strong> Energy into hot water.• Highly efficient gas fired back-up– <strong>The</strong>rmal efficiency of up to 96%• Load matchingmodulating gas firedburner <strong>with</strong> a 3 to 1turndown• Low Nox Emissions.Meets SCAQMD Rule1146.2• No chimney required;direct vent usingplastic pipe• Ability to vent up to85 equivalent feet oflength• High Impact plasticjacket eliminates dents.• 2” of non-CFCpolyureth<strong>an</strong>e foaminsulation.• Less th<strong>an</strong> 1/2 degreeper hour heat loss(R17).• Self diagnosticelectronic control<strong>with</strong> digital readout forwater temperature, setpoint <strong>an</strong>d differentialsettings.• Removable front coverallows easy access toburner assemblyLow <strong>Water</strong> Cut-offassures that the t<strong>an</strong>kwill not operate unlessit is filled <strong>with</strong> waterHigh Limit SafetyUpper TemperatureSensor accuratelymeasures temperatureto control burner inputDigital Displayfor system monitoring<strong>an</strong>d temperatureadjustmentLower TemperatureSensor accuratelymeasures temperatureto control burner inputIntake Connectioneasy installation<strong>with</strong> PVC Plastic PipeControl WellCold <strong>Water</strong> Inletbottom feed cold waterto help removesediment frombottom of t<strong>an</strong>k• Auxiliary Connections for air h<strong>an</strong>dlers orradi<strong>an</strong>t heat.• Gas –Back up Temperature R<strong>an</strong>ge from70 F to 160 F• Zero clear<strong>an</strong>ce to all combustiblesurfaces.• Factory installed AGA/ASME rated T&Prelief valve.Hot <strong>Water</strong> Outletdip tube draws all the hot waterfrom the top of the t<strong>an</strong>k near thedome. Improved amount of hotwater delivery from the t<strong>an</strong>k.Temperature <strong>an</strong>dPress Relief ValveAuxiliary Connection2" Foam Insulation1/2 degree per hourheat lossPlastic Outer jacketwill not rust!Dent resist<strong>an</strong>tBack-up HeatExch<strong>an</strong>gerStainless Steel/Cupronickel316L Stainless SteelConstructionAuxiliary ConnectionModulating BurnerAssembly3 to 1 TurndownExhaust Connectioneasy installation <strong>with</strong>PVC Plastic Pipe<strong>Solar</strong> Heat Exch<strong>an</strong>ger

Dimensional InformationAUXILIARYCONNECTIONLEFT SIDEHOT WATEROUTLETFRONTSYSTEMRELIEFRIGHT SIDEHIGH LIMITSAFETYLOW WATERCUT-OFFBUPPER TEMP GASSENSOR LINEAIRINTAKEEXHAUSTVENTLOCCONDENSATELINELOWER TEMPSENSOR EFGKNCONTROLWELLDACOLD WATERINLETHEAT EXHANGERCOLD INLETJHHEAT EXHANGERHOT OUTLETMAUXILIARYCONNECTIONMODEL#GALLONS A B C D E F G H J K L M N OPH-80S 80 23" 72" 64" 5-1/4" 32" 29" 25-1/2" 5-3/4" 9-3/4" 27-3/4" 64" 36" 32" 64"PH-119S119 27" 74" 66" 7-1/4" 34" 31" 27-1/2" 7-1/2" 11-1/2" 25-3/4" 66" 40" 34" 66"ALL DIMENSIONS ARE APPROXIMATEPHOENIX SOLAR WATER HEATER DIMENSIONSMODEL # GALLONS BTU'SPH-80S 80PH-119S 119PHOENIX SOLAR WATER HEATER SPECIFICATIONS130,000199,000130,000199,000AIR INTAKE/EXHAUSTVENT SIZE2"3"2"3"WATERINLET/OUTLETSIZEHEATEXCHANGERSIZEAUXILIARYCONN.GASLINECONN.SYSTEMRELIEFPIPESIZESHIPPINGWEIGHT1-1/2" NPT 1" 1" 3/4" 3/4" 245 LBS.1-1/2" NPT 1" 1" 3/4" 3/4" 415 LBS.LP-179-SRev. 8/21/07

Piping OptionsPHOENIX SOLAR PIPINGSOLAR AIR RELEASE VENTSOLAR COLLECTOR SENSORSOLAR COLLECTORHOT WATEROUTLETGASSUPPLYT & P RELIEF VALVEBALL VALVECIRCULATORCLOSED LOOPRE-CIRCULATEDLINEHOTWATEROUTLETANTI-SCALDMIXING VALVEAUXILIARYCONNECTIONAUXILIARYCONNECTIONBALL VALVEBALLVALVEEXPANSIONTANKPRESSURERELIEF VALVESOLAR CONTROLCOLD WATERINLETBALLVALVEEXPANSIONTANKBACKFLOWPREVENTERINTAKE AIRVENTDRY WELLFOR SOLAR SENSORDRAIN VALVECOLD WATER INLETAUXILLIARY CATCH PANEXHAUSTVENTCONDENSATELINECHECKVALVESOLAR HEAT EXCHANGERSOLAR HEATEXCHANGER SUPPLYSOLAR HEATEXCHANGER RETURNFILL VALVEBALL VALVETEMP/PRESSUREGAUGEDRAIN VALVELP-201-ARev. 10/05/07PHOENIX SOLAR PIPING WITH AIR HANDLERSOLAR AIR RELEASE VENTSOLAR COLLECTOR SENSORCIRCULATOR(see note 7)SOLAR COLLECTOR*CHECK WITH AIR HANDLERMANUFACTURER FOR PROPER SIZINGAIRHANDLER *CLOSED LOOPRE-CIRCULATEDLINEHOT WATEROUTLETGASSUPPLYBALL VALVECIRCULATORAUXILIARYCONNECTIONHOTWATEROUTLETTEMP/PRESSURERELIEF VALVEBALL VALVEANTI-SCALDMIXING VALVEBACKUP HEATEXCHANGEREXPANSIONTANKTEMPERATURE AND PRESSURERELIEF VALVEEXPANSIONTANKINTAKE AIRVENTAUXILIARYCONNECTIONFILL VALVEBACKFLOWPREVENTERCONDENSATELINEBALL VALVENOTES:COLDWATERINLETBALL VALVETANK SENSORDRAIN VALVECOLD WATER INLETEXHAUST VENTSOLAR HEAT EXCHANGER1. THIS DRAWING IS MEANT TO SHOW A SYSTEM PIPING CONCEPT ONLY. THE INSTALLER IS RESPONSIBLE FOR ALL EQUIPMENT AND DETAILINGBY LOCAL CODES.2. ANTI-FREEZE, NON- POTABLE HEAT TRANSFER FLUID SHALL BE USED FOR THE SOLAR HEAT EXCHANGER CIRCUIT ONLY. NEVER NTRODUCEANTI-FREEZE SOLUTION TO ANY OTHER CONNECTION OTHER THAN THE SOLAR HEAT EXCHANGER.3. IF THERE IS A CHECK VALVE ON THE COLD WATER FEED LINE, A THERMAL EXPANSION TANK SUITABLE FOR POTABLE WATER MUST BE SIZEDAND INSTALLED WITHIN THIS PIPING SYSTEM BETWEEN THE CHECK VALVE AND THE COLD WATER INLET OF THE SOLAR WATER HEATER.4. AN ANTI-SCALD MIXING VALVE IS RECOMMENDED IF THE DOMESTIC HOT WATER SETTING IS ABOVE 120F.5. A MINIMUM OF 12 DIAMETERS OF STRAIGHT PIPE MUST BE INSTALLED UPSTREAM OF ALL CIRCULATORS.6. MAKE SURE TANK IS FULLY PURGED OF AIR BEFORE POWER IS TURNED ON TO THE BACKUP HEAT SOURCE.7. CIRCULATORS SHOWN IN THE HYDRONIC BOILER PIPING ABOVE SHOULD HAVE AN INTEGRAL FLOW CHECK OR ALTERNATELY USE A STOCK PUMP WITH AN EXTERNALSPRING TYPE CHECK VALVE. (CIRCULATORS WITH INTEGRAL FLOW CHECKS ARE NOT TO BE USED IN SOLAR SYSTEMS DUE TO EXTREMETEMPERATURES.)CHECKVALVECOPPER DISCHARGE LINESOLAR HEAT TO SUITABLE OPEN DRAINEXCHANGER SUPPLYSOLAR HEATEXCHANGER RETURNDRAIN VALVESOLARCONTROLLERTEMPERATURE/PRESSURE GAUGELP-179-RRev. 10/05/07

Venting OptionsSIDEWALL VENTING WITH TEE (INTAKE) ANDSIDEWALL VENTING COUPLING WITH EXHAUST TEE (INTAKE) ANDCOUPLING EXHAUST12"MIN.1"MIN.EXTERIOR WALLModel<strong>Solar</strong> Recovery CapacitiesGallonCapacityInput BTU/hrHeated <strong>Water</strong>Volume ofGas Back-Upat <strong>First</strong> DrawRecovery Of Back Upin Minutes65˚ Rise90˚ RisePH199-119S 119 66,000–199000 61 GAL 10 MIN 14 MINPH199-80S 80 66,000–199000 41 GAL 7 MIN 10 MINPH130-119S 119 44,000–130000 61 GAL 16 MIN 21 MINPH130-80S 80 44,000–130000 41 GAL 11 MIN 15 MINEXHAUSTINTAKESUPPORT BRACKETSMUST BE USED ONALL HORIZONTALAND VERTICAL PIPING1"MIN.CONCENTRIC VENT KITPART# KGAVT0501CVT - 2"KGAVT0601CVT - 3"EXTERIOR WALLLEFT SIDE VIEWLEFT SIDE VIEWIMPORTANT:INTAKE LEG MUST BE FACING UPINTAKEEXHAUSTLP-201-CSIDEWALL VENTING WITH TEE (INTAKE) ANDSIDEWALL VENTING WITH TEE (INTAKE) ANDCOUPLING (EXHAUST)SUPPORT BRACKETSMUST BE USED ONALL HORIZONTALAND VERTICAL PIPINGLP-201-BSpecification<strong>The</strong> Phoenix <strong>Water</strong> <strong>Heater</strong> shall bem<strong>an</strong>ufactured by Heat Tr<strong>an</strong>sfer <strong>Products</strong>,<strong>Inc</strong>. <strong>with</strong> identification of model numberPH________. <strong>The</strong> water heater shall bea sealed combustion system, taking onlyoutside air for combustion <strong>an</strong>d exhaustingthe flue gas <strong>with</strong> PVC Schedule 40 or 80PVC, or CPVC solid core pipe. <strong>The</strong> heateras well as all related intake air <strong>an</strong>dexhaust intake air <strong>an</strong>d exhaust gas pipingshall be approved for zero clear<strong>an</strong>ce to<strong>an</strong>y combustible surface. <strong>The</strong> units totalcombined equivalent venting length,including fitting allow<strong>an</strong>ces for boththe intake air <strong>an</strong>d exhaust gas shall notexceed 85’ (in the units native size asm<strong>an</strong>ufactured <strong>an</strong>d stated on the unitmodel product data sheet) in 2”, or 3” pipeor 125’ for the next size up of 3” or 4” fromthe heaters location.<strong>The</strong> solar heaters t<strong>an</strong>k shall be constructedof 316L stainless steel. <strong>The</strong> primary gasfired condensing heat exch<strong>an</strong>ger shall beconstructed of 90/10 cupronickel. <strong>The</strong>secondary gas fired heat exch<strong>an</strong>ger shallbe constructed of 800H stainless steel <strong>an</strong>d90/10 cupronickel. <strong>The</strong> t<strong>an</strong>k insulation shallbe water blown foam 2” thick in the sidewall <strong>with</strong> a rating of R14.2 <strong>an</strong>d 3” thick inthe top <strong>with</strong> a rating of R21.3. Insulationshall be enclosed in a plastic jacket on thesides as well as the top <strong>an</strong>d bottom. Allcomponents shall be located on the frontof the heater for easy access <strong>an</strong>dserviceability. All related hardware shallbe constructed of stainless steel studs<strong>with</strong> brass nuts for serviceability. All waterconnection nipples shall be constructed ofstainless steel <strong>an</strong>d be attached to the sideof the t<strong>an</strong>k. <strong>The</strong> top <strong>an</strong>d bottom of the t<strong>an</strong>kshall be smooth <strong>with</strong> no pipe tappings onthe top or legs on the bottom.<strong>Solar</strong> models shall have <strong>an</strong> additionalinternal heat exch<strong>an</strong>ger on the bottom ofthe t<strong>an</strong>k to connect to a solar system.<strong>The</strong> heaters shall be UL/ULC listed <strong>an</strong>dwill exceed the minimum efficiencyrequirements of ASHRAE 90.1b -1992. Allheaters shall be approved in accord<strong>an</strong>ce<strong>with</strong> ANSI Z 21.10.3. All heaters will besupplied <strong>with</strong> a factory installed ASMErated temperature <strong>an</strong>d pressure reliefvalve. All heaters shall be supplied <strong>with</strong>a factory installed low water cutoff, <strong>an</strong>dupper hot water sensor, <strong>an</strong>d lower coldwater sensor. All heaters shall be furnished<strong>with</strong> a factory installed condensate trapassembly ready for easy connection to afield supplied condensate drain.<strong>The</strong> heater shall have <strong>an</strong> <strong>integrated</strong> digitalcontroller device <strong>with</strong> integral diagnostics,LED fault <strong>an</strong>d temperature settingsfor establishing set point, temperaturedifferential. Ignition shall be <strong>with</strong> directspark <strong>with</strong> ignition taking place at a pre-setignition speed for the burner blower. <strong>The</strong>control shall utilize <strong>an</strong> algorithm to fullyadjust the burner modulating firing ratewhile maintaining the desired temperature.<strong>The</strong> pre-mix stainless steel burner uses a120 volt motor <strong>with</strong> pulse wave modulationcontrol to ch<strong>an</strong>ge the f<strong>an</strong> speed, thus thecombustion air volume of fuel <strong>an</strong>d airthrough the burner to establish <strong>an</strong> infiniteBTU input r<strong>an</strong>ge equal to the water heatingset point requirement. <strong>The</strong> digital LEDcontrol display shall provide me<strong>an</strong>s, viapush buttons, for adjustments of operatingtemperatures, differential adjustment, ECOreset, service mode, <strong>an</strong>d real time statusmode. In addition there shall be provided acomputer connection via laptop computerfor perpetual history including all faultcodes, <strong>an</strong>d hours of operation above 50%of input, below 50% of input as well as realtime status reporting of all operations. <strong>The</strong>burner assembly shall be mounted so as tobe easily removed as <strong>an</strong> integral unit foreasy serviceability.<strong>The</strong> heater shall be in compli<strong>an</strong>ce <strong>with</strong>the NOx Emissions limit as set forth inSCAQMD Rule 1146.2 – 1998.<strong>The</strong> heater shall be factory assembled; testfired for correct BTU input <strong>an</strong>d adjusted forproper combustion parameters. Completeoperating <strong>an</strong>d installation instructionsshall be furnished <strong>with</strong> every heater aspackaged by the m<strong>an</strong>ufacturer <strong>with</strong> theheater for shipping.Copyright 2008www.htproducts.com LP-201 Rev. 2/1/08