Panorama – AustriaTechnical data:Heat output■ 1,170 kW at 80°C/60°C flow / returntemperatures■ -12°C external temperature, min.22°C room temperature;■ Medium - waterCooling requirement■ 965 kW at 6°C/12°C flow / returntemperatures■ 32°C external temperature. 26°Croom temperature;■ Medium - waterFrom this so called loop the central riserslead vertically into the upper floors. Thepipes for the floors branch off again to supplythe individual fan coils. These horizontalcooling water distributor pipes are laidtogether in the false floor with the centralheating pipes.The fan coils in the office areas are equippedwith the following HERZ products inthe field of heating:■ DR-T-90 control valves■ STRÖMAX TS-90-E thermostatic valveswith measuring nipples■ 7710 thermostatic valves.In the field of cooling■ HERZ-GP control valves■ HERZ thermostatic valves with STRÖ-MAX TS-90-E test points■ HERZ 7710 electro-thermal driveswere used.The heating medium temperature iscontrolled in the boiler house independentlyof the external temperature. Thecapacity of the fan coil is controlledusing a room thermostat. The supplycircuits with the shut-off and controlfittings branch off the risers. The pipesoff the risers lead to the individual fancoils in the false floor. The café and businessareas are equipped with warmwater floor convectors with HERZ-DR-T-90 regulation valves and RL-5 returnvalves as well as with steel panel radiatorswith built-in valve fittings (RL-5and MINI thermostatic head) and/or viawarm air through air heating. The pipedistribution from the risers to individualfan coils lead through to the floor ofthe ground floor and every pipe branchingoff is equipped with HERZSTRÖMAX 4117 M shut-off and controlfittings.SERIES: The Austrian industry museumsToilet and plumbing items –the museum for historicalplumbing artefactsin GmundenIn this unusual museum there are more than 300items from the field of bathroom ceramics, representingthe history of hygiene.In 1998 the unique collection of raritiesfrom the town of Gmunden put togetherby Fritz Lischka from the Laufen companyover the years, has been made availableon permanent loan and has found anew home in the protected “Pepöckhaus”in the Traungasse.Since then the costly artistically designedwashbasins, toilet lids, bidets – includingone that belonged to Empress Elisabeth –bathing chairs and baths – are now on showto the public. The exhibition gives an interestingoverview of changing hygiene throughthe ages and the varied history of the WC.The history of the bath and WCA toilet with a kind of water flush existed inancient times, and forerunners of our flushingtoilets today were first invented in the16 th century. The inventor of the first modernwater closet (WC) was the Englishman,Sir John Harrington. In 1589 he hada mansion built with a WC. Indeed, thisWC still very much looked like a dunny,but it had a water reservoir from which thetoilet bowl could be filled with water. Thisfirst WC was also around before QueenHERZ customers and partners had a greatdeal of fun at the anniversary football tournamentof the Austria Gala Team versus theElektra <strong>Herz</strong> Team, which finally ended in ascore of 5-1 for the “Oldstars”. After theirperformance on the pitch, Walter “Schoko”Schachner and Heribert Weber also took careof the atmosphere at the HERZ table. WernerMocharitsch, Hans Mocharitsch junior, HansMocharitsch senior, Heimo Hojas and RolandBumberger (both ÖAG), Joachim Mastnakand Günter Brauneis (SHT), Michael Kolarand Gert Gerold celebrated together at thesubsequent VIP gala with the Styrian HERZrepresentative, Erwin Kollmann.Elizabeth I. As itwas popular, asimilar one wasinstalled at RichmondCastle.The flush wouldnot work at firstThis costly water closet(around 1800) was“disguised” as a pile ofbooks and was found inGmunden.however and temporarily gave way tochamber pots and commodes of all kindswhich often stood camouflaged as sofas oreven books in the middle of the living areas.As well as the history of hygiene and theWC, the development of porcelain in generaland ceramic bathroom products inparticular is the subject of the Gmundenmuseum. “History around the house”rounds off this walk through an unusualmuseum.Sanitärmuseum Klo & So (Plumbing museumof toilets and bathroom fittings)Traungasse 4, A-4810 Gmunden, Austria1 +43/(0)7612/794-425E-mail: museum@gmunden.ooe.gv.atwww.museen.gmunden.atOpen between 1st May and 26 th October,Tuesday to Sunday.Photo left to right, above / below: Erwin Kollmann(HERZ), DI Hans Mocharitsch,“Schoko” Schachner, Heribert Weber, JoachimMastnak and Günter BrauneisSource / photos: Catalogue of toilets and bathroomequipment / plumbing museum in Gmunden14 3/2005

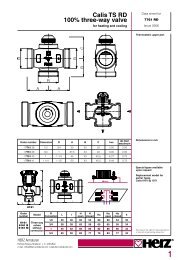

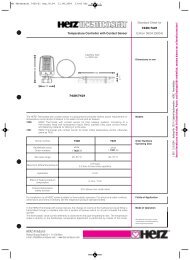

HERZ FeuerungstechnikBio heat from HERZ for theBurgenland wine-growing areaThe woodchip-operated BioMatic combi equipment inNeckenmarkt with a heat output of 800 kW, takes careof environmentally-friendly energy supply.Both types of HERZ BioMatic equipmentwith a heat output of 400 kW each areequipped with their own ash extractorspecially built for the equipment.Since 22nd December 2004 the woodchip-fuelledcombi equipment fromHERZ has been operating in theBurgenland wine region of Neckenmarkt.Seven households, 28 factories and two publicbuildings are currently being suppliedwith bio heat from the local heat supplyequipment. There is also an option for heatsupply for 60 additional houses, and duringthe course of 2005 another ten wereincluded.Intelligent, automated combiequipmentThe HERZ heating equipment, which wasdesigned and built in close collaborationwith the Riebenbauer technical officeand operated by Neckenmarkt districtheating company, consists of two woodchipboilers with a heat output of 400 kWeach. Both installations of the BioMatictype are made into combi equipmentusing BioControl 3000. The intelligentcontrols on the one hand allow optimumcombustion and automation of the equipment,and on the other hand ensureequal usage and optimum deployment ofboth pieces of equipment and thus optimumprovision of fuel.The combi or twin equipment was chosenin order to achieve better coverage of thepartial load area. That means, for example,that only one unit is in operation duringthe transition period, as only part of theheat output and not the full 800 kW is required.Therefore it is always possible toachieve optimum efficiency and therebysave energy.Perfectly planned heating houseThe newly built heating house consists ofa boiler room, a control room and a woodchipstore (store capacity 1,000 m 3 ). Eachof the two HERZ boilers is loaded via tworoom extractors. The boiler equipmentwas constructed for an operating temperatureof 95°C and a maximum operatingpressure of 3 bar. The heat outlet hasbeen equipped with changeover stations,which are fitted with plate heat exchangers.Thus there is a system separationbetween the pre-insulated pipe network(primary network) and the heating equipment(secondary network) in the individualobjects.In the control room there are electronicswitchboards for electrical distributionand switchboards that contain the controland operation equipment by which thewhole plant is automatically controlled.The fuel output is carried out via removalfrom the room and screw conveyor to eachwoodchip boiler with the relevant burnbackprotection in place. In the boilerroom there is also expansion equipmentwith controls, the pump group and a12,000 litre buffer store.Automatic ash removalA special feature of this equipment is theautomatic ash removal. The ashes whichfall down from the combustion chamber,the fly ash from the automatic heat exchangercleaning system and from bothHORIZONTAL SECTION OF HEATING ROOMdrinkingwater pipecontrol roomheating roombuffermulti-cyclones are taken out in an ashremoval system designed and built byHERZ, into a container outside the boilerroom. Here it is possible to speak of almost100 % automated equipment with continuousdust submission under 25 mg/Nm 3 .This design guarantees that the boilerroom remains dust-free and clean.Through the automatic ash removal of allash waste into a container located outsidethe boiler room, with a volume of around2m 3 , the continual cleaning of the flue gasaffected parts is guaranteed. The ashwaste is also used as fertiliser.Environmentally-friendly fuel fromthe surroundingsThe fuel is stored in the woodchip store.Only untreated wood in the form of forestwood chips is used as fuel. A moveable threepartlid is attached to the roof constructionof the woodchip store. The fuel is suppliedby members of the community or externalsuppliers. Each year around 1,700 metres ofloose woodchips is required. All the woodchipis taken from Neckenmarkt’s ownforests.The ground plan ofthe boiler roomshows the configurationof the combiequipment includingdust cutterand automatic ashremoval in ahydraulically drivencontainer outsidethe heatingcentres.3/2005 15