Riteflex® TPE-E - Hi Polymers

Riteflex® TPE-E - Hi Polymers

Riteflex® TPE-E - Hi Polymers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

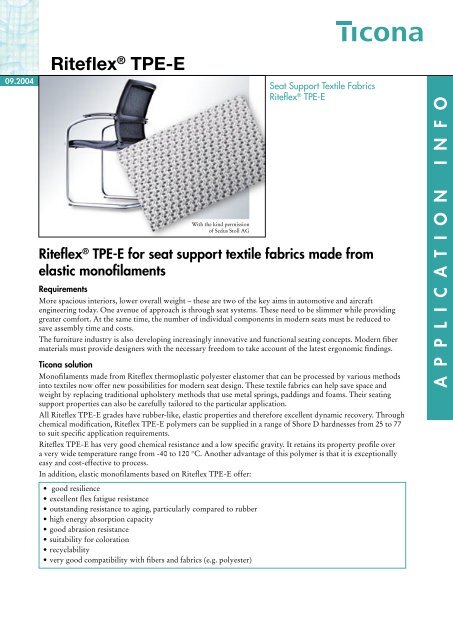

09.2004Riteflex ® <strong>TPE</strong>-ESeat Support Textile FabricsRiteflex ® <strong>TPE</strong>-ERiteflex ® <strong>TPE</strong>-E for seat support textile fabrics made fromelastic monofilamentsRequirementsMore spacious interiors, lower overall weight – these are two of the key aims in automotive and aircraftengineering today. One avenue of approach is through seat systems. These need to be slimmer while providinggreater comfort. At the same time, the number of individual components in modern seats must be reduced tosave assembly time and costs.The furniture industry is also developing increasingly innovative and functional seating concepts. Modern fibermaterials must provide designers with the necessary freedom to take account of the latest ergonomic findings.Ticona solutionWith the kind permissionof Sedus Stoll AGMonofilaments made from Riteflex thermoplastic polyester elastomer that can be processed by various methodsinto textiles now offer new possibilities for modern seat design. These textile fabrics can help save space andweight by replacing traditional upholstery methods that use metal springs, paddings and foams. Their seatingsupport properties can also be carefully tailored to the particular application.All Riteflex <strong>TPE</strong>-E grades have rubber-like, elastic properties and therefore excellent dynamic recovery. Throughchemical modification, Riteflex <strong>TPE</strong>-E polymers can be supplied in a range of Shore D hardnesses from 25 to 77to suit specific application requirements.Riteflex <strong>TPE</strong>-E has very good chemical resistance and a low specific gravity. It retains its property profile overa very wide temperature range from -40 to 120 °C. Another advantage of this polymer is that it is exceptionallyeasy and cost-effective to process.In addition, elastic monofilaments based on Riteflex <strong>TPE</strong>-E offer:A P P L I C A T I O N I N F O• good resilience• excellent flex fatigue resistance• outstanding resistance to aging, particularly compared to rubber• high energy absorption capacity• good abrasion resistance• suitability for coloration• recyclability• very good compatibility with fibers and fabrics (e.g. polyester)

A P P L I C A T I O N I N F OTicona, a business of Celanese AG, is a leading global supplier of high performanceengineering thermoplastics that are successfully used in injection molding and extrusionapplications in a broad range of end-use markets.Ticona offers a variety of polymer grades that help to meet the increasing requirementsof technical textile applications, such as higher temperature and chemical resistance inharsh environments, good elasticity combined with strength, and conformity withapprovals for medical applications or food contact.Due to a wide range of melt viscosities these high quality polymers can be formed byvarious common technologies to manufacture meltblown and spunbond nonwovens,monofilaments, multifilaments and staple fibers. Successful commercial applicationsmade from these polymers can be found in markets such as automotive, industrial,medical and filtration.The Ticona portfolio of fiber-spinning polymers includes the following products:Fortron ® polyphenylene sulfide (PPS)Celanex ® thermoplastic polyester (PBT)Riteflex ® thermoplastic polyester elastomer (<strong>TPE</strong>-E)Hostaform ® polyoxymethylene copolymer (POM)Topas ® cyclic olefin copolymer (COC)NOTICE TO USERS:The information contained in this publication should not be construed as a promise or guarantee of specific properties of ourproducts. Any determination of the suitability of a particular material and design for any use contemplated by the user is thesole responsibility of the user. We strongly recommend that users seek and adhere to the manufacturer’s current instructionsfor handling each material they use. Any existing intellectual property rights must be observed.EuropeTicona GmbHInformation ServicePh.: +49 (0) 180-5842662 (Germany)+49 (0) 69-30516299 (Europe)Fax: +49 (0) 180-2021202eMail: infoservice@ticona.deInternet: www.ticona.comAmericasTicona LLCProduct Information ServicePh.: +1-800-833-4882Fax: +1-908-598-4306eMail: prodinfo@ticona.comInternet: www.ticona.com