ROOFS WITH PHOTOVOLTAIC SYSTEMS - Index S.p.A.

ROOFS WITH PHOTOVOLTAIC SYSTEMS - Index S.p.A.

ROOFS WITH PHOTOVOLTAIC SYSTEMS - Index S.p.A.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

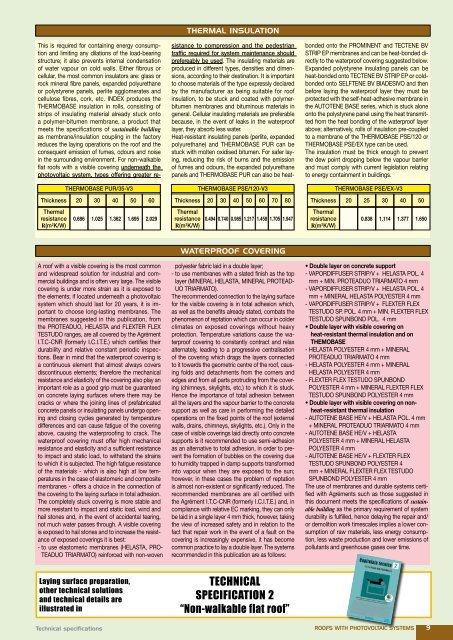

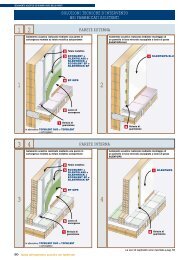

THERMAL INSULATIONThis is required for containing energy consumptionand limiting any dilations of the load-bearingstructure; it also prevents internal condensationof water vapour on cold walls. Either fibrous orcellular, the most common insulators are: glass orrock mineral fibre panels, expanded polyurethaneor polystyrene panels, perlite agglomerates andcellulose fibres, cork, etc. INDEX produces theTHERMOBASE insulation in rolls, consisting ofstrips of insulating material already stuck ontoa polymer-bitumen membrane, a product thatmeets the specifications of sustainable buildingas membrane/insulation coupling in the factoryreduces the laying operations on the roof and theconsequent emission of fumes, odours and noisein the surrounding environment. For non-walkableflat roofs with a visible covering underneath thephotovoltaic system, types offering greater resistanceto compression and the pedestriantraffic required for system maintenance shouldprefereably be used. The insulating materials areproduced in different types, densities and dimensions,according to their destination. It is importantto choose materials of the type expressly declaredby the manufacturer as being suitable for roofinsulation, to be stuck and coated with polymerbitumenmembranes and bituminous materials ingeneral. Cellular insulating materials are preferablebecause, in the event of leaks in the waterprooflayer, they absorb less water.Heat-resistant insulating panels (perlite, expandedpolyurethane) and THERMOBASE PUR can bestuck with molten oxidised bitumen. For safer laying,reducing the risk of burns and the emissionof fumes and odours, the expanded polyurethanepanels and THERMOBASE PUR can also be heatbondedonto the PROMINENT and TECTENE BVSTRIP EP membranes and can be heat-bonded directlyto the waterproof covering suggested below.Expanded polystyrene insulating panels can beheat-bonded onto TECTENE BV STRIP EP or coldbondedonto SELFTENE BV BIADESIVO and thenbefore laying the waterproof layer they must beprotected with the self-heat-adhesive membrane inthe AUTOTENE BASE series, which is stuck aloneonto the polystyrene panel using the heat transmittedfrom the heat bonding of the waterproof layerabove; alternatively, rolls of insulation pre-coupledto a membrane of the THERMOBASE PSE/120 orTHERMOBASE PSE/EX type can be used.The insulation must be thick enough to preventthe dew point dropping below the vapour barrierand must comply with current legislation relatingto energy containment in buildings.THERMOBASE PUR/35-V3THERMOBASE PSE/120-V3THERMOBASE PSE/EX-V3Thickness20 30405060Thickness 20 30 40 50 60 7080Thickness20 25304050ThermalresistanceR(m 2 K/W)0.686 1.0251.3621.6952.029ThermalresistanceR(m 2 K/W)0.494 0.740 0.985 1.217 1.458 1.705 1.947ThermalresistanceR(m 2 K/W)0.8381.1141.3771.650WATERPROOF COVERINGA roof with a visible covering is the most commonand widespread solution for industrial and commercialbuildings and is often very large. The visiblecovering is under more strain as it is exposed tothe elements; if located underneath a photovoltaicsystem which should last for 20 years, it is importantto choose long-lasting membranes. Themembranes suggested in this publication, fromthe PROTEADUO, HELASTA and FLEXTER FLEXTESTUDO ranges, are all covered by the AgrémentI.T.C-CNR (formerly I.C.I.T.E.) which certifies theirdurability and relative constant periodic inspections.Bear in mind that the waterproof covering isa continuous element that almost always coversdiscontinuous elements; therefore the mechanicalresistance and elasticity of the covering also play animportant role as a good grip must be guaranteedon concrete laying surfaces where there may becracks or where the joining lines of prefabricatedconcrete panels or insulating panels undergo openingand closing cycles generated by temperaturedifferences and can cause fatigue of the coveringabove, causing the waterproofing to crack. Thewaterproof covering must offer high mechanicalresistance and elasticity and a sufficient resistanceto impact and static load, to withstand the strainsto which it is subjected. The high fatigue resistanceof the materials - which is also high at low temperaturesin the case of elastomeric and compositemembranes - offers a choice in the connection ofthe covering to the laying surface in total adhesion.The completely stuck covering is more stable andmore resistant to impact and static load, wind andhail stones and, in the event of accidental tearing,not much water passes through. A visible coveringis exposed to hail stones and to increase the resistanceof exposed coverings it is best:- to use elastomeric membranes (HELASTA, PRO-TEADUO TRIARMATO) reinforced with non-wovenpolyester fabric laid in a double layer;- to use membranes with a slated finish as the toplayer (MINERAL HELASTA, MINERAL PROTEAD-UO TRIARMATO).The recommended connection to the laying surfacefor the visible covering is in total adhesion which,as well as the benefits already stated, combats thephenomenon of reptation which can occur in colderclimates on exposed coverings without heavyprotection. Temperature variations cause the waterproofcovering to constantly contract and relaxalternately, leading to a progressive centralisationof the covering which drags the layers connectedto it towards the geometric centre of the roof, causingfolds and detachments from the corners andedges and from all parts protruding from the covering(chimneys, skylights, etc.) to which it is stuck.Hence the importance of total adhesion betweenall the layers and the vapour barrier to the concretesupport as well as care in performing the detailedoperations on the fixed points of the roof (externalwalls, drains, chimneys, skylights, etc.). Only in thecase of visible coverings laid directly onto concretesupports is it recommended to use semi-adhesionas an alternative to total adhesion, in order to preventthe formation of bubbles on the covering dueto humidity trapped in damp supports transformedinto vapour when they are exposed to the sun;however, in these cases the problem of reptationis almost non-existent or significantly reduced. Therecommended membranes are all certified withthe Agrément I.T.C-CNR (formerly I.C.I.T.E.) and, incompliance with relative EC marking, they can onlybe laid in a single layer 4 mm thick, however, takingthe view of increased safety and in relation to thefact that repair work in the event of a fault on thecovering is increasingly expensive, it has becomecommon practice to lay a double layer. The systemsrecommended in this publication are as follows:• Double layer on concrete support- VAPORDIFFUSER STRIP/V + HELASTA POL. 4mm + MIN. PROTEADUO TRIARMATO 4 mm- VAPORDIFFUSER STRIP/V + HELASTA POL. 4mm + MINERAL HELASTA POLYESTER 4 mm- VAPORDIFFUSER STRIP/V + FLEXTER FLEXTESTUDO SP. POL. 4 mm + MIN. FLEXTER FLEXTESTUDO SPUNBOND POL. 4 mm• Double layer with visible covering onheat-resistant thermal insulation and onTHEMOBASE- HELASTA POLYESTER 4 mm + MINERALPROTEADUO TRIARMATO 4 mm- HELASTA POLYESTER 4 mm + MINERALHELASTA POLYESTER 4 mm- FLEXTER FLEX TESTUDO SPUNBONDPOLYESTER 4 mm + MINERAL FLEXTER FLEXTESTUDO SPUNBOND POLYESTER 4 mm• Double layer with visible covering on nonheat-resistantthermal insulation- AUTOTENE BASE HE/V + HELASTA POL. 4 mm+ MINERAL PROTEADUO TRIARMATO 4 mm- AUTOTENE BASE HE/V + HELASTAPOLYESTER 4 mm + MINERAL HELASTAPOLYESTER 4 mm- AUTOTENE BASE HE/V + FLEXTER FLEXTESTUDO SPUNBOND POLYESTER 4mm + MINERAL FLEXTER FLEX TESTUDOSPUNBOND POLYESTER 4 mmThe use of membranes and durable systems certifiedwith Agréments such as those suggested inthis document meets the specifications of sustainablebuilding as the primary requirement of systemdurability is fulfilled, hence delaying the repair and/or demolition work timescales implies a lower consumptionof raw materials, less energy consumption,less waste production and lower emissions ofpollutants and greenhouse gases over time.Laying surface preparation,other technical solutionsand technical details areillustrated inTECHNICALSPECIFICATION 2“Non-walkable flat roof”Technical specifications<strong>ROOFS</strong> <strong>WITH</strong> <strong>PHOTOVOLTAIC</strong> <strong>SYSTEMS</strong>9