Rosedale Products' Versatile Basket Filters ... - Filtration News

Rosedale Products' Versatile Basket Filters ... - Filtration News

Rosedale Products' Versatile Basket Filters ... - Filtration News

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

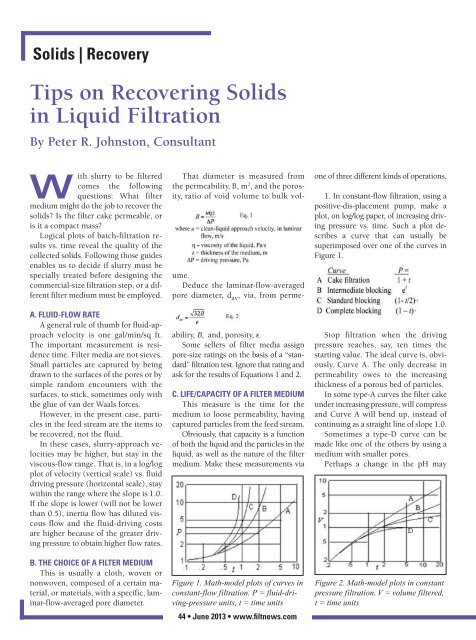

Solids | RecoveryTips on Recovering Solidsin Liquid <strong>Filtration</strong>By Peter R. Johnston, ConsultantWith slurry to be filteredcomes the followingquestions: What filtermedium might do the job to recover thesolids? Is the filter cake permeable, oris it a compact mass?Logical plots of batch-filtration resultsvs. time reveal the quality of thecollected solids. Following those guidesenables us to decide if slurry must bespecially treated before designing thecommercial-size filtration step, or a differentfilter medium must be employed.A. FLUID-FLOW RATEA general rule of thumb for fluid-approachvelocity is one gal/min/sq ft.The important measurement is residencetime. Filter media are not sieves.Small particles are captured by beingdrawn to the surfaces of the pores or bysimple random encounters with thesurfaces, to stick, sometimes only withthe glue of van der Waals forces.However, in the present case, particlesin the feed stream are the items tobe recovered, not the fluid.In these cases, slurry-approach velocitiesmay be higher, but stay in theviscous-flow range. That is, in a log/logplot of velocity (vertical scale) vs. fluiddriving pressure (horizontal scale), staywithin the range where the slope is 1.0.If the slope is lower (will not be lowerthan 0.5), inertia flow has diluted viscousflow and the fluid-driving costsare higher because of the greater drivingpressure to obtain higher flow rates.B. THE CHOICE OF A FILTER MEDIUMThis is usually a cloth, woven ornonwoven, composed of a certain material,or materials, with a specific, laminar-flow-averagedpore diameter.That diameter is measured fromthe permeability, B, m 2 , and the porosity,ratio of void volume to bulk volume.Deduce the laminar-flow-averagedpore diameter, d av , via, from permeabiliry,B, and, porosity, ε.Some sellers of filter media assignpore-size ratings on the basis of a “standard”filtration test. Ignore that rating andask for the results of Equations 1 and 2.C. LIFE/CAPACITY OF A FILTER MEDIUMThis measure is the time for themedium to loose permeability, havingcaptured particles from the feed stream.Obviously, that capacity is a functionof both the liquid and the particles in theliquid, as well as the nature of the filtermedium. Make these measurements viaFigure 1. Math-model plots of curves inconstant-flow filtration. P = fluid-driving-pressureunits, t = time units44 • June 2013 • www.filtnews.comone of three different kinds of operations.1. In constant-flow filtration, using apositive-dis-placement pump, make aplot, on log/log paper, of increasing drivingpressure vs. time. Such a plot describesa curve that can usually besuperimposed over one of the curves inFigure 1.Stop filtration when the drivingpressure reaches, say, ten times thestarting value. The ideal curve is, obviously,Curve A. The only decrease inpermeability owes to the increasingthickness of a porous bed of particles.In some type-A curves the filter cakeunder increasing pressure, will compressand Curve A will bend up, instead ofcontinuing as a straight line of slope 1.0.Sometimes a type-D curve can bemade like one of the others by using amedium with smaller pores.Perhaps a change in the pH mayFigure 2. Math-model plots in constantpressure filtration. V = volume filtered,t = time units