Rosa - Total.com

Rosa - Total.com

Rosa - Total.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DEsIgN aND<br />

faBrICaTIoN: a TrULy<br />

gLoBaL UNDErTaKINg<br />

KEy DaTEs<br />

December 2004:<br />

Start of fabrication of the Christmas trees.<br />

March 2005:<br />

Start of fabrication of the FPSO modules<br />

and assembly of the subsea manifolds.<br />

May 2005:<br />

Start of fabrication of Pipe in Pipe quad<br />

joints.<br />

December 2005:<br />

Start of riser tower assembly.<br />

LoCaL CoNTENT: TraNsfErrINg KNoW-HoW IN aNgoLa<br />

The contractual strategy deployed by <strong>Total</strong> aimed to<br />

maximize the benefi ts for the Angolan economy. The<br />

momentum created in the country’s oil services<br />

industry – as seen by the construction of extensive<br />

infrastructure – translated to nearly three million<br />

hours of work for Angola’s onshore fabrication yards<br />

and logistical hubs.<br />

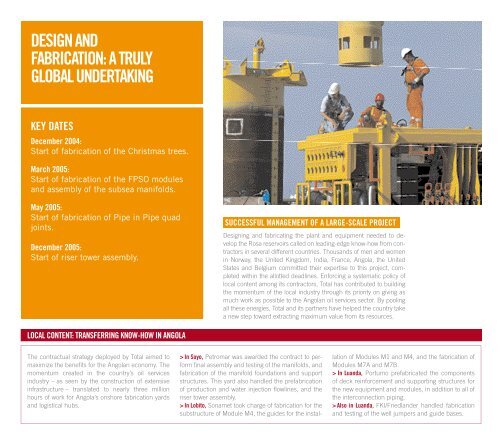

sUCCEssfUL MaNagEMENT of a LargE-sCaLE ProJECT<br />

Designing and fabricating the plant and equipment needed to develop<br />

the <strong>Rosa</strong> reservoirs called on leading-edge know-how from contractors<br />

in several different countries. Thousands of men and women<br />

in Norway, the United Kingdom, India, France, Angola, the United<br />

States and Belgium <strong>com</strong>mitted their expertise to this project, <strong>com</strong>pleted<br />

within the allotted deadlines. Enforcing a systematic policy of<br />

local content among its contractors, <strong>Total</strong> has contributed to building<br />

the momentum of the local industry through its priority on giving as<br />

much work as possible to the Angolan oil services sector. By pooling<br />

all these energies, <strong>Total</strong> and its partners have helped the country take<br />

a new step toward extracting maximum value from its resources.<br />

> In soyo, Petromar was awarded the contract to perform<br />

fi nal assembly and testing of the manifolds, and<br />

fabrication of the manifold foundations and support<br />

structures. This yard also handled the prefabrication<br />

of production and water injection fl owlines, and the<br />

riser tower assembly.<br />

> In Lobito, Sonamet took charge of fabrication for the<br />

substructure of Module M4, the guides for the instal-<br />

lation of Modules M1 and M4, and the fabrication of<br />

Modules M7A and M7B.<br />

> In Luanda, Portumo prefabricated the <strong>com</strong>ponents<br />

of deck reinforcement and supporting structures for<br />

the new equipment and modules, in addition to all of<br />

the interconnection piping.<br />

> also in Luanda, FKI/Friedlander handled fabrication<br />

and testing of the well jumpers and guide bases.