to view article - Sutter Masonry

to view article - Sutter Masonry

to view article - Sutter Masonry

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

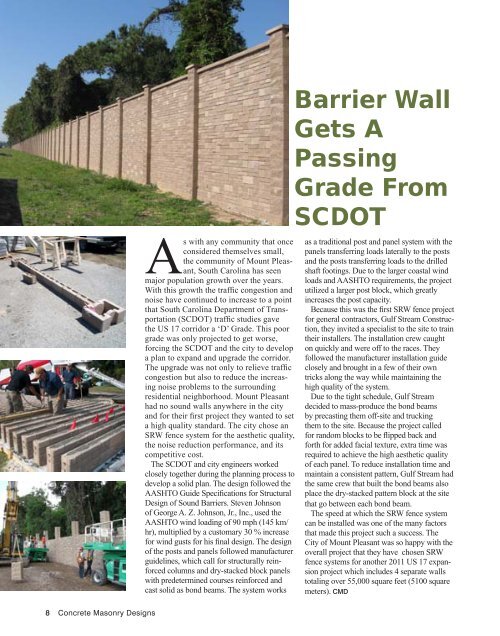

8 Concrete <strong>Masonry</strong> DesignsAs with any community that onceconsidered themselves small,the community of Mount Pleasant,South Carolina has seenmajor population growth over the years.With this growth the traffic congestion andnoise have continued <strong>to</strong> increase <strong>to</strong> a pointthat South Carolina Department of Transportation(SCDOT) traffic studies gavethe US 17 corridor a ‘D’ Grade. This poorgrade was only projected <strong>to</strong> get worse,forcing the SCDOT and the city <strong>to</strong> developa plan <strong>to</strong> expand and upgrade the corridor.The upgrade was not only <strong>to</strong> relieve trafficcongestion but also <strong>to</strong> reduce the increasingnoise problems <strong>to</strong> the surroundingresidential neighborhood. Mount Pleasanthad no sound walls anywhere in the cityand for their first project they wanted <strong>to</strong> seta high quality standard. The city chose anSRW fence system for the aesthetic quality,the noise reduction performance, and itscompetitive cost.The SCDOT and city engineers workedclosely <strong>to</strong>gether during the planning process <strong>to</strong>develop a solid plan. The design followed theAASHTO Guide Specifications for StructuralDesign of Sound Barriers. Steven Johnsonof George A. Z. Johnson, Jr., Inc., used theAASHTO wind loading of 90 mph (145 km/hr), multiplied by a cus<strong>to</strong>mary 30 % increasefor wind gusts for his final design. The designof the posts and panels followed manufacturerguidelines, which call for structurally reinforcedcolumns and dry-stacked block panelswith predetermined courses reinforced andcast solid as bond beams. The system worksBarrier WallGets APassingGrade FromSCDOTas a traditional post and panel system with thepanels transferring loads laterally <strong>to</strong> the postsand the posts transferring loads <strong>to</strong> the drilledshaft footings. Due <strong>to</strong> the larger coastal windloads and AASHTO requirements, the projectutilized a larger post block, which greatlyincreases the post capacity.Because this was the first SRW fence projectfor general contrac<strong>to</strong>rs, Gulf Stream Construction,they invited a specialist <strong>to</strong> the site <strong>to</strong> traintheir installers. The installation crew caugh<strong>to</strong>n quickly and were off <strong>to</strong> the races. Theyfollowed the manufacturer installation guideclosely and brought in a few of their owntricks along the way while maintaining thehigh quality of the system.Due <strong>to</strong> the tight schedule, Gulf Streamdecided <strong>to</strong> mass-produce the bond beamsby precasting them off-site and truckingthem <strong>to</strong> the site. Because the project calledfor random blocks <strong>to</strong> be flipped back andforth for added facial texture, extra time wasrequired <strong>to</strong> achieve the high aesthetic qualityof each panel. To reduce installation time andmaintain a consistent pattern, Gulf Stream hadthe same crew that built the bond beams alsoplace the dry-stacked pattern block at the sitethat go between each bond beam.The speed at which the SRW fence systemcan be installed was one of the many fac<strong>to</strong>rsthat made this project such a success. TheCity of Mount Pleasant was so happy with theoverall project that they have chosen SRWfence systems for another 2011 US 17 expansionproject which includes 4 separate walls<strong>to</strong>taling over 55,000 square feet (5100 squaremeters). CMD