d of broadcast NAB cartridge machines includingthree new products: a new NAB cartridge knownas the Sapphire, which offers full compatibilitywith existing carts but with improved specs; anautomatic telephone balance unit HY02 availablefree -standing or rackmount; and the Micro DS, anFSK data system for storage and retrieval ofinformation each time a cart is played. SonyBroadcast: featuring the PCM -3348 digitalmultitrack in two different configurations, onewill be linked to the new MXP -3056 56- channelmixing console, the second PCM -3348 will beoperating with the PCM- 3324A. The PCM -34022 -track recorder and a new product the SDP -1000a digital 2- channel effects system. Other newproducts include a portable DAT recorder theTCD -D10 Pro, the 2 -track recorder APR 5003V,the 24 -track recorder APR 24, the MXP 2026broadcast console and the ECM MS -5 electretcondenser microphone. Soundcraft: UK debutof the 3200 32 -bus multitrack recording console ina split configuration with 36 inputs and a rangeof innovative facilities and features. Also featuredis the enhanced Reims console, the newautomation system for the 6000 series and newmodule options for the SAC 200 on -air console.Existing products include series 200 BVE withVSA 24 serial interface. Sound Engineer &Producer: UK recording magazine. Sound OnSound: musician orientated recording magazine.Sound Technology: new products from Alesisinclude the Quadraverb 16 bit multi- effectsprocessor; the first UK showing of the 1622mixer, designed primarily as an auxiliary studiomixer and the MEQ -230 30 -band graphicequaliser; the 1622 and MEQ -30 featureIntegrated Monolithic Surface Technology, a newprocess that makes more efficient use of materialand labour. From Aphex new products are theAural Exciter Type III; the studio clock, a fullfunction SMPTE to MIDI converter as well as anApple Macintosh MIDI interface; the AphexImpulse 12 -input analogue to MIDI percussiontrigger; and the Aphex Feel Factory, the firstalgorithmic feel composer that allows the user tomanipulate MIDI timing and velocity informationfrom an existing sequence or drum machinepattern intuitively and in realtime; all the Ashlyprocessors for PA installation; the C -Lab 64 -trackMIDI recording software with the new HumanTouch tempo interface and the Combiner, anexpansion interface for the Atari computer. Newprograms include Explorer Ml, an editor/librarianfor the Korg M1 synthesiser; from Digidesign thenew Sound Tools digital recording and editingsystem for the Apple Macintosh offering hard diskmastering and editing. The full range of JLCooper mixer automation and SMPTE/MIDIproducts includes the new PPS 100 SMPTE toMIDI converter and event generator and theFadermaster MIDI command controller; Oberheimproducts include the new OB 8k multitimbralsynthesiser/keyboard; Symetrix range of studiosignal processing. Soundtracs: featured will bethree new products on show for the first time inthe UK, the SPA 3200, the FMB and the FM-AFV. The SPA 3200 is a new PA console; the FMseries broadcast mixer, the FMB is a new `on -air'console available in two sizes accommodating 16or 24 channels; the FM AFV is an audio followsvideo controller enabling up to eight channels ofaudio on an FMX console to be controlled fromany video editing system with either BVE orgeneral purpose interfaces. The FM AFV isavailable factory fitted or as a retrofit. Allestablished consoles will be on show as well asthe Tracmix fader automation system. SSEMarketing: new products include the DSP62 Studio Sound, June 1989package for the Audio Precision's System Onecomputer -controlled audio test system, allowingthe Audio Precision to analyse audio in thedigital domain and carry out FFT measurement.New from Schoeps is a 2- channel microphoneamplifier with phantom supply and M/S matrix.SSL: demonstrated will be the newScreenSound digital editing, mixing and recordingsystem for off -line video and film post -productionand audio -for -video editing applications.ScreenSound interfaces with VTR/VCRs and filmreproducers with full machine control. It alsointerfaces at machine level with the QuantelHarry digital video editing system, and in theHarry mode offers fully interactive audio andvision editing. Also featured will be the 01 digitalproduction centre, an integrated digital audiorecording, processing and editing system; the SL4000 G series master studio system for multitrackrecording and mixing; the G series studiocomputer console automation system; and theTotal Recall computer system. Stirling Audio:products include DDA's AMR 24 -track console,Otani MTR100A 2 inch analogue machine,Lexicon 480L with new version 3.0 software,Sanken CU-44X transformerless microphone, theKeyboard Unit and System Supervisor of the Lynxpost -production system, Alpha Audio Boss 2,moving faders from Digital Creations, AudioKinetics Reflex automation system and the widerange of Mogami audio and video cable. Studio:monthly studio news magazine. Studiomaster:a new digital module for the Studiofex system,SF812 stereo digital reverb. Also on showStudiomaster's range of accessories including theAC01 active crossover and FCP1 4- channelphantom power supply. Studiomaster also promisesome un -named surprise new products. StudioSpares: wide range of studio equipment, spareparts and ancilliary supplies for the professionaluser. Studio Timeline: showing the Optifile IIautomation system, Crystal noise eliminators, theBulletin Board equipment for sale listing andStereolith DuettoDCS 900 A/D converter from DataConversion SystemsWORLDWIDE AGENTSAUSTRALIA: A.T.T. AUDIO CONTROLS PTY LTDMELBOURNE (03) 379 -1511AUSTRIA: AUDIOSALESMOEDLING (02236) 26123BELGIUM: T.E.M.ZELLIK (02) 466 -5010CANADA: OMNIMEDIA CORP.MONTREAL (514) 636 -9971DENMARK PER MEISTRUP PRODUCTIONSKARLSLUNDE (02)151300FRANCE: REGISCENEPARIS (01) 4396 -5050GREECE: ALPHA SOUNDATHENS (01) 363 -8317HOLLAND: T.E.M.BREDA (076) 812872HONG KONG /CHINA: TOM LEE MUSIC COHONK KONG (3) 730 -1098INDONESIA: PT AUVINDO MERZEN PRIMAJAKARTA (01) 323029ISRAEL: BARKAIRAMAT -GAN (03) 735178ITALY: AUDIO LINKPARMA (0521) 598723/4JAPAN: EDGETECH (JAPAN) LTDTOKYO (03) 295-4731KOREA: YUNG NAK SO RI SA COSEOUL (01) 267 -9697NORWAY: NORDTEK EQUIPMENTOSLO (02) 231590PHILIPPINES: STAGE CRAFT INTERNATIONAL INCMANILA (02) 834 -0539PORTUGAL: CASA CADIS ARTIGOS MUSICALS LTDOPORTO (02) 0384456SINGAPORE /MALAYSIA: SWEE LEESINGAPORE (03) 336 -2307SPAIN: LEXONBARCELONA (03) 203 -4804SWEDEN INTERSONICSTOCKHOLM (08) 744 5853SWITZERLAND: SINECSCHÖNENWERD (64) 413747THAILAND: BANGKOK CINE /GRAPHIC CENTREBANGKOK (02) 314 -3570KCM BANGKOK (02) 222 -4712TURKEY. NEFANISTANBUL (01)160-4514UK: FIRST AUDIO LTDBRIGHTON (0273) 693610U.S.A.: E.D.C.NEW YORK (914) 677 -6478WEST GERMANY ADAM HALLUSINGEN (6081) 16031

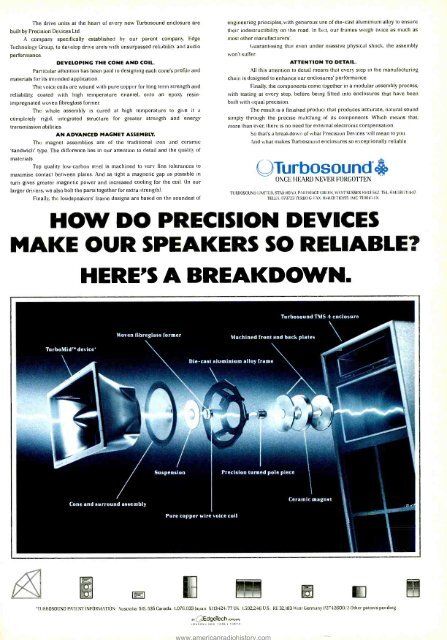

The drive units at the heart of every new Turbosound enclosure arebuilt by Precision Devices Ltd.A company specifically established by our parent company, EdgeTechnology Group, to develop drive units with unsurpassed reliability and audioperformance.DEVELOPING THE CONE AND COIL.Particular attention has been paid to designing each cone's profile andmaterials for its intended application.The voice coils are wound with pure copper for long term strength andreliability, coated with high temperature enamel, onto an epoxy resin -impregnated woven fibreglass former.The whole assembly is cured at high temperature to give it acompletely rigid, integrated structure for greater strength and energytransmission abilities.AN ADVANCED MAGNET ASSEMBLY.The magnet assemblies are of the traditional iron and ceramic'sandwich' type. The difference lies in our attention to detail and the quality ofmaterials.Top quality low- carbon steel is machined to very fine tolerances tomaximise contact between plates. And as tight a magnetic gap as possible inturn gives greater magnetic power and increased cooling for the coil. (In ourlarger drivers, we also bolt the parts together for extra strength).Finally, the loudspeakers' frame designs are based on the soundest ofengineering principles, with generous use of die -cast aluminium alloy to ensuretheir indestructibility on the road. In fact, our frames weigh twice as much asmost other manufacturers'.Guaranteeing that even under massive physical shock, the assemblywon't suffer.ATTENTION TO DETAIL.All this attention to detail means that every step in the manufacturingchain is designed to enhance our enclosures' performance.Finally, the components come together in a modular assembly process,with testing at every step, before being fitted into enclosures that have beenbuilt with equal precision.The result is a finished product that produces accurate, natural soundsimply through the precise matching of its components. Which means that,more than ever, there is no need for external electronic compensation.So that's a breakdown of what Precision Devices will mean to you.And what makes Turbosound enclosures so exceptionally reliable.OTurbosound4`ONCE HEARD NEVER FORGOTTENTURBOSOUND LIMITED, STAR ROAD, PARTRIDGE GREEN, WEST SUSSEX RH13 5EZ. TEL: (0403) 711447.TELEX: 878723 TURBO G. FAX (0403) 710155. IMc: TURBO -UKHOW DO PRECISION DEVICESMAKE OUR SPEAKERS SO RELIABLE?HERE'S A BREAKDOWN.Turbosound TMS 4 enclosureTurboMid'" device'Woven fibreglass formerDie -cast aluminiumMachines front and back platesframek.SuspensionPrecision turned pole pieceCone and surround assemblyCeramic magnetPure copper wire voice coilPKILDr_1lLEI'TURBOSOUND PATENT INFORMATION: Australia: 515, 535 Canada: 1,076,033 Japan: X113424/77 UK: 1,592,246 U.S.: RE 32,183 West Germany P2742600/2 Other patents pending.a QEdgeTechLONDON NEW YORK TOKYO

- Page 1:

June 1989STUDIOAND BROADCAST ENGINE

- Page 4 and 5:

Sony Broadcast& CommunicationsBroad

- Page 6 and 7:

NEUTRIKSWISSconnectorsFed up with w

- Page 8 and 9:

lLET USINTRODUCE YOUTO A FRIENDTHE

- Page 10 and 11:

®XSP56001R20B77G8824Ur*.......t+00

- Page 12 and 13:

MUSIC i RECORDINGLA B NEWSTelephone

- Page 14 and 15:

C/)WDudderidgeacquires FocusritePhi

- Page 16 and 17:

GLW Enterprisesacquires HarrisonSys

- Page 18 and 19:

AgenciesSynton of Holland have sign

- Page 20 and 21: C :SOUND© GraphicAudio EditingFirs

- Page 22 and 23: ContractsThe Home Service has recei

- Page 24 and 25: 1Soundlab active audio splitterSoun

- Page 26 and 27: 42'21 111H1H-"b9I Illlllll IIIIIIII

- Page 28 and 29: The DC 24 MultiLFunctionDy, ñíami

- Page 30 and 31: AlbRTW digital masteringsystemRTW h

- Page 32 and 33: The round the world round of round

- Page 34 and 35: ,14GENELi CFINLAND, 7htaantie 17, P

- Page 36 and 37: SolidStatelogic G Series NewsReal W

- Page 38 and 39: SolidStateLogicNew Purpose - built,

- Page 40 and 41: SolidStateLogicDi 'tal Audio NewsDi

- Page 42 and 43: SolidStateLogicCompany NewsExpansio

- Page 44 and 45: REPORTER JOURNALISTPRO -CASSETTE RE

- Page 46 and 47: THE ADVANTAGES of a STUDIOCONDENSER

- Page 48 and 49: AES HAMBURG=BY ANDY ROSE, DIRECTOR,

- Page 50 and 51: 1n seems easy enough,al sampling to

- Page 52 and 53: 14e last count the number ofBrent r

- Page 54 and 55: cthe question `What if we swapped t

- Page 56 and 57: aFIG 5Appearancehead finding audio

- Page 58 and 59: AKGacousCicsADVANCEDMICROPHONETECHN

- Page 60 and 61: 'Recently a few dealers have compla

- Page 62 and 63: tWl £Na«uvv«««:w,p/ N.»iH{t.M

- Page 64 and 65: Film -Tech PAM 42 portable audio mi

- Page 66 and 67: Q Concept, Soundmix and Multimix. H

- Page 68 and 69: d include from Cutec a switchable 1

- Page 72 and 73: 4GOLD LINEumaJAPORTABLE RTA1/3 OCTA

- Page 74 and 75: efflefingSoundtracs FMB series mixi

- Page 76 and 77: Auio...if you don't see what you wa

- Page 78 and 79: -nvasigh Midl'ladP9t/'knnIFveuuenaY

- Page 80 and 81: A STRONG TEAMD&R DAYNERwoinpThis co

- Page 82 and 83: ULTRASOUN DJanet Angus visits a Lon

- Page 84 and 85: The Recognized Standard in Audio Te

- Page 86 and 87: 4 The sample rate converter is used

- Page 88 and 89: www.americanradiohistory.comDSP THE

- Page 90 and 91: INTRODUCINGOUR NEWM0DEIrTèP325THE

- Page 92 and 93: VCASINVESTIGATEDPART ONEBen Duncan

- Page 94 and 95: Q root extractor or exponentiator.

- Page 96 and 97: MORE CO\TROLThere's the sound: big,

- Page 98 and 99: Q voltage (VBE) and collector curre

- Page 100 and 101: '2)1)2). t)YJÌr2lYlá)`tÌ :% i) _

- Page 102 and 103: SINE WAVE1 2 3 4 5 6 7FREQUENCYSQUA

- Page 104 and 105: The studio was dark except for the

- Page 106 and 107: capacitance is fired by grounding.S

- Page 108 and 109: IZWQ U_VW1--Fostex D-20A technical

- Page 110 and 111: function by the toggle switch label

- Page 112 and 113: Other indicatorsand switchesThe maj

- Page 114 and 115: ConceptualdCDCfg114111wR-aatojuiai

- Page 116 and 117: Details of the Fostex DAT and timec

- Page 118 and 119: BSS DPR -502A user report on a MIDI

- Page 120 and 121:

preserve the full sound of the drum

- Page 122 and 123:

www.americanradiohistory.comSoundcr

- Page 124 and 125:

the EQ section. It can be switched

- Page 126 and 127:

AND BROADCAST ENGINEERINGYOUR SINGL

- Page 128 and 129:

S1TUATIGIOACANTSALES ENGINEERWith B

- Page 130 and 131:

RVICESSI TUATIONS VOCAwPORKY'S MAST

- Page 132 and 133:

INDEX TO ADVERTISERSAbacusAdams Smi

- Page 134:

REALISEYOURASPIRATIONSSTUDER'S COST