ATSRAC Task 9 Draft EZAP NPRM and Advisory Circular

Draft EZAP NPRM and Advisory Circular 120-XX (ATSRAC Task 9 ...

Draft EZAP NPRM and Advisory Circular 120-XX (ATSRAC Task 9 ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>ATSRAC</strong> <strong>Task</strong> 9<strong>Draft</strong> <strong>EZAP</strong> <strong>NPRM</strong><strong>and</strong><strong>Advisory</strong> <strong>Circular</strong>Presented by:R<strong>and</strong>y M. BorenNorthwest AirlinesChair, <strong>ATSRAC</strong> T9HWG

<strong>ATSRAC</strong> <strong>Task</strong> 3•Enhancement of InspectionCriteria <strong>and</strong> Expectations•Maintenance ProgramEnhancement‣Maintenance Practices‣<strong>EZAP</strong>

<strong>ATSRAC</strong> <strong>Task</strong> 9•<strong>Draft</strong> SFAR <strong>and</strong> other rulelanguage to require‣<strong>EZAP</strong>‣Protection <strong>and</strong> caution information‣Training•<strong>Draft</strong> A.C. for method ofcompliance

<strong>EZAP</strong>Enhanced Zonal AnalysisProcedure

1) minimize accumulation ofcombustible materials,

2) address wiring discrepancies,

3) address installationswhere wiring is in closeproximity to both primary<strong>and</strong> backup flight controls.

<strong>Draft</strong> <strong>EZAP</strong> <strong>NPRM</strong>

SFAR Portion of <strong>NPRM</strong>M<strong>and</strong>ates TC/STC Holders to applycertain new certificationrequirements to existing aircraft

Rule Change Portion of <strong>NPRM</strong>M<strong>and</strong>ates new requirements forinstructions for continuedairworthiness for new TC/STC’s,<strong>and</strong> new operating requirements forOperators <strong>and</strong> Repair Stations

Effect on TC/STC Holders

SFAR Effect on TC/STC Holders- For existing designs….1. TC/STC Holders must perform ananalytical logic procedure specificallydesigned to identify applicable <strong>and</strong>effective tasks that minimizeaccumulation of combustible materials,address wiring discrepancies, <strong>and</strong>address installations where wiring is inclose proximity to both primary <strong>and</strong>backup flight controls.

SFAR Effect on TC/STC Holders- For existing designs….2. TC/STC Holders must communicate toFAA <strong>and</strong> operators the results of theanalytical logic procedure.

SFAR Effect on TC/STC Holders- For existing designs….3. TC/STC Holders must updateInstructions for ContinuedAirworthiness to include tasksderived from the analytical logicprocedure.

SFAR Effect on TC/STC Holders- For existing designs….4. TC/STC Holders must ensure that thest<strong>and</strong>ard practices section of themaintenance instructions includeprotection <strong>and</strong> caution information tominimize contamination <strong>and</strong> accidentaldamage to electrical wiringinterconnection systems.

SFAR Effect on TC/STC Holders- For existing designs…5. TC/STC Holders must include protection<strong>and</strong> caution information to minimizecontamination <strong>and</strong> accidental damage toelectrical wiring interconnectionsystems in all newly createdmaintenance instructions, includingservice bulletins, where applicable.

Rule Change Effect on TC/STC Holders- For new designs…Part 25, Appendix H - Instructions forContinued Airworthiness1. Scheduled maintenance instructions forelectrical wiring interconnection systemsshall include tasks derived from ananalytical logic procedure that provides ameans to identify applicable <strong>and</strong> effectivetasks …

Rule Change Effect on TC/STC Holders- For new designs…Part 25, Appendix H - Instructions forContinued Airworthiness (continued)… that minimize accumulation ofcombustible materials, address wiringdiscrepancies, <strong>and</strong> address installationswhere wiring is in close proximity to bothprimary <strong>and</strong> backup flight controls.

Rule Change Effect on TC/STC Holders- For new designs…Part 25, Appendix H - Instructions forContinued Airworthiness (continued)2. Instructions for maintenance, alteration,or repairs must include protection <strong>and</strong>caution information designed to minimizecontamination <strong>and</strong> accidental damage toelectrical wiring interconnection systemswhere applicable.

Rule Change Effect on TC/STC Holders- For new designs…Part 25, Appendix H - Instructions forContinued Airworthiness (continued)3. Instructions for maintenance, alteration,or repairs of electrical wiringinterconnection systems must be in ast<strong>and</strong>ard format, <strong>and</strong> must include wireseparation guidelines <strong>and</strong> special wiringidentification requirements.

Rule Change Effect on TC/STC Holders- For new designs…Part 25, Appendix H - Instructions forContinued Airworthiness (continued)4. Instructions for continued airworthinessof electrical wiring interconnectionsystems must include electrical loaddata, <strong>and</strong> instructions for updatingelectrical load data.

Rule Change Effect on TC/STC HoldersPart 25, New Rule – <strong>EZAP</strong> forModifications1. For each new modification to a TC/STC, theTC/STC Holder shall determine if themodification requires application of ananalytical logic procedure that provides ameans to identify applicable <strong>and</strong> effective tasksthat minimize accumulation of combustiblematerials, address wiring discrepancies, <strong>and</strong>address installations where wiring is in closeproximity to both primary <strong>and</strong> backup flightcontrols.

Rule Change Effect on TC/STC HoldersPart 25, New Rule – <strong>EZAP</strong> forModifications2. Apply the analytical logic procedure for eachmodification as determined in (1.).3. Include tasks derived from the application ofthe analytical logic procedure in themodification instructions. These tasks shallbe uniquely identified in the instructions forfuture traceability.

<strong>Draft</strong> <strong>EZAP</strong> <strong>NPRM</strong>Effect on Operators<strong>and</strong>Repair Stations

<strong>NPRM</strong> Effect on Operators&Repair Stations1. Special Maintenance Program Requirements2. EWIS Training Program Requirements3. Analysis of “Orphan” STC’s

1. Special Maintenance ProgramRequirementsa) Protection <strong>and</strong> Caution Information,Part 91, 121, 125, <strong>and</strong> 129 OperatorsMaintenance instructions must includeprotection <strong>and</strong> caution information designed tominimize contamination <strong>and</strong> accidentaldamage to electrical wiring interconnectionsystems where applicable.

1. Special Maintenance ProgramRequirements (continued)a) Protection <strong>and</strong> Caution Information,Part 145 Repair StationsThe Repair Station General InstructionsManual must include protection <strong>and</strong> cautioninformation designed to minimizecontamination <strong>and</strong> accidental damage toelectrical wiring interconnection systemswhere applicable.

1. Special Maintenance ProgramRequirements (continued)b) Analytically Derived EWIS <strong>Task</strong>sPart 91, 121, 125, <strong>and</strong> 129 OperatorsThe maintenance program must includeinstructions for the continued airworthiness ofelectrical wiring interconnection systems thatare developed using an analytical logicprocedure that provides a means to identifyapplicable <strong>and</strong> effective tasks ….

1. Special Maintenance ProgramRequirements (continued)… that minimize the accumulation ofcombustible materials, address wiringdiscrepancies, <strong>and</strong> address installationswhere wiring is in close proximity to bothprimary <strong>and</strong> backup flight controls.

2. EWIS Training Program RequirementsPart 121, 125, <strong>and</strong> 129 Operators, <strong>and</strong>Part 145 Repair StationsEach operator/repair station must have atraining program that accomplishes thefollowing:

2. EWIS Training Program Requirements(continued)a) Ensures acceptable awareness of wiring asa system that requires adherence to properprocedures, methods, techniques, <strong>and</strong>practicesTarget Audience: All persons who performmaintenance, inspection, alteration orcleaning of aircraft.

2. EWIS Training Program Requirements(continued)b) Ensures an acceptable knowledge ofhousekeeping practices to be followedduring the performance of maintenance,inspection, alteration, <strong>and</strong> cleaning in orderto minimize contamination <strong>and</strong> accidentaldamage to electrical wiring interconnectionsystems.Target Audience: All persons who performmaintenance, inspection, alteration, orcleaning of aircraft.

2. EWIS Training Program Requirements(continued)c) Ensures acceptable knowledge ofprocedures, techniques, <strong>and</strong> practices to beused when performing maintenance,inspection, alteration, <strong>and</strong> cleaning ofelectrical wiring interconnection systems.Target Audience: All persons who performmaintenance, inspection, alteration, <strong>and</strong>cleaning of electrical wiring interconnectionsystems. The training should be specific tothe tasks they perform.

3. Analysis of Orphan STC’sPart 91, 121, 125, <strong>and</strong> 129 OperatorsFor each STC for which there is no viable STCHolder to comply with the requirements ofSFAR xxx…..

3. Analysis of Orphan STC’sa) Determine if the STC requires application ofan analytical logic procedure that providesa means to identify applicable <strong>and</strong> effectivetasks that minimize the accumulation ofcombustible materials, address wiringdiscrepancies, <strong>and</strong> address installationswhere wiring is in close proximity to bothprimary <strong>and</strong> backup flight controls.

3. Analysis of Orphan STC’sb) Apply the analytical logic procedure foreach STC affectedc) Amend the aircraft maintenance programas required based on the results of theanalytical logic procedure

<strong>Draft</strong> <strong>EZAP</strong><strong>Advisory</strong> <strong>Circular</strong>

<strong>Draft</strong> <strong>EZAP</strong> A.C.EWIS DefinitionInspection DefinitionsGuidance for GVI / Zonal InspectionsMaintenance Practices<strong>EZAP</strong> Logic

EWIS – Electrical WiringInterconnection SystemAn electrical connection between two or morepoints including the associated terminationdevices <strong>and</strong> the necessary means for itsinstallation <strong>and</strong> identification.

Included in EWIS:(1) Wires <strong>and</strong> cables(2) Bus bars(3) Connection to electrical devices(4) Circuit breakers or other circuit protectiondevices(5) Connectors <strong>and</strong> accessories(6) Electrical grounding <strong>and</strong> bonding devices(7) Electrical splices

Included in EWIS:(8) Materials used to provide additionalprotection for wires(9) Shield or braids(10) Conduits that have electrical terminationfor the purpose of bonding(11) Clamps <strong>and</strong> other devices used to route<strong>and</strong> support the wire bundle(12) Cable tie devices(13) Labels or other means of identification(14) Pressure seals associated with EWIS

Not Included in EWIS:(1) Wiring inside avionics equipment,(2) Equipment including non-requiredmiscellaneous equipment qualified toenvironmental conditions <strong>and</strong> testingprocedures approved by the Administratorother than those specifically included in thisdefinition,(3) Equipment qualified to a technical st<strong>and</strong>ardorder(4) Portable, carry on, or otherwise nonpermanentlymounted electrical equipment.(5) Fiber optics

Inspection of EWIS

GVI – General Visual InspectionA visual examination of an interior or exterior area,installation, or assembly to detect obviousdamage, failure or irregularity.This level of inspection is made from within touchingdistance unless otherwise specified. A mirror maybe necessary to enhance visual access to allexposed surfaces in the inspection area.This level of inspection is made under normallyavailable lighting conditions such as daylight,hangar lighting, flashlight or droplight <strong>and</strong> mayrequire removal or opening of access panels ordoors.St<strong>and</strong>s, ladders or platforms may be required to gainproximity to the area being checked.

GVI – General Visual InspectionA visual examination of an interior orexterior area, installation, or assemblyto detect obvious damage, failure orirregularity.

GVI – General Visual InspectionGVI is accomplished within touchingdistance unless otherwise specified.

GVI – General Visual InspectionGVI allows use of a mirror to enhancevisual access to all exposed surfacesin the inspection area.

Zonal InspectionA collective term comprising selectedGeneral Visual Inspections <strong>and</strong> visualchecks that are applied to each zone,defined by access <strong>and</strong> area, to checksystem <strong>and</strong> power plant installations<strong>and</strong> structure for security <strong>and</strong> generalcondition.

DET - Detailed InspectionAn intensive examination of a specific item,installation, or assembly to detect damage,failure or irregularity. Available lighting isnormally supplemented with a direct sourceof good lighting at an intensity deemedappropriate. Inspection aids such as mirrors,magnifying lenses or other means may benecessary. Surface cleaning <strong>and</strong> elaborateaccess procedures may be required.

DET - Detailed InspectionNot the same as DVI…DET allows tactile examination todetermine condition.

Guidance for GVI / ZonalInspection of EWIS

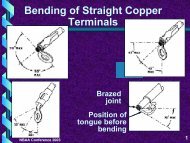

EWIS Discrepancies Detectable by GVI /Zonal InspectionWiring / Wire Bundles• Wire-to-wire or wire-to-structure contact/chafing• Wire bundle sagging or improperly secured• Wires damaged (obvious damage due tomechanical impact, overheat, localized chafing,etc.)• Lacing tape <strong>and</strong>/or ties missing/incorrectlyinstalled• Wiring protection sheath/conduit deformity orincorrectly installed• End of sheath rubbing on end attachment device• Grommet missing or damaged

EWIS Discrepancies Detectable by GVI /Zonal InspectionWiring / Wire Bundles (continued)• Dust <strong>and</strong> lint accumulation• Surface contamination by metal shavings/swarf• Contamination by liquids• Deterioration of previous repairs (e.g., splices)• Deterioration of production splices• Inappropriate repairs (e.g., incorrect splice)• Inappropriate attachments to or separation fromfluid lines

EWIS Discrepancies Detectable by GVI /Zonal InspectionConnectors• External corrosion on receptacles• Backshell broken• Rubber pad or packing on backshell missing• No backshell wire securing device• Fool-proofing chain broken• Missing or broken safety wire• Discoloration/evidence of overheat on terminallugs/blocks• Torque stripe misalignment

Maintenance Practices

Learned Complacency- Institutionalized acceptance ofdiscrepant conditions

Common Sense“…Clean <strong>and</strong> protect as you go”

<strong>EZAP</strong> Logic Chart