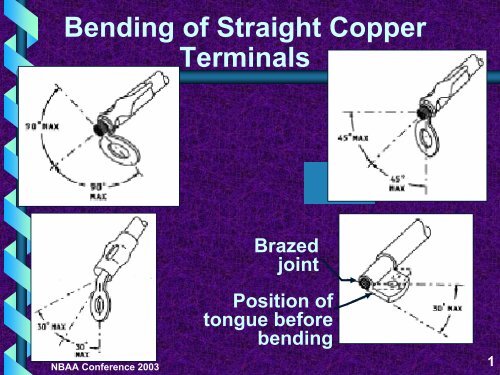

Bending of Straight Copper Terminals

Bending of Straight Copper Terminals

Bending of Straight Copper Terminals

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Terminal StripsBarriers to prevent adjacent studsfrom contacting each otherCurrent should be carried by terminalcontact surface and not by studStuds anchored against rotationReplace defective studs with studs<strong>of</strong> same size and material, mountsecurely, tighten terminal securing nutNBAA Conference 20032

Terminal Strips, cont.Mount strips so loose metallic objectscannot fall across terminal• Provide spare stud for breaks andfuture expansion• Inspect terminal periodically for looseconnections, metallic objects, dirt, andgrease accumulation Can cause arcing, resulting in fireor systems failureNBAA Conference 20033

<strong>Terminals</strong> on circuit breakersNBAA Conference 20034

Power feeder terminalsNBAA Conference 20035

Terminal LugsConnect wiring to terminal block studsNo more than 4 lugs, or 3 lugs anda bus bar, per studLug hole size should match studdiameter• Greatest diameter on bottom,smallest on top• Tightening terminal connectionsshould not deform lugsNBAA Conference 20036

Terminal Lugs, cont.Aluminum lugs• Crimped to aluminum wire only Special attention needed to guardagainst excessive voltage drop atterminal junction• Inadequate terminal contact area• Stacking errors• Improper torquing• Use calibrated crimp toolsNBAA Conference 20037

TerminalStacking(like materials)NutLock washerFlat washer<strong>Copper</strong>terminal lugsTerminal studNBAA Conference 20038

Terminal Stacking(unlike materials)NutLock washerFlat washer<strong>Copper</strong> terminalFlatwashersAluminumterminalsTerminal studNBAA Conference 20039

TerminalStackingMethodsCrimp barrel(belly up)NutLockwasherFlatwasherCrimp barrel(belly down)One-Sided Entry With Two <strong>Terminals</strong>NBAA Conference 200310

TerminalStackingMethods, cont.Crimp barrel(belly down)in “V” splitNutLockwasherFlat washerCrimp barrel(belly up) incenter <strong>of</strong> “V”One-Sided Entry With 3 <strong>Terminals</strong>NBAA Conference 200311

TerminalStackingMethods, cont.NutLock washerFlat washerCrimp barrel(belly up) in“V” splitCrimp barrel(belly down)in “V” splitOne-Sided Entry With 4 <strong>Terminals</strong>NBAA Conference 200312

Terminal Tightening HardwareIncorrectSpaceNutLockwasherFlatwasherCorrectLock washernot compressedLock washer compressedNBAA Conference 200313

Washer Size SelectionImproperly-sized washerRaised portion <strong>of</strong>terminalNon-self locking nutSplit lockwasherSteel washersCorrectAluminumterminalNBAA Conference 200314

Example: Terminal StackingATo prevent corrosionfrom dissimilar metals,put a cadmium washerbetween aluminum andcopper terminals.NBAA Conference 200315WF4