Fire Safety in Hidden Inaccessible Areas - Center for Advanced ...

Fire Safety in Hidden Inaccessible Areas - Center for Advanced ...

Fire Safety in Hidden Inaccessible Areas - Center for Advanced ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Concerns with <strong>Fire</strong> <strong>Safety</strong> <strong>in</strong><strong>Hidden</strong> <strong>Inaccessible</strong> <strong>Areas</strong>Gus SarkosManager, <strong>Fire</strong> <strong>Safety</strong> SectionFAA Wm. J. Hughes Tech. Ctr.Atlantic City Airport, NJATSRAC Meet<strong>in</strong>gJanuary 23 – 24, 2002Atlanta, Georgia

WFD•Similar to the AASR•Compliance to operational requirements wouldrequire design approval holders develop<strong>in</strong>g thenecessary data and documentation.•There<strong>for</strong>e, we are also consider<strong>in</strong>g propos<strong>in</strong>g anew rule to require design approval holders todevelop life limits and actions to preclude WFD

Delta MD-88C<strong>in</strong>c<strong>in</strong>nati, OhioSeptember 17, 1999

Air Tran DC9Greensboro, NCAugust 8, 2000

Boe<strong>in</strong>g 757Copenhagen, DenmarkNovember 15, 2000

American MD-80Dulles AirportNovember 29, 2000

Air Tran DC9Atlanta, GANovember 29, 2000

Thermal Acoustic Insulation! FAA Developed Improved <strong>Fire</strong> Test Method(Radiant Panel Test) (DOT/FAA/AR-99/44)! Drivers– Swiss Air MD-11 Accident– Prior Incidents <strong>in</strong> Ch<strong>in</strong>a, Italy, and Copenhagen– Demonstrated Inadequacy of Vertical BunsenBurner Test Method (DOT/FAA/AT-97/58)! Attic Mock-Up Test Results– Films exhibit range of <strong>Fire</strong> Per<strong>for</strong>mance– <strong>Fire</strong> Per<strong>for</strong>mance a function of ignition source<strong>in</strong>tensity

Intermediate Scale FlamePropagation Test Arrangement

Intermediate ScaleTemperature vs. TimeComparison

Thermal Acoustic Insulation! AD Issue <strong>in</strong> May 2000– Requires replacement of Metallized Mylar Film (>700 A/C)with<strong>in</strong> 5 years (6/05)– MM only film consistently ignited with Electric Arc(DOT/FAA/AR-TN00/20)– Replacement films require zero flame spread <strong>in</strong> new RadiantPanel Test! NPRM Issued <strong>in</strong> September 2000– Requires Zero Flame Spread Films <strong>in</strong> production aircraftwith<strong>in</strong> two years of the effective date! Concern– Presence of MM and Non-Zero Flame Spread Films <strong>in</strong>Majority of Fleet

Insulation Tape andHook & Loop! Tape and H&L used <strong>in</strong> ProductionAircraft! Tape used to repair <strong>in</strong>sulation batts! Tape and H&L are tested <strong>for</strong>flammability per FAR 25.853– TSB unable to determ<strong>in</strong>e if MD-11 tapetested <strong>for</strong> Flammability

Insulation Tape andHook & Loop! Recent FAA Flammability Tests– Taped Swiss Air MD-11 Batts and Supplier H&Lmore flammable than film covers– Tape Results Variable (Good/Bad)! FAA develop<strong>in</strong>g standard test procedures <strong>for</strong>Tape and H&L to support planned AC <strong>for</strong>Insulation F<strong>in</strong>al Rule! Concern: Flammable Tape and H&L <strong>in</strong> In-Service Aircraft

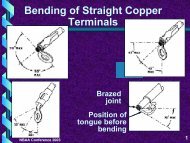

PVC Wir<strong>in</strong>g! PVC wir<strong>in</strong>g used <strong>in</strong> early aircraft! PVC is significantly more flammablethan Kapton or Fluoropolymer Wir<strong>in</strong>g! Recent FAA Flammability Tests (LargeScale)– PVC most flammable aircraft wir<strong>in</strong>g tested– PVC produced largest quantity of smoke– PVC failed FAR 25.869 (60° Test)

60° Bunsen Burner TestResults <strong>for</strong> Aircraft Wir<strong>in</strong>gWireBurn Length After FlameDescription (Inches) (Seconds) Dripp<strong>in</strong>gsPVC/Nylon 14.8 121 0Crossl<strong>in</strong>ked ETFE 1.8 0 0PTFE/Polyimide/PTFE 1.2 0 0PTFE/Mica 1 0 0Polyimide 1.5 0 0Crossl<strong>in</strong>ked Polyalkene 3

Intermediate Scale Wir<strong>in</strong>g<strong>Fire</strong> Test Fixture

Intermediate Scale <strong>Fire</strong> TestResults <strong>for</strong> Aircraft Wir<strong>in</strong>gWire description(Test bundle- number of wires)Length(<strong>in</strong>ches)Flame(seconds)Dripp<strong>in</strong>gs(seconds)Smoke(subjective)PVC/Nylon -25 28 45 0 denseCrossl<strong>in</strong>ked ETFE- 25 12 0 0 mediumPTFE/Polyimide/PTFE -25 8.5 0 0 lowPTFE/Mica -25 6 0 0 lowPolyimide -25 8 0 0 lowCrossl<strong>in</strong>ked Polyalkene -25 12 0 0 lowZero Halogen -10 44 14010 dripsreporteddensePlenum Cable -10 29 0 0 mediumRiser Cable -10 31 0 0 medium

PVC Wir<strong>in</strong>g! 60° Bunsen Burner Test– Not a severe test– Does not challenge superior fire resistance ofKapton and Fluoropolymer Wir<strong>in</strong>g– Added to FAR’s <strong>in</strong> 1972– Prior to 1972, no explicit test requirement <strong>for</strong>wir<strong>in</strong>g! Concern: flammability of PVC wir<strong>in</strong>g <strong>in</strong> olderaircraft

Drip Shield/DuctAdhesive Problem! Discovered that adhesive used <strong>in</strong> Cockpit Drip Shieldand ECS ducts did not meet FAR 25.853– Also failed proposed Radiant Panel Test <strong>for</strong> <strong>in</strong>sulation! Problem corrected <strong>in</strong> production aircraft! AD Issued <strong>for</strong> In-Service Aircraft <strong>in</strong> Fall 2000– Install Burnthrough Resistant Barrier to isolate area abovecockpit drip shield– Remove <strong>in</strong>sulation/glue from duct and replace with FRmaterials– Six year compliance period

! Concerns:Drip Shield/DuctAdhesive Problem– Flammability of Drip Shield/Duct adhesive– Vulnerability of Drip Shield/Adhesive to lightn<strong>in</strong>gstrike– Flammability of Kevlar Drip Shield

Dust Seal Problem! Dust seal protects Emergency Oxygen Unit! MD-80 Incident on November 30, 1999 atRaleigh Durham– PSU fire at Gate– <strong>Fire</strong> damaged oxygen canister, masks, metallizedMylar <strong>in</strong>sulation, dust seal, etc.– Dust seal not tested/not compliant with FAR25.853! AD to be Issued! Concern: Flammable Dust Seals

Contam<strong>in</strong>ation! Contam<strong>in</strong>ation causes materials to be moreflammable! Includes l<strong>in</strong>t, dust, combustion <strong>in</strong>hibit<strong>in</strong>gcompounds, etc.! Classic Example (Delta L-1011, 3/17/91)– In flight fire enroute Frank<strong>for</strong>t to Atlanta– <strong>Fire</strong> started below floor and spread up sidewall– Ext<strong>in</strong>guished with Halon 1211

DeltaL-1011Frankfurt to Atlanta (Goose Bay, Canada)March 17, 1991

Contam<strong>in</strong>ation! TSB/NTSB Concerns withContam<strong>in</strong>ation– Significant: 3/8 <strong>in</strong>ch average; over 2 <strong>in</strong>ches<strong>in</strong> some areas– Contam<strong>in</strong>ation also found <strong>in</strong> random<strong>in</strong>spection of other aircraft– Recommended changes <strong>in</strong> ma<strong>in</strong>tenance toaddress

Contam<strong>in</strong>ation! Past FAA <strong>Fire</strong> Tests (DOT/FAA/CT-91/2)– Insulation without CIC Self-Ext<strong>in</strong>guish<strong>in</strong>g– Insulation with CIC Burned Completely! CIC Residue found on materials! Concern: Enhanced materialflammability caused by contam<strong>in</strong>ation

US AirMD-80Buffalo, NYJanuary 18, 1990

Conclusions! In-Flight fires orig<strong>in</strong>at<strong>in</strong>g <strong>in</strong> <strong>Hidden</strong> <strong>Areas</strong> area risk to aviation safety! Most hidden fires are caused by electricalproblems! Non-Compliance with <strong>Fire</strong> <strong>Safety</strong> Regulationshave been uncovered! <strong>Fire</strong> <strong>Safety</strong> Problems and Improvements are<strong>in</strong> various stages of correction and study! It is impossible to predict the relative risk ofserious fires occurr<strong>in</strong>g <strong>in</strong> <strong>Hidden</strong> <strong>Areas</strong> orLocations