Original article - Ethiopian Review

Original article - Ethiopian Review

Original article - Ethiopian Review

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

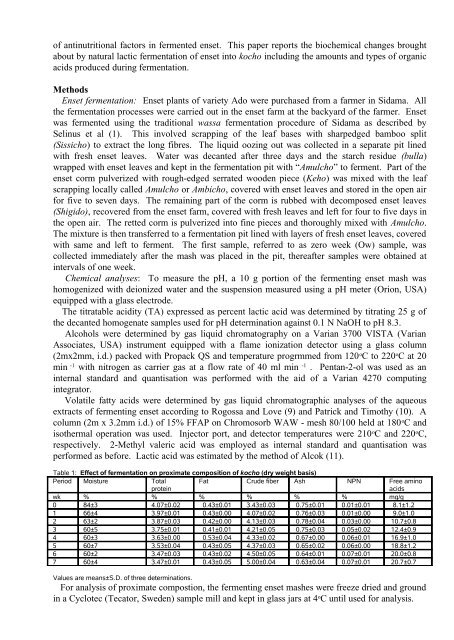

of antinutritional factors in fermented enset. This paper reports the biochemical changes broughtabout by natural lactic fermentation of enset into kocho including the amounts and types of organicacids produced during fermentation.MethodsEnset fermentation: Enset plants of variety Ado were purchased from a farmer in Sidama. Allthe fermentation processes were carried out in the enset farm at the backyard of the farmer. Ensetwas fermented using the traditional wassa fermentation procedure of Sidama as described bySelinus et al (1). This involved scrapping of the leaf bases with sharpedged bamboo split(Sissicho) to extract the long fibres. The liquid oozing out was collected in a separate pit linedwith fresh enset leaves. Water was decanted after three days and the starch residue (bulla)wrapped with enset leaves and kept in the fermentation pit with “Amulcho” to ferment. Part of theenset corm pulverized with rough-edged serrated wooden piece (Keho) was mixed with the leafscrapping locally called Amulcho or Ambicho, covered with enset leaves and stored in the open airfor five to seven days. The remaining part of the corm is rubbed with decomposed enset leaves(Shigido), recovered from the enset farm, covered with fresh leaves and left for four to five days inthe open air. The retted corm is pulverized into fine pieces and thoroughly mixed with Amulcho.The mixture is then transferred to a fermentation pit lined with layers of fresh enset leaves, coveredwith same and left to ferment. The first sample, referred to as zero week (Ow) sample, wascollected immediately after the mash was placed in the pit, thereafter samples were obtained atintervals of one week.Chemical analyses: To measure the pH, a 10 g portion of the fermenting enset mash washomogenized with deionized water and the suspension measured using a pH meter (Orion, USA)equipped with a glass electrode.The titratable acidity (TA) expressed as percent lactic acid was determined by titrating 25 g ofthe decanted homogenate samples used for pH determination against 0.1 N NaOH to pH 8.3.Alcohols were determined by gas liquid chromatography on a Varian 3700 VISTA (VarianAssociates, USA) instrument equipped with a flame ionization detector using a glass column(2mx2mm, i.d.) packed with Propack QS and temperature progrmmed from 120 o C to 220 o C at 20min -1 with nitrogen as carrier gas at a flow rate of 40 ml min -1 . Pentan-2-ol was used as aninternal standard and quantisation was performed with the aid of a Varian 4270 computingintegrator.Volatile fatty acids were determined by gas liquid chromatographic analyses of the aqueousextracts of fermenting enset according to Rogossa and Love (9) and Patrick and Timothy (10). Acolumn (2m x 3.2mm i.d.) of 15% FFAP on Chromosorb WAW - mesh 80/100 held at 180 o C andisothermal operation was used. Injector port, and detector temperatures were 210 o C and 220 o C,respectively. 2-Methyl valeric acid was employed as internal standard and quantisation wasperformed as before. Lactic acid was estimated by the method of Alcok (11).Table 1: Effect of fermentation on proximate composition of kocho (dry weight basis)Period Moisture TotalproteinFat Crude fiber Ash NPN Free aminoacidswk % % % % % % mg/g0 84±3 4.07±0.02 0.43±0.01 3.43±0.03 0.75±0.01 0.01±0.01 8.1±1.21 66±4 3.97±0.01 0.43±0.00 4.07±0.02 0.76±0.03 0.01±0.00 9.0±1.02 63±2 3.87±0.03 0.42±0.00 4.13±0.03 0.78±0.04 0.03±0.00 10.7±0.83 60±5 3.75±0.01 0.41±0.01 4.21±0.05 0.75±0.03 0.05±0.02 12.4±0.94 60±3 3.63±0.00 0.53±0.04 4.33±0.02 0.67±0.00 0.06±0.01 16.9±1.05 60±7 3.53±0.04 0.43±0.05 4.37±0.03 0.65±0.02 0.06±0.00 18.8±1.26 60±2 3.47±0.03 0.43±0.02 4.50±0.05 0.64±0.01 0.07±0.01 20.0±0.87 60±4 3.47±0.01 0.43±0.05 5.00±0.04 0.63±0.04 0.07±0.01 20.7±0.7Values are means±S.D. of three determinations.For analysis of proximate compostion, the fermenting enset mashes were freeze dried and groundin a Cyclotec (Tecator, Sweden) sample mill and kept in glass jars at 4 o C until used for analysis.

![to read the full report [pdf, Amharic] - Ethiopian Review](https://img.yumpu.com/52737829/1/190x245/to-read-the-full-report-pdf-amharic-ethiopian-review.jpg?quality=85)