Stage 2F Acid Sulphate Soils Management Plan - Newcastle Coal ...

Stage 2F Acid Sulphate Soils Management Plan - Newcastle Coal ...

Stage 2F Acid Sulphate Soils Management Plan - Newcastle Coal ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

NEWCASTLE COAL INFRASTRUCTURE GROUPCOAL EXPORT TERMINALPROJECT APPROVAL (06_0009)COAL EXPORT TERMINALACID SULFATE SOIL MANAGEMENT PLANRevision Specialist Review/Input Distribution DoP ApprovalASSMP-R01-D RCA Australia DoP 23 July 2007ASSMP-R02-A - DoP 21 September 2010ASSMP-R03-B - DP&I 14 June 2012JUNE 2012Project No. NCIG-07-02/1Document No. ASSMP-R03-B.DOC

<strong>Acid</strong> Sulfate Soil <strong>Management</strong> <strong>Plan</strong>PREFACEIn accordance with Condition 1.10, Schedule 2 of the Project Approval (06_0009), the specified time period forthis <strong>Acid</strong> Sulfate Soil <strong>Management</strong> <strong>Plan</strong> (ASSMP) is for the <strong>Stage</strong> <strong>2F</strong> construction phase (i.e. approximately25 months commencing in the first quarter of 2012) of the <strong>Newcastle</strong> <strong>Coal</strong> Infrastructure Group <strong>Coal</strong> ExportTerminal up to 66 million tonnes per annum capacity. Notwithstanding, any subsequent revision of this CNMPduring the Project construction phase will be submitted to the Director-General of the Department of <strong>Plan</strong>ning andInfrastructure for approval.1 INTRODUCTIONThe <strong>Newcastle</strong> <strong>Coal</strong> Infrastructure Group (NCIG) <strong>Coal</strong> Export Terminal (CET) (the Project) is located onKooragang Island in <strong>Newcastle</strong>, New South Wales (NSW) (Figure 1). The overall Project includes theconstruction and operation of a CET up to 66 million tonnes per annum (Mtpa), including associated rail and coalhandling infrastructure and wharf/shiploading facilities on the south arm of the Hunter River.NCIG is the proponent of the Project and is a consortium of the following six companies:Hunter Valley Energy <strong>Coal</strong> Limited;Centennial <strong>Coal</strong> Company Limited;Gloucester <strong>Coal</strong> Pty Limited;Peabody Energy Australia <strong>Coal</strong> Pty Limited;Yancoal Australia Limited; andWhitehaven <strong>Coal</strong> Limited.NCIG was granted Project Approval (06_0009) on 13 April 2007. Construction of <strong>Stage</strong> 1 of the Projectcommenced in January 2008, with operations of the <strong>Stage</strong> 1 Project components commencing in the third quarterof 2010. These works allow the CET to operate up to the initial Project capacity of 30 Mtpa. The <strong>Stage</strong> 1 Projectcomponents included the construction of:rail infrastructure including one train unloading station;the southern portion of the coal storage area including two combined stacker/reclaimers; andwharf facilities including one shiploader and two shipping berths.The <strong>Stage</strong> 2AA construction activities commenced in the fourth quarter of 2010. The construction phase isexpected to continue until mid-2012 and, when complete, will increase the capacity of the CET to 53 Mtpa. The<strong>Stage</strong> 2AA Project components include the construction of:a second train unloading station and associated rail infrastructure;a portion of the coal storage area including a third combined stacker/reclaimer; anda second shiploader.<strong>Stage</strong> <strong>2F</strong> of the Project is anticipated to commence in the first quarter of 2012 and the construction phase isexpected to take approximately two years. When <strong>Stage</strong> <strong>2F</strong> activities are complete the CET will be able to operateat the maximum approved capacity of 66 Mtpa. The <strong>Stage</strong> <strong>2F</strong> Project components will include the construction of(Figure 2):the northern portion of the coal storage area including the fourth combined stacker reclaimer; andwharf facilities including the third shipping berth (K10); andThe northern rail spur will be constructed as a separate package of works, and as such does not form a part ofthis ASSMP.1

6 370 000 N6 368 000 NHunter378 000 EMAITLANDPacific HighwayRiverTomagoIndustrialEstate380 000 E382 000 EPORT STEPHENSTomago Road384 000 ELEGENDApproximate Extent of Project Key Components6 370 000 NHigh Capacity Optional Inlet Rail Spur and RailSidingsLocal Government Area BoundaryNature ReserveMangrove Area386 000 E0 12Kilometres6 368 000 NTOMAGOHEXHAM6 366 000 NKOORAGANG WETLANDREHABILITATION PROJECTASH ISLANDFullerton Cove6 366 000 NKOORAGANG NATURE RESERVE6 364 000 NHEXHAMSWAMPNATURERESERVEKOORAGANGNATURERESERVENCIG <strong>Coal</strong> Export TerminalHunter River (North Arm)6 364 000 NKOORAGANGISLANDFERN BAY6 362 000 NSHORTLANDWETLANDSHunterRiverPORT WARATAH COAL SERVICESKOORAGANG COAL TERMINAL(At Full Development)6 362 000 NHexhamSwampSHORTLANDSANDGATE(South Arm)Steel RiverCormorant RoadSTOCKTON SANDSPITWARABROOKMAYFIELDWESTMAYFIELDNORTHOneSteel6 360 000 NBIRMINGHAMGARDENSJESMONDUniversity of<strong>Newcastle</strong>NORTH LAMBTONCALLAGHANWARATAH WESTPacific Highway HighwayMAIN NORTHERN RAILWAYWARATAHMAYFIELDIndustrialDriveMAYFIELDEASTIntertrade Industrial ParkPORT WARATAHCOAL SERVICESCARRINGTON COAL TERMINALStockton Channel6 360 000 NStocktonBight6 358 000 NNEWCASTLEGEORGETOWNTIGHES HILLPortHunter6 358 000 NRANKIN PARKLAKEMACQUARIE6 356 000 NNEW LAMBTONHEIGHTS378 000 EBLACKBUTTRESERVELAMBTONNEW LAMBTON380 000 EADAMSTOWNBROADMEADOW382 000 EHAMILTONNORTHISLINGTONHAMILTONHAMILTON SOUTHMARYVILLEHAMILTONEASTNEWCASTLEWESTTHE JUNCTION384 000 ECARRINGTONCOOKS HILLHunter RiverNEWCASTLECBDSTOCKTONNEWCASTLE EASTSource: NCIG (2006); Connell THE HILL Hatch (2006); RLMC (2006); UBD (2002)386 000 E6 356 000 NACID SULFATE SOIL MANAGEMENT PLANFIGURE BAR BEACH 1Project LocationNCIG-07-02 Task 1 ASSMP 2010_001A

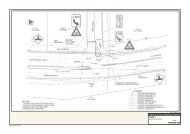

L.P./////// // // //\\\\\K9\\\\\\\\\\\\\\ \\\\\\///\\\\ \ \\\\\ \\\////// / / /384 000 ESTAGE <strong>2F</strong> ACTIVITIESKOORAGANG NATURE RESERVEConstruction ofFourth CombinedStacker/ReclaimerHunter River (North Arm)Pacific National Access Road6 362 000 NRoadCormorant RoadEgret StreetCormorant RoadCurlew StreetRaven StreetStreetSandpiperTeal StreetCloseTeal Street/ / / // // // / // / / / / /Heron RoadX-ING\ \\ \Industrial Drive6 360 000 N384 000 E382 000 EDelta Access RoadCormorantTourle StreetPacific Highway382 000 E380 000 EKOORAGANG6 362 000 NHunter River (South Arm)6 360 000 NKO O RAGANG ISLANDDelta EMD AustraliaTourle StreetBridgeMAYFIELDWESTMAYFIELDNORTHMAYFIELDPrimarySettling PondsSecondarySettlingPond<strong>Coal</strong> Storage AreaOverflowPondWater Tanks andPump StationsAdministration, Workshopsand CarparkEnergy AustraliaSubstationISLAND MAINLINELEGENDSite Access PointRail Infrastructure CorridorConveyorsTransfer PointsWARABROOKShipping Berth<strong>Coal</strong> StockpilesHunter Wetlands National ParkNature ReserveMangrove AreaKooragang Island Waste Emplacement FacilityTrainUnloadingStationsPORT WARATAH COAL SERVICESKOORAGANG COAL TERMINAL(At Full Development)Wharf Facilitiesand ShiploadersRail Spurs andRail SidingsRailOverpassRail LoopsU-turn LoopConveyorOverpassCombinedStacker/ReclaimerBlue CircleSouthern CementConveyors OverCormorant RoadK10 K9 K8Existing CormorantRoad RoundaboutK7 K6 K5 K4Steel RiverPWCS FinesDisposal AreaSITE D2Road LevelCrossingOneSteelOriginEnergyConstruction ofThird BerthSITE D1SITE A1SITE A20 400Metres800Intertrade Industrial ParkSource: NCIG (2006, 2010); Connell Hatch (2006);LPI NSW (2001a, 2001b, 2001c, 2002)ACID SULFATE SOIL MANAGEMENT PLANFIGURE 2Project General Arrangement380 000 ENCIG-07-02 Task1 ASSMP <strong>2F</strong>_001D

<strong>Acid</strong> Sulfate Soil <strong>Management</strong> <strong>Plan</strong>Dredging activities for the construction of the third shipping berth will be conducted as a component of <strong>Stage</strong> <strong>2F</strong>works. All dredging activities will be conducted in accordance with the Extension of Shipping Channels, Port of<strong>Newcastle</strong> Development Consent (DA 134-3-2003-i). Approximately 807,000 cubic metres of material would bedredged to develop the third shipping berth, however reclamation of dredged material will not form a componentof the <strong>Stage</strong> <strong>2F</strong> construction activities. All dredged material will be disposed of in an offshore spoil ground inaccordance with State and Federal legislation. NCIG’s dredging Environment Protection Licence and SeaDumping Permit have been revised to comply with the relevant legislation.The environmental management described in this document is specifically designed to ensure the constructionactivity outlined for <strong>Stage</strong> <strong>2F</strong> is undertaken in a manner compliant with the requirements of the Project Approval(06_0009).This <strong>Coal</strong> Export Terminal <strong>Acid</strong> Sulfate Soil <strong>Management</strong> <strong>Plan</strong> (CET ASSMP) has been prepared in accordancewith Condition 7.3(a), Schedule 2 of the Project Approval (06_0009). Table 1 indicates where each component ofCondition 7.3(a), Schedule 2 of the Project Approval is addressed within this CET ASSMP.Table 1Condition 7.3(a), Schedule 2 of Project Approval (06_0009)Project Approval (06_0009) Condition7 ENVIRONMENTAL MANAGEMENTConstruction Environmental <strong>Management</strong> <strong>Plan</strong>7.3 As part of the construction environmental management plan for the project required undercondition 7.2 of this approval, the proponent shall prepare and implement the following:a) where soil testing prior to the commencement of construction identifies the presence of acidsulfate soils, an <strong>Acid</strong> Sulfate Soil <strong>Management</strong> <strong>Plan</strong> prepared in accordance withguidance provided in <strong>Acid</strong> Sulfate Soil Manual (<strong>Acid</strong> Sulfate Soil <strong>Management</strong> AdvisoryCommittee, 1998);Section Addressed inthis DocumentThis CET ASSMPThis CET ASSMP forms part of the Construction Environmental <strong>Management</strong> <strong>Plan</strong>.Previous soil testing and assessments of the acid sulfate soil (ASS) risk at the Project site (Section 3.1) havedetermined the potential ASS risk to be limited. Due to the location of the Project and the requirement for limitedexcavations (i.e. primarily associated with the train unloading station), a residual risk of encountering ASSremains.This CET ASSMP has been prepared to provide sampling, validation and management measures if ASS isencountered during construction of <strong>Stage</strong> <strong>2F</strong> of the Project.A separate Extension of Shipping Channels, Port of <strong>Newcastle</strong> <strong>Acid</strong> Sulfate Soil <strong>Management</strong> <strong>Plan</strong> (DredgingASSMP) was developed for the Extension of Shipping Channels, Port of <strong>Newcastle</strong> in accordance withCondition B4.5(c), Schedule 2, Sub-Schedule B of the Port Consent:B4.5 As part of the Dredging Environmental <strong>Management</strong> <strong>Plan</strong> required under condition B4.4 of this consent, thefollowing <strong>Management</strong> <strong>Plan</strong>s shall be prepared and implemented:…c) an <strong>Acid</strong> Sulfate Soil <strong>Management</strong> <strong>Plan</strong> to detail measures to be implemented in relation to themanagement and handling of any potential or actual acid sulfate soils on the site. The <strong>Plan</strong> shall beprepared in accordance with guidance provided in <strong>Acid</strong> Sulfate Soil Manual (<strong>Acid</strong> Sulfate Soil<strong>Management</strong> Advisory Committee, 1998).The Dredging ASSMP details measures to be implemented in relation to the management and handling ofpotential acid sulfate soils (PASS) or ASS dredge material from the Extension of Shipping Channels, Port of<strong>Newcastle</strong> including material that has been beneficially re-used at the Project site, and the management andtreatment of this material and associated runoff on the Project site.This CET ASSMP has been prepared to assist NCIG in the implementation of appropriate environmentalmanagement measures during the construction of <strong>Stage</strong> <strong>2F</strong> of the Project. Where there is any conflict betweenthe provisions of this CET ASSMP and any Contractors’ obligations under their respective Contracts, including the4

<strong>Acid</strong> Sulfate Soil <strong>Management</strong> <strong>Plan</strong>various statutory requirements (i.e. licences, permits, Project Approval conditions and relevant laws), the Contractand statutory requirements are to take precedence. In the case of any real or perceived ambiguity betweenelements of this CET ASSMP and the above statutory requirements the Contractor shall first gain clarificationfrom NCIG prior to implementing that element of this CET ASSMP over which the ambiguity is identified.The remainder of this CET ASSMP is structured as follows:Section 2:Section 3:Section 4:Section 5:Provides a definition of ASS and potential environmental effects.Details ASS management measures including sampling, criteria, treatment processes,monitoring and contingency measures.Describes the reporting and review requirements of this CET ASSMP.Lists references cited in this CET ASSMP.2 ACID SULFATE SOILSEstuarine sediments of coastal NSW from the Holocene geological age may contain iron pyrite, the mainconstituent of ASS. These sediments are generally found below 5 metres (m) Australian Height Datum (AHD),typically in coastal and floodplain areas. Pyritic sediments can be divided into classes based on their oxidisedstate. If the pyritic material is being oxidised it will generally have a pH of less than 4.0 and is called actual acidsulfate soil (AASS). If the pyrite material is below the water table and has not been oxidised, it is termed potentialacid sulfate soil (PASS) and generally has a pH of greater than 4.0. The pH has the potential to become muchlower when the PASS is exposed to oxygen. Sediment which, after the addition of hydrogen peroxide, has a pHof less than 2.5 strongly indicates the presence of ASS (Australian Sulfate <strong>Soils</strong> <strong>Management</strong> AdvisoryCommittee [ASSMAC], 1998).Disturbance or poor management and use of ASS can generate sulfuric acid and salts. ASS can lower soil andwater pH and increase salinity, reducing or precluding vegetation growth and producing soil conditions which maybe detrimental to concrete and steel components of structures.The release of sulfuric acid from ASS often mobilises metals such as aluminium, iron and magnesium fromotherwise stable soil matrices. Elevated concentrations of such elements in site runoff may result in changeswhich are potentially detrimental to receiving water bodies and associated aquatic organisms.3 ACID SULFATE SOIL MANAGEMENTIn accordance with Condition 7.3(a), Schedule 2 of Project Approval (06_0009), this CET ASSMP has beendeveloped in accordance with the guidance provided in the <strong>Acid</strong> Sulfate Soil Manual (ASSMAC, 1998). Asdescribed in Section 1, this CET ASSMP addresses the management of ASS identified during excavations on theProject site. The Dredging ASSMP details measures to be implemented in relation to the management andhandling of PASS or ASS dredge material from the Extension of Shipping Channels, Port of <strong>Newcastle</strong> includingmaterial that has been beneficially re-used at the Project site, and the management and treatment of this materialand associated runoff on the Project site.5

<strong>Acid</strong> Sulfate Soil <strong>Management</strong> <strong>Plan</strong>3.1 SITE DESCRIPTIONSection 4 of the <strong>Newcastle</strong> <strong>Coal</strong> Infrastructure Group <strong>Coal</strong> Export Terminal Environmental Assessment (EA)(NCIG, 2006) provides a detailed description of the Project site. In particular, Section 4.1.1 of the EA provides:LanduseThe Project is located on Kooragang Island, which lies near the mouth of the Hunter River, approximately 6 km north-westof the <strong>Newcastle</strong> Central Business District (CBD) (Figure 1-2). Kooragang Island is characterised by a combination ofport, marine and industrial landuses in the south, the Kooragang Nature Reserve in the north, and the Kooragang WetlandRehabilitation Project in the west.The Project is located on the southern side of Kooragang Island on the south arm of the Hunter River. As described inSection 3.2, the Project site comprises land zoned Zone 4(b) (Port and Industry), Zone 5(a) (Special Uses Zone – ArterialRoad) and an unzoned area (Hunter River) by the <strong>Newcastle</strong> LEP (Figure 1-4). The current landuse of the Project sitecomprises licensed landfill activities and vacant industrial land. RLMC currently holds EPL 6437 for the disposal of SolidWaste Class 2 at the KIWEF (Figure 2-1).…Historical landuses of the Project site include grazing, land reclamation and the long term disposal of dredge spoil andindustrial waste (Appendix D). A series of plans and aerial photographs are provided on Figures 4-1 and 4-2, whichillustrate the landuse changes from agricultural development to progressive reclamation of land and deposition of dredgespoil and landfill material to develop the current land surface in the Project site.Landforms and Local TopographyKooragang Island was originally a series of deltaic islands (including Ash Island, Dempsey Island and Moscheto Island)near the mouth of the Hunter River (Figures 4-1 and 4-2). The original islands were low-lying and were susceptible toflooding and subject to tidal influence. Kooragang Island was formed by progressive land reclamation operations whichmodified the original islands into a single island by in-filling of tidal mudflats and creeks.The topography of Kooragang Island, including the Project site, is generally flat and low lying. Elevations within theProject site vary from approximately 0.7 m to 12 m AHD (Figure 4 -3). There are a number of depressions thatintermittently fill with surface runoff. The most notable of these depressions are Big Pond, which is located in the northwestof the Project coal storage area and Deep Pond, the southern end of which would be traversed by the Projectnorthern rail spur should it be required when the Project is fully developed to 66 Mtpa (Figure 4-3).In relation to ASS, Section 4.1.1 of the EA provides:The soils of Kooragang Island generally reflect those placed there by land reclamation operations. The natural soil profileacross Kooragang Island (below fill materials) generally consists of an upper clay layer (soft silty sandy clay), a sandylayer (loose to dense sand), a lower clay layer (stiff to very stiff sandy silty clay), soft rock layers (siltstone and mudstone)and hard rock layers (sandstone) (Connell-Hatch, 2005). Due to the presence of the various fill materials and thehistorical flow paths of the Hunter River and its tributaries, the depth of each of the soil layers varies significantly over theProject site (ibid.). …<strong>Acid</strong> Sulfate <strong>Soils</strong>The Department of Land and Water Conservation (DLWC) (1997) <strong>Acid</strong> Sulfate Soil – <strong>Plan</strong>ning Mapping identifies fiveclasses of land based on the probability of the occurrence of acid sulfate soils, for planning purposes (Section 3.3.2). Themajority of the Project site is considered to be Class 2 on the Potential <strong>Acid</strong> Sulfate <strong>Soils</strong> <strong>Plan</strong>ning Map (DLWC, 1997).Areas identified as consisting of Class 2 soils require development consent for any works below the ground surface or forworks that may lower the groundwater table.…Class 1 land within the Project site is generally restricted to the Hunter River and foreshore. The south arm of the HunterRiver (including the dredge material) is generally classified as Class 1 land (DLWC, 1997). Areas identified as consistingof Class 1 soils require development consent for any works.…6

<strong>Acid</strong> Sulfate Soil <strong>Management</strong> <strong>Plan</strong>Previous assessments of the ASS character of the Project area have divided the site into four land investigationareas (e.g. Land Contamination and Groundwater Assessment [RCA, 2006]), which are used here for thedescription of existing information presented below and in the further sections of this report. The assessmentareas are shown on Figure 2, and are described below:Site A1 – including the Project coal storage area.Site A2 – south of Cormorant Road including the Project wharf facilities and shiploaders.Site D1 – the portion of the Kooragang Island Waste Emplacement (KIWEF) west of the Delta access roadthat is traversed by the Project rail infrastructure corridor.Site D2 – the portion of the KIWEF between the Delta access road and the Pacific National access road thatis traversed by the Project rail infrastructure corridor and train unloading stations.The Land Contamination and Groundwater Assessment (RCA, 2006) prepared for the EA provides the followinginformation relevant to ASS:URS (Reference 14) suggested that potential acid sulphate soils are present approximately 3 to 3.5 m below ground level[on Site A1]. It is expected that these potential acid sulphate soils would not develop into acid sulphate soils due to thepresence of natural buffering agents in the soil (Reference 5).Excavations on Site A1 would only have minimal and temporary local interference with the sub soil (Reference 2) andtherefore acid sulphate soils are unlikely to be disturbed.…There have been no acid sulphate soils previously identified at Site A2.…Excavations on Sites D1 and D2 would require very little cut into the existing soil (Reference 2), therefore minimising thelikelihood of disturbing acid sulphate soils.Testing during <strong>Stage</strong> 1 and <strong>Stage</strong> 2AA construction activities found that material excavated during railinfrastructure works was generally not acid forming. Some 60 samples of dredged and excavated material havebeen tested since April 2008 and of these only five samples were classified as ASS (Table 2). Those materialsclassified as ASS were all from samples taken from dredged material during <strong>Stage</strong> 1 construction activities. NoASS was identified in material excavated during <strong>Stage</strong> 1 or <strong>Stage</strong> 2AA of the Project. The dredged materialidentified as ASS was subsequently monitored and managed as follows:materials tested and determined to be self-buffering;materials mixed with shell grit sand and allowed to self-buffer; andmaterials remained in a non-oxidising environment.Given that the limited excavation works required for <strong>Stage</strong> <strong>2F</strong> of the Project will be in areas that have previouslybeen tested for ASS and found to be low risk (i.e. Site A1, Site A2 and Site D1), it is expected that the potentialrisk of ASS will be limited.7

<strong>Acid</strong> Sulfate Soil <strong>Management</strong> <strong>Plan</strong>Table 2<strong>Acid</strong> Sulfate Soil Testing ResultsSampleNumberSampleDate11 9/09/2008LocationTrain UnloadingStation StockpileTexture andGritJet black,blocky, organicclaypHF 1 pHFOX 2 Classification Action8.1 2.8 ASS20 13/10/2008 South Stockpile Black sand, silty 7.99 3.7 ASS27 24/11/2008 Foreshore Wharf30 1/04/2009 Foreshore Wharf36 5/08/2009Source: after NCIG (2011).1 pHF = Field pH test.2 pHFOX = Field pH peroxide test.RailembankmentMangrovematerialBlack silty mud,fine sandWetlandsediment rich inorganic material4.78 1.47 ASS6.61 2.6 ASS3.22 1.5 ASSLab tested -Self-bufferingmaterialSelf-bufferingmaterial, mixed withshell grit sand andallowed to breakdownMaterial returnedunderwater toprevent oxidationMaterial moved toASS treatment areaMaterial coveredwith a sealing laverwhile still wet3.2 PROJECT DESCRIPTIONAs described in Section 1, the approved Project includes the construction and operation of a CET up to 66 Mtpa,including associated rail and coal handling infrastructure and wharf/shiploading facilities on the south arm of theHunter River. A detailed description of the Project is provided in Section 2 of the EA.As described in Section 3.1, PASS material has been identified below portions of the Project site (NCIG, 2006)and ASS material during construction of <strong>Stage</strong> 1 of the Project. Therefore, excavations required during theconstruction of <strong>Stage</strong> <strong>2F</strong> of the Project have the potential to intercept PASS material. Project elements havetherefore been designed to minimise excavations. Limited excavations will be required during the construction of<strong>Stage</strong> <strong>2F</strong> of the Project, including (NCIG, 2006):foundations for the third berth;development of surface water management infrastructure including temporary re-profiling of land forconstruction purposes.A description of these Project components is provided in Sections 3.2.1 to 3.2.2.3.2.1 Berth ConstructionEarthworks associated with the construction of the third berth primarily involves placement of fill and preloadmaterial, however some minor excavation work will be required for the preparation of foundations.All excavations required for the construction of Project berth infrastructure are undertaken in accordance withprocedures described in Section 3.4.8

<strong>Acid</strong> Sulfate Soil <strong>Management</strong> <strong>Plan</strong>3.2.2 Surface Water <strong>Management</strong> InfrastructureA network of stormwater drains, primary and secondary settling ponds and an overflow pond will be used tomanage runoff on and around the site. All site water management structures are lined with low permeabilitymaterials (e.g. compacted clay or geo-membrane) to minimise the potential for leakage.All excavations required for the construction of Project surface water management infrastructure are undertakenin accordance with procedures described in Section 3.4.3.3 POTENTIAL ACID SULFATE SOIL IMPACTSWhere works impact on the existing estuarine soils, there is the potential to disturb ASS and these works willrequire the implementation of the controls detailed in this management plan. Whilst the following informationrelates to specific activities, all activities that disturb estuarine soils will be assessed for acid generating potentialand treated accordingly.Project elements have been designed to minimise excavations. As described in Section 3.2, limited excavationswill be required during the construction of <strong>Stage</strong> <strong>2F</strong> of the Project. These excavations have the potential tointercept ASS.Any activities (e.g. excavations or groundwater extraction) that have the potential to lower the water table mayenhance the oxidation of sediments. Where excavation is below the water table and into the estuarine soils,drawdown on the water table is possible which may expose PASS soils. This can result in exposure of previouslysaturated sediments allowing oxidation of PASS and acid generation.It is expected that the groundwater table will recover to within the vicinity of its original level after backfilling.3.4 ACID SULFATE SOIL MANAGEMENT STRATEGYPrior to any excavation on-site, a representative surface and sub-surface soil sampling and analysis program willbe undertaken in order to characterise the material to be excavated. The sampling program will be undertaken inaccordance with the <strong>Acid</strong> Sulfate Soil Manual (ASSMAC, 1998). A description of the sampling program isprovided in Section 3.4.1.3.4.1 Sampling ProgramThe sampling program will be conducted in accordance with the <strong>Acid</strong> Sulfate Soil Manual (ASSMAC, 1998) priorto any excavation that will extend into the natural soil profile. A sampling program will be developed for eachProject element described in Section 3.2 as follows:foundations for the third berth;development of surface water management infrastructure including temporary re-profiling of land forconstruction purposes.The sampling intensity (i.e. number of samples, depth and sample size) will be as required in the <strong>Acid</strong> Sulfate SoilManual (ASSMAC, 1998) for the area and volume of each excavation.3.4.2 Assessment CriteriaThe NSW <strong>Acid</strong> Sulfate Soil <strong>Management</strong> Advisory Committee (ASSMAC), <strong>Acid</strong> Sulfate Soil Manual (1998),presents guidelines for the sampling, determination and management of ASS materials dependent on the quantityof material to be disturbed and the type of disturbance (linear, bulk). The guidelines provided in the <strong>Acid</strong> SulfateSoil Manual (ASSMAC, 1998) are considered appropriate for use at the Project site.The <strong>Acid</strong> Sulfate Soil Manual (ASSMAC, 1998) outlines ‘Action Criteria’ based on laboratory analysis of ASScharacteristics. These Action Criteria are based on the soil texture together with the volume of material which isto be disturbed to determine if the material is to be managed as an ASS. The Action Criteria provided in Table 3can also be used to assess ‘neutralisation’ of lime treated soils.9

<strong>Acid</strong> Sulfate Soil <strong>Management</strong> <strong>Plan</strong>Table 3Action Criteria for Assessing <strong>Soils</strong> with regard to <strong>Acid</strong> Sulfate Soil CharacteristicsTextureType of MaterialApproximateClay Content(%1000 tonnes disturbed)Sulphur Trail% Sulphuroxidisable(oven dry basis)<strong>Acid</strong> TrailMol H + /t Total(oven dry basis)Coarse Texture(Sands to loamysands)≤ 5 0.03 18 0.03 18Medium Texture(Sandy loams tolight clays)5-40 0.06 36 0.03 18Fine Texture(Medium toheavy clays and≥ 40 0.1 62 0.03 18silty clays)Source: after ASSMAC (1998).1 Mol H + /t = moles of hydrogen ions per tonne.The results of each sampling program will be compared with the Action Criteria provided in Table 3 to determine ifany treatment is required. Materials that are below the Action Criteria provided in Table 3 will be beneficiallyreused on-site. Material that is determined to be unsuitable for beneficial reuse on-site will be temporarilystockpiled on-site before being either treated and reused or transported to a licensed for treatment(Section 3.4.3).The characteristics of all soil materials will be recorded during excavation and movement on-site. Records willinclude a description of the excavated soil and the depth and location of its source and final placement.3.4.3 Treatment ProcessAs described in Section 3.1, during <strong>Stage</strong> 1 of the Project the sampling program only identified five samples asASS during construction works. One sample from dredged material was found to contain ASS and was returnedto the foreshore to prevent the material from oxidising. Laboratory analysis of two dredge material samples foundthe soils to be self-buffering, i.e. no treatment was necessary to minimise the ASS risk associated with oxidationof the soil. The soils were mixed with shell grit sand and allowed to break down without further treatment. Thesoil identified in the fourth positive sample was moved to the ASS treatment area and treated. The soil identifiedin the fifth positive sample was capped with a sealing layer to prevent oxidation.If required during <strong>Stage</strong> <strong>2F</strong> of the Project, excavated soil identified as PASS or ASS will be temporarily stockpiledon-site before being either treated and reused or transported to a licensed facility for treatment. Treatment areaswill be bunded and have low permeability liners (e.g. compacted clay or geo-membrane). The treatment area willbe divided into a minimum of two areas separated by a bund wall. One area is for treatment and one forstockpiling the treated soils.The treatment area will require a settlement pond to collect any runoff. The settlement pond will be designed for a1 in 10 year, 1 hour storm duration capacity. Any runoff or fines collected in the settlement pond will requireassessment prior to decommissioning of the settlement pond.The control of acid generation from excavated soil will be achieved by neutralisation using lime, where required.There are numerous types of suitable lime including agricultural lime, hydrated lime, calcined magnesia anddolomite. These vary in their neutralising requirements and the choice depends on cost and availability.Excavated soil will be spread out in a maximum 0.3 m deep layer and covered with the required amount of lime.The required lime dose rate (i.e. kilogram of lime/tonne of material) will be determined from the results of soiltesting in accordance with the <strong>Acid</strong> Sulfate Soil Manual (ASSMAC, 1998). Lime treatment will be then undertakenby tyning lime and soil aeration with a rotary hoe or similar to obtain thorough mixing and aeration. Treatment ofsoils delivered to the treatment area will be undertaken within one day of delivery, where practicable.10

<strong>Acid</strong> Sulfate Soil <strong>Management</strong> <strong>Plan</strong>Final validation sampling of treated soils will be conducted at the completion of treatment to determine if theneutralisation process has been successful. Validation sampling will be conducted in accordance with the <strong>Acid</strong>Sulfate Soil Manual (ASSMAC, 1998). The soil will be considered neutralised if the results are below the ActionCriteria outlined in Table 3. Additional lime treatment will be conducted if validation sampling determines the soilis not below the Action Criteria outlined in Table 3.Once treatment is satisfactorily complete, the material will be capped (within the encapsulated cell) with anappropriate cover layer in accordance with Benchmarks 1 and 2 in Environmental Guidelines: Solid WasteLandfills (Environment Protection Authority [EPA], 1996), beneficially reused on the Project site or removed fromthe site for treatment at a licensed facility.3.4.4 Water <strong>Management</strong> during Excavations and TreatmentWater that accumulates in excavations during Project construction will be tested to determine its quality.Depending on the quality of this water it will be pumped to dedicated detention ponds (e.g. treatment settlementpond) or (if the water quality is suitable) pumped to the site drainage network for storage on-site and re-use.In accordance with Condition 7.3(b), Schedule 2 of Project Approval (06_0009), a Construction Surface Water<strong>Management</strong> <strong>Plan</strong> (CSWMP) has been developed for the Project. The CSWMP includes a description of the sitedrainage network design. The CSWMP also forms part of the Construction Environmental <strong>Management</strong> <strong>Plan</strong> withthis CET ASSMP.Water that is considered to be of unsuitable quality for re-use will be temporarily stored within dedicated detentionponds (e.g. treatment settlement pond) with low permeability liners (e.g. compacted clay or geo-membrane)before being treated for re-use and/or removed from the site and disposed of by a licensed contractor.Water that accumulates in the treatment settlement pond will be treated for re-use and/or removed from the siteand disposed of by a licensed contractor. Fines (from the treatment area) that collect in the settlement pond willbe periodically tested/analysed and if necessary treated as described in Sections 3.4.1, 3.4.2 and 3.4.3.3.5 MONITORING3.5.1 <strong>Acid</strong> Sulfate <strong>Soils</strong>As described in Section 3.4, a representative surface and sub-surface soil sampling and analysis program will beundertaken for the Project elements requiring excavations into the natural soil profile (Section 3.2) in order tocharacterise material to be excavated. The presence or otherwise of ASS will be identified during this surfaceand sub-surface soil sampling and analysis program.3.5.2 Surface WaterA CSWMP has been developed for the Project in accordance with Condition 7.3(b), Schedule 2 of ProjectApproval (06_0009). The CSWMP includes a surface water monitoring program for the Project. The CSWMPalso forms part of the Construction Environmental <strong>Management</strong> <strong>Plan</strong> with this CET ASSMP.11

<strong>Acid</strong> Sulfate Soil <strong>Management</strong> <strong>Plan</strong>3.6 CONTINGENCY MEASURESAs described in Section 3.4, final validation sampling of treated soils will be conducted at the completion oftreatment to determine if the neutralisation process has been successful prior to the material being capped (withinthe encapsulated cell) with an appropriate cover layer in accordance with Benchmarks 1 and 2 in EnvironmentalGuidelines: Solid Waste Landfills (EPA, 1996), beneficially reused on the Project site or removed from the site fortreatment at a licensed facility.If validation sampling determines that neutralisation using lime is ineffective, NCIG will investigate alternativetreatment technologies, including (but not limited to) the management strategies included in the<strong>Acid</strong> Sulfate Soil Manual (ASSMAC, 1998).4 REPORTING AND REVIEWIn accordance with Condition 8.1, Schedule 2, of the Project Approval (06_0009), the Director-General will benotified of any incident with actual or potential significant off-site impacts on people or the biophysicalenvironment as soon as practicable after the occurrence of the incident. The Director-General will be providedwith written details of the incident within seven days of the date on which the incident occurred.NCIG will prepare an Annual Environmental <strong>Management</strong> Report (AEMR) that reviews the performance of theProject against this CET ASSMP, provides an overview of environmental management actions and summarisesmonitoring results over the 12 month reporting period. The AEMR will be distributed to relevant governmentagencies and stakeholders, and copies provided to other interested parties, if requested.In accordance with Condition 6.4, Schedule 2 of Project Approval (06_0009), this CET ASSMP will be madeavailable on the NCIG website.5 REFERENCES<strong>Acid</strong> Sulfate Soil <strong>Management</strong> Advisory Committee (1998) <strong>Acid</strong> Sulfate Soil Manual.Environment Protection Authority (1996) Environmental Guidelines: Solid Waste Landfills.<strong>Newcastle</strong> <strong>Coal</strong> Infrastructure Group (2006) <strong>Newcastle</strong> <strong>Coal</strong> Infrastructure Group <strong>Coal</strong> Export TerminalEnvironmental Assessment.RCA Australia (2006) Land Contamination and Groundwater Assessment, <strong>Newcastle</strong> <strong>Coal</strong> Infrastructure Group<strong>Coal</strong> Export Terminal, Kooragang Island.12