nonelectrical

Relays + PWEx Panels + Transformers.pdf - Douglas Lighting Control

Relays + PWEx Panels + Transformers.pdf - Douglas Lighting Control

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

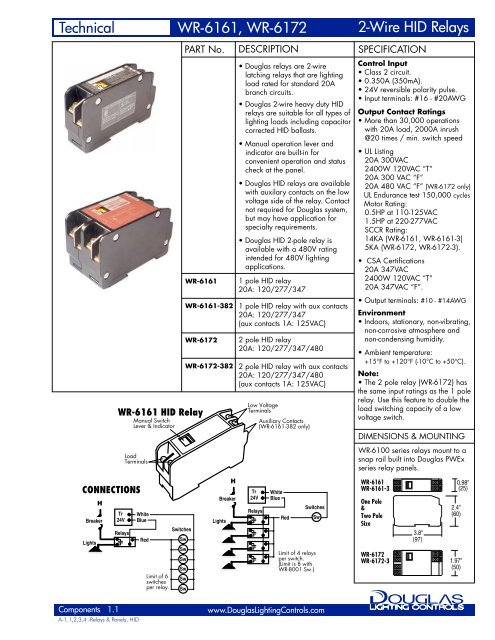

Technical<br />

WR-6161, WR-6172<br />

2-Wire HID Relays<br />

2-WIRE RELAY TECHNOLOGY<br />

• Douglas 2-wire relays utilize an ingenious control method that<br />

permits simple and minimal wiring. All functions for low voltage<br />

control: on, off, indication and location are provided with<br />

only a 2-wire connection of which one is often a common. All<br />

Douglas relays manufactured over the past 30 years utilize the<br />

same principle. Thus, any Douglas switching device is<br />

compatible with any model of Douglas relay.<br />

Manual<br />

Lever<br />

Detailed 2-wire Relay / Switch Circuit<br />

Transformer<br />

24VAC<br />

W<br />

B<br />

Blue<br />

White<br />

2-wire Switch<br />

Switch<br />

Operational Principle<br />

• A negative pulse turns the relay ON and a positive pulse turns it<br />

OFF. Using a diode, an AC signal can be rectified to turn the relay<br />

either ON or OFF. Douglas switches have 2 diodes built into the<br />

switch to provide the ON and OFF signals.<br />

• The relay has 2 similar diodes built inside that are in series with the<br />

relay coil. The diodes in the relay act as gates for the switch signal.<br />

• To turn the relay ON or OFF, the rocker switch completes the circuit<br />

by selecting the ON or OFF diode. If the diode selected is in the<br />

same direction as the gate diode in the relay, the relay will switch. If<br />

the gate diode is not in the correct direction, then nothing will<br />

happen since the relay is already in the correct state for the action<br />

selected by the switch. When the switch is released, a spring returns<br />

it to the central neutral position .<br />

• Indication (ON state) and location (OFF state) are obtained by<br />

utilizing LED diodes built into the switch. Only the LED which is<br />

connected in the same direction as the gate diode in the relay will<br />

light. Although the LED current passes through the relay coil, it is<br />

not large enough to cause the relay to trip. However, there is a limit:<br />

the maximum number of LED switches that can be connected to the<br />

same relay is . 6<br />

• For additional convenience (especially during installation) all standard<br />

models have a manual control lever and indicator permitting a <strong>nonelectrical</strong><br />

method of switching and status check at the panel.<br />

Latch to lock relay ON<br />

or OFF (actually done<br />

with magnetics)<br />

Tr<br />

Tr<br />

W<br />

B<br />

Relay<br />

W<br />

B<br />

2-wire<br />

Relay<br />

Gate Diodes<br />

Relay Coil<br />

Red<br />

Control Diodes<br />

Switch<br />

Switching ON<br />

Switch pressed to ON position.<br />

ON pulse ( ) sent to relay and<br />

relay begins to switch over to ON .<br />

Switch<br />

Detailed LED Switch Circuit *<br />

Transformer<br />

24VAC<br />

W<br />

B<br />

Blue<br />

White<br />

LED 2-wire Switch<br />

ON<br />

ON<br />

Relay<br />

Switched ON<br />

Relay completed switching to ON position.<br />

OFF gate diode engaged and ON pulse<br />

from switch is stopped by OFF gate diode.<br />

Relay ready for OFF pulse.<br />

2-wire Relay<br />

Red<br />

Gate Diodes<br />

Relay Coil<br />

OFF<br />

OFF<br />

Control<br />

Diodes<br />

LED<br />

Indicator Diodes<br />

Current limiting<br />

Resistor<br />

Tr<br />

W<br />

B<br />

Switch<br />

*<br />

LED Switch circuit actually not<br />

as shown. Switch is functionally<br />

similar except rocker switch is<br />

replaced with single push button.<br />

Relay<br />

Switching OFF<br />

Switch pressed to OFF position.<br />

OFF pulse ( ) sent to relay and<br />

relay begins to switch over to OFF.<br />

Components 1.2<br />

A-1.1,2,3,4 -Relays & Panels, HID<br />

www.DouglasLightingControls.com

Technical<br />

Relay Panels for HID Relays<br />

PWEx Panels<br />

PART No.<br />

PWEx Panels<br />

DESCRIPTION<br />

• Douglas PWEx series relay<br />

panels are a versatile line of<br />

panels used for WR-6161 &<br />

WR-6172 relays.<br />

• Standard sizes range from 6 - 72<br />

relays. (Note:WR-6172= 2 relays).<br />

• A panel consists of the enclosure<br />

(tub), the interior and the cover.<br />

Enclosures are installed in the<br />

rough-in stage and interiors are<br />

installed and connected after<br />

wires are pulled.<br />

• Interior has snap brackets for<br />

mounting relays and DIN rail in<br />

the centre for mounting control<br />

components.<br />

• Box knockouts are located so that<br />

panels of the same horizontal or<br />

vertical dimension can be joined<br />

with conduit nipples.<br />

SPECIFICATION<br />

• Enclosures and covers are made<br />

of steel coated with ANSI/ASA<br />

61 Grey. Coating is heat fused<br />

polyesther epoxy finish applied<br />

on all surfaces.<br />

• Interior insert is made from<br />

aluminum, stell and plastic parts.<br />

Certifications<br />

• UL listed, CSA approved.<br />

EEMAC/NEMA 1 Standard.<br />

Options<br />

• Hinged, surface or flush covers.<br />

Covers are reversable for either<br />

left-to-right or right-to-left door<br />

opening. Driphoods (surface<br />

mount only). NEMA 3 standards.<br />

Special paint colors. Voltage<br />

dividers to divide line voltage<br />

compartment for different line<br />

voltages.<br />

4"<br />

4"<br />

Compartment Style<br />

Barrier Layout<br />

4"<br />

CAPACITY<br />

6 12 24<br />

PART No.<br />

PWE0 - C06M - ** PWE1 - C12M - ** PWE2 - C24M - **<br />

SIZE (H x W x D)<br />

12 x 12 x 4.25 20 x 14 x 4.25 33 x 14 x 4.25<br />

PWEx Panel Numbering System<br />

** Add cover style number at end of P/N<br />

Enclosure<br />

PWEx<br />

C<br />

W<br />

Interior<br />

xx<br />

M<br />

S1<br />

F2<br />

Cover<br />

or<br />

S3<br />

F4<br />

4½"<br />

3"<br />

Box Code<br />

Barrier Layout<br />

Compartment: C<br />

Wireway: W<br />

Capacity<br />

Relay Code<br />

HID relays: M<br />

Screw-on<br />

Surface: S1<br />

Flush: F2<br />

Hinged<br />

Surface: S3<br />

Flush: F4<br />

4½"<br />

3"<br />

4½"<br />

3"<br />

4½"<br />

3"<br />

Symbols<br />

Low voltage area<br />

Line voltage area<br />

HID relay<br />

Transformer<br />

Wireway Style<br />

Barrier Layout<br />

CAPACITY<br />

PART No.<br />

SIZE (H x W x D)<br />

6"<br />

24<br />

PWE3 - W24M - **<br />

27 x 20 x 4.25<br />

6" 6"<br />

36 48 72<br />

PWE4 - W36M - ** PWE6 - W48M - ** PWE8 - W72M - **<br />

33 x 20 x 4.25<br />

** Add cover style number at end of P/N<br />

39 x 20 x 4.25<br />

7"<br />

54 x 20 x 4.25<br />

Components 1.3<br />

A-1.1,2,3,4 -Relays & Panels, HID<br />

www.DouglasLightingControls.com

Technical<br />

Relay Panels for HID Relays<br />

PWEx Panels<br />

PWEx Panels: Exploded View<br />

Drip Shields<br />

Optional, surface cover<br />

panels only.<br />

Screw-on<br />

Covers<br />

Hinged Covers<br />

Surface (S1) or<br />

Surface (S3) or Flush (F4). Flush (F2)<br />

Install right side up or upside down<br />

for right-to-left or left-to-right door.<br />

The inner trim of the hinged cover<br />

covers over all of the line voltage wiring.<br />

Access to the relay's manual control<br />

levers is in the low voltage compartment.<br />

Relay Interior<br />

Relays mount to HID snap rails.<br />

Barriers are located to provide the<br />

line / low voltage division.<br />

Transformers mount to 1/2" knock<br />

outs located in the barrier.<br />

Control components are mounted<br />

to DIN rail in center of interior.<br />

Pre-assembled PWEx panels will<br />

have panel schedules completed<br />

according to information provided<br />

and all low voltage control<br />

connections pre-wired.<br />

INSTALLATION & ASSEMBLY<br />

PWEx series relay panels for Douglas HID relays are supplied<br />

with a separate interior. All of the components and barriers are<br />

mounted to the interior.<br />

Stacking Panels<br />

Panels of equal dimension on a<br />

side have matching KO pattern<br />

to provide easy stacking.<br />

PWEx panels are primarily intended for projects where the interior<br />

is factory pre-assembled. To install the relay panel the following<br />

sequence is recommended:<br />

1) Mount the empty enclosure onto the wall and pull wires. It is<br />

recommended that all (or most) of the wires be pulled prior to<br />

installing the interior. This will prevent component damage<br />

from the wire pulling operation.<br />

2) Relay line voltage terminals are sized for a maximum of<br />

12AWG wire.<br />

For low voltage wiring 18AWG solid is recommended.<br />

3) Once the wires have been pulled, install the interior and bolt it<br />

into place. Make line connections to relays according to the<br />

panel schedule provided. If there is no schedule, identify<br />

circuits on a blank schedule.<br />

4) To test circuit, turn circuit breaker off, use manual lever to turn<br />

relay on and then turn on the circuit breaker. This will help<br />

prevent relay contact welding due to dead shorts.<br />

5) Verify that the schedule matches the lights operated by the<br />

relay.<br />

6) Once the line circuits are connected and verified, connect low<br />

voltage switch wiring to relays or devices.<br />

Components 1.4<br />

A-1.1,2,3,4 -Relays & Panels, HID<br />

www.DouglasLightingControls.com

Technical<br />

WR-4075, WR-4040<br />

Transformers<br />

CONNECTIONS<br />

Lights<br />

H<br />

Breaker<br />

Transformer<br />

24VAC<br />

W<br />

B<br />

Relays<br />

Number of Relays<br />

per Switch<br />

White<br />

Blue<br />

Red<br />

PART No.<br />

WR-4075-<br />

120/277<br />

WR-4075-<br />

120/347<br />

WR-4075-240<br />

Wire Length<br />

One way measure<br />

in feet (meters)<br />

WR-4040-120<br />

WIRE DISTANCE CHART - 18Ga Wire<br />

120/277V Primary<br />

: 24VAC* Secondary<br />

120/347V Primary<br />

: 24VAC* Secondary<br />

240V Primary<br />

: 24VAC* Secondary<br />

One-way Measurement - feet (meters)<br />

Wire Gauge<br />

American<br />

Wire Gauge<br />

DESCRIPTION<br />

The transformer supplies the<br />

switching for Douglas 2-wire relay<br />

control. 2-wire relays are latching<br />

type and only require power to<br />

switch on or off. One transformer is<br />

sufficient to service many relays<br />

and devices.<br />

WR-4075 Series: Standard Duty<br />

• 40VA steady draw, 75VA pulsed draw.<br />

• Current limiting and internally fused with an<br />

automatically resetting thermal fuse.<br />

* Secondary voltage varies from<br />

24V to 29V depending upon load.<br />

WR-4040 Series: Light Duty<br />

• 40VA steady draw, 40VA pulsed draw.<br />

• Current limiting and internally fused with a one<br />

time event fuse.<br />

120V Primary : 24VAC Secondary<br />

Sw<br />

SPECIFICATION<br />

Input<br />

• Line voltage 120,240,277 or<br />

347V. Select correct model fo<br />

line voltage.<br />

Output<br />

• 24VAC at full load. At no or low<br />

loads, the voltage is 29V. As the<br />

current draw increases, the<br />

transformer voltage decreases. A<br />

fully loaded class 2 transformer<br />

will output 24V.<br />

• Douglas products are designed to<br />

operate correctly over the entire<br />

range of voltages provided by th<br />

transformer.<br />

Class 2 - Current Limiting<br />

• Transformers that are approved<br />

for powering Class 2 circuits are<br />

current limited to prevent<br />

excessive currents caused by<br />

shorts. This is a key safety feature<br />

to help prevent fires from shorts.<br />

• The Class 2 current limiting<br />

feature permits the use of wire<br />

that is of a light gauge and has<br />

less stringent insulation<br />

requirements.<br />

Environment<br />

• Indoors, stationary, non-vibrating,<br />

non-corrosive atmosphere and<br />

non-condensing humidity.<br />

• Ambient temperature:<br />

-20°F to +120°F (-28°C to +50°C)<br />

Approvals & Certifications<br />

• UL Approved<br />

• CSA Certified<br />

DIMENSIONS & MOUNTING<br />

Douglas transformers have a<br />

nipple & mounting nut suited for a<br />

7/8" hole (1/2" pipe hole & tread size)<br />

3.15<br />

WR-4075<br />

Series<br />

Transformers<br />

1.5A & 3.0A rated switches<br />

(WR-8001, WR-8501, WR-8503)<br />

1<br />

2<br />

3<br />

4<br />

2000 (600)<br />

1500 (450)<br />

1000 (300)<br />

500 (150)<br />

18 AWG<br />

18 AWG<br />

18 AWG<br />

18 AWG<br />

2.56<br />

2.38<br />

6"wire<br />

3.15<br />

WR-4040<br />

Series<br />

Transformer<br />

3.0 A rated switches<br />

(WR-8001, WRK-8201)<br />

6<br />

8<br />

300 (90)<br />

160 (50)<br />

18 AWG<br />

18 AWG<br />

2.00<br />

6"wire<br />

2.87<br />

Components 2.1<br />

A-2.1,2 -Relays & Panels, Transformers<br />

www.DouglasLightingControls.com

Technical<br />

WR-4075, WR-4040<br />

Transformers<br />

Lights<br />

H<br />

Breaker<br />

Relay Panel Schematic<br />

Transformer<br />

24VAC<br />

W<br />

B<br />

Relay<br />

Relay Panel<br />

Switching from<br />

many Locations<br />

Sw<br />

Sw<br />

Sw<br />

TRANSFORMER LOADS<br />

Douglas relays do not use any power while in the latched on or off<br />

state. Power is only used when the relay switches over.<br />

In the vast majority of cases, only 1 transformer per relay panel<br />

will be all that is required. Theoretically, there is no limit to the<br />

amount of relays that can be switched by 1 transformer.<br />

There are Douglas devices other than relays that do use low<br />

amounts of steady state power. For example, the LEDs of the LED<br />

style switches use power. Relay scanners, time clocks, and other<br />

electronic devices also use power. If a large number of these<br />

devices are powered by one transformer, do a "LOADING<br />

CALCULATION" to ensure that there is no overload. In the rare<br />

case there is an overload, split the circuits and use more than 1<br />

transformer.<br />

Relays<br />

Relay<br />

Scanner<br />

Electric current available for<br />

switching relays and for losses<br />

due to wiring lengths.<br />

W B<br />

Switching<br />

Large Loads<br />

Sw<br />

Switching from<br />

a Distance<br />

Sw<br />

Switching<br />

Control Devices<br />

(Group Switching)<br />

Sw<br />

Switching<br />

Individual Loads<br />

Sw<br />

Sw<br />

Transformer Loading Diagram<br />

Steady loads are deducted from current limit to determine<br />

momentary current available relay switching.<br />

3000mA<br />

1600 mA<br />

700 mA<br />

0 mA<br />

Momentary<br />

Switching<br />

current limit<br />

(75VA or 3000mA)<br />

(WR-4075 series only)<br />

Steady state<br />

current limit<br />

(40VA or 1600mA)<br />

300mA 400mA<br />

100 LED<br />

Switches<br />

2 Scanners &<br />

1 Photocell<br />

LOADING CALCULATIONS<br />

If a large number of devices are being connected to a transformer,<br />

check to ensure that the transformer loading is correct. The<br />

example shown below illustrates the method of calculation.<br />

EXAMPLE: A system has the following components.<br />

100 LED switches<br />

48 2-wire relays<br />

2 Relay scanners<br />

1 Photocell controller<br />

Check how many relays can be switched at one time.<br />

A) Calculate the maximum number of relays that can be switched<br />

at one time ignoring wiring distance:<br />

1) Total the steady state current requirement<br />

Led Switches 100 x 4mA = 400mA<br />

Relays 48 x 0mA = 0mA<br />

Relay Scanners 2 x 100mA = 200mA<br />

Photocell Controller 1 x 100mA = 100mA<br />

700mA<br />

2) Check that the steady state current requirement does not<br />

exceed 1.6 Amperes. In the rare cases that the steady state<br />

current exceeds 1.6 A, extra transformers will have to be<br />

added and circuitry will have to be split.<br />

For this example, the steady state current is 700mA which<br />

is less than 1.6 amperes (1600mA).<br />

3) Subtract the steady state current from the total momentary<br />

current available to obtain the amount of current available<br />

for switching relays.<br />

Total current available form a WR-4075 series transformer<br />

for a momentary switching pulse is 3000mA (75VA).<br />

For this example, the current available for switching relays<br />

is 2300mA (3000 - 700).<br />

4) Divide the total available relay current by the current draw<br />

of a relay (350mA) to obtain the maximum number of relays<br />

that can be switched at one time.<br />

2300 ÷ 350 = 6.57 - Round the answer down to 6 relays.<br />

B) The maximum number of relays that can be switched at one<br />

time is either the value obtained by the above calculation or<br />

the value determined by the maximum wiring distance allowed<br />

- WHICHEVER IS LESS.<br />

If the wire distance is 600 feet and the wire gauge is #18 AWG,<br />

then the limit is 4 relays, not 6 relays (see wire distance chart).<br />

Components 2.2<br />

A-2.1,2 -Relays & Panels, Transformers<br />

www.DouglasLightingControls.com