UltraLight Steel Auto Body - Final Report - American Iron & Steel ...

UltraLight Steel Auto Body - Final Report - American Iron & Steel ...

UltraLight Steel Auto Body - Final Report - American Iron & Steel ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

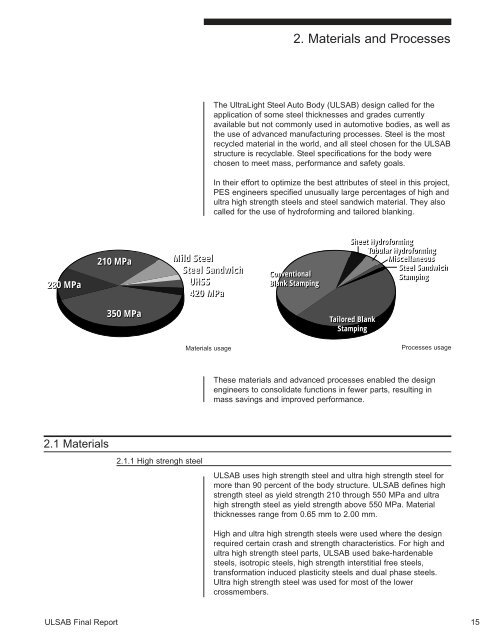

280 MPa<br />

2.1 Materials<br />

210 MPa<br />

ULSAB <strong>Final</strong> <strong>Report</strong><br />

350 MPa<br />

2.1.1 High strengh steel<br />

Mild <strong>Steel</strong><br />

<strong>Steel</strong> Sandwich<br />

UHSS<br />

420 MPa<br />

Materials usage<br />

2. Materials and Processes<br />

The <strong>UltraLight</strong> <strong>Steel</strong> <strong>Auto</strong> <strong>Body</strong> (ULSAB) design called for the<br />

application of some steel thicknesses and grades currently<br />

available but not commonly used in automotive bodies, as well as<br />

the use of advanced manufacturing processes. <strong>Steel</strong> is the most<br />

recycled material in the world, and all steel chosen for the ULSAB<br />

structure is recyclable. <strong>Steel</strong> specifications for the body were<br />

chosen to meet mass, performance and safety goals.<br />

In their effort to optimize the best attributes of steel in this project,<br />

PES engineers specified unusually large percentages of high and<br />

ultra high strength steels and steel sandwich material. They also<br />

called for the use of hydroforming and tailored blanking.<br />

Conventional<br />

Blank Stamping<br />

Sheet Hydroforming<br />

Tubular Hydroforming<br />

Miscellaneous<br />

<strong>Steel</strong> Sandwich<br />

Stamping<br />

Tailored Blank<br />

Stamping<br />

Processes usage<br />

These materials and advanced processes enabled the design<br />

engineers to consolidate functions in fewer parts, resulting in<br />

mass savings and improved performance.<br />

ULSAB uses high strength steel and ultra high strength steel for<br />

more than 90 percent of the body structure. ULSAB defines high<br />

strength steel as yield strength 210 through 550 MPa and ultra<br />

high strength steel as yield strength above 550 MPa. Material<br />

thicknesses range from 0.65 mm to 2.00 mm.<br />

High and ultra high strength steels were used where the design<br />

required certain crash and strength characteristics. For high and<br />

ultra high strength steel parts, ULSAB used bake-hardenable<br />

steels, isotropic steels, high strength interstitial free steels,<br />

transformation induced plasticity steels and dual phase steels.<br />

Ultra high strength steel was used for most of the lower<br />

crossmembers.<br />

15