UltraLight Steel Auto Body - Final Report - American Iron & Steel ...

UltraLight Steel Auto Body - Final Report - American Iron & Steel ...

UltraLight Steel Auto Body - Final Report - American Iron & Steel ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ULSAB <strong>Final</strong> <strong>Report</strong><br />

3.5.2 Adhesive bonding<br />

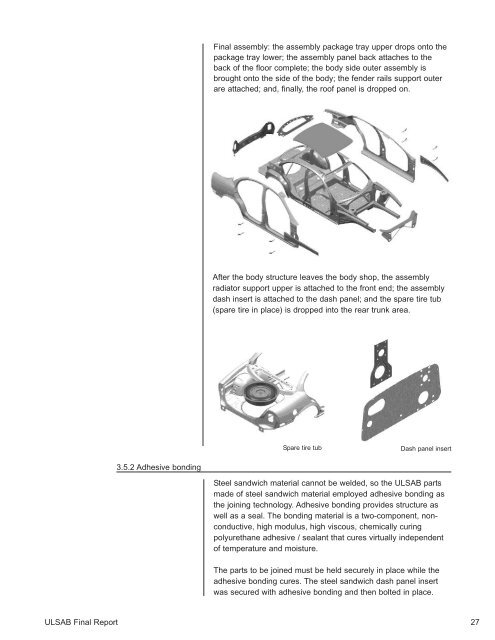

<strong>Final</strong> assembly: the assembly package tray upper drops onto the<br />

package tray lower; the assembly panel back attaches to the<br />

back of the floor complete; the body side outer assembly is<br />

brought onto the side of the body; the fender rails support outer<br />

are attached; and, finally, the roof panel is dropped on.<br />

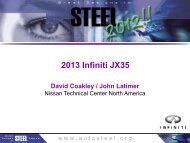

After the body structure leaves the body shop, the assembly<br />

radiator support upper is attached to the front end; the assembly<br />

dash insert is attached to the dash panel; and the spare tire tub<br />

(spare tire in place) is dropped into the rear trunk area.<br />

Spare tire tub<br />

Dash panel insert<br />

<strong>Steel</strong> sandwich material cannot be welded, so the ULSAB parts<br />

made of steel sandwich material employed adhesive bonding as<br />

the joining technology. Adhesive bonding provides structure as<br />

well as a seal. The bonding material is a two-component, nonconductive,<br />

high modulus, high viscous, chemically curing<br />

polyurethane adhesive / sealant that cures virtually independent<br />

of temperature and moisture.<br />

The parts to be joined must be held securely in place while the<br />

adhesive bonding cures. The steel sandwich dash panel insert<br />

was secured with adhesive bonding and then bolted in place.<br />

27