1 ADVANCE for Executive Insight

1 ADVANCE for Executive Insight

1 ADVANCE for Executive Insight

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

clinical lab efficiency<br />

<strong>Executive</strong>-level<br />

administrators<br />

would be wellserved<br />

to understand<br />

how strategic<br />

investments<br />

can help critical<br />

laboratory functions<br />

drive even<br />

greater levels of<br />

productivity, quality<br />

and efficiency,<br />

delivering favorable<br />

returns on<br />

investment (ROI)<br />

and service level<br />

improvements,<br />

while simultaneously<br />

reducing<br />

potential operational<br />

and patient<br />

care errors.<br />

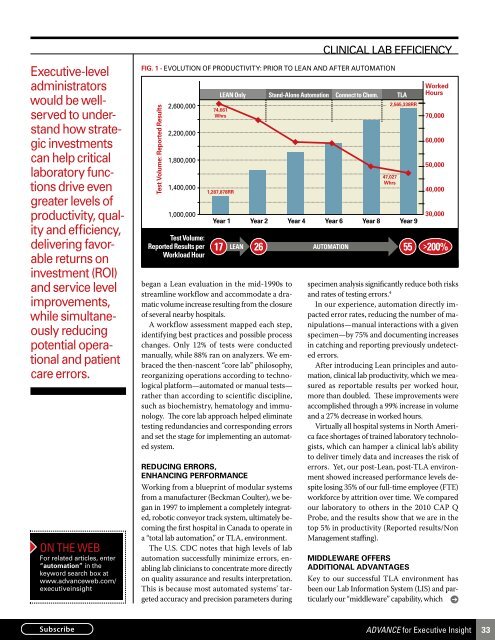

FIG. 1 - EVOLUTION of productivity: PRIOR to lean and after automation<br />

Test Volume: Reported Results<br />

2,600,000<br />

2,200,000<br />

1,800,000<br />

1,400,000<br />

1,000,000<br />

Test Volume:<br />

Reported Results per<br />

Workload Hour<br />

began a Lean evaluation in the mid-1990s to<br />

streamline workflow and accommodate a dramatic<br />

volume increase resulting from the closure<br />

of several nearby hospitals.<br />

A workflow assessment mapped each step,<br />

identifying best practices and possible process<br />

changes. Only 12% of tests were conducted<br />

manually, while 88% ran on analyzers. We embraced<br />

the then-nascent “core lab” philosophy,<br />

reorganizing operations according to technological<br />

plat<strong>for</strong>m—automated or manual tests—<br />

rather than according to scientific discipline,<br />

such as biochemistry, hematology and immunology.<br />

The core lab approach helped eliminate<br />

testing redundancies and corresponding errors<br />

and set the stage <strong>for</strong> implementing an automated<br />

system.<br />

Reducing Errors,<br />

Enhancing Per<strong>for</strong>mance<br />

Working from a blueprint of modular systems<br />

from a manufacturer (Beckman Coulter), we began<br />

in 1997 to implement a completely integrated,<br />

robotic conveyor track system, ultimately becoming<br />

the first hospital in Canada to operate in<br />

a “total lab automation,” or TLA, environment.<br />

The U.S. CDC notes that high levels of lab<br />

automation successfully minimize errors, enabling<br />

lab clinicians to concentrate more directly<br />

on quality assurance and results interpretation.<br />

This is because most automated systems’ targeted<br />

accuracy and precision parameters during<br />

LEAN Only Stand-Alone Automation Connect to Chem. TLA<br />

74,661<br />

Whrs<br />

1,287,878RR<br />

47,027<br />

Whrs<br />

2,565,338RR<br />

Year 1 Year 2 Year 4 Year 6 Year 8 Year 9<br />

Worked<br />

Hours<br />

70,000<br />

60,000<br />

50,000<br />

40,000<br />

30,000<br />

17 LEAN 26 automation<br />

55 >200%<br />

specimen analysis significantly reduce both risks<br />

and rates of testing errors. 4<br />

In our experience, automation directly impacted<br />

error rates, reducing the number of manipulations—manual<br />

interactions with a given<br />

specimen—by 75% and documenting increases<br />

in catching and reporting previously undetected<br />

errors.<br />

After introducing Lean principles and automation,<br />

clinical lab productivity, which we measured<br />

as reportable results per worked hour,<br />

more than doubled. These improvements were<br />

accomplished through a 99% increase in volume<br />

and a 27% decrease in worked hours.<br />

Virtually all hospital systems in North America<br />

face shortages of trained laboratory technologists,<br />

which can hamper a clinical lab’s ability<br />

to deliver timely data and increases the risk of<br />

errors. Yet, our post-Lean, post-TLA environment<br />

showed increased per<strong>for</strong>mance levels despite<br />

losing 35% of our full-time employee (FTE)<br />

work<strong>for</strong>ce by attrition over time. We compared<br />

our laboratory to others in the 2010 CAP Q<br />

Probe, and the results show that we are in the<br />

top 5% in productivity (Reported results/Non<br />

Management staffing).<br />

Middleware Offers<br />

Additional Advantages<br />

Key to our successful TLA environment has<br />

been our Lab In<strong>for</strong>mation System (LIS) and particularly<br />

our “middleware” capability, which<br />

<strong>ADVANCE</strong> <strong>for</strong> <strong>Executive</strong> <strong>Insight</strong><br />

33