POINT EXTRACTION

UK_point extraction2 kor - Søfartens Arbejdsmiljøråd

UK_point extraction2 kor - Søfartens Arbejdsmiljøråd

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

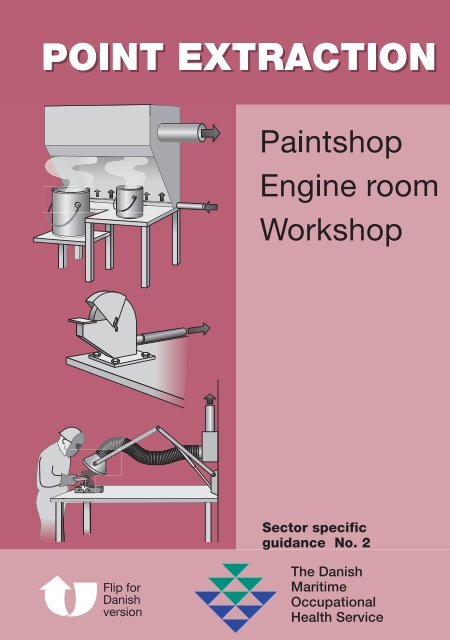

Sector specific guidance No. 2<br />

<strong>POINT</strong><br />

<strong>EXTRACTION</strong><br />

Paintshop<br />

Engine room<br />

Workshop<br />

The Danish Maritime Occupational Health Service<br />

2001

Copyright: The Danish Maritime Occupational Health Service<br />

ISBN number 87-986883-8-3<br />

Print: JBK Offset ApS, Ishøj, Denmark<br />

Text: Jens Voxtrup Petersen, CASA and Bjarne Pless, BST Aarhus<br />

Drawings: Pelle Søborg<br />

Production: Tegneriet ApS, Copenhagen<br />

Translation: Joanna Thompson<br />

Published by<br />

Sale and distribution from<br />

Søfartens Arbejdsmiljøråd<br />

Amaliegade 33 B<br />

DK-1256 Copenhagen K<br />

Denmark<br />

Phone: +45 33 11 18 33<br />

Fax: +45 33 11 14 60<br />

www.seahealth.dk<br />

E-mail: info@seahealth.dk<br />

Iver C. Weilbach & Co. A/S<br />

Toldbodgade 35<br />

DK-1253 Copenhagen K<br />

Denmark<br />

Phone: +45 33 13 59 27<br />

Fax: +45 33 93 59 27<br />

E-mail: nautical@weilbach.dk

Why publish sector specific guidance<br />

on point extraction?<br />

Airborne pollution is an undesirable yet unavoidable<br />

consequence of human activities. If a person,<br />

in the course of his work, comes into contact with<br />

harmful fumes or toxic vapours from chemicals, his<br />

health can be adversely affected. Pollution can<br />

have harmful effects on the mucus membranes,<br />

the skin and on breathing. It can cause both acute<br />

effects as well as long-term, chronic effects. Shortness<br />

of breath and loss of consciousness are examples<br />

of acute effects, while asthma, chronic<br />

bronchitis and cancer can be the results of more<br />

long-term exposure.<br />

As a starting point, the law requires that any work<br />

on board a merchant vessel should be carried out<br />

in an entirely appropriate way with regard to health<br />

and safety. This means that persons may not/<br />

should not be exposed to unnecessary harmful influences<br />

that, in either the short or the long term,<br />

can have bad effects on their health.<br />

Consequently, representatives of the shipping industry<br />

have collaborated in preparing this sector<br />

specific guidance. The purpose has been to establish<br />

a form of sound and accepted practice in the<br />

elimination of airborne pollution by means of point<br />

extraction.<br />

The guidelines have been submitted to the Danish<br />

Maritime Authority and any comments are included<br />

in the text.<br />

Legislation<br />

The guidelines are based on the following:<br />

• Legal notice no. 554 of 21st June 2000 on Safety at Sea, with subsequent amendments.<br />

• Directive B from the Danish Maritime Authority on the construction and equipping of vessels etc.<br />

Chapter B II-4: The design and equipping of workrooms and workplaces. 1st January 2001.<br />

• The Danish Maritime Authority’s technical regulation no. 6 of 3rd July 1997: On mechanical extraction<br />

from a closed area used for handling paints, and from workplaces on ships.<br />

Prevention with point extraction and ventilation<br />

The best prevention is naturally to entirely avoid airborne pollution, e.g. by changing the working<br />

process or by changing to other products that do not pollute. A good form of prevention can also be<br />

achieved by eliminating pollution by means of mechanical point extraction. In certain cases it is not possible<br />

to eliminate the pollution in a sufficiently effective way. In these cases, damage to health must be<br />

prevented by the use of suitable personal protection.<br />

Sector specific guidance, The Danish Maritime Occupational Health Service:<br />

Point extraction - Why publish sector specific guidance on point extraction?<br />

3

When should point extraction and room<br />

ventilation be established?<br />

Mechanical forms of point extraction should be designed<br />

to efficiently reduce airborne pollution. It is<br />

not sufficient to reduce airborne pollution to a possible<br />

limit value, if the pollution is actually unnecessary<br />

pollution. Forms of extraction should<br />

be, as far as possible, established in direct connection<br />

to the polluting working process.<br />

Even though extraction is effective, some forms of<br />

pollution on account of their character or of the<br />

character of the working process itself, can bypass<br />

the extraction point and in this way spread to the<br />

working area. This, for instance, can be the case<br />

with welding. In such circumstances, point extraction<br />

should be supplemented with ventilation at the<br />

workplace.<br />

Furthermore, in many situations small widespread<br />

sources of pollution can occur in areas where it is<br />

not reasonable or not possible to establish extraction<br />

at each individual part of the working process.<br />

In such cases, ventilation at the workplace should<br />

also be established.<br />

Air in and air out<br />

Ventilation plants should normally be set up with balanced amounts of air, i.e. that the amount of fresh<br />

air that is introduced corresponds to the amount of air extracted. On the other hand, in workrooms<br />

where it is undesirable to allow airborne pollution from surrounding areas, overpressure should be<br />

maintained, that is to say that more air is blown into the room than is sucked out.<br />

The additional air should ensure an effective replacement of the air that is extracted. The air that is let<br />

in should be fresh and should have a suitable temperature. It would be ideal if the replacement air did<br />

not result in draughts in places where crewmembers are present (the populated zone). By fresh air is<br />

meant here that this should be the best possible exterior air from the surrounding area. The air is taken<br />

into the area in such a way that there is no danger of a short circuit. A short circuit means that the inlet<br />

air (replaced air) would be polluted with air from other sources, e.g. from the funnel.<br />

Explanation of terms<br />

This guideline uses a number of terms, which are also used in the legislation:<br />

• Work room: Any area of the ship where work is carried out, such as on the bridge, engine room, galleys,<br />

control rooms, workshops, paint shops, offices or similar areas.<br />

• Fixed workplace: The place in a work room or other area where work is regularly carried out, such<br />

as at work tables, machines, cleaning basins, pressure test stands, cooking areas and places where<br />

paint is mixed and the relevant working tools are cleaned etc.<br />

• Separate mechanical suction: Mechanical suction systems that are not connected to other ventilation<br />

systems.<br />

• Mechanical point extraction: Extraction that removes airborne particles, vapours and gases,<br />

aerosols and similar forms of pollution as close to the source as possible.<br />

• Unnecessary effects: Effects, which can be considerably reduced in extent and against which it appears<br />

reasonable to initiate preventative measures.<br />

• Open deck: A deck that is entirely open above and on at least two of its sides.<br />

4<br />

Sector specific guidance The Danish Maritime Occupational Health Service:<br />

Point extraction - When should point extraction and room ventilation be established?

Figure 1<br />

Point extraction should provide the air with suitable velocity so that pollution can be trapped and<br />

conducted away from persons (induction speed)<br />

Requirements as to mechanical extraction<br />

• If a working process at a fixed workplace generates<br />

dust, vapours, gases, aerosols or similar,<br />

which are unnecessary, harmful to health,<br />

explosive or irritating in some way, then fixed<br />

mechanical point extraction must be established.<br />

The room should have a supply of fresh<br />

air from an open deck (replacement air).<br />

• Consequently, point extraction should be established<br />

at welding sites, pressure testing<br />

stands, cleaning basins used for the washing<br />

of engine parts, cooking areas in galleys,<br />

large-scale dish washers and similar fixed<br />

workplaces where substances and materials<br />

are handled and the tools used in these<br />

processes are cleaned etc.<br />

• Point extraction should have a suitable induction<br />

speed (away from the person, see figure<br />

1), which is dependent on the type of pollution<br />

in question. The following examples can be<br />

mentioned: Welding 0.5-1.0 metres per second,<br />

cleaning basins (heated and unheated)<br />

0.2-0.5 metres per second, mixing/-cleaning<br />

areas in the paint shop 0.2-0.5 metres per<br />

second.<br />

• At workplaces that cannot be considered<br />

fixed places and where the same effects as<br />

stated under the first point can occur, portable<br />

suction equipment and/or suitable personal<br />

protection should be used.<br />

• The extracted air must be conducted to a free<br />

deck and must not be led back into the work<br />

room or any other rooms on the ship via the<br />

ventilation systems (re-circulation)<br />

• All extraction systems positioned at fixed<br />

workplaces should be equipped with some<br />

form of operational indication that can warn<br />

of insufficient functional ability.<br />

Sector specific guidance The Danish Maritime Occupational Health Service:<br />

Point extraction - When should point extraction and room ventilation be established?<br />

5

How to make point extraction<br />

doors, from the inlet of replacement air etc. It is still<br />

necessary, however, to consider crosscurrents of air<br />

when positioning the tornado.<br />

From a tornado hood, which is 1 meter wide, about<br />

1,000 cubic metres per hour must be extracted in<br />

order to create an induction speed of about 0.25<br />

metres per second.<br />

Extraction duct on a mobile swing arm<br />

Figure 2<br />

An extraction duct (extraction head) can eliminate<br />

pollution in the immediate proximity of the opening<br />

of the duct. This means that it should be relatively<br />

precisely positioned in relation to the source of the<br />

pollution. The question of whether or not the process<br />

generates heat should also be considered.<br />

Figure 3<br />

Tornado<br />

The Tornado system consists of a specially<br />

constructed hood. By means of the positioning of<br />

the extraction and assisted by an air control a horizontal<br />

spiral movement, which is extremely stable, is<br />

created. When the tornado hood is correctly dimensioned,<br />

completely covers the worktable and is<br />

switched on, the necessary air velocity and direction<br />

will be achieved. This applies whatever the<br />

crewmember is engaged in doing, whether the process<br />

generates heat or not, and regardless of at<br />

which part of the table the crewmember carries out<br />

the working process.<br />

The amount of air that can be extracted through<br />

the extraction duct depends on the size of the duct<br />

and the distance to the source of the pollution. In<br />

order to be able to eliminate pollution from a welding<br />

operation at a distance of 30-40 cm or at a mixing<br />

table, the pipe connection to the extraction<br />

duct should be about 160 mm and the volume of<br />

extraction should be about 1,000 cubic metres per<br />

hour. If the extraction duct can be kept at about 10<br />

cm from a welding operation, it would be enough<br />

with a 50 mm pipe, a small extraction duct and a<br />

volume of air amounting to 200 – 400 cubic metres<br />

per hour.<br />

Rear edge extraction (slit extraction)<br />

At a fixed worktable, pollution can be eliminated<br />

with the help of an extraction slit positioned on the<br />

rear edge of the table. Such a slit extractor should<br />

be precisely dimensioned if it is to have the desired<br />

effect. The catch velocity is highest directly over the<br />

table and is rapidly reduced with increased height.<br />

As the tornado consists of a hood with a rear plate<br />

and some side plates, a certain degree of protection<br />

against cross currents is provided, e.g. from open<br />

6<br />

Sector specific guidance The Danish Maritime Occupational Health Service:<br />

Point extraction - How to make point extraction

This method can be quite effective in eliminating<br />

"cold" pollution such as vapours from cold cleaning<br />

basins. The method cannot be used, however,<br />

if heat is generated through the process. Neither is<br />

the method suitable if the source of pollution occurs<br />

slightly above the surface of the table, as for<br />

example, when stirring paint in the large paint containers.<br />

The method is extremely sensitive to<br />

crosscurrents of air.<br />

second should be extracted, corresponding to<br />

about 125 cubic metres per hour per kW. As in the<br />

case of other types of point extraction, extractor<br />

hoods are extremely sensitive to cross currents of<br />

air.<br />

The necessary volume of extraction air depends on<br />

the length of the slit and on the distance between<br />

the work process and the slit, but in general, it<br />

would be between 1,000 and 2,000 cubic metres/per<br />

hour.<br />

Extractor hoods<br />

When heat is generated in connection with pollution,<br />

e.g. at a cooker in the galley, an extractor<br />

hood may be used. The extractor hood should be<br />

positioned so that the distance between the upper<br />

side of the cooker and the lower side of the hood is<br />

as short as possible and the size of the hood<br />

should exceed the size of the cooker by about 25<br />

cm on all free sides.<br />

Figure 4<br />

The necessary extraction volume depends on the<br />

transmission to e.g. the stove. For each kilowatt<br />

supplied to the normal stove, about 35 litres per<br />

Figure 5<br />

Important things to remember:<br />

It is important to be aware of the exact type of pollution that should be eliminated with point extraction.<br />

If it is hot welding fumes, the point extraction must be positioned at a point above the welding site. On<br />

the other hand, if the pollution stems from vapours released by stirring or mixing paint, there is no heat<br />

generated by this process, so it is useless to attempt to eliminate the pollution at a higher point by<br />

means of an extractor hood.<br />

In many engine rooms and workshops, strong currents of inlet air can occur (turbulence). This means<br />

that pollution, regardless of whether it is hot or cold airborne pollution can be spread around the area.<br />

In such areas it is impossible to get point extraction to work efficiently. The still air movement is necessary<br />

in order that point extraction can work effectively and this can be assessed in connection with a<br />

workplace evaluation. A protective screen can solve this.<br />

Sector specific guidance The Danish Maritime Occupational Health Service:<br />

Point extraction - How to make point extraction<br />

7

How to make point extraction<br />

Encapsulation<br />

The most efficient form of point extraction is to encapsulate<br />

the process and make sure that there is<br />

negative pressure within the encapsulation. The<br />

better the encapsulation, the smaller the volume of<br />

air it is necessary to extract.<br />

Re-circulation<br />

In general, all air that is extracted from a polluting<br />

process should be led to the outside and no shortcircuiting<br />

may occur, or the polluted air will be<br />

drawn in again via openings, blowers etc. In many<br />

cases, this means that the outlet air from the engine<br />

room must be conducted up through the casing.<br />

In a few individual cases (e.g. when pressure testing<br />

fuel valves), it is permitted to purify the air and<br />

re-conduct it back into the room (re-circulation). In<br />

other special cases, it may also be permitted to<br />

conduct the polluted air a short distance up inside<br />

the casing, though this requires an exemption from<br />

the Danish Maritime Authority.<br />

Figure 6<br />

Suggestions for point extraction in a paint shop<br />

Efficient point extraction should be established at<br />

fixed work places in the paint shop. This can be<br />

achieved by means of the following:<br />

• Tornado<br />

• Extraction duct<br />

• Rear edge extraction<br />

The tornado principle is the most efficient. When the<br />

tornado hood is positioned over the worktable and<br />

switched on, it will create the necessary air velocity<br />

and air current direction regardless of whether the<br />

operation concerns stirring, mixing or pouring from<br />

one container to another. By employing a worktable<br />

that has been adjusted to different heights, both extraction<br />

and ergonomics (working positions) will be<br />

improved.<br />

An extraction duct can create the necessary induction<br />

speed over a radius of 30-40 cm. This means<br />

that the duct must be placed close to the paint container<br />

and must be moved when pouring from one<br />

paint container to another. As this is not easy for one<br />

person to do in practice, the task is often neglected<br />

and consequently the method is not very effective.<br />

8<br />

Sector specific guidance The Danish Maritime Occupational Health Service:<br />

Point extraction - How to make point extraction

Rear edge extraction can be used for the purpose,<br />

but in many cases it is not sufficient, since in most<br />

cases pollution is not generated at table height but<br />

at a somewhat higher point over the table.<br />

The volumes of extracted air with all three methods<br />

will normally be over about 1,000 cubic metres<br />

per hour, which in most cases will meet the<br />

Danish Maritime Authority’s requirement that the air<br />

in a paint shop should be replaced at least six times<br />

every hour.<br />

As a risk of explosion is present, the electrical<br />

equipment that is used in paint shops should be explosion-proof.<br />

At the same time, it must be possible<br />

to close down the ventilation system from outside<br />

the room. The release button should be placed in<br />

connection with the release for the required firefighting<br />

equipment.<br />

Figur 7<br />

Requirements regarding paint shops and storerooms<br />

A paint shop is an area where paint, organic solvents and non-inflammable liquids are handled and<br />

where used containers are stored. With regard to floor space, the room should be large enough for one<br />

person. In any concrete evaluation of the area, however, the amount of paint used, the types of paint<br />

and whether or not minor repairs are also carried out in the room, will be taken into account. The legislative<br />

requirements include:<br />

• The room must have access from a open deck or a ro/ro deck and should have the required ventilation<br />

as well as being designed for the purpose, including having a free flooring area of at least 4<br />

square metres. (For new ships built after 1st January 2001)<br />

• The workroom for the handling of paint etc. should be equipped with some form of mechanical point<br />

extraction at the fixed workplace. The frequency of air replacement (change of air) in the room<br />

should be at least 6 times per hour.<br />

• Point extraction should have a suitable induction speed of between 0.2-0.5 metres per second at<br />

mixing and cleaning areas.<br />

• Storerooms that are solely used for the storage of paint, organic solvents, inflammable liquids etc.<br />

must be equipped with a form of room ventilation that replaces the air at least 6 times per hour.<br />

Sector specific guidance The Danish Maritime Occupational Health Service:<br />

Point extraction - How to make point extraction<br />

9

Suggestions for extraction in engine rooms<br />

and workshops<br />

Welding in fixed workplaces<br />

The principle requirement to extraction from a welding<br />

operation is that it should create an effective<br />

air movement away from the crewmember towards<br />

the extraction. During the working process, extremely<br />

high temperatures are generated. This<br />

means that the extraction should take place on the<br />

opposite side of the item being welded in relation<br />

to the crewmember and slightly raised over the<br />

welding station. These conditions can be met both<br />

by a tornado or an extraction duct.<br />

Extractor duct<br />

The extractor duct can be mounted on a swing arm<br />

or can be fixed by means of magnets. Depending<br />

on the size, the duct can eliminate pollution from a<br />

welding operation at a distance of between 10 cm<br />

(small duct) and 30-40 cm (large duct), if it is correctly<br />

mounted. In most situations, this will solve<br />

the problem. If the welding operation is of longer<br />

duration, this should be taken into account by<br />

moving the extractor duct along as the welding<br />

operation progresses.<br />

The tornado principle was, in fact, developed for<br />

precisely this purpose. With this principle, the<br />

crewmember does not need to move the point extraction<br />

while he is engaged in welding – as long as<br />

the welding takes place on the side of the worktable<br />

covered by the tornado hood.<br />

Welding at non-fixed workplaces<br />

In the case of welding operations around the ship<br />

(in closed areas or where the air is still), the requirements<br />

as to extraction are the same as mentioned<br />

above.<br />

Figure 8<br />

10<br />

Sector specific guidance The Danish Maritime Occupational Health Service:<br />

Point extraction - Suggestions for extraction in engine rooms and workshops

Figure 9<br />

Mobile extractor<br />

The only possibility of eliminating pollution is to use<br />

a mobile ventilator with flexible hoses and a suitable<br />

extractor duct. It is possible to find ventilators<br />

that can extract a small amount of air at high pressure<br />

and here the small extractor ducts can be<br />

utilised.<br />

There are also other ventilators that can handle<br />

larger amounts of air at a lower pressure, which<br />

means that larger extractor ducts can be used. The<br />

advantage of these larger ducts is that they can<br />

trap pollution at greater distances.<br />

Sector specific guidance The Danish Maritime Occupational Health Service:<br />

Point extraction - Suggestions for extraction in engine rooms and workshops<br />

11

Suggestions for extraction in engine rooms and<br />

workshops<br />

Figure 10<br />

Grinding<br />

The use of grinders causes a great deal of pollution<br />

in the form of cutting and grinding dust as well as<br />

possible gases from the surface treatment operation.<br />

This type of pollution ought to be removed by<br />

means of point extraction.<br />

It is possible to mount various extractor ducts<br />

directly onto the grinder, but they only have a positive<br />

effect if the surfaces being ground are horizontal.<br />

They have practically no effect when welding<br />

edges or when materials are being cut and, in<br />

fact, only get in the way.<br />

During welding, it is necessary to use the extractor<br />

ducts or the tornado principle at the fixed workplaces.<br />

On the other hand, it must be admitted that<br />

neither of these methods can totally eliminate the<br />

pollution. It is important that a breathing apparatus<br />

is always used while carrying out these operations.<br />

should have a filter that prevents the grinding dust<br />

being led into the ducts, as there is a risk that the<br />

ducts and the ventilator could become blocked.<br />

Encapsulation of the grindstone<br />

The grindstone/grinding machine should be encapsulated<br />

as much as possible in order that the<br />

extraction is effective. Many of the machines on<br />

the market are encapsulated and equipped with a<br />

suction pipe. In many cases the encapsulation can<br />

easily be improved.<br />

The necessary amount of air from a disc grinder or<br />

a grinding machine would be about 400 to 1,000<br />

cubic metres per hour, depending on the width and<br />

the encapsulation.<br />

In the engine room or in the workshop, there is often<br />

a disc grinder or a grinding machine. These<br />

should be equipped with point extraction that<br />

12<br />

Sector specific guidance The Danish Maritime Occupational Health Service:<br />

Point extraction - Suggestions for extraction in engine rooms and workshops

Testing of fuel valves<br />

When fuel valves are tested, very small amounts of<br />

extremely fine spray oil fumes can occur. These<br />

must be eliminated before they reach the<br />

crewmember’s breathing zone.<br />

Since the process does not need to take place in<br />

an open area, it should be enclosed and in fact this<br />

is the only correct method of dealing with the<br />

problem.<br />

To implement encapsulation that is more or less<br />

air-free, it is necessary only to remove a very small<br />

quantity of air. Mostly this will be under 100 cubic<br />

metres per hour. This air must be led out into the<br />

open air.<br />

Other polluting working processes<br />

There are other working processes that ought to be<br />

evaluated for the possibility of pollution. One example<br />

is the changing of fuel oil filters where, when<br />

the filter is opened, certain amounts of oil aerosols<br />

can rise up into the crewmember’s breathing zone.<br />

The same thing can happen when, for example,<br />

rotor caps and hot engines are inspected.<br />

One possible solution is to use a mobile ventilator<br />

(the same type as that used when welding) and<br />

lead the air from this to a fixed suction tube. It is not<br />

permitted to re-circulate extracted air, even though<br />

it may have been cleaned through a filter.<br />

One possibility is to use an ejector pump and an oil<br />

filter (the same type that is used in a breathing<br />

apparatus) and subsequently lead the very small<br />

amount of air back into the room. This kind of<br />

equipment is produced by several manufacturers<br />

and in principle is approved by the Danish Maritime<br />

Authority.<br />

Room extraction in general<br />

Since point extraction is not capable of eliminating all the pollution generated by a process, it is always<br />

preferable that there is general extraction in all workshops, testing stations etc. The amount of air that<br />

should be extracted cannot be fixed on a general basis. This will depend on factors such as the process<br />

and on the extent that crewmembers use point extraction.<br />

Sector specific guidance The Danish Maritime Occupational Health Service:<br />

Point extraction - Suggestions for extraction in engine rooms and workshops<br />

13

Suggestions for suction over cleaning<br />

processes<br />

On a ship, there will always be a number of engine<br />

parts etc. that regularly have to be cleaned and this<br />

can be done in several ways.<br />

Washing machines and ultrasound basins<br />

The most appropriate method of cleaning engine<br />

parts etc. is to use closed washing machines, in<br />

which the type of extraction that empties the machine<br />

of hot steam before it is opened, has been<br />

established.<br />

One possibility that has recently become more<br />

widespread is the use of ultrasonic basins. The<br />

cleaning water in these is not so harmful to health<br />

as the oil products that were previously used, and<br />

if the temperature in the basin is kept down to 35-<br />

40 degrees Centigrade, problems should not arise.<br />

The use of compressed air in connection with<br />

cleaning work ought to be reduced to a minimum,<br />

since a normal point extraction is seldom strong<br />

enough to catch the aerosols generated by this.<br />

Ordinary cleaning basins<br />

Point extraction should be established in connection<br />

with the "ordinary" cleaning basins, from<br />

where vapours are released. Since the cleaning liquid<br />

is not heated, the problem can be solved in<br />

various ways:<br />

• Tornado system<br />

• Rear edge extraction (slit extraction)<br />

• Suction funnel<br />

On the other hand, if the temperature is increased<br />

to e.g. 80 degrees Centigrade, which often happens,<br />

the hot steam from the basins could result in<br />

considerable damage to the mucus membranes<br />

and this means that point extraction should be established.<br />

As it is the heat from the heated basins that is the<br />

problem, the only solution is to eliminate the vapours<br />

by means of an extractor fan, or even better,<br />

a tornado hood.<br />

The tornado hood can be established with a relatively<br />

broad slit so that there is still space for a<br />

crane hook to get in over the basin.<br />

An ordinary extractor fan can also be used, but this<br />

is more sensitive to crosscurrents of air and it<br />

should therefore be equipped with plates down to<br />

the basin, preferably on three of the sides.<br />

Figure 11<br />

14<br />

Sector specific guidance The Danish Maritime Occupational Health Service:<br />

Point extraction - Suggestions for suction over cleaning processes

The tornado principle is the most effective. When<br />

the tornado hood is positioned over the basin and<br />

is switched on, the necessary air velocity and<br />

direction will be established. Another advantage<br />

is that it can be equipped with a slit in the front<br />

and top plates, so that a crane hook can get in<br />

over the basin.<br />

A rear edge extractor can also be used, but this is<br />

more sensitive to any cross currents. At the same<br />

time, it is likely that, if the distance from the rear<br />

wall to the front of the basin is relatively large,<br />

then greater amounts of air will have to be used<br />

than with a tornado.<br />

In the case of very small cleaning basins, it is possible<br />

to use an extractor duct placed either on a<br />

swing arm or with magnets.<br />

Figure 12<br />

Suggestion for suction in the galley<br />

In the galley, it is necessary to establish point extraction in the form of an extractor fan over cookers,<br />

deep fryers, ovens etc. See figure 5 and the example on page 20.<br />

The amount of air used should be adapted to the actual consumption. It is not unusual that about 1,000<br />

cubic metres of air per hour is removed from a small galley. In a small room it can be a problem to supply<br />

replacement air without exposing crewmembers to draughts and without the extraction effect being<br />

ruined by cross currents of air.<br />

Sector specific guidance The Danish Maritime Occupational Health Service:<br />

Point extraction - Suggestions for suction over cleaning processes<br />

15

Checking correct functioning and giving<br />

instructions<br />

All extraction systems should be equipped with<br />

operational indications for malfunction. This means<br />

that crewmembers should be able to see whether<br />

suction is in progress and that the system functions<br />

sufficiently well to eliminate the type of pollution<br />

in question.<br />

The crewmembers should be given instructions as<br />

to how these operational indicators work, as well<br />

as instructions on what to do if the extraction is<br />

not sufficient.<br />

Smoke pipettes/ smoke tubes are recommended<br />

for the testing of the efficiency of the suction. The<br />

"cold" smoke is blown out at a typical place of<br />

pollution and the movement of the smoke can be<br />

followed.<br />

Maintenance<br />

Figure 13<br />

The easiest and cheapest method of establishing<br />

an operational indication is to use a U-pipe manometer,<br />

which shows the pressure in the duct<br />

system.<br />

In cases where blocking can occur at the extraction<br />

point e.g. extractor fans, this solution is not<br />

sufficient. Here it is necessary to mount a gauge in<br />

the duct system with a connected U-manometer.<br />

Any form of mechanical point extraction should be<br />

regularly cleaned and maintained. It is recommended<br />

that a drawing of the extractor system<br />

along with data on air volume and inspection routines<br />

should be kept on file.<br />

A supplier should provide detailed and complete<br />

directions for use of a ventilation plant. These<br />

should include the necessary operational and<br />

maintenance instructions as well as a set of main<br />

drawings.<br />

When a large-scale plant is ordered, it should be a<br />

matter of course that the plant is delivered fully<br />

operational with test results that prove that the<br />

plant functions efficiently. This should be checked<br />

before use.<br />

Figure 14<br />

During internal cleaning or repairs to ducts or<br />

similar where harmful substances are released,<br />

each person concerned should use a breathing<br />

apparatus.<br />

16<br />

Sector specific guidance The Danish Maritime Occupational Health Service:<br />

Point extraction - Checking correct functioning and giving instructions

Read more about it<br />

• Legal notice no. 554 of 21st June, with subsequent amendments.<br />

• Directive A from the Danish Maritime Authority. Technical regulation on the working environment on<br />

ships.<br />

• Directive B from the Danish Maritime Authority. Technical regulation on the construction and equipping<br />

of vessels etc. Chapter ll-4 The design and equipping of workrooms and workplaces.<br />

• Directive B from the Danish Maritime Authority. Technical regulation on the construction and equipping<br />

of vessels etc. Chapter ll-1, Construction – building, interior planning and stability, machinery and<br />

electrical equipment, also Chapter ll-2, Construction – fire prevention, discovery and extinguishing of<br />

fires.<br />

• Technical regulation no. 6 of 3rd July 1997 on mechanical extraction from closed areas used for the<br />

handling of paint etc. and from workplaces on ships.<br />

Home pages:<br />

• The Danish Maritime Authority: www.sofartsstyrelsen.dk<br />

• The Danish Maritime Occupational Health Service: www.seahealth.dk<br />

Sector specific guidance The Danish Maritime Occupational Health Service:<br />

Point extraction - Read more about it<br />

17

Examples<br />

Example 1 – Washing machine<br />

This washing machine is equipped with an extractor at the<br />

top. It has been installed in an engine workshop on a Danish<br />

passenger vessel built in 1978. The item to be washed, is<br />

placed in the basket, which is then pushed into the machine.<br />

Large, heavy engine parts can be placed in the washing machine<br />

by means of a running conveyor, so it is not necessary<br />

to lift them.<br />

Example 3 – Encapsulated washing basin<br />

An extractor has also been fitted into the top of this washing<br />

basin. The basin is used for cleaning smaller engine parts in<br />

the engine workshop. The plexi-glass plate closes downwards,<br />

so that steam does not escape into the area. This solution<br />

is also particularly well suited for use in areas with<br />

strong crosscurrents.<br />

18<br />

Example 2 – Encapsulated washing basin<br />

An extractor has been fitted into the top of the encapsulation<br />

on a washing basin. The washing basin, which has been<br />

placed in an engine workshop, is used to clean smaller machine<br />

parts. When something is washed in the basin, the<br />

plexi-glass plate comes down and closes over the basin so<br />

that steam does not escape into the area. This solution is<br />

particularly suitable for areas with strong crosscurrents.<br />

Guidelines for the shipping industry The Danish Maritime Occupational Health Service:<br />

Point extraction - Examples<br />

Example 4 – Pressure testing stand<br />

An extractor has been fitted into the right side of the pressuretesting<br />

stand, which is used to test fuel valves and is positioned<br />

in the engine workshop. The valve is fitted into the top<br />

of the stand and during the testing it is possible to see the<br />

process through the plexi-glass.

Example 5 – Transportable local suction<br />

Transportable local suction can be used in connection With<br />

tasks to be carried out at random places around the ship. It is<br />

particularly suitable for welding jobs outside the welding<br />

workshop or where there is no permanent local suction. In addition,<br />

it can be used to ventilate tanks before entry.<br />

Example 7 – Tornado<br />

This tornado has been installed in a paint shop. One half of the<br />

mixing table can be adjusted in height so that the upper edge<br />

of the paint container is always at the same level, regardless<br />

of whether the container holds 20 litres or 5 litres of paint. The<br />

control air is taken direct from the area, while extracted air is<br />

conducted out into the open air. The tornado screen is<br />

equipped with a u-pipe manometer, so that the operator can<br />

check the efficiency of the extraction process.<br />

Example 6 – Swing-arm extractor with suction duct<br />

This swing-arm with a suction duct has been installed in a<br />

welding workshop. When welding is in progress, the suction<br />

can be adjusted to the best possible position to catch the<br />

fumes containing welding dust.<br />

Example 8 – Grinding machine<br />

This grinder is placed in an engine workshop. A suction duct<br />

has been fitted to the back of the grinder so that part of the<br />

pollution is led away from the operator. It is also a good idea<br />

to utilise the same principle on other similar machines. The<br />

best effect of this suction process is achieved by encapsulating<br />

the grinder/machine as much as possible.<br />

Guidelines for the shipping industry The Danish Maritime Occupational Health Service:<br />

Point extraction - Examples<br />

19

Example 9 – Local suction in the galley<br />

An extractor hood has been fitted over the cooker in the galley.<br />

The extractor hood is about 20 cm larger than the cooker<br />

on all sides, so that pollution is effectively eliminated.<br />

Example 10 – Rear-edge extractor<br />

This washing basins is positioned in the engine room. In order<br />

to have space to submerge large engine parts in the basin, a<br />

rear-edge extractor has been fitted onto the basin. This makes<br />

sure that any pollution is absorbed away from the person<br />

working at the basin.<br />

20<br />

Guidelines for the shipping industry The Danish Maritime Occupational Health Service:<br />

Point extraction - Examples