Conveying with ease For more efficient conveying of heavy-duty loads

Conveying with ease For more efficient conveying of heavy-duty loads

Conveying with ease For more efficient conveying of heavy-duty loads

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Conveying</strong> <strong>with</strong> <strong>ease</strong><br />

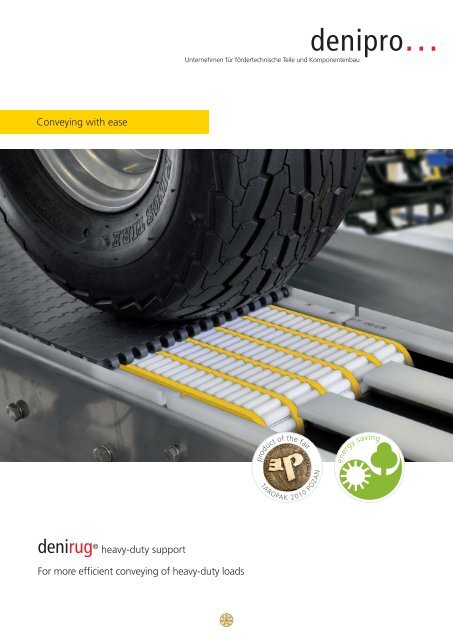

denirug ® <strong>heavy</strong>-<strong>duty</strong> support<br />

<strong>For</strong> <strong>more</strong> effi cient <strong>conveying</strong> <strong>of</strong> <strong>heavy</strong>-<strong>duty</strong> <strong>loads</strong><br />

product <strong>of</strong> the fair<br />

TAROPAK 2010 POZAN

denirug ® <strong>heavy</strong>-<strong>duty</strong> supports<br />

Energy consumption and wear and tear in modular belt<br />

and standard belt conveyors incr<strong>ease</strong> substantially<br />

when <strong>loads</strong> are heavier. denirug ® <strong>heavy</strong>-<strong>duty</strong> supports<br />

replace wasteful sliding friction between belt and<br />

support <strong>with</strong> rolling friction. As a result, they cut energy<br />

consumption drastically, incr<strong>ease</strong> reliability and tap into<br />

new areas for <strong>heavy</strong>-<strong>duty</strong> <strong>conveying</strong>.<br />

The benefi ts <strong>of</strong> denirug ® <strong>heavy</strong>-<strong>duty</strong> supports:<br />

– much lower energy costs<br />

– less wear and tear<br />

– <strong>more</strong> reliable operation and no maintenance<br />

– greater <strong>conveying</strong> speed<br />

– fewer transfer points and drive stations<br />

– very low angles <strong>of</strong> inclination in gravity conveyors<br />

– virtually any sizes <strong>of</strong> conveyor belt and low conveyor<br />

heights at the same time<br />

<strong>with</strong>out denirug ®<br />

µ = 0.2 – 0.3<br />

<strong>with</strong> denirug ®<br />

µ = 0.02 – 0.03<br />

An experimental setup at TU Chemnitz produced<br />

clear results: Using a denirug@ <strong>heavy</strong>-<strong>duty</strong> support<br />

reduces the friction coeffi cient µ by around 90 %.<br />

F R<br />

F R<br />

The denirug ® principle<br />

Similarly to linear guidance systems, denirug ®<br />

<strong>heavy</strong>-<strong>duty</strong> supports operate <strong>with</strong> axle-free continuous<br />

rollers. Because the rollers are very strong and the pitch<br />

between them small, the extremely smooth-running<br />

system can <strong>with</strong>stand very <strong>heavy</strong> <strong>loads</strong>.<br />

60<br />

[Nm]<br />

Drive torque<br />

0<br />

Drive torques in <strong>heavy</strong>-<strong>duty</strong> range<br />

Conventional technology<br />

(Sliding strips, laminar<br />

removal devices)<br />

denirug ® <strong>heavy</strong>-<strong>duty</strong> support<br />

0 Load<br />

[N] 6000

The basic denirug ® elements<br />

Basic denirug ® elements are roller bearings ready to fi t<br />

that can be combined to make rolling supports in virtually<br />

any length and width. Integration into existing conveyors<br />

is easy.<br />

The basic denirug ® elements:<br />

– are simply placed behind or next to one another on an<br />

even surface and clamped, screwed or glued or affi xed<br />

in other ways in the position required;<br />

– Replace slider beds and sliding strips as supports for<br />

modular and standard belt conveyors;<br />

– Directly support <strong>heavy</strong>-<strong>duty</strong> <strong>loads</strong>.<br />

An example <strong>of</strong> a confi guration:<br />

The denirug ® modules<br />

denirug ® modules are ready-for-use modular belt sections<br />

<strong>with</strong> integrated basic denirug ® elements. Users can<br />

combine them very easily to produce smooth-running<br />

sections in almost any length and width.<br />

The denirug ® modules:<br />

– are affi xed behind or next to one another <strong>with</strong> special<br />

adhesive tape or screws;<br />

– can be combined to make closed surfaces which can<br />

be walked on;<br />

– <strong>of</strong>fer <strong>heavy</strong>-<strong>duty</strong> <strong>loads</strong> full support;<br />

– are <strong>of</strong>ten an alternative to live rollers;<br />

– can reliably absorb high levels <strong>of</strong> transverse force.<br />

An example <strong>of</strong> a confi guration:

Denipro AG, Weinfelden/TG, Switzerland<br />

WRH, Ferag AG, WRH Marketing AG, Hinwil/ZH, Switzerland<br />

Company pr<strong>of</strong>i le<br />

Denipro AG whose headquarters are in Weinfelden (Switzerland),<br />

produces well-engineered <strong>conveying</strong> technology which<br />

sets the standard in integrated production logistics. The<br />

manufacturing company specialises in the mass production<br />

<strong>of</strong> chains and grippers and their assembly. Denipro AG also<br />

uses effi cient processes, matched perfectly to the customer’s<br />

requirement pr<strong>of</strong>i les, to manufacture components and subassemblies<br />

for Ferag AG in Hinwil, Switzerland.<br />

Using this know-how as a basis, Denipro AG develops and<br />

constructs mass production components and modules for<br />

the <strong>conveying</strong> technology industry. The <strong>conveying</strong> technology<br />

used in new applications for rolling principles means that<br />

friction resistances are being eliminated in many instances.<br />

This opens up other sectors or industry outside the graphics<br />

sector for the company.<br />

WRH Walter Reist Holding AG is the owner <strong>of</strong> Denipro AG.<br />

The company also owns Ferag AG and WRH Marketing AG<br />

in Hinwil, Switzerland.<br />

Denipro AG<br />

Tannenwiesenstrasse 5<br />

CH-8570 Weinfelden<br />

Phone +41 71 626 47 47<br />

Fax +41 71 626 48 48<br />

info@denipro.com<br />

www.denipro.com<br />

DG_leafl et_EN_0010_09.10