Conveying with ease For more efficient modular belt operation ...

Conveying with ease For more efficient modular belt operation ...

Conveying with ease For more efficient modular belt operation ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

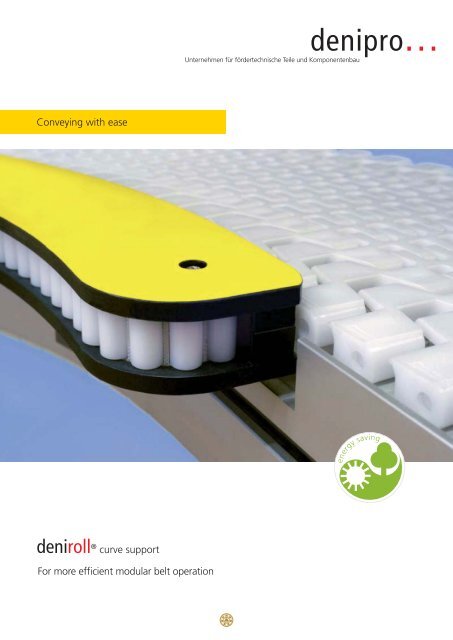

<strong>Conveying</strong> <strong>with</strong> <strong>ease</strong><br />

deniroll ® curve support<br />

<strong>For</strong> <strong>more</strong> effi cient <strong>modular</strong> <strong>belt</strong> <strong>operation</strong>

deniroll ®<br />

Similarly to linear guidance systems, deniroll ® curve<br />

supports have guided rollers and therefore replace<br />

wasteful sliding friction by rolling friction. Therefore,<br />

in comparison <strong>with</strong> conventional guidance systems,<br />

deniroll ® offers a range of advantages in terms of<br />

design and <strong>operation</strong>. deniroll ® curve supports are<br />

available in a number of different designs for all<br />

<strong>modular</strong> <strong>belt</strong> systems and all curve angles and radii.<br />

The principle:<br />

the <strong>modular</strong> <strong>belt</strong> is guided on a roller <strong>belt</strong><br />

on the curve’s inner radius.<br />

Results of a Chemnitz University of Technology comparison<br />

were clear: using deniroll ® curve supports (spiral conveyor,<br />

line approx. 20 m, 6 x 90˚ curves)<br />

– cuts power consumption by 60 %<br />

– only requires 1 of 3 drive units<br />

– makes several transfer points redundant.<br />

More effi cient <strong>modular</strong> <strong>belt</strong> <strong>operation</strong><br />

due to<br />

– reduced energy costs<br />

– lower load on chains<br />

– less wear and tear<br />

– fewer transfer points<br />

– higher conveying speed<br />

Modular <strong>belt</strong> load<br />

Energy requirement<br />

100%<br />

conventional<br />

technology deniroll ®<br />

Modular <strong>belt</strong> load<br />

Conveyor length<br />

Up to 60% lower<br />

40%<br />

conventional<br />

technology<br />

deniroll ®<br />

Denipro AG<br />

Tannenwiesenstrasse 5<br />

CH-8570 Weinfelden<br />

Phone +41 71 626 47 47<br />

Fax +41 71 626 48 48<br />

info@denipro.com<br />

www.denipro.com