SPIDER® Avalanche - Geobrugg AG

SPIDER® Avalanche - Geobrugg AG

SPIDER® Avalanche - Geobrugg AG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Intervento di stabilizzazione della Valanga San Michele (VB) / documentazione tecnica / gennaio 2010<br />

<strong>Avalanche</strong> prevention installation at San<br />

Michele in Val Formazza.<br />

SPIDER ® <strong>Avalanche</strong>: safe and quick to install<br />

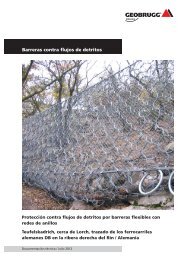

Fig.1: Flight-ready equipment at the<br />

loading site<br />

Fig.2: High-level supply using a<br />

transporter bar with three support<br />

uprights and the corresponding netting<br />

2<br />

Work on stabilizing the snow cover was carried out in the area of San Michele,<br />

upstream of the town, on the left-hand snow-line of the Formazza Valley<br />

(province of Verbania). The work carried out adds to a pre-existing installation,<br />

deemed inadequate by the local authority, as the equipment, installed<br />

in the 1990s, showed clear signs of wear.<br />

The planning choice was to add to the existing snow cover stabilization installation<br />

within the detachment area, using structures approved by the Davos<br />

Institute, internationally recognized as the main authority in the fi eld of snowrelated<br />

phenomena. This choice was guided by research into the safety of the<br />

installation, not only in the immediate future, but also in the medium and long<br />

term, given that the structures approved by the Davos Institute have been<br />

tested in the fi eld, and were designed to provide safety and durability.<br />

The system used was <strong>Geobrugg</strong>’s new “SPIDER ® <strong>Avalanche</strong>,” a development<br />

of the tried-and-tested <strong>Geobrugg</strong> avalanche protection system. The new system<br />

is characterized by the replacement of the traditional triangular rope<br />

panels with rectangular panels of netting consisting of spiral rope made up<br />

of pre-stressed steel wires galvanized with aluminum-zinc alloy (GEOBRUGG<br />

SUPERCOATING ® ). This allows for the creation of a netting retention area that<br />

has fewer gaps and is easier and quicker to install as well as helping to keep<br />

costs down during the production phase, thus meaning a lower price for the<br />

end user.<br />

The site for installing the barrier opened on September 5 and closed on October<br />

30 2009. The work was carried out in two separate phases: fi rst the<br />

laying-out and insertion of the anchors, then the installation of the superstructure.<br />

The two phases were separated by a period of inactivity on the site<br />

due to adverse weather and conditions on the site.<br />

During the phase preceding the laying-out, <strong>Geobrugg</strong>’s Technical Department<br />

worked with the laying company to optimize the laying-out and the number<br />

of supports. The materials for the superstructure arrived on site at the same<br />

time as the start of work, and were therefore available as soon as they were<br />

supplied to the high level by helicopter.<br />

Manufacture and identifi cation by means of data plates made it easier to di-<br />

stinguish the different types of anchor, facilitating their positioning by helicopter<br />

at the correct points on the site. The transporter bar provided for the<br />

helicopter transportation – developed as a result of <strong>Geobrugg</strong>’s experience in<br />

the high-level working sector – facilitated materials supply operations. Anchor<br />

insertion operations were completed within the timeframes established.