TECCO slope stabilization system - Geobrugg AG

TECCO slope stabilization system - Geobrugg AG

TECCO slope stabilization system - Geobrugg AG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

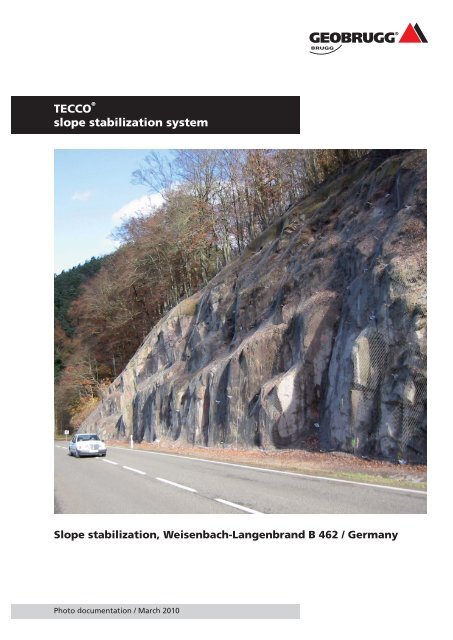

<strong>TECCO</strong> ®<br />

<strong>slope</strong> <strong>stabilization</strong> <strong>system</strong><br />

Slope <strong>stabilization</strong>, Weisenbach-Langenbrand B 462 / Germany<br />

Photo documentation / March 2010

Slope <strong>stabilization</strong> / Photo documentation / March 2010<br />

<strong>TECCO</strong> ®<br />

<strong>slope</strong> <strong>stabilization</strong><br />

Weisenbach-Langenbrand / Germany<br />

2<br />

Object: Slope 2.10, Weisenbach-Langenbrand in the<br />

Murgtal region, alongside the B 462 road<br />

Building promoter: Federal Republic of Germany, represented by the<br />

Karlsruhe Regional Council, Construction Offi ce<br />

Mitte (Central), Germany<br />

Geotechnical investigations,<br />

planning, construction<br />

supervision: Ingenieurgruppe Geotechnik GbR, Kirchzarten,<br />

Germany<br />

Contractor: Sachtleben Mining Services GmbH, Wolfach,<br />

Germany<br />

Implementation: October/November 2009<br />

Slope <strong>stabilization</strong>: <strong>TECCO</strong> ® -mesh covering in combination with nails<br />

Max. <strong>slope</strong> height: H = approx. 15 m<br />

Subsoil: Granite<br />

Area: 2‘000 m2 Slope gradient: α = 80 degrees<br />

Mesh: <strong>TECCO</strong> ® -<strong>system</strong> G65/3 mm<br />

Erosion control mat: TECMAT<br />

Spike plates: <strong>TECCO</strong> ® -<strong>system</strong> G65/3 mm<br />

Nails: GEWI D = 32 mm<br />

Nail length: L = 6 m / 3 m<br />

Nail grid: a = b = 3 m<br />

As part of the general geotechnical mapping of rock <strong>slope</strong>s along the B 462 in the<br />

Rastatt district, the <strong>slope</strong> at Weisenbach-Langenbrand was evaluated as being a<br />

high-risk area for rockfalls and avalanches. The rock is made of a fi ssured granite<br />

known as Forbach granite. The side-cut for the road formed a <strong>slope</strong> up to 15 m<br />

high and with an average inclination of around 80°. Protection was provided in the<br />

form of a light protruding rockfall protection net. The rockfall catchment area in<br />

relation to the road is less than 2 m. There was nothing to limit the rockfall catchment<br />

area. Fissures in the fault structure undercut the <strong>slope</strong> at an angle of around<br />

30°. Bodies of rock can thus come away from the <strong>slope</strong> and slide down the fault.<br />

In March 2007, a rockfall occurred in which a body of rock came loose from the<br />

upper section of the <strong>slope</strong>, broke through the fl imsy net and landed on the road.<br />

The <strong>TECCO</strong> ® <strong>slope</strong> <strong>stabilization</strong> <strong>system</strong> was recommended as a protective measure.<br />

The rock nails (GEWI 32 mm) are 6 m long in the fi eld and 3 m long at the edges. A<br />

nail grid of 3 x 3 m was proposed, with the nails being inserted in <strong>slope</strong> troughs<br />

where possible. This can lead to variations in the grid. In addition to the boundary<br />

ropes, vertical and horizontal lateral ropes were envisaged, which were also designed<br />

for insertion into <strong>slope</strong> troughs in order to obtain the maximum possible mesh<br />

tension. A one-meter-high rockfall interception apron was installed at the head of<br />

the <strong>slope</strong>. An erosion control mat was laid over the sediment layer at the top end<br />

of the <strong>slope</strong>. The old net had previously been removed and the <strong>slope</strong> cleared.

Incised <strong>slope</strong> of heavily fi ssured Forbach<br />

granite; high risk of rockfalls and<br />

avalanches<br />

Investigation of the <strong>slope</strong> by geologists/<br />

the road construction authorities<br />

Testing the nail tension<br />

3

Slope <strong>stabilization</strong> / Photo documentation / March 2010<br />

Cost-effective insertion of the nails<br />

from a drilling platform with a drilling<br />

mount fi xed to the side<br />

4

Installation of <strong>TECCO</strong> ® -mesh, ropes and<br />

spike plates<br />

Elevated support at the top of the <strong>slope</strong><br />

edge with rear anchoring of the GEWI /<br />

eyes<br />

Erosion control mat in the sediment<br />

zone above the <strong>slope</strong> edge<br />

5

Slope <strong>stabilization</strong> / Photo documentation / March 2010<br />

Horizontal and vertical ropes, mounted<br />

in gullies using <strong>TECCO</strong> ® , ensure that the<br />

whole of the unstable <strong>slope</strong> is under<br />

tension<br />

6

Traffi c on the B 462 protected from<br />

rockfall<br />

The integrated nature of the solution<br />

also preserves the plant cover and<br />

allows nature to thrive. The <strong>TECCO</strong> ®<br />

mesh that is laid guarantees that plant<br />

cover can be kept short at no great<br />

effort or expense. In the future, no<br />

more large woody plants – whose roots<br />

would further loosen the rock – will be<br />

able to establish themselves.<br />

Source: Karlsruhe Regional Council,<br />

Construction Offi ce Mitte (Central),<br />

Germany<br />

7

<strong>Geobrugg</strong> protects people and infrastructure from the<br />

forces of nature<br />

It is the task of our engineers (and partners) to analyze the problem<br />

together with you in detail and then, together with local consultants,<br />

to present solutions. Painstaking planning is not the only<br />

thing you can expect from us, however; since we have our own<br />

production plants on three continents, we can offer not only short<br />

delivery paths and times, but also optimal local customer service.<br />

With a view towards a trouble-free execution, we deliver preassembled<br />

and clearly identifi ed <strong>system</strong> components right to the construction<br />

site. There we provide support, if desired, including technical<br />

support – from installation right on up until acceptance of the structure.<br />

A company of the BRUGG Group<br />

Rockfall barriers<br />

Rockfall drapes<br />

Slope <strong>stabilization</strong><br />

Mudfl ow barriers<br />

Avalanche structures<br />

Protective structures for mines<br />

Special applications<br />

<strong>Geobrugg</strong> <strong>AG</strong><br />

Geohazard Solutions<br />

Aachstrasse 11 • CH-8590 Romanshorn<br />

Tel. +41 71 466 81 55 • Fax +41 71 466 81 50<br />

www.geobrugg.com • info@geobrugg.com<br />

ISO 9001 certifi ed 1.202.25.EN.1102