SPIDER® Avalanche - Geobrugg AG

SPIDER® Avalanche - Geobrugg AG

SPIDER® Avalanche - Geobrugg AG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

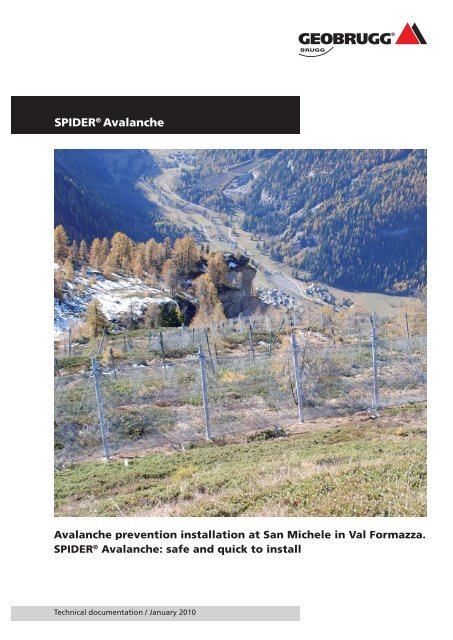

SPIDER ® <strong>Avalanche</strong><br />

<strong>Avalanche</strong> prevention installation at San Michele in Val Formazza.<br />

SPIDER ® <strong>Avalanche</strong>: safe and quick to install<br />

Technical documentation / January 2010

Intervento di stabilizzazione della Valanga San Michele (VB) / documentazione tecnica / gennaio 2010<br />

<strong>Avalanche</strong> prevention installation at San<br />

Michele in Val Formazza.<br />

SPIDER ® <strong>Avalanche</strong>: safe and quick to install<br />

Fig.1: Flight-ready equipment at the<br />

loading site<br />

Fig.2: High-level supply using a<br />

transporter bar with three support<br />

uprights and the corresponding netting<br />

2<br />

Work on stabilizing the snow cover was carried out in the area of San Michele,<br />

upstream of the town, on the left-hand snow-line of the Formazza Valley<br />

(province of Verbania). The work carried out adds to a pre-existing installation,<br />

deemed inadequate by the local authority, as the equipment, installed<br />

in the 1990s, showed clear signs of wear.<br />

The planning choice was to add to the existing snow cover stabilization installation<br />

within the detachment area, using structures approved by the Davos<br />

Institute, internationally recognized as the main authority in the fi eld of snowrelated<br />

phenomena. This choice was guided by research into the safety of the<br />

installation, not only in the immediate future, but also in the medium and long<br />

term, given that the structures approved by the Davos Institute have been<br />

tested in the fi eld, and were designed to provide safety and durability.<br />

The system used was <strong>Geobrugg</strong>’s new “SPIDER ® <strong>Avalanche</strong>,” a development<br />

of the tried-and-tested <strong>Geobrugg</strong> avalanche protection system. The new system<br />

is characterized by the replacement of the traditional triangular rope<br />

panels with rectangular panels of netting consisting of spiral rope made up<br />

of pre-stressed steel wires galvanized with aluminum-zinc alloy (GEOBRUGG<br />

SUPERCOATING ® ). This allows for the creation of a netting retention area that<br />

has fewer gaps and is easier and quicker to install as well as helping to keep<br />

costs down during the production phase, thus meaning a lower price for the<br />

end user.<br />

The site for installing the barrier opened on September 5 and closed on October<br />

30 2009. The work was carried out in two separate phases: fi rst the<br />

laying-out and insertion of the anchors, then the installation of the superstructure.<br />

The two phases were separated by a period of inactivity on the site<br />

due to adverse weather and conditions on the site.<br />

During the phase preceding the laying-out, <strong>Geobrugg</strong>’s Technical Department<br />

worked with the laying company to optimize the laying-out and the number<br />

of supports. The materials for the superstructure arrived on site at the same<br />

time as the start of work, and were therefore available as soon as they were<br />

supplied to the high level by helicopter.<br />

Manufacture and identifi cation by means of data plates made it easier to di-<br />

stinguish the different types of anchor, facilitating their positioning by helicopter<br />

at the correct points on the site. The transporter bar provided for the<br />

helicopter transportation – developed as a result of <strong>Geobrugg</strong>’s experience in<br />

the high-level working sector – facilitated materials supply operations. Anchor<br />

insertion operations were completed within the timeframes established.

Upon completion of the anchor insertion operations, the superstructure was<br />

prepared at the loading site, located in a car park at the bottom of the valley,<br />

ready for transportation by helicopter. It was possible to carry out the barrier<br />

line pre-assembly operations quickly as the number of connectors required<br />

had been kept to a minimum and the components were easily identifi able,<br />

being countermarked with labels identifying every single item.<br />

The fl ight phases were completed within seven days. A “typical day” schedu-<br />

led the presence of the helicopter for around one hour early in the morning,<br />

after which linking and bolting of the clamps and chains was carried out. At<br />

the end of the seven days of fl ying, the barrier lines (twelve in total) had been<br />

completed.<br />

The work on the site was then completed within 54 consecutive calendar days,<br />

including days affected by bad weather and some interruptions to the fl ying<br />

operations due to excessive wind.<br />

GEOBRUGG SPIDER ® <strong>Avalanche</strong> System<br />

Type of avalanche protection Dk 3.0 - N 2.5<br />

Total linear meters 384 m<br />

Number of lines 12<br />

Height of struts 4 m<br />

Days of helicopter transportation 7 days<br />

Total days on site 54 days<br />

Days spent on foundations 47 days<br />

Length of mountain-side anchors 5 m<br />

Length of valley-side anchors 4 m<br />

Length of strut underpinning 3 m<br />

Days spent on superstructure 7 days<br />

Daily rate of installation of super-structure 55 m / day<br />

Fig.3 + 4: Completed barriers<br />

Table 1: summary of the main site data<br />

3

<strong>Geobrugg</strong> protects people and infrastructures from the<br />

forces of nature<br />

It is the task of our engineers and partners to analyze the problem<br />

together with you in detail and then, together with local consultants,<br />

to present solutions. Painstaking planning is not the only thing you<br />

can expect from us, however; since we have our own production<br />

plants on three continents, we can offer not only short delivery paths<br />

and times, but also optimal local customer service. With a view towards<br />

a trouble-free execution, we deliver preassembled and clearly<br />

identifi ed system components right to the construction site. There<br />

we provide support, if desired, including technical support – from<br />

installation right on up until acceptance of the structure.<br />

Rockfall barriers<br />

Rockfall drapes<br />

Slope stabilization systems<br />

Debris fl ow barriers<br />

<strong>Avalanche</strong> prevention structures<br />

Open pit rockfall barriers<br />

Special applications<br />

<strong>Geobrugg</strong> <strong>AG</strong><br />

Geohazard Solutions<br />

Aachstrasse 11 • CH-8590 Romanshorn • Switzerland<br />

Phone +41 71 466 81 55 • Fax +41 71 466 81 50<br />

www.geobrugg.com • info@geobrugg.com<br />

A company of the BRUGG Group ISO 9001 certifi ed<br />

1.404.04.EN.1001