MILLER Newsletter 2015 Final with cream Small

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

IDENTIFY, AIM, EXECUTE<br />

DRIVEN TO BE THE BEST<br />

Table of Contents<br />

A Message From Leo 3<br />

Featured Accomplishments 4<br />

Achievements & Awards 5<br />

The McAsphalt Report 10<br />

Corporate Highlights & Latest Developments 16<br />

25 Year Club Members In Memoriam 17<br />

The 25 Year Club 17<br />

Retirements 18<br />

Miller Moments 18<br />

The CARE Program 20<br />

Remembering Our Colleagues 22<br />

MSO & Paveseal 25<br />

GTA Operations 26<br />

Brennan Paving & Construction 27<br />

Brennan Paving Limited - Port Colborne 33<br />

GTA Sales 34<br />

Ontario Pavement Products Group 36<br />

Corporate Technical Group 40<br />

Miller Capilano Maintenance Corp bc 42<br />

Miller Aggregates 43<br />

Miller Northern Operations 44<br />

Quebec Operations 49<br />

Equipment & Shops 50<br />

Georgian Bay Operations 52<br />

Cottage Country Operations 56<br />

SAFETY 57<br />

Eastern Ontario Operations 58<br />

Southwestern Ontario Operations 59<br />

Maritimes Operations 64<br />

Southeastern US Operations - Atlanta GA 69<br />

Cement & Ready-Mix Concrete Operations 70<br />

Waste Management Operations 75<br />

Miller Environmental Corp - Winnipeg Mb 81<br />

Miller Maintenance - AMCs Ontario 82<br />

Miller Infrastructures & P3s 86<br />

Transit Operations 88<br />

Recreation Operations 89<br />

Social Functions 90<br />

Fantastic Feedback 94<br />

Community Involvement 98<br />

A Message From Leo<br />

<strong>MILLER</strong> VISION<br />

“VISION DEFINES A COMPANY’S PURPOSE,<br />

FOCUSES ON GOALS AND ASPIRATIONS”<br />

As a young lad I would sit on the curb in front of my<br />

family home and watch the E. C. King trucks go by. I<br />

was fascinated <strong>with</strong> construction equipment, and my<br />

vision was to one day own a construction company.<br />

Vision is imperative to reaching goals, sustainable<br />

growth and long-term success. One of our largest<br />

investments is our employees. By providing you <strong>with</strong><br />

the tools and training to perform at your optimum<br />

level to succeed, the company succeeds.<br />

Last year we introduced the “Miller Institute of Excellence” which has proven to<br />

be positive and effective. Miller employees are valued and appreciated and offering<br />

further education allows for personal achievement.<br />

Last fall I announced our participation in “Aon Hewitt’s Best Employer Study”<br />

which will take place this spring. All employees are invited to engage in this confidential<br />

survey which will help us better understand what you, the employee,<br />

thinks about working at Miller and in your specific business unit. Your opinion is a<br />

valuable instrument in making us aware of what we are doing right and where improvement<br />

may be required. Learning from each other is powerful and is another<br />

step in continuing to make positive change while reaching personal and company<br />

goals and aspirations.<br />

Your commitment to excellence is appreciated and continues to have you and the<br />

company recognized as “ONLY THE BEST”.<br />

Leo McArthur,<br />

President & CEO<br />

Special thanks to the ‘<strong>Newsletter</strong> Committee’ , Blair McArthur, Ryan Essex, Francine Fowles, and Scott Woodard.<br />

Proofread by: Jennifer Campbell<br />

2 <strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

<strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

3<br />

www.millergroup.ca<br />

www.mcasphalt.com

IDENTIFY, AIM, EXECUTE<br />

DRIVEN TO BE THE BEST<br />

Featured Accomplishments<br />

After some 5 years of active construction on the Extension of the 404, Miller turned over the newly built Highway to the Ministry<br />

of Transportation and celebrated its opening <strong>with</strong> the Ribbon Cutting.<br />

Very few firms could take on such a task and be able to deliver on a demanding project schedule of this nature. Numerous challenges<br />

were encountered during the construction of the project but through the cooperation of all branches of Miller divisions,<br />

these impacts were minimized allowing the project to be completed this summer.<br />

Congratulations<br />

to the Brennan<br />

Civil Group for<br />

a job well done,<br />

and once again<br />

demonstrating<br />

why Miller is<br />

“ONLY THE BEST”<br />

and continues to<br />

be an Industry<br />

Leader!!<br />

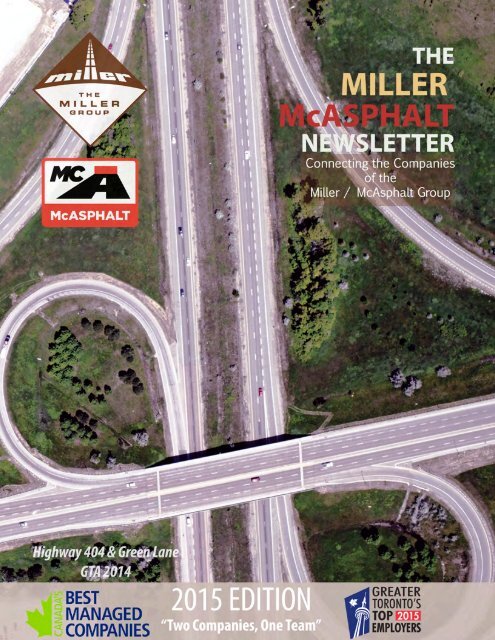

The cover of this<br />

newsletter shows<br />

one of the interchanges<br />

on the<br />

404 at Davis Dr in<br />

Newmarket.<br />

From left to right: Winston Ramirez, Barrie Brayford, Blair McArthur, Leo McArthur, Tom Johnston, Rick Tamburro, Steve Moote, Jerry<br />

Buck<br />

ONTARIO’S BEST IN CONCRETE CONSTRUCTION<br />

Construction of the 13 KM, four lane extension on Highway 404 and Green Lane was recognized because of the value Miller<br />

Group’s concrete pavement delivered to this critical infrastructure project.<br />

Construction on the Highway 404 Extension was completed by Miller Paving Limited for the Ontario Ministry of Transportation.<br />

The extension will remove up to 22,000 vehicles daily off of the local roads, reduce travel times for commuters and commercial vehicles,<br />

and support regional economic development. This project required the dedication of teams from our Paving and Concrete<br />

Divisions to ensure the success of this project. Congratulations on a job well done by all!<br />

Achievements & Awards<br />

Leo McArthur & The Miller Group<br />

Honoured by Character Community Foundation of York Region<br />

On November 6, 2014 Leo McArthur and The Miller Group were honoured by the<br />

Character Community Foundation of York Region for their continued development and<br />

ongoing expansion of Character development across York Region.<br />

The Foundation’s mission is to engage organizations in positive character development<br />

and to work toward the vision of having York Region lead in community character<br />

development.<br />

Leo has supported and integrated this initiative into The Miller Group of companies<br />

and continually promotes the work of the Foundation recognizing him as a true Community<br />

Champion.<br />

Congratulations Leo you are a Champion to us and we thank you for instilling good<br />

character attributes <strong>with</strong>in The Miller Group.<br />

Leo McArthur, Don Cousens<br />

King Beamish Award - Ontario Hot Mix Producers to Murray Ritchie -At the March 26th 2014<br />

Ontario Hot Mix Producers Annual meeting held in Collingwood, The Murray Group Limited’s<br />

Murray Ritchie received the King Beamish Excellence Award.<br />

The King Beamish Excellence Award recognizes an OHMPA member who has made an exemplary<br />

voluntary contribution to the works of the Association over a period of time and has<br />

demonstrated the qualities that exemplify leadership, motivation and inspiration related to<br />

participation in the Association. Murray is also a past recipient of The OHMPA “Earl Kee” Award<br />

for Outstanding service in 2007.<br />

Murray was President of the Ontario Hot Mix Producers Association in 2006 and again in 2012,<br />

and President of the Conestoga Heavy Construction Association in 2004-2006. Murray presently<br />

sits as an advisory board member of the Centre for Pavement and Transportation Technology<br />

(CPATT) based at the University of Waterloo and is General Manager of The Murray Group<br />

Limited.<br />

Blair McArthur was honoured by the OWMA, receiving the “Executive of the Year” award.<br />

This awards program recognizes and rewards those individuals who excel in their fields by showing<br />

excellence, exemplary customer service, entrepreneurship, innovation and perseverance.<br />

The evaluation criteria consist of;<br />

• Vision and Leadership – Blair has guided Miller Waste to new levels of growth,<br />

achievement and recognition.<br />

• Innovative Business Achievements – Uniqueness <strong>with</strong>in the Waste Management<br />

sector and its relationships <strong>with</strong> employees and customers/residents.<br />

• Social/Environmental Responsibility – Community and environmental responsibility<br />

and sustainability.<br />

• External Value- Delivering superior customer value.<br />

• Ethics Dimension – Recognized as a beacon of excellence, commanding respect<br />

from sector peers and upholds high ethical standards.<br />

Congratulations Blair on this recognition and we thank you and all the employees that<br />

made this possible.<br />

Blair McArthur<br />

4 <strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

<strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

5<br />

www.millergroup.ca<br />

www.mcasphalt.com

IDENTIFY, AIM, EXECUTE<br />

DRIVEN TO BE THE BEST<br />

Achievements & Awards<br />

2014 OHMPA TRILLIUM AWARD RECIPIENTS - The Ontario Hot Mix Producer (OHMPA) Trillium awards<br />

are presented to hot mix plants who demonstrate excellence in appearance, operations, environment, safety, permitting and compliance,<br />

community relations, and industry participation. In 2014, Miller Paving was presented recertification awards for all seven<br />

of the submitted plants which were judged according to our internal auditing process including a third-party reference, photographs,<br />

and a video. They include the CMI 150 Portable plant stationed in Gowganda during auditing, Pave-Al, EC King Chesley,<br />

North Bay (NFN), Timmins, Mosport, and Uxbridge. No other hot mix plants received the award in 2014.<br />

Currently, Miller has 23 of its Ontario plants <strong>with</strong> active Trillium certificates.<br />

Only six other plants other than Miller hold valid, up to date,<br />

Trillium status in Ontario. Since 2002, ninety three (93) asphalt plants<br />

in Ontario have been certified or re-certified to Trillium Status and<br />

Miller holds 54 of those awards. Since 2008 Miller has received 48 of<br />

the 66 total award certifications or recertifications that have been<br />

presented to industry producers by The Ontario Hot Mix Producers<br />

Association.<br />

The Miller Group takes great pride in<br />

the efficient operation of its plants and<br />

the dedication of its employees to the<br />

maintenance and appearance of its<br />

assets.<br />

Achievements & Awards<br />

Miller Named GTA Top Employer for the<br />

6th Consecutive year! We are proud to be recognized as one of<br />

Greater Toronto’s Top Employers for <strong>2015</strong>. This award recognizes leading organizations<br />

in the Greater Toronto areas that offer an exceptional place to work. The<br />

Miller Group is committed to attracting and retaining highly skilled and dedicated<br />

employees so that we can provide our customers <strong>with</strong> the best possible service.<br />

Top employers are selected because they have superior work environments, and<br />

are great places to work. Being one of GTA’s Top Employers for <strong>2015</strong> reaffirms that<br />

The Miller Group is not only an employer of choice but also a great place to work!<br />

The Canada's Best Managed Companies designation symbolizes Canadian corporate<br />

success: companies focused on their core vision, creating stakeholder value and excelling in the<br />

global economy. The program has continued to raise the profile of Canadian-owned businesses that<br />

have:<br />

• outperformed their competitors<br />

• created thousands of jobs<br />

• achieved sustainable growth<br />

• excelled both at home and abroad<br />

Miller is proud to hold this achievement and has done so since 2010.<br />

Another true symbol of being “Only The Best”<br />

Gerry Boccia accepted the award for Pave-Al<br />

from Bentley Ehgoetz, OHMPA President.<br />

From left to right, are Justin Baxter for<br />

Mosport and Uxbridge, Amma Wakefiled for<br />

CMI150 Drum plant, Trevor Moore for North<br />

Bay, and Dave Sykes for Chesley, EC King.<br />

Special thanks to Paul Thistle and the<br />

Pickering shop for all their help.<br />

2014 RMCAO Truck<br />

Rodeo<br />

E C King<br />

(Chesley)<br />

Batch -<br />

Owen<br />

Sound Area<br />

Mosport<br />

Drum Plant<br />

Timmins<br />

Batch<br />

Pave-al<br />

Drum /<br />

Coater<br />

Miller has never had any of our submissions denied because we continue to upgrade our assets in accordance <strong>with</strong> current Environmental<br />

requirements and test each of our operations for conformance to OHMPA “Best Practices” and Governmental Legislation.<br />

As plants must be certified every three years, Trillium Awards are an ongoing reminder of the standards which each operation<br />

must maintain as an integral part of The Miller Group’s internal audit process and commitment to safety, the environment, and<br />

the communities in which we live and operate. Congratulations to all our participants and to Brian Eyers for leading this initiative.<br />

Another great example of being “Only The Best.”<br />

1st Place - Bryan Houston<br />

3rd Place - John Lefebvre<br />

The Ready Mixed Concrete<br />

Association of Ontario<br />

(RMCAO) held its annual<br />

truck rodeo Sunday August<br />

17th at Miller Waste Systems,<br />

Pickering. 24 drivers representing<br />

concrete suppliers<br />

from across Ontario competed<br />

in a 9 event driving course<br />

and pre-trip inspection.<br />

Representing Miller Concrete<br />

were James Formica (Whitby),<br />

Bryan Houston (Aurora), and<br />

John Lefebvre (Aurora). We<br />

are proud to announce that<br />

Bryan Houston is the Ontario<br />

Champion, finishing in 1st<br />

place. John Lefebvre finished<br />

3rd. Congratulations guys!<br />

“Only The Best”<br />

6 <strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

<strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

7<br />

www.millergroup.ca<br />

www.mcasphalt.com

IDENTIFY, AIM, EXECUTE<br />

DRIVEN TO BE THE BEST<br />

Achievements & Awards<br />

ARRA Elects Ryan Essex <strong>2015</strong>-2016<br />

President<br />

During its recent 39th Annual Meeting in Paris, France, during<br />

the first Pavement Preservation & Recycling (World) Summit<br />

held February 22 – 25, <strong>2015</strong>, the membership of the Asphalt<br />

Recycling & Reclaiming<br />

Association<br />

(ARRA) elected Ryan<br />

Essex, of Miller Paving<br />

Limited, to the<br />

office of President<br />

for the <strong>2015</strong>-2016<br />

term.<br />

Miller - The Leader in Industry<br />

Steve Smith President of the Ontario Hot<br />

Mix Producers Association for <strong>2015</strong><br />

Steve is honoured and excited to take on the important and<br />

challenging role as President of the Ontario Hot Mix Producers<br />

Association for <strong>2015</strong>. The industry is continually facing numerous<br />

challenges <strong>with</strong> regard to hot<br />

mix asphalt and he looks forward to<br />

leading this association to analysis<br />

and solutions for these challenges.<br />

He also looks forward to continuing<br />

to develop our relationship <strong>with</strong> the<br />

Ministry of Transportation, Municipalities<br />

and other stakeholders as<br />

well as working <strong>with</strong> the industry<br />

leaders that help make this association<br />

so great.<br />

2014 Miller Waste Truck Rodeo Results<br />

I would like to thank all of the competitors who attended the truck competition in Pickering on Sunday June 1, 2014. There were<br />

close to 30 participants this year representing all of our divisions from across Ontario. It was a great day had by all and the weather<br />

could not have been nicer. The winners of each class were:<br />

Association Representation<br />

Miller Transit Bus Roadeo Awards<br />

Achievements & Awards<br />

Blair McArthur Named President of ORBA<br />

Congratulations to Blair McArthur for being named the President<br />

of the Ontario Road Builders’ Association (ORBA). Blair<br />

became the 88th President of ORBA on February 10, <strong>2015</strong> at<br />

ORBA’s annual convention held at the Royal York Hotel.<br />

Twenty five years earlier, in 1990, Leo McArthur was named<br />

ORBA’s President. Leo and Blair represent the fourth father/son<br />

President team in ORBA’s 88 year history. I guess the saying “the<br />

fruit does not fall far from the tree” may be applicable in this<br />

instance!<br />

Matt Kellar – Markham - Front End<br />

Darrell McLeod –North Bay - Roll Off<br />

Perry Wall – Durham - Top Loader<br />

Brad Zandbergen- Ottawa - Real Loader<br />

Other winners include:<br />

Top-Load Recycle - 2nd Place – Tim London –Durham District, Rear Loader – 2nd Place – Ryan Morrison – Markham District, Front End – 2nd<br />

Place – Mahadeo Chulu – Markham District, Roll-Off –2nd Place – Dale Carmichael – North Bay District, Top Rookie of the competition went to<br />

Luke Proctor – Kawartha Lakes District, Grand Champion - was awarded to Perry Wall – Durham District<br />

2014 Ontario Waste Management Association Truck Rodeo<br />

Congratulations go out to five of our Collection Service Representatives, Ryan Morrison and Matt Keller from our Markham operation,<br />

Perry Wall and Tim London from our Durham operation and Darrell McLeod from our North Bay operation. Ryan finished 3rd<br />

overall in the Rear Load class, Matt finished 2nd in the Front-End, Perry and Tim finished 2nd and 3rd respectively in the Top Load<br />

Recycle class while Darrell finished 3rd in the Roll-Off class. All five drivers represented Miller Waste at the Provincial Championships<br />

held in Barrie on July 12, 2014. This competition is an opportunity for the best drivers in Ontario to compete for the “hardware”,<br />

prize money and a chance to represent Ontario at the Nationals. All five will have competed in the Straight Truck – 2-axle<br />

class.<br />

Congratulations Dorell Atkinson<br />

Grand Champion 2014 YRT/Viva Bus Roadeo!<br />

The Region presented Dorell Atkinson his YRT BUS Roadeo<br />

Championship Ring and to Dan Sguigna, a VP ring for his<br />

support of the annual roadeo and the operators. It is the<br />

first ring awarded since the competition started seven<br />

years ago.<br />

Amma wins Norman W. McLeod Award<br />

In the fall of 2014 in Winnipeg, Amma Wakefield won the prestigious<br />

Norman W. McLeod Award for the Best Technical Presentation at the 2013<br />

Canadian Technical Asphalt Association conference on “Characterizing<br />

Warm and Hot Mix Asphalt Strength through Internal Aggregate Structure<br />

Analysis”. The Norman W. McLeod Award is given to a presenter for<br />

their excellence in oral presentation. The award winner is selected by participants<br />

at the annual CTAA Conference by a confidential voting process.<br />

Amma’s co-authors for the paper were Ryan Essex and Trevor Moore.<br />

Congratulations to Bentley Ehgoetz, Director of<br />

Operations, for his appointment as President of the<br />

Ontario Hotmix Producers for 2014.<br />

In order from left to right, Ryan Morrison, Matt Keller, Tim London, Darrel McLeod, and Perry Wall.<br />

This is Amma’s second time being recognized for this award.<br />

Congratulations!<br />

8 <strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

<strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

9<br />

www.millergroup.ca<br />

www.mcasphalt.com

IDENTIFY, AIM, EXECUTE<br />

DRIVEN TO BE THE BEST<br />

The McAsphalt Report<br />

Our Brand and the McAsphalt Advantage<br />

“The MCA Advantage” is a defining feature of the McAsphalt<br />

brand. The MCA Advantage is both a branding<br />

effort and a reflection of an organizational culture that<br />

encourages continual improvement. In recent years,<br />

McAsphalt has been actively diversifying operations<br />

from marine fuels to environmentally friendly asphalt<br />

products. The MCA Advantage has been the driving<br />

force behind these initiatives as we continually adapt to<br />

meet consumer demand. The overarching goal of our<br />

branding effort is to garner an even stronger reputation<br />

for being a firm that is easy to do business <strong>with</strong>.<br />

The New Kid on the Block in Edmonton<br />

The McAsphalt Report<br />

Picture Left - Our new facility<br />

in Edmonton.<br />

Greatly expanding our<br />

geographic presence, the<br />

Edmonton facility is strategically<br />

placed to serve<br />

our customers throughout<br />

Alberta, Northern British<br />

Columbia right up to<br />

Alaska.<br />

The MCA Advantage as defined for<br />

our paving customers:<br />

‘The MCA Advantage’ a description of our unique expertise, experience<br />

and commitment to our customers.<br />

With the MCA Advantage, you get a partner<br />

and advisor who will consult <strong>with</strong> you about<br />

mix design, specifications, technical services<br />

and the selection of materials to develop<br />

innovative, modified products that can be<br />

custom-designed to offer additional benefits,<br />

such as peak performance in unique conditions,<br />

improved field performance, greater<br />

environmental and health benefits, and significant<br />

long-term cost savings, resulting in lower<br />

“total cost of ownership” .<br />

McAsphalt, MMTL & Sterling join forces in Hamilton<br />

Our Trucks are rolling billboards and an excellent<br />

example of the McAsphalt Brand<br />

As we close in on the final phase of rolling out our<br />

new “Brand Identity” complete <strong>with</strong> website, everyone<br />

should be becoming familiar <strong>with</strong> the “Brand”. We have<br />

a specific concept in mind for McAsphalt and everything<br />

no matter how trivial it appears impacts our<br />

image and how others perceive us. We believe we are<br />

professional in how we conduct ourselves personally<br />

and in business; we are setting the bar high for ourselves<br />

and our competition.<br />

McAsphalt is on schedule to have the new website up<br />

and operational for March <strong>2015</strong>, which will be upon us<br />

before we know it!<br />

The McAsphalt Marketing booth goes<br />

on tour to our customers in <strong>2015</strong>!<br />

McAsphalt, MMTL and the Sterling Fuels offices have joined<br />

forces in one location at the Hamilton Port.<br />

Hamilton Environmental Excellence<br />

Award<br />

McAsphalt’s Hamilton Terminal was awarded the annual Environmental<br />

Excellence Award from the Hamilton Port Authority.<br />

The annual award recognizes the company’s contribution to<br />

respect for and protection of the environment.<br />

$5,000 associated <strong>with</strong> the award was donated to the Royal<br />

Botanical Gardens and its Growing Up Green campaign, which<br />

is focused on marsh restoration in Cootes Paradise.<br />

Joel Gardner (left) and Peter Oddi (right) accepting the award<br />

on behalf of McAsphalt.<br />

10 <strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

<strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

11<br />

www.millergroup.ca<br />

www.mcasphalt.com

IDENTIFY, AIM, EXECUTE<br />

DRIVEN TO BE THE BEST<br />

The McAsphalt Report<br />

Bring on the Rail Cars<br />

It is <strong>with</strong> great pleasure we announce the completion of the Hamilton rail project.<br />

We went through 3 busy months at the terminal installing a new railcar offloading<br />

system which includes a steam heating system.<br />

We added some new features to our offloading system such as the capacity to use<br />

the two pumps separately at the same time so we can now offload product from<br />

different railcars.<br />

Thanks to the direct connection between the offloading header and the new<br />

loading arm at the loading platform, the system is now capable of offloading product from railcars and loading it Hamilton Rail<br />

directly to tankers <strong>with</strong>out needing to stock it at the plant - a solution that allows us to move product quickly and avoid reducing<br />

the stock capacity at the plant.<br />

The steam heating system has a condensate return line feature which has<br />

the cost advantage of reducing the use of water, chemicals and energy<br />

during its operation. By reducing the use of these materials this system is<br />

not only more efficient but it is also the most environmentally friendly.<br />

Rail systems are also being constructed in other areas of Ontario. Pictured<br />

left is the rail system in Windsor and the picture shown above is the soonto-be<br />

Oshawa rail system.<br />

Windsow Rail<br />

Integration Update – MCA Business Operating System<br />

- 2014 signaled the end of a 3 year cycle for our certified (9001/14001) management<br />

system. A significant milestone was reached when Sterling Fuels incorporated all activities<br />

and operations into the system, eliminating silos of information and ensuring key<br />

data can be selectively shared across the company which further reduces risk while<br />

capitalizing on opportunities. In addition, the Eastern region was sampled this fall by<br />

Intertek, our 3rd party registrar, as part of the annual surveillance audit schedule. All<br />

locations proved that the ongoing integration provides a clear, holistic picture of all<br />

aspects of our organization, how they affect each other, and their associated risks.<br />

As part of the integrated approach, in <strong>2015</strong> we will be working <strong>with</strong> the transportation department, including MMTL and Sterling<br />

Fuels Hamilton, ensuring that we are committed to all areas of our business, from managing employee’s needs, monitoring competitor’s<br />

activities and encouraging best practices, to minimizing risks and maximizing resources. We are acting in step <strong>with</strong> the<br />

“McAsphalt Culture of Excellence”.<br />

McAsphalt’s Integrated Management System<br />

The McAsphalt Business Operating System, known as the Integrated Management<br />

System (IMS) is the approach we as a company have taken to document past and<br />

present best practices in all Business Processes.<br />

The purpose of this documentation is to ensure organizational<br />

coherence of Company performance.<br />

Employees improve and sustain<br />

business by following the Plan,<br />

Do, Check, Act Concepts of our<br />

quality assurance and IMS programs.<br />

The McAsphalt Report<br />

Oshawa Rail<br />

Rain or Snow, our Customers<br />

are Covered<br />

Pictured below, <strong>with</strong> assistance from a<br />

coastguard Ice Breaker the McAsphalt’s Norman<br />

McLeod is seen sailing through winter’s fury.<br />

McAsphalt Marine Transportation Limited<br />

The Durham Police came aboard the John J Carrick and Victorious in June while the<br />

vessel was secured at McAsphalt in Oshawa. The main reason for their visit was to<br />

give a tour to their marine department and tactical squad and for them to see what<br />

it would be like to board to a commercial vessel. None of them had been on-board a<br />

commercial vessel before. They came down <strong>with</strong> 2 small vessels and came up on the<br />

gangway. From there they were given a tour of the Tug and Barge.<br />

They ran several scenarios regarding disgruntled employees, hostage takeovers,<br />

terrorist activities, stowaways and any other suspicious activity. They checked out<br />

the thickness of the glass,<br />

doors, portholes and other means of escape and entry points. They had<br />

plenty of questions and raised good points in regards to their training.<br />

They were very grateful for the tour and pass along their thanks and<br />

gratitude.<br />

Pictured (right) from the bridge; the Algoma Dartmouth<br />

navigates rough seas on its way to pick up<br />

fuel for Sterling Fuels Limited at Point Tupper on<br />

Cape Breton Island. The storage facility on Cape<br />

Breton Island is a great location for fuel satisfying<br />

the demand of Sterling customers, which include<br />

some of the largest Cargo Ships sailing the East<br />

coast from Europe and the Americas.<br />

Sterling Fuels and Miller Bring Business in<br />

from the Great Lakes<br />

The Windsor Dock is bringing in business for The Miller Group and Sterling<br />

Fuels Team that work to coordinate the offloading of shipments and<br />

refueling.<br />

The north dock is now complete, expanding Sterling’s ability to serve<br />

more customers.<br />

Fuel Delivery North Atlantic<br />

Fill ‘Er Up! Pictured left, the Sterling Energy is seen filling a<br />

customer’s tank in Hamilton.<br />

The Sterling Energy has been gaining a reputation for being a time<br />

saver for vessels in the Hamilton harbour when it comes to refueling.<br />

12 <strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

<strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

13<br />

www.millergroup.ca<br />

www.mcasphalt.com

IDENTIFY, AIM, EXECUTE<br />

DRIVEN TO BE THE BEST<br />

The McAsphalt Report<br />

Making Big Waves<br />

Canadian Shield Making Big Strides<br />

The McAsphalt Report<br />

Peter Kelly returned to his home town of Windsor in 1993 when McAsphalt Industries<br />

Ltd. purchased a marine terminal from Ultramar Canada. Having been closed<br />

for over a year, there were no employees, no suppliers, and no customers. John<br />

Carrick Sr., McAsphalt’s owner and President, tasked Peter Kelly to make the trip<br />

to Windsor and make Sterling Marine Fuels a viable operation.<br />

Today, Sterling is a premier land and marine fueling operation <strong>with</strong> storage and<br />

blending capabilities of over a million barrels of petroleum products, from gasoline<br />

to asphalt. Peter is currently the 2014 – <strong>2015</strong> Marine Club President, a post<br />

also held by Adrian Mitterhuber and Roy Hickingbottom who held the position<br />

years prior.<br />

In 3 years Canadian Shield has made their presence known from coast to coast <strong>with</strong> terminals in<br />

nearly 15 cities and plans to expand. They are also looking at company owned store fronts and private<br />

distributorships to better serve customers locally.<br />

Canadian Shield is already gaining positive recognition for its products. The projects that have been<br />

completed <strong>with</strong> Liquid Road TM , a bituminous surface treatment, on municipal roads and over chip<br />

seals, have achieved a lot of praise and have created excitement for what the future of road maintenance<br />

has to come. This achievement, along <strong>with</strong> a regular maintenance program <strong>with</strong> Canadian<br />

Shield’s SealMaster products, gives us the ability to achieve and maintain high quality roads <strong>with</strong>out<br />

the expense and time that is involved in replacing asphalt fully.<br />

Canadian Shield prides itself on being the first in Canada and in a very short period of time, to spread<br />

its distribution from coast to coast. With the push for more environmentally friendly Canadian manufactured<br />

products, SealMaster products are just that, all water based asphalt emulsions that are<br />

environmentally friendly. This allows Canadian Shield to be the corporately responsible company its<br />

founders aspired for it to be.<br />

CAL Trucking<br />

2014 was an exceptional year for Continental Asphalt Logistics (CAL) logging nearly 3,000,000 KM <strong>with</strong><br />

company owned tanks.<br />

Nustar Terminal<br />

Pictured right, this vessel was chartered by Sterling<br />

to expand fuel operation into the Atlantic<br />

Canada. Here the vessels are seen transferring<br />

marine fuels to the Algo Dartmouth which is<br />

on charter to Sterling. After filling up <strong>with</strong> fuel<br />

the ‘Dartmouth’ will service various ships in the<br />

Halifax harbour acting as a “mobile gas station”<br />

to save our customer’s time and money.<br />

We serviced a customer base that extends from Whitehorse in the Yukon to Winnipeg, Manitoba as well as reaching south into<br />

Montana and many points in between. CAL’s employees have established a reputation for punctual service in an industry that has<br />

barely seven months to achieve a year’s goals.<br />

The standards established by CAL and its employees over the years will help propel the company in future years.<br />

Eastern Passage<br />

Facility<br />

Pictured left is a permanent solution,<br />

as current plans to complete<br />

a fuel storage tank at our Eastern<br />

Passage facility are well under<br />

way. This additional storage will<br />

increase options for Sterling as<br />

we work towards servicing Ocean<br />

going vessels traveling around<br />

the globe.<br />

14 <strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

<strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

15<br />

www.millergroup.ca<br />

www.mcasphalt.com

IDENTIFY, AIM, EXECUTE<br />

DRIVEN TO BE THE BEST<br />

Corporate Highlights & Latest Developments<br />

The Miller Group Acquires Jennison Construction Ltd<br />

2014 also saw the addition of Jennison Construction<br />

Ltd, in the Grand Bend area of Ontario,<br />

to the Lavis Contracting Co. Limited. Jennison<br />

has been operated by four brothers, Bill,<br />

Richard, Steven and Gary for forty years <strong>with</strong><br />

its own crushing and screening equipment<br />

along <strong>with</strong> various gravel resources. Jennison<br />

Construction Ltd is a very reputable company<br />

in aggregate supply in South Western Ontario<br />

and is a great addition to Lavis and the Miller<br />

Group of Companies.<br />

Bill Jennison, Richard Jennison, Leo McArthur, Steven Jennison, Gary Jennison<br />

Best Employer Study – Aon Hewitt<br />

As recently announced by Leo McArthur, President and CEO the Miller Group, this<br />

spring the Miller Group will distribute a survey to all employees asking for their<br />

opinions on their work environment, the people they work <strong>with</strong> and for, and our<br />

human resources practices such as benefits, pension, vacation time, training and<br />

development, etc. The results of this survey will help us better understand what you<br />

the employees think about working at Miller and in your specific business unit. Being<br />

a Best Employers is important to us. Whether or not we make the list of Best Employer in Canada for <strong>2015</strong>, taking part in the study<br />

enables us to benchmark our progress on that journey.<br />

The 25 Year Club<br />

THIS YEAR IS THE CELEBRATION OF THE NEW INCOMING MEMBERS FOR<br />

2014 AND <strong>2015</strong><br />

Their years of service, dedication and assistance in developing<br />

The Miller Group is greatly appreciated by Leo and the company.<br />

CELEBRATION DETAILS TO FOLLOW<br />

REMINDER – We like to keep in contact <strong>with</strong> our 25 Year Club members.<br />

Please send your photos, news and articles of interest to;<br />

Francine.fowles@millergroup.ca<br />

The information we hope to receive from this survey will help us recognize and acknowledge the things we do well at the Miller<br />

Group, and better understand where we may need to make improvements.<br />

All employees across the organization will receive an invitation in the spring of <strong>2015</strong> to complete an Employee Opinion Survey. All<br />

responses will be analyzed by Aon Hewitt and will be treated <strong>with</strong> complete confidentiality.<br />

If you have any questions about the survey please contact the Human Resources Department. To learn more about Hewitt’s Best<br />

Employers in Canada study, please visit the Best Employers Web site at<br />

www.hewitt.com/bestemployerscanada.<br />

Thank you in advance for participating.<br />

The Miller Institute of Excellence is the basis of the Miller Group’s learning<br />

culture. Igniting innovation and enhancing individual and organizational effectiveness, MIE is<br />

a dynamic, industry-leading resource for all Miller Group employees to enhance their current<br />

skills and develop new ones.<br />

Although MIE is only in its second year our goal is to offer interactive and engaging learning<br />

programs that are designed to specifically meet the needs of all employees, through a variety<br />

of delivery methods including classroom instruction, e-learning, books, videos, and mentoring.<br />

As an industry leader, the Miller Group employees have a wealth of experience and knowledge,<br />

and we believe this knowledge is a vital resource that should be shared. Learning from internal<br />

experts is one of the ways we can help you to develop and build your career.<br />

MIE programs consists of technical ‘how to’ sessions to sessions that keep you on top of changing industry regulations. We offer<br />

a Management Development program that provides our managers <strong>with</strong> training and coaching services to help them and their<br />

teams achieve exceptional high performance. Through MIE our employees will have the learning tools they need to drive their<br />

career and development. Our goal is to provide Miller employees the knowledge and information they need to succeed each and<br />

every day and MIE will helps us achieve this goal!<br />

25 Year Club Members In Memoriam<br />

George Wylie - June 2014<br />

Isobel St. Amour (wife of Louis St. Amour) - June 2014<br />

John Stephens - June 2014<br />

Bill Williamson - July 2014<br />

Tony Morra - July 2014<br />

Mariette Poirer (wife of Steve Carruthers) - January <strong>2015</strong><br />

Rocco Colangelo - November 2014<br />

Keith Davidson, McAsphalt - February <strong>2015</strong><br />

John Morrison - January 2014<br />

16 <strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

<strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

17<br />

www.millergroup.ca<br />

www.mcasphalt.com

IDENTIFY, AIM, EXECUTE<br />

DRIVEN TO BE THE BEST<br />

Retirements<br />

Thank you for your time here at Miller! Be sure to find time to enjoy yourselves, we’ve got it from here.<br />

The 2014-<strong>2015</strong> Group<br />

Bernard Maynard - Miller Transit<br />

Patricia Clayton - MPL Brechin<br />

Bryan Foebel - Miller Maintenance, Niagara<br />

Robert A Wiseman - MPL, North Bay<br />

Daryl Rowlandson - Miller Paving Northern<br />

Russ McConnell - MPL Cement<br />

Eric Wong - Miller Transit<br />

Russell Cameron - Miller Maintenance, New Liskeard<br />

Jack McKay - Thunder Bay Highway Maintenance Limited<br />

Sal Catania - MPL, GTA Paving<br />

James Jackson - Miller Waste Systems<br />

Susan Enscott - Miller Waste Systems<br />

John McKean - MSO Construction<br />

Trevor Griffith - Miller Waste Systems<br />

Martin Harrington - Miller Paving Northern<br />

Zoilo Custodio - Transit<br />

Oswald Moore - Transit<br />

Grant Lickiss - MPL<br />

Jack Wannamaker - MPL Arnprior<br />

Robert Forget - Miller Waste Systems<br />

Len Brown - MPL Concrete<br />

Take Our Kids to Work Day, 2014<br />

Miller Moments<br />

On November 5, 2014 The Miller Group was proud to host the annual “Take Our Kids to<br />

Work Day.” Fifteen, grade nine, students participated in this program <strong>with</strong> the assistance of several helpful and enthusiastic employees.<br />

Students had a busy day visiting various sites and learning about The Miller Group from our skilled professionals. “Take<br />

Our Kids to Work Day” provided the students <strong>with</strong> an understanding of their parents/relatives duties and responsibilities at The<br />

Miller Group. Thanks to The Miller Group employees, the students had an informative and enjoyable day.<br />

Miller Moments<br />

Two little girls set up a lemonade<br />

stand for the crew. The boys<br />

all bought a glass and we gave<br />

them each our last two miller<br />

hats.<br />

Glenn Fernandes son Joseph's 2nd birthday.<br />

In training for a job on a Miller crew<br />

Alyssa Lamanna attended the "Take our kids to work" <strong>with</strong> the Miller company on November 5th. (Granddaughter of Rocky Lamanna,<br />

superintendent of Bloomington Downs). I was very impressed by your agenda and experience you provided for these grade 9 students. The<br />

tours and wearing the equipment made it such a hands on experience and so much fun.<br />

John Jessup of Smith’s Construction and his family<br />

built the snowman which stands 13 1/2 feet tall. It<br />

is made <strong>with</strong> 3 silage wrapped bales of hay. The<br />

snowman is located at the farm of John and Lori<br />

Jessup. Pictured <strong>with</strong> the snowman are John and<br />

Lori's children Carter and Riley, niece and nephew<br />

Kennedy and Colby and cousins Sadie and Seth.<br />

Celebrating Allyson Pathak (Fletcher)<br />

upcoming nuptials<br />

Chris Ladouceur of MPL Markham<br />

Shop, passed his exam and is now a<br />

qualified truck and coach mechanic.<br />

I wanted to say thank you and that you did a great job providing them <strong>with</strong> a real life experience; She told me she loved it. We showed<br />

off her photo and certificate to friends and family. :-) Thank you and when it's time for my other two daughters to attend "Take Our Kids<br />

to Work", I hope they can experience what Alyssa did. Have a nice day - Annette Lamanna<br />

Otto Henderson was having birthday and his mother called in and asked if he could see a garbage truck up close, apparently he<br />

just loves them. We couldn’t promise anything because it was a<br />

collection day and obviously that is the priority, but we decided<br />

to see if Miller could have a truck there to make this little guy’s<br />

day even more special.<br />

Miller had the truck there for 11 am, and we met <strong>with</strong> the safety<br />

trainer from Miller to ensure we did everything properly to make<br />

sure no one got hurt. The birthday boy was just awe struck the<br />

whole time, and the parents were so thankful. Sanida Aljic put<br />

together a bag of goodies for Otto and that just put him over the<br />

moon, his mother was crying and couldn’t thank us enough.<br />

Great job goes out to Sanida for organizing this whole thing,<br />

John Barbosa and Scott Joyce were a huge help in making this<br />

all happen. BTW- he is the little guy in the blue checkered jacket<br />

and beige pants in the photos.<br />

18 <strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

<strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

19<br />

www.millergroup.ca<br />

www.mcasphalt.com

IDENTIFY, AIM, EXECUTE<br />

DRIVEN TO BE THE BEST<br />

The CARE Program<br />

Over the years the CARE program has generated hundreds of original and ingenious ways to make Miller a<br />

more efficient, safer and planet friendly company. The idea to have our employees send in their suggestions<br />

as part of this program has been around since 2001 and has proved to be a great success. As you will see<br />

from the submissions below our employees are always looking for ways to improve our processes and make<br />

our jobs safer and more productive. The CARE program encourages all Miller employees to participate and<br />

looks forward to another great year. “Only the Best”<br />

Featured Submissions<br />

CARE Suggestion #1849 - Herman van Kessel - Miller<br />

Maintenance Limited – Manchester Patrol Yard<br />

This suggestion created a lateral ram on a tractor that<br />

pushes/pulls a section of plow-blade cutting edge to<br />

cut-off sand-gravel berm build-up. It is much quicker<br />

than manual rake & shovel, but still leaves a berm on<br />

the side-slope. The issue we experience on the Area<br />

Maintenance Contracts are gravel berms underneath<br />

the guiderail – both 3 cable guiderail and steel beam<br />

guiderail. These gravel berms<br />

are caused from years of plowing<br />

shoulders and also from not<br />

removing them on an ongoing<br />

basis. According to our contract<br />

<strong>with</strong> MTO, anything that “impedes<br />

the shoulder drainage to function<br />

as designed” costs us immediately<br />

$3,000 per occurrence and an additional<br />

$1,000 for each additional<br />

day that is left uncorrected after<br />

detection or being made aware.<br />

In the past we have utilized an internal<br />

mini-excavator <strong>with</strong> a steel<br />

plate attachment to the bucket to<br />

try and remove the berms from<br />

under the guiderail. This does work to some extent but it is very<br />

slow and the bucket doesn’t always fit under the rail.<br />

Over the past year, Herman designed and built - <strong>with</strong> the help of<br />

a licensed welder/fabricator - a berm removal device that could<br />

attach to one of our existing John Deere 2355 Tractors to remove<br />

the berms under the guiderail. It has the option of a 4ft or 6ft blade<br />

attachment, depending on whether you need to remove berm<br />

from cable guiderail or steel beam guiderail. This tractor is designed<br />

to work solely off the shoulder (in most cases where there is a full<br />

width shoulder) which would result in only requiring a blocker truck<br />

behind the tractor – resulting in a 2 man crew as opposed to our<br />

Herman van Kessel - left, pictured <strong>with</strong> foreman Matthew previous 5-6 man crew. As well, this tractor has the option of pulling<br />

Burrows. Miller Maintenance Durham - Manchester the gravel out to the front side of the guiderail, should you require to<br />

have the gravel on the shoulder towards the edge line…..by pulling a couple pins, it can also do the opposite and push the berm<br />

to the back through the posts, should you have too much material out on the shoulder…..this machine can do either operation.<br />

CARE Suggestion #1833 - Bob Dillon of Miller Paving Limited Markham Dispatch<br />

Division<br />

CARE Suggestion #1817 - Elvis Gonzales of Talon Sebeq<br />

Roadwatch system kits that are installed have a weak sensor and are<br />

installed in a way that can cause corrosion. Elvis installed sensors directly<br />

into the mirror, improved sealing, and added a temperature display<br />

in-cab. The cables were routed using original manufacturer power and<br />

heated mirrors. He also integrated the temperature display into the<br />

upper front panel of the truck cab. Before this idea the outside bracket<br />

for mirror mounting that the manufacturer provides leaves the inner<br />

circuit board quite vulnerable to the elements, and this idea of “internalizing”<br />

the core of the unit has worked well. As an invention, it will save<br />

replacement costs from premature failures.<br />

The CARE Program<br />

Bob Dillon identified that the<br />

water line for the road grinder<br />

was rubbing off the paint on the<br />

tanker. Bob suggested that a bar<br />

that hooks into the toe hook hole<br />

on the front bumper of the tank<br />

will solve this issue.<br />

CARE Suggestion #1799 - Matt Burrows and Dave Tracey of Miller Maintenance Limited – Manchester Patrol Yard<br />

This suggestion was awarded for an adjustment made to the<br />

lighting on the brand new snow plow combination units Miller<br />

Maintenance received for their 13 year contract. There was an<br />

issue <strong>with</strong> how the lights were<br />

installed on the rear of the trucks.<br />

The amber and blue lights were<br />

continually filling <strong>with</strong> water and<br />

burning out after one storm. By<br />

turning the lights around, this<br />

has not been a problem again.<br />

Not only does this easy switch<br />

save the company money on<br />

repeat replacements of these<br />

lights, but it also reduces down<br />

time for the winter units and the<br />

need to have mechanics service<br />

these trucks more often than<br />

they should. This idea was gerenated<br />

by Matt Burrows and the<br />

work was done by Dave Tracey.<br />

20 <strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

<strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

21<br />

www.millergroup.ca<br />

www.mcasphalt.com

IDENTIFY, AIM, EXECUTE<br />

DRIVEN TO BE THE BEST<br />

Remembering Our Colleagues<br />

Tom Hennessey - Miller Waste Systems<br />

It is <strong>with</strong> great sadness that we announce the passing of our dear friend and colleague Tom Hennessey,<br />

Manager Business Development, Miller Waste Systems, on Tuesday September 16, 2014<br />

after a short illness.<br />

Tom joined the Miller/McAsphalt team in 1989 after retiring from his position of Senior Executive<br />

<strong>with</strong> Imperial Oil. Tom was the driving force in getting Miller/McAsphalt started in the service<br />

station business through McAsphalt Petroleum in the late 80's and 90's. In 1999 Tom joined Miller<br />

Waste Systems and played a major part in its growth and development over the years. He was<br />

instrumental in getting Miller started in the compost business and played a key role in the establishment<br />

of Miller's Bloomington Compost site and Miller's Compost facility in Halifax.<br />

Tom has served both as National Chair, and most recently, Ontario Regional Chair of The Compost<br />

Council of Canada. His dedication to the advancement of organics recycling and the compost<br />

industry was exceptional , contributing to the success of both Miller Compost and the industry<br />

as a whole. At the annual conference in Halifax this year Tom was to be presented The Compost<br />

Council of Canada's Compost Industry Pioneer Award recognizing Tom's lifetime commitment to<br />

The Compost Council of Canada and his tireless efforts towards assisting the compost industry.<br />

Tom was a key figure at the Compost Council of Canada and an advocate for the entire compost<br />

industry. He will be greatly missed.<br />

Richard MacDonald - MacDonald Paving & Construction<br />

Richard retired, after 40 years of service, as Vice President of MacDonald Paving & Construction<br />

Ltd., a company which his father established and was acquired by The Miller<br />

Group in 2007.<br />

Richard was happiest spending time <strong>with</strong> his family, in his back yard or attending<br />

Wildcats games and cherished his 1974 Plymouth Barracuda. He is sadly missed by his<br />

wife Francine, children Cheryl and James as well as many family members, friends and<br />

business colleagues.<br />

Remembering Our Colleagues<br />

We were very saddened to hear about the passing of our good friend and loyal cement tanker<br />

driver Tom Deakins on April 12, 2014. Tom started <strong>with</strong> Miller Cement in its early days in the<br />

90’s and was a key factor in the success of the group and its excellent personalized service.<br />

Tom would always greet his customers <strong>with</strong> a big smile and one of his many great country<br />

sayings. He could lift our spirits on the darkest of days and our customers would often ask<br />

specifically for Tom to make the delivery.<br />

Tom was the very essence of a “Miller Man” who always stepped forward to do what was<br />

necessary and when we needed help dispatching and loading out powder cement at our silos<br />

in Owen Sound he was there for us and of course did a great job in that role as well. Anyone<br />

who knew him will remember that he never finished a conversation <strong>with</strong>out mentioning his “Buttercup” - the love of his life. In<br />

the last few years of his career he decided to work a little closer to home and switched over to our E.C. King Contracting operation<br />

in Owen Sound running short hauls until 2006. Tom will be sadly missed by his family, friends, fellow workers and customers.<br />

Tony Pereira - Pave-Al<br />

On May 4th, 2014 Pave-Al lost a longtime friend and colleague <strong>with</strong> the passing of Tony<br />

Pereira. For over 20 years, Tony worked at Pave-Al as a concrete foreman, establishing<br />

himself as one of the most skilled and experienced foremen in the industry. Over recent<br />

years, Tony spent most of his time working on the Highway 7 VIVA H3 project as the lead<br />

concrete foreman for Pave-Al’s crews. Tony was respected and admired by all who knew<br />

him, and will be greatly missed.<br />

Joe Bettencourt - MSO Construction<br />

It is <strong>with</strong> sadness that we announce the sudden<br />

passing of one of our drivers Joe Bettencourt<br />

on Thursday, March 5, <strong>2015</strong>. Joe who was at the<br />

age of 54, had been a dedicated driver <strong>with</strong> MSO<br />

since 2012, but more importantly was a devoted<br />

father, uncle, and soon to be grandfather. Joe will<br />

be sadly missed by everyone at MSO.<br />

Tom Deakins - Miller Cement<br />

David Atkinson - Miller Waste Systems<br />

March 20, 1988 - November 9, 2014<br />

It takes a minute to find a special person, an hour to appreciate them, and a day<br />

to love them, but it takes a lifetime to forget them.<br />

Many of us met David a little over 2 years ago when he started <strong>with</strong> Miller. In<br />

that time, he made many friends and became a trusted member of the employee<br />

committee at the York Region Waste Management Centre. He was the kind<br />

of hard working, friendly, young man that made coming to work a bit easier<br />

for all of us. Even outside of work, it didn’t matter if it was a fun day outdoors, a<br />

day playing video games or beers <strong>with</strong> the boys; it was always a good time <strong>with</strong><br />

David.<br />

It is hard to lose such a great co-worker and friend, but one day we will meet<br />

again. Until then, Rest in Peace.<br />

Miller / McAsphalt Memory Tree<br />

Monique Sibb touched many of our lives during her years <strong>with</strong> Miller<br />

as she was also the President of the Employee Committee and well<br />

known by employees at all the Miller Group offices.<br />

It seemed fitting when some of the ladies from the office requested a<br />

tree be planted in memory of Monique. With that request it was decided<br />

to plant the tree at the beautiful setting of Vivian Pond but also<br />

extend the tribute a bit further.<br />

It is sad to say that we have many employees that have passed away<br />

therefore we appropriately named the tree the “MEMORY TREE” which<br />

is dedicated to ALL Miller/McAsphalt employees who have passed on.<br />

Rob & Dylan Sibb, Monsignor John Weber<br />

22 <strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

<strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

23<br />

www.millergroup.ca<br />

www.mcasphalt.com

IDENTIFY, AIM, EXECUTE<br />

DRIVEN TO BE THE BEST<br />

MSO Construction Limited<br />

2014 brought restructuring to MSO Construction. Chris Edgar was appointed Manager and<br />

moved his office to the Etobicoke site in order to lead this division.<br />

We also welcomed some new staff to MSO : James Frazer as MSO Shop Foreman. Jim Carroll as<br />

Supervisor Surface Treatment. Crystal Urquhart as Office Administrator and Zafer Kaoukdji as<br />

mechanic. All have done a great job and been well accepted . Thanks Guy’s and Gal.<br />

Micro Surfacing<br />

2014 was probably the busiest Micro Surfacing season<br />

to date. Led by Brad Fulton who secured 2 large Manitoba<br />

contracts and many local jobs our two crews were<br />

busy late into October.<br />

The crews, up to the task, hit the ground running under<br />

the direction of Dave, Mark and Shaun completing a<br />

large volume in a 3 month period. During this time<br />

the crews achieved multiple records previously held by<br />

competing contractors. In addition we received excellent<br />

reviews by our customer proving that we are “Only<br />

The Best”. Great job by all.<br />

Surface Treatment<br />

Jim Carroll took over the crew that is tasked <strong>with</strong> our more northern projects and did a great job completing that work and<br />

keeping the customers happy. That crew had a very successful stint in the Kenora area and completed all projects by the end of<br />

September a great accomplishment in itself , allowing<br />

adequate time to prepare for our winter operations.<br />

Ted McGillivary was back at the helm of our southern<br />

crew and had these projects wrapped up in late September<br />

as well after a trip on the MS Chi-Cheemaun<br />

to Manitoulin Island and the North Shore to complete<br />

some late tendered work in that area. Over all despite<br />

some rather challenging weather conditions to start<br />

the season everything went well. Thank you to all<br />

those involved.<br />

Dynapatch<br />

The crew was busy on various jobs across<br />

Southern/Central Ontario including Chatham-Kent,<br />

Lambton County, New Tecumseth<br />

and Town of Vaughan. We added a new customer<br />

this summer; Southgate Township used<br />

the dynapatch to strengthen shoulders and<br />

edges of the road prior to a micro surfacing<br />

application. Robert Gagnon took over the<br />

task of supervising this crew in mid stride<br />

and completed the work in fine fashion. Our<br />

people’s ability and flexibility to take on the<br />

unexpected makes us “Only the Best”.<br />

MSO Construction Limited Continued<br />

Equipment & Haulage<br />

Working closely <strong>with</strong> the Miller Transportation and Logistics<br />

Group the MSO fleet of tankers and floats kept busy all summer<br />

long ensuring liquid loads were delivered on time to asphalt<br />

plants and crews.<br />

MSO & Paveseal<br />

Winter Operations<br />

Winter 2013-2014 proved to be a challenging year for our people<br />

in winter works contracts. MSO holds multiple winter maintenance<br />

contracts <strong>with</strong> 407 ETR, City of Burlington, Oakville and<br />

Miller Maintenance on the 400 Series HWY’s. The hard work and dedication of winter staff demonstrates their ability to be Only the<br />

Best.<br />

This year MSO was successful in bidding the first tendered<br />

winter maintenance contract <strong>with</strong> the 407 ETR.<br />

Securing winter work on the highway for an additional<br />

8 years and options for 4 more, at the conclusion<br />

we will have provided maintenance to the 407 for<br />

over 30 years.<br />

MSO Shop<br />

MSO shop continued to be busy for the year dealing<br />

<strong>with</strong> the difficult winter and keeping equipment up<br />

and running through some of the worst storms in<br />

recent memory. Our mechanics work diligently to ensure<br />

that equipment is working and operating safely,<br />

these guy’s are Only the Best.<br />

The shop is responsible for ensuring the MSO fleet is ready to work at any time. They prepare over 100 winter trucks to make sure<br />

they are ready to go into winter operations. The shop also prepares all of our specialized summer equipment, making sure this<br />

equipment is ready for the busy summer construction season.<br />

Paveseal Limited<br />

Summer 2014 was a busy season for the hot in place asphalt patching machines operating<br />

under the Paveseal branch of MSO Construction. 4 Units operated continuously through the<br />

summer working on 4 City of Toronto contracts and other area Municipalities. This year the District<br />

of Muskoka utilized the process<br />

and worked a machine for more than<br />

a month in the spring prior to other<br />

contract work. Thank you to the hard<br />

working operators of these units for<br />

a successful 2014 season.<br />

24 <strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

<strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

25<br />

www.millergroup.ca<br />

www.mcasphalt.com

IDENTIFY, AIM, EXECUTE<br />

DRIVEN TO BE THE BEST<br />

GTA Operations<br />

Whitby Paving & Construction<br />

This year saw the start of Hwy 407 expanding to the east from Pickering and <strong>with</strong> this growth the Whitby Paving & Construction<br />

division needed to keep pace. We have strengthened our strong paving presence to include grading, sewer works and concrete<br />

curb & sidewalk operations. The goal is to be a self-performing operation, to minimize subcontracting and to better position<br />

ourselves to be a totally vertically integrated material, paving and construction operation. With an Asphalt Cement facility, Ready<br />

Mix operation, three asphalt plants and multiple pits & quarry operations <strong>with</strong>in Durham Region we want to be the supplier and<br />

contractor of choice for the East GTA market and continue to keep pace <strong>with</strong> the growing infrastructure east of Toronto.<br />

Below are several projects performed in 2014:<br />

Toronto Paving Group<br />

In Fall of 2014 the Toronto Paving Group successfully<br />

executed a new process, involving the quick turnaround<br />

rehabilitation of the bridge deck on the Hwy<br />

401 to Leslie St. off ramp in the City of Toronto. This<br />

work was contracted by the Ministry of Transportation-Ontario.<br />

Brennan Paving & Construction<br />

Region of Durham Reconstruction of Courtice Road –<br />

self performing all sewer works<br />

MTO 2013-4004 Hwy<br />

115 – Penhall our<br />

Concrete Grooving<br />

subcontractor<br />

MTO 2013-4004 Hwy 115 – internally constructed storage ponds<br />

to settle our concrete grooving operations effluent<br />

D2013-013 Region of Durham Overlay (Region Road 57 at<br />

Ceasarea) – self performed all excavation<br />

D2013-013 Region of Durham Overlay (Region<br />

Road 57 at Ceasarea) – rented a screening plant to<br />

perform all topsoil operations on site.<br />

This expedited bridge repair was made possible due<br />

to the successful production and application of two<br />

lifts of a Waterproofing Asphalt Mixture, circumventing<br />

the need for conventional waterproofing and<br />

paving.<br />

The goal of this Contract was to eliminate the long,<br />

drawn out process involved in conventional repair<br />

methods to a bridge of this nature. The conventional<br />

manner of repair would involve a two stage traffic<br />

approach, isolating one half of the structure at a<br />

time, utilizing temporary traffic paint, the installation<br />

of Temporary Concrete barrier wall, deck asphalt<br />

removal, bridge deck delamination repair utilizing<br />

conventional concrete patching, waterproofing<br />

utilizing conventional hot tar and protection board<br />

methods, followed by conventional Hot Mix Asphalt<br />

paving. One stage of this conventional process would<br />

take approximately two to three weeks. A project of<br />

this magnitude would require two stages, requiring<br />

from four to six weeks of activity <strong>with</strong> resulting traffic<br />

reductions. Brennan’s successful production and application<br />

of the Waterproofing Asphalt Mix, coupled<br />

<strong>with</strong> the successful application of a rapid set concrete patching mix has allowed the construction duration on this project to be<br />

compressed to a two weekend partial closure of the highway ramp, eliminating up to six weeks of traffic impediment and traffic<br />

slow down, substantially reducing the carbon footprint caused by idling vehicles, stuck in traffic jams.<br />

This project was only the second time this manner of construction was tendered by the Ministry of Transportation of Ontario. With<br />

limited success on the first work of this type, executed by one of our competitors, the Ministry had specified contractually that all<br />

steps in the production and placement of the mix must be monitored –continually- by representatives of the Chase Corporation.<br />

To that end, two engineering representatives from Chase travelled from the United States to witness Brennan’s operations. All<br />

aspects of our plant production, material handling, haulage, deck preparation, mix placement, finishing and compaction were<br />

very closely scrutinized. This was a scrutiny which Brennan welcomed. All aspects of the production and placement criteria met or<br />

exceeded the recommendations set forth by both Chase and the Ministry<br />

26 <strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

<strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

27<br />

www.millergroup.ca<br />

www.mcasphalt.com

IDENTIFY, AIM, EXECUTE<br />

DRIVEN TO BE THE BEST<br />

Brennan Paving & Construction<br />

Hwy 407 East Extension - Durham Region (Construction General Partnership)<br />

Brennan Paving and Construction was awarded work on the Highway 407 East Extension project for pre-cast culverts and structures,<br />

sewer and grading works in August 2013. Ground breaking<br />

commenced promptly in September 2013. On-site management and<br />

field staff work diligently to ensure all activities are done at above<br />

normal standards from office related to on-site works. Our team at<br />

the 407 project is fully committed to ensuring that The Miller Group<br />

is recognized for quality, safety and efficiency of work. The COR program<br />

has already been implemented on this project, getting ready<br />

for certification.<br />

Our team strives to have an above standard working relationship<br />

<strong>with</strong> our Client and sub-contractors to ensure work proceeds in a<br />

Brennan Paving & Construction<br />

GTA Construction – Concrete Paving MTO 2010-2001 (Hwy 404 Extension)<br />

The project involved concrete paving for the 404 extension<br />

from Green Lane to Queensville Side Road.<br />

For this project, Miller Concrete supplied the concrete for the<br />

project <strong>with</strong> our Erie Strayer Portable Concrete batch plant.<br />

Mainline Pavement was placed <strong>with</strong> our Gomaco PS-2600<br />

Placer/Spreader, Gomaco GHP-2800 2-Lane Paver and Gomaco<br />

IDBI (In-the-pan dowel bar inserter). During placement,<br />

in order to provide a smooth riding surface, a Gomaco GSI<br />

Smoothness Indicator was utilized. Deceleration lanes were<br />

completed <strong>with</strong> our Gomaco Commander III and CMI MTP-<br />

4004 Belt Placer.<br />

Earth excavation on Hwy 407 East Extension<br />

Cast-in-place concrete in Con-Span pre-cast culvert footings<br />

This section of the Hwy 407 was originally awarded to another contractor but the Hwy 407 East<br />

Group had serious doubts of that contractor’s capability of fulfilling the high expectations of<br />

the Group. They subsequently awarded the project to Brennan Paving.<br />

This new section includes, among other activities, 500,000 m3 of earth excavation and supply<br />

and placement of over 400,000 tons of Granular A from Miller’s Carden Quarry. Day after day,<br />

the Hwy 407 East Group looks at Brennan and Miller as reliable and dependable resources to<br />

assure excellent quality of<br />

work and on-time delivery.<br />

smooth, efficient, and profitable manner. Since the start of<br />

the project, 407ECGP contract administrators have looked<br />

for Brennan’s assistance on items which are beyond the<br />

original contract. Brennan has attained additional work by<br />

not only having a great relationship <strong>with</strong> the Client, but also<br />

<strong>with</strong>in the team at the 407 project. That way, Brennan has<br />

become the “Contractor of Choice” by the 407ECGP Team.<br />

Brennan was recently awarded another section of earth<br />

work in the west area (Segment A1) of the new highway.<br />

The Hwy 407 East Group needed to accelerate construction<br />

operations and they knew that Brennan would achieve any<br />

commitments we made on the project.<br />

Different Divisions of<br />

the Miller Group; Miller<br />

Aggregates, Miller Concrete,<br />

Transportation and<br />

Logistics, Miller Paving, Installation of pre-cast culvert arches<br />

and Brennan, have come<br />

together on the Hwy 407 East project to show once again that<br />

we are Only the Best!<br />

The Spider Saw in action<br />

Miller Paving utilized our ‘spider saw’ on this project.<br />

Unique in Canada to The Miller Group, this equipment<br />

performs the transverse relief cutting for our concrete<br />

paving work. Not only does this equipment ensure<br />

a perfect linear cut across the joint; it is also capable<br />

of performing this work at approximately double the<br />

rate as per conventional methods – ensuring that no<br />

random cracks develop due to late sawcutting.<br />

Miller Paving received a bonus on the concrete paving for the project due to the high level of quality associated <strong>with</strong> the ready<br />

mix concrete that was supplied and for the smoothness of the end product. This high level of quality proves our position <strong>with</strong>in<br />

the industry as – ONLY THE BEST!<br />

METROLINX Georgetown South Corridor Noisewall Construction<br />

In 2014 Brennan Paving and Construction landed their first<br />

Metrolinx contract to construct new 5.0m high noise walls<br />

and security fencing along the Metrolinx railway corridor<br />

for the Union Pearson Express (UP Service). Project value<br />

of $87.3M<br />

The project runs <strong>with</strong>in the railway corridor from downtown<br />

Toronto at Strachan Avenue to the north limit of<br />

Hwy 27 (approximately 13 km/ 26km of fence line) and our<br />

contract is made of 8.7 km of Noisewall, 10 km of Security<br />

fence and 6 km of Chain link and Farm fence.<br />

Target completion for this project is June <strong>2015</strong> to be ahead<br />

of the Pan-Am games.<br />

The noise walls are designed, built, and supplied by Armtec, a leading international supplier of these systems.<br />

Ditching for sub-drain installation<br />

28 <strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

<strong>MILLER</strong> / McASPHALT NEWSLETTER <strong>2015</strong> EDITION<br />

www.millergroup.ca<br />

www.mcasphalt.com<br />

29

IDENTIFY, AIM, EXECUTE<br />

DRIVEN TO BE THE BEST<br />

Brennan Paving & Construction<br />

VIVA D1 artist rendering of Davis Drive in Newmarket<br />

Viva Next D1 Project<br />

Brennan’s contract <strong>with</strong> Kiewit Ellis-Don (KED),<br />

a 3.0 km long Design-Build “Viva Next” Bus<br />

Rapid Transit expansion project ‘D1’ in Newmarket<br />

continued into its third year in 2014<br />

<strong>with</strong> construction along Davis Drive from<br />

Yonge Street easterly past the Southlake Regional<br />

Health Centre (Hospital) to Roxborough<br />

Road and Patterson Street. This rapid transportation<br />

network involves the widening of Davis<br />

Drive and the construction of a dedicated<br />

center-lane Bus Rapidway. The project also<br />

includes the construction of six semi-enclosed<br />

stations at various locations throughout the<br />

Rapidway including the installation of intelligent<br />

transportation systems. Additionally, the construction of 3 culvert extensions, installation of a new box culvert crossing Davis<br />

Drive, reconstructing the underground infrastructure (water/sanitary/storm), 18 retaining walls, and the widening and replacement<br />

of Keith Bridge are required. The project kicked off in 2011 <strong>with</strong> D1 Early Works construction helping to facilitate the required<br />

utility re-locations, and was completed in November of 2011. The civil portion of the D1 Project is valued at $54.2M.<br />

The location of the Viva Next project poses many interesting construction challenges due to the limited space for traffic and pedestrian<br />

diversion along the busy Davis Drive corridor. Traffic has been reduced to one lane in each direction <strong>with</strong> a centre median<br />

lane to facilitate left turns.<br />