AUTUMN

1SflouO

1SflouO

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

| contents page | news | events | advertisers’ index | contact |<br />

Metal AM in Japan<br />

Mutoh developed a metal AM system<br />

using arc-welding process in 2014.<br />

Yamazaki Mazak Co., a leading<br />

machine tool company, launched<br />

a hybrid type AM system combined<br />

with laser cladding and 5-axis milling<br />

in 2014 (Fig. 6) [9]. These machines<br />

are used for repairing and small lot<br />

production of very difficult-to-cut<br />

materials such as those used in<br />

the aerospace, energy and medical<br />

industries.<br />

Industrial applications for<br />

metal AM technology in<br />

Japan<br />

Mould and die making<br />

As mentioned above, the sales of<br />

metal AM systems in Japan have<br />

increased rapidly since 2013. Mould<br />

and die makers have installed hybrid<br />

Powder Bed Fusion machines to<br />

improve the performance of moulds<br />

by the effective arrangement of<br />

water cooling pipes and formation<br />

of deep rib as show in Fig. 7. These<br />

high performance moulds bring a<br />

significant reduction in moulding<br />

time along with quality improvements<br />

in finished products. According to<br />

an article published in Nikkei in<br />

June 2013, Panasonic planed to<br />

facilitate the mass production of<br />

home appliances using metal AM<br />

technology. It was stated that the use<br />

of metal AM technology for tooling<br />

would reduce production costs<br />

by 30% and significantly shorten<br />

manufacturing lead-time.<br />

OPM Laboratory Co., Ltd., a die<br />

design and milling-combined laser<br />

metal sintering process service<br />

bureau, was awarded a contract<br />

for research and application<br />

development using a hybrid laser<br />

PBF type machine [10].<br />

Aerospace<br />

The Japan Aerospace Exploration<br />

Agency (JAXA) plans to launch<br />

a new large-scale test rocket in<br />

2020. Mitsubishi Heavy Industries<br />

(MHI) therefore announced that it is<br />

considering using metal 3D printing<br />

to manufacture rocket parts as<br />

JAXA’s partner [11].<br />

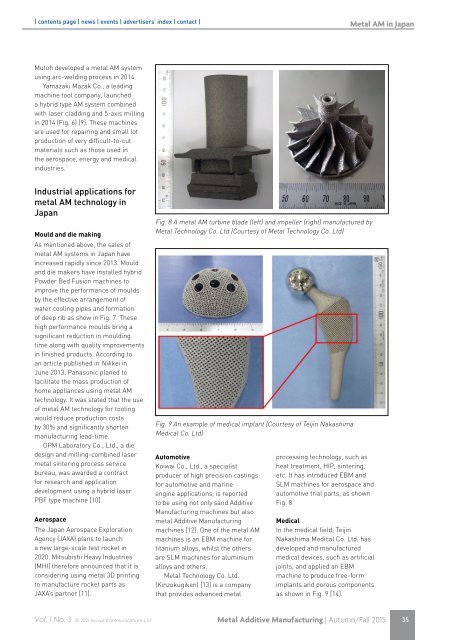

Fig. 8 A metal AM turbine blade (left) and impeller (right) manufactured by<br />

Metal Technology Co. Ltd (Courtesy of Metal Technology Co. Ltd)<br />

Fig. 9 An example of medical implant (Courtesy of Teijin Nakashima<br />

Medical Co. Ltd)<br />

Automotive<br />

Koiwai Co., Ltd., a specialist<br />

producer of high precision castings<br />

for automotive and marine<br />

engine applications, is reported<br />

to be using not only sand Additive<br />

Manufacturing machines but also<br />

metal Additive Manufacturing<br />

machines [12]. One of the metal AM<br />

machines is an EBM machine for<br />

titanium alloys, whilst the others<br />

are SLM machines for aluminium<br />

alloys and others.<br />

Metal Technology Co. Ltd.<br />

(Kinzokugiken) [13] is a company<br />

that provides advanced metal<br />

processing technology, such as<br />

heat treatment, HIP, sintering,<br />

etc. It has introduced EBM and<br />

SLM machines for aerospace and<br />

automotive trial parts, as shown<br />

Fig. 8<br />

Medical<br />

In the medical field, Teijin<br />

Nakashima Medical Co. Ltd. has<br />

developed and manufactured<br />

medical devices, such as artificial<br />

joints, and applied an EBM<br />

machine to produce free-form<br />

implants and porous components<br />

as shown in Fig. 9 [14].<br />

Vol. 1 No. 3 © 2015 Inovar Communications Ltd<br />

Metal Additive Manufacturing | Autumn/Fall 2015 35