AUTUMN

1SflouO

1SflouO

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Additive Manufacturing at PM Titanium 2015<br />

| contents page | news | events | advertisers’ index | contact |<br />

Fig. 6 Optical micrographs of heat treated samples built by EBM. (a) HT1. (b) HT3/HIP. (c) HT6/HIP [2]<br />

Max. Stress [MPa]<br />

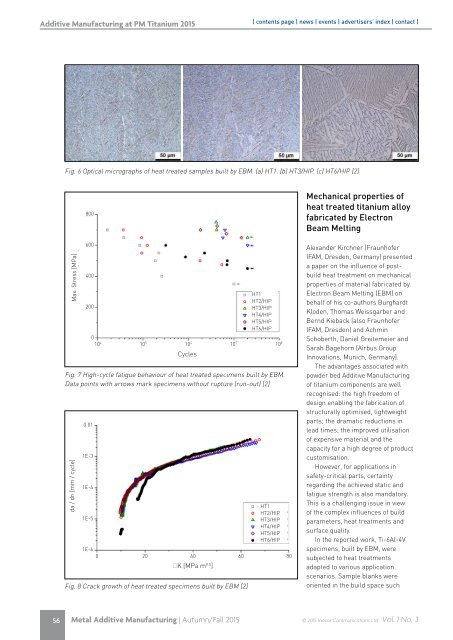

Fig. 7 High-cycle fatigue behaviour of heat treated specimens built by EBM.<br />

Data points with arrows mark specimens without rupture (run-out) [2]<br />

da / dn [mm / cycle]<br />

800<br />

600<br />

400<br />

200<br />

0.01<br />

1E-3<br />

1E-4<br />

1E-5<br />

0<br />

10 4<br />

1E-6<br />

0<br />

10 5<br />

10 6 10 7 10 8<br />

Cycles<br />

20 40 60 80<br />

ΔK [MPa m 0.5 ]<br />

Fig. 8 Crack growth of heat treated specimens built by EBM [2]<br />

HT1<br />

HT2/HIP<br />

HT3/HIP<br />

HT4/HIP<br />

HT5/HIP<br />

HT6/HIP<br />

HT1<br />

HT2/HIP<br />

HT3/HIP<br />

HT4/HIP<br />

HT5/HIP<br />

HT6/HIP<br />

Mechanical properties of<br />

heat treated titanium alloy<br />

fabricated by Electron<br />

Beam Melting<br />

Alexander Kirchner (Fraunhofer<br />

IFAM, Dresden, Germany) presented<br />

a paper on the influence of postbuild<br />

heat treatment on mechanical<br />

properties of material fabricated by<br />

Electron Beam Melting (EBM) on<br />

behalf of his co-authors Burghardt<br />

Kloden, Thomas Weissgarber and<br />

Bernd Kieback (also Fraunhofer<br />

IFAM, Dresden) and Achmin<br />

Schoberth, Daniel Greitemeier and<br />

Sarah Bagehorn (Airbus Group<br />

Innovations, Munich, Germany).<br />

The advantages associated with<br />

powder bed Additive Manufacturing<br />

of titanium components are well<br />

recognised: the high freedom of<br />

design enabling the fabrication of<br />

structurally optimised, lightweight<br />

parts; the dramatic reductions in<br />

lead times; the improved utilisation<br />

of expensive material and the<br />

capacity for a high degree of product<br />

customisation.<br />

However, for applications in<br />

safety-critical parts, certainty<br />

regarding the achieved static and<br />

fatigue strength is also mandatory.<br />

This is a challenging issue in view<br />

of the complex influences of build<br />

parameters, heat treatments and<br />

surface quality.<br />

In the reported work, Ti-6Al-4V<br />

specimens, built by EBM, were<br />

subjected to heat treatments<br />

adapted to various application<br />

scenarios. Sample blanks were<br />

oriented in the build space such<br />

56 Metal Additive Manufacturing | Autumn/Fall 2015<br />

© 2015 Inovar Communications Ltd Vol. 1 No. 3