Magazin "take off" - Issue 26 - FACC

Magazin "take off" - Issue 26 - FACC

Magazin "take off" - Issue 26 - FACC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

New Project:<br />

<strong>FACC</strong> develops and manufactures<br />

SSJ100 Cargo Compartment<br />

<strong>FACC</strong> Business Solutions:<br />

Competence in Process Management<br />

Consulting and Training<br />

Milestone:<br />

<strong>FACC</strong> Delivers 3000 th Shipset<br />

of Ram Air Inlets to Airbus<br />

<strong>26</strong><br />

07.10<br />

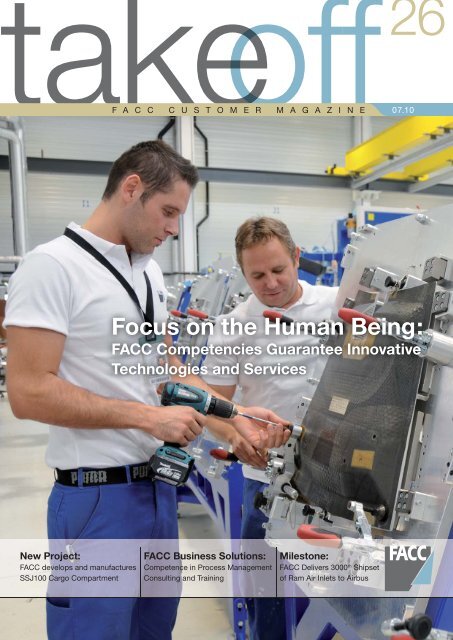

Focus on the Human Being:<br />

<strong>FACC</strong> Competencies Guarantee Innovative<br />

Technologies and Services

2<br />

<strong>take</strong>off F A C C C U S T O M E R M A G A Z I N E<br />

EDITORIAL CONTENTS<br />

Dear readers,<br />

Market data and news from the industry point out that<br />

the aviation branch is noticeably recovering. These are<br />

good conditions for suppliers as well. Even though uncertainties<br />

are still putting a strain on the mood on the<br />

market, notifi cations of both leading airplane manufacturers<br />

that they will once again expand production<br />

rates at least for the basic models A320 and Boeing<br />

737 are testimonials for an upward trend. Growth generators<br />

are still the high demand for airplanes in Asian<br />

countries, above all China, India, the Middle East and<br />

Russia. These are markets that <strong>FACC</strong> is also aiming<br />

for, namely in two strategic directions. On the one<br />

hand we are in business there as a supplier and on<br />

the following pages we will report about the recently<br />

begun cooperation with the Russian aerospace companies<br />

Sukhoi and Aerocomposit. On the other hand<br />

these regions are also interesting for the company as<br />

procurement markets. <strong>FACC</strong> works closely together<br />

with up-and-coming Asian supplier partners who by<br />

starting to act as aviation sub-suppliers want to profi t<br />

from the growth in the region. <strong>FACC</strong> wants to optimize<br />

the added value within the expanded supply chain by<br />

carrying through a targeted supplier qualifi cation and<br />

development program which is implemented by <strong>FACC</strong><br />

Business Solutions. <strong>FACC</strong> Business Solutions can<br />

profi t from many years of experience in working on international<br />

projects and also from the comprehensive<br />

competency of its employees and provides a tailored<br />

transfer of know-how. Read more about the comprehensive<br />

consultation and service spectrum of <strong>FACC</strong><br />

Business Solutions.<br />

As the most recent milestone for <strong>FACC</strong>, we would<br />

like to present the delivery of the 3000th shipset of Ram<br />

Air Inlets for the A320 family. You will also be informed<br />

about the expansion of the successful cooperation<br />

with Aviation Partners Boeing on the winglet program.<br />

One thing is sure – without the comprehensive competence<br />

and the excellent work done by the employees<br />

of <strong>FACC</strong>, such success stories would not be possible.<br />

On behalf of the entire team of editors, I hope you<br />

enjoy reading this issue of <strong>take</strong> off.<br />

Andrea Schachinger<br />

Editor<br />

PS.: We welcome your ideas and comments.<br />

<strong>take</strong>off@facc.at<br />

04 Developed in Record Time:<br />

Cargo Compartment for the SSJ100<br />

06 <strong>FACC</strong> Business Solutions:<br />

Competence in Process Management<br />

Consulting and Training<br />

10 Chinese VIPs Visit <strong>FACC</strong><br />

11 Winglets:<br />

Partnership With APB Extended<br />

12 3,000 th Ram Air Inlet<br />

Delivered to Airbus<br />

13 DIEHL Aircabin Supplier Award<br />

Goes to <strong>FACC</strong><br />

14 Supplier Award<br />

<strong>FACC</strong> Honours Their Best Suppliers<br />

15 Da Blechhauf‘n<br />

Live in Concert<br />

Published by: <strong>FACC</strong> AG, Fischerstraße 9, A-4910 Ried/Austria. Editorial Staff: Walter<br />

Stephan, Thomas Pleli, Robert Machtlinger, Andrea Schachinger. Photos: Manfred Lang<br />

Klagenfurt, Airbus Toulouse, Alois Furtner Ried, UAC Moskau, Saertex Saerbeck, SCAC<br />

Moskau, Austrian Airlines Wien, CYTEC, DIEHL Aircabin Laupheim, Hirnschrodt Ried, Pointecker<br />

Mehrnbach, <strong>FACC</strong> Ried. Design and Composition: Oskar Pointecker, 4941 Mehrnbach.

About a half year has passed<br />

since the Chinese aviation concern<br />

XAC acquired the majority of<br />

shares of <strong>FACC</strong>. These six months<br />

have been not only very labor intensive,<br />

but above all very successful<br />

for the “new” <strong>FACC</strong> AG. In the<br />

following lines I would like to go<br />

into detail about but a few of many<br />

events.<br />

A Positive Balance Sheet<br />

for the Financial Year<br />

The 2009/10 business year<br />

proved to be a diffi cult one for the<br />

aviation industry due to the economic<br />

environment and the effects<br />

of the crisis led to a stagnation of<br />

turnover for <strong>FACC</strong> AG. This is a development<br />

that will also continue<br />

into the current business year. It<br />

is so much the more satisfying to<br />

know that the move towards positive<br />

results in the operational area<br />

could be carried over to this year.<br />

The results of the profi t or loss on<br />

ordinary activities in the last year<br />

came to around 10.88 million euros<br />

in spite of a massive slump in the<br />

segment of business jets and ongoing<br />

major investments in product<br />

development.<br />

Retaining the Status Quo of<br />

<strong>FACC</strong> AG as an Independent<br />

Company and Continuing<br />

the Current Strategy<br />

Initially, the change of ownership<br />

structure of <strong>FACC</strong> and the<br />

resulting insecurity caused concern<br />

among our main customers<br />

regarding the future development<br />

of the company as a supplier. This<br />

subsequently caused them to be<br />

reluctant to give <strong>FACC</strong> new orders,<br />

which I could fully understand.<br />

Management and the new <strong>FACC</strong><br />

shareholders were, and still are,<br />

greatly concerned about calming<br />

and dispersing these misgivings. In<br />

presentations to and intense discussions<br />

with our customers, we<br />

were able to convince them that un-<br />

F A C C C U S T O M E R M A G A Z I N E<br />

Delivering Excellence and Value<br />

der the new ownership, the strategy<br />

of <strong>FACC</strong> AG will be unchanged and<br />

<strong>FACC</strong> AG will continue to operate as<br />

an independent company, working<br />

as a reliable partner with customers<br />

and suppliers all over the world. I<br />

was pleased to get the impression<br />

during numerous discussions that<br />

our customers and partners honor<br />

our commitment and plan to continue<br />

to put their trust in us. The<br />

recent placement of new orders for<br />

existing as well as for new aircraft<br />

programs has confi rmed this.<br />

As I see it, the core of our company<br />

strategy is to create added<br />

value for our customers through<br />

advanced products and services.<br />

In the process we want to position<br />

ourselves globally among the market<br />

leaders in technology, quality<br />

and costs in the three segments<br />

of aerosturctures, interiors and engine/nacelles.<br />

The “new” <strong>FACC</strong> AG<br />

can only be successful if it continues<br />

to receive further orders from<br />

companies that have been customers<br />

for years. Together with our<br />

international partners with whom<br />

we operate high-tech productions<br />

facilities and engineering offi ces in<br />

aviation growth markets, we want<br />

to remain interesting for our customers<br />

as a supplier and strategic<br />

partner by fulfi lling offset obligations<br />

in the strong markets.<br />

2010 – And Beyond:<br />

If we dare to <strong>take</strong> a look at the<br />

development of the aviation industry<br />

in the past decade, we can<br />

see that growth averaged only 1.6<br />

percent annually over 10 years and<br />

was almost exclusively in the regions<br />

of India, China, the Middle<br />

East and Russia - in regions that<br />

show strong economic growth and<br />

are in the USD economic zone. In<br />

addition, 2010 will be important in<br />

setting the future direction in the<br />

aviation market – in the segment of<br />

airplanes with seating for between<br />

125 and 225 we expect a re-orientation.<br />

There has been much discussion<br />

about whether the popular<br />

A320 and Boeing 737 models will<br />

be re-engined or simply replaced<br />

by new models; which other models<br />

will succeed on<br />

the market; and with<br />

how many other<br />

companies Airbus<br />

and Boeing will<br />

have to share their<br />

duopoly. These are<br />

questions that will<br />

be answered in the<br />

coming months.<br />

One thing is<br />

very important for<br />

<strong>FACC</strong>: we want to be<br />

present in the new<br />

growth markets as<br />

well as in new airplane<br />

programs, be<br />

it a re-engined version<br />

or successor<br />

of the Airbus A320 or Boeing 737,<br />

an MS-21, a C919, the Bombardier<br />

CSeries or others. With this goal<br />

in mind we are intensifying our research<br />

activities. In the process<br />

we are increasingly integrating our<br />

international supplier partners in<br />

order to be well-positioned with a<br />

global and innovative supply chain<br />

for world wide operations.<br />

“Delivering excellence and<br />

value” has always been our motto.<br />

This will not change with the “new”<br />

<strong>FACC</strong> AG and the new ownership<br />

structure. Thanks to our experience,<br />

our employees and our topquality<br />

technology, we will continue<br />

to perform excellent work for our<br />

partners and offer the best possible<br />

benefi ts for our customers.<br />

Walter A. Stephan<br />

Chairman of the Board<br />

<strong>FACC</strong> AG<br />

<strong>take</strong>off<br />

3

4<br />

<strong>take</strong>off F A C C C U S T O M E R M A G A Z I N E<br />

Developed in Record Time:<br />

Cargo Compartment<br />

for the SSJ100<br />

Time-to-market is a decisive success factor in the<br />

aviation industry. Those who are able to serve their<br />

customers quickly and with innovative added value<br />

can strengthen and expand their market position on a<br />

permanent basis. With the development of the cargo<br />

compartment for the SSJ100 regional jet, <strong>FACC</strong> has<br />

proven that launching a product speedily is no empty<br />

buzzword. This has enabled <strong>FACC</strong> to land the airplane<br />

manufacturer Sukhoi as a new customer and to<br />

open Russia as a new market.<br />

A mere three months passed<br />

from the granting of the contract<br />

to the fi rst delivery of the complete<br />

cargo compartment for the Superjet<br />

100, a new Russian passenger<br />

plane designed to carry 70 to 100<br />

passengers. In adherence to the<br />

strict project plan, <strong>FACC</strong> carried out<br />

the design, engineering, production,<br />

qualifi cation and certifi cation of the<br />

approximately 150 different components<br />

in this short time. In addition,<br />

the production tools had to be<br />

designed and built, numerous tests<br />

and the development and qualifi -<br />

cation of new processes had to be<br />

carried out. “We were able to stick<br />

to the tight schedule due to the fact<br />

that an experienced team worked<br />

according to the principle of concurrent<br />

engineering and prepared many<br />

work steps simultaneously,” said<br />

Erich Pamminger, the <strong>FACC</strong> chief<br />

engineer responsible for the project.<br />

“The open nature of our Russian<br />

business partner in project management,<br />

which made fast decisions<br />

possible when questions arose, and<br />

the smoothly running corporate cooperation<br />

helped to move the project<br />

along so swiftly.”<br />

At the end of March 2010, an<br />

<strong>FACC</strong> team travelled to Komsomolsk<br />

in the far east of Russia to carry<br />

out the fi rst installation of the cargo<br />

compartment on site at Sukhoi Civil<br />

Aircraft Company (SCAC). By June<br />

2010, on the basis of the experience<br />

of this fi rst installation individual design<br />

adjustments were carried out,<br />

the development phase of the project<br />

was successfully completed and the<br />

components were handed over for<br />

series production. In 2010 <strong>FACC</strong> will<br />

deliver a total of 10 cargo compartments<br />

and beginning 2011 the production<br />

rate will reach a volume of up<br />

to 60 per year.<br />

Complex System and Innovative<br />

Processes<br />

The contract covers the deliv-<br />

ery of front (5.5 m long x 2 m wide<br />

x 1 m high) and rear (6.4 m long<br />

x 2 m wide x 1 m high) cargo compartments.<br />

The main components<br />

are the ceiling and sidewall panels,<br />

gap covers and door linings. The<br />

entire cargo compartment is a sophisticated,<br />

complex system that<br />

has to fulfi l the strict requirements<br />

concerning technology, equipment<br />

and safety. “<strong>FACC</strong> has had years of<br />

experience with the manufacturing of<br />

individual cargo compartment components,”<br />

Pamminger explained.<br />

“This project is the fi rst time we have<br />

<strong>take</strong>n on the responsibility for the<br />

entire system including the electrical<br />

system, decompression and burnthrough<br />

resistance. This has given us<br />

the opportunity to once again prove

our comprehensive competence as<br />

a development and production partner.”<br />

In designing the various components,<br />

strict international standards<br />

for smoke gas tightness and burnthough<br />

resistance had to be <strong>take</strong>n<br />

into consideration.<br />

It was a totally new experience<br />

for <strong>FACC</strong> to develop a decompression<br />

valve along with its opening<br />

mechanism as well as the light and<br />

electrical supply with electrical components<br />

developed and qualifi ed<br />

by <strong>FACC</strong> for the fi rst time. A large<br />

share of the panels are produced using<br />

compression molding, whereby<br />

<strong>FACC</strong> has developed a new curing<br />

process that makes it possible to<br />

cure the panels in a very short process<br />

time.<br />

F A C C C U S T O M E R M A G A Z I N E<br />

Sukhoi Civil Aircraft Company<br />

and Superjet 100<br />

Sukhoi Civil Aircraft Company<br />

(SCAC) is a joint venture between<br />

Sukhoi Company (75%-1 share) and<br />

Alenia Aeronautica (25%+1 share)<br />

which is located in Moscow. SCAC<br />

was founded in 2000 with the goal of<br />

building new airplane models for civil<br />

aviation. SCAC has three production<br />

facilities in Komsomolsk, Novosibirsk<br />

and Voronezh, and more than 2,000<br />

employees.<br />

The company’s largest project is<br />

the manufacturing of the new airplane<br />

family Sukhoi Superjet 100. The two<br />

versions of the twin engine regional<br />

jet, the SSJ100-95B/LR and -75B/<br />

LR, built for 70 to 100 passengers, is<br />

a jewel in the crown of Russia’s civil<br />

aircraft industry. The fi rst passenger<br />

plane to be completely newly developed<br />

since the fall of communist<br />

Russia, it has also been designed for<br />

the global market, through the strategic<br />

partnership with Alenia Aeronautica<br />

and the help of around 30 western<br />

suppliers. SCAC concentrates on<br />

the area of design and development,<br />

marketing sales, and production as<br />

well as certifi cation of the planes.<br />

The worldwide after-sales support<br />

and sales in developed markets are<br />

overseen by Superjet International,<br />

a joint venture founded by Sukhoi<br />

Company and Alenia Aeronautica.<br />

Boeing Commercial Airplanes advises<br />

SCAC on the project, Snecma is a<br />

risk sharing partner. The fi rst fl ight of<br />

the SSJ100 took place in May 2008,<br />

and the commissioning of the fi rst<br />

plane by the Armenian airline Armavia<br />

is planned for 2010.<br />

<strong>take</strong>off<br />

5

6<br />

<strong>take</strong>off F A C C C U S T O M E R M A G A Z I N E<br />

<strong>FACC</strong> Business Solutions:<br />

Competence in Process Management<br />

Consulting and Training<br />

Turn-key business solutions are part of the basic requirements that OEM customers<br />

demand of their tier 1 suppliers. <strong>FACC</strong> has established an integrated product<br />

process chain – reaching from basic research to development, production and<br />

product support. As a partner to their customers, <strong>FACC</strong> is responsible for securing<br />

and improving all processes at <strong>FACC</strong> as well as in the supply chain.<br />

For strategic reasons, <strong>FACC</strong> is<br />

strengthening the cooperation with<br />

international suppliers, especially<br />

with the aviation industry in emerging<br />

markets. Companies in the global<br />

partner-supplier network carry<br />

out many composite and assembly<br />

operations for <strong>FACC</strong>. The tasks that<br />

are <strong>take</strong>n over by the suppliers are<br />

getting more and more complex.<br />

As a part of <strong>FACC</strong> Services, com-<br />

prehensive training programs developed<br />

for <strong>FACC</strong> employees are<br />

also offered to <strong>FACC</strong> partner companies.<br />

The “<strong>FACC</strong> Business Solutions”<br />

Guarantee Maximal<br />

Effi ciency<br />

The goal of the <strong>FACC</strong> Business<br />

Solutions is to effi ciently pass on to<br />

partner companies and suppliers<br />

the process know-how that <strong>FACC</strong><br />

has developed. Know-how transfer<br />

serves to accelerate supplier<br />

development and at the same time<br />

ensure the fl ow down of high level<br />

of quality requirements that is delivered<br />

from <strong>FACC</strong>. <strong>FACC</strong> provides<br />

services from a modular system<br />

that are specially customized to the<br />

partners requirement. This modular

<strong>FACC</strong> Business Solutions<br />

R&D<br />

<strong>FACC</strong> Business<br />

Solutions cover all<br />

areas in the process<br />

chain. Process management<br />

consulting<br />

and training are<br />

offered according<br />

to the need of the<br />

supplier partner as<br />

a total package or in<br />

individual modules.<br />

F A C C C U S T O M E R M A G A Z I N E<br />

Conceptual<br />

Design<br />

Product<br />

Support &<br />

Repair<br />

system includes consulting during<br />

the planning of product processes,<br />

concepts and layouts for<br />

machines and production facilities,<br />

the support and certifi cation during<br />

implementation of such facilities<br />

and equipment, the production<br />

start-up, as well as project and risk<br />

management, the consulting to establish<br />

quality assurance systems,<br />

engineering training or the training<br />

of the employees of suppliers.<br />

Employee Training and<br />

Qualifi cation as the Focus<br />

of Supplier Development<br />

A part of <strong>FACC</strong> Business Solutions<br />

is the targeted training and<br />

qualifi cation of employees of production<br />

partners. The competence<br />

of the employee in handling production<br />

means and processes so<br />

that the highest degree of effi ciency<br />

and cost-effectiveness are guar-<br />

Detail Design<br />

& Analyses<br />

Certifi cation<br />

& Testing<br />

anteed ensures the total success of<br />

the company. <strong>FACC</strong> follows an integral<br />

approach that already places<br />

the human being in the center of<br />

attention already in the course of<br />

production logistics - and this naturally<br />

also means that the employees<br />

must be as qualifi ed as possible.<br />

The instruction courses that <strong>FACC</strong><br />

offers are of cutting-edge quality<br />

as far as technology and teaching<br />

methods are concerned. Competent<br />

and seasoned employees<br />

provide practical consultation and<br />

instruction and contribute to the<br />

successful shaping of the suppliercustomer<br />

relationship. The foundations<br />

for these services are the long<br />

years of experience in numerous<br />

international large-scale projects<br />

for customers who support the<br />

strategy of <strong>FACC</strong> to outsource production<br />

projects to growth markets.<br />

Besides technical skills, the trainers<br />

possess a great deal of fl exibili-<br />

Material &<br />

Process<br />

Engineering<br />

Q-Engineering/<br />

Inspection<br />

ty, good foreign language skills and<br />

the necessary skills in dealing with<br />

foreign cultures and people.<br />

Besides their own locations or<br />

project support offi ces on site, it is<br />

above all the <strong>FACC</strong> training center<br />

that conveys to the suppliers comprehensive<br />

knowledge in the areas<br />

of composite engineering and composite<br />

production through specially<br />

planned training measures and<br />

establishes concrete and lasting<br />

competencies in the supply chain.<br />

Targeted training guarantees a pool<br />

of qualifi ed personnel and a further<br />

result smooth and effi cient production<br />

at the supplier’s location. In addition<br />

to qualifying the employees<br />

for the required work processes,<br />

great value is placed on the awareness<br />

of quality and the conveyance<br />

of the corporate and work philosophy<br />

of <strong>FACC</strong>.<br />

>><br />

<strong>take</strong>off<br />

Manufacturing<br />

Engineering<br />

Industrialization<br />

7

8<br />

Fig. 1<br />

Fig. 2<br />

<strong>take</strong>off F A C C C U S T O M E R M A G A Z I N E<br />

Modular Advanced Trainee Programm<br />

Block 1 Block 2 Block 3<br />

Theoretical /<br />

Classroom Training<br />

Composite<br />

– History / future of<br />

composites in the<br />

aerospace business<br />

– Components &<br />

materials<br />

– Facility & equipment<br />

– Tools & jigs<br />

– Production fl ow<br />

– Material<br />

administration<br />

– Bonding techniques<br />

Basic Operation<br />

Training (dual training:<br />

classroom & workshop<br />

training)<br />

– Lay-up process<br />

– Composite handling<br />

– Tool preparation /<br />

debagging<br />

– Core manufacturing /<br />

core preparation<br />

– Assembly processes<br />

– Quality basic<br />

Mainly workshop training<br />

combined with theorical<br />

input<br />

6 – 12 months timeline<br />

Modular Advanced Trainee Programm<br />

Welcome<br />

Training Modules<br />

Classroom Training<br />

Production<br />

Basics<br />

Blue Collar Trainings<br />

Trainings for Manufacturing / Quality Engineering<br />

Trainings for Program / Project Management<br />

Trainings for Operations / Planning<br />

Trainings for Engineering (Design & Stress)<br />

Evaluation / Testings<br />

On-the-job / Project<br />

oriented Engineering<br />

Training in Specialized<br />

Areas:<br />

– Manufacturing<br />

Engineering<br />

– Quality Engineering<br />

– Program/Project<br />

Management<br />

– Planning &<br />

Operations<br />

Output:<br />

– Project assignment<br />

(result)<br />

– Project documentation/paper<br />

– Project presentation<br />

Trainee Project / Documentation (Reports)<br />

Achieve<br />

Certifi cates<br />

KPI review meetings Presentation<br />

A Modular Concept for<br />

Custom-Made Turn-Key<br />

Solutions<br />

<strong>FACC</strong>’s training program includes<br />

more that 60 courses that<br />

are taught by around 20 in-company<br />

trainers – predominantly <strong>FACC</strong><br />

technical experts. In the framework<br />

of this training program new as well<br />

as existing employees are trained<br />

for their particular tasks. On the basis<br />

of the <strong>FACC</strong> in-company technical<br />

experts and the training experience<br />

of the <strong>FACC</strong> training center,<br />

a modular training concept has<br />

been developed specially for technically<br />

specifi c training in order to<br />

develop a global supply chain. The<br />

advantage of this modular system<br />

is that specifi c topics can be covered<br />

individually, depending on the<br />

complexity of the product. At the<br />

beginning of the training program,<br />

which is usually held within a time<br />

period of from 6 to 12 months, basic<br />

theoretical knowledge is dealt<br />

with, so to speak the fundamentals<br />

of the entire training (see block 1 in<br />

fi gure 1). Building on the foundation<br />

of block 1, technical topics of<br />

individual areas are then dealt with.<br />

Depending on the level of knowledge<br />

of the trainees, block 2 consists<br />

of a practical segment in the<br />

<strong>FACC</strong> training center and in specifi c<br />

productions areas, combined with<br />

theoretical input that are conveyed<br />

in classic classroom training. Block<br />

3 deals with product-specifi c training.<br />

In this phase the learners are<br />

trained on the job by <strong>FACC</strong> trainers.<br />

The trainees are instructed using all<br />

of the tools, processes, and auxiliary<br />

materials utilized at <strong>FACC</strong> specifi<br />

cally for each product or work<br />

area. In the process the progress<br />

that has been made is assessed in

egular intervals by the <strong>FACC</strong> team<br />

and this information is passed on to<br />

the supplier/partner, so that appropriate<br />

action can be <strong>take</strong>n in due<br />

time.<br />

In addition to classic blue collar<br />

courses, which are already being<br />

held for partners in Malaysia,<br />

India, the United Arab Emirates<br />

and China, among other locations,<br />

<strong>FACC</strong> also offers the opportunity<br />

to train technicians in the areas of<br />

manufacturing engineering, quality,<br />

project management and operations<br />

& planning in the framework<br />

(see Fig. 2). This trainee program<br />

consists of a theory segment as<br />

well as a practical part that teaches<br />

basic knowledge of materials and<br />

their preparation processes. In the<br />

following project-orientated block<br />

the trainees work in different areas<br />

on current projects, whereby the<br />

knowledge and skills which they<br />

learn and compile must be documented<br />

in a project paper.<br />

The range of instruction offered<br />

by <strong>FACC</strong> can also be <strong>take</strong>n advantage<br />

of by the supply partners at<br />

their own locations, should they so<br />

choose. In this case <strong>FACC</strong> determines<br />

the venue of the instruction,<br />

F A C C C U S T O M E R M A G A Z I N E<br />

helps in the choice of the trainees<br />

and sets up tailored teaching materials.<br />

If needed, <strong>FACC</strong> provides experienced<br />

trainers for a determined<br />

time period, who can be consulted<br />

during the implementation of the<br />

training program.<br />

Optimized Added Value –<br />

Increased Competitiveness<br />

The advantages of what <strong>FACC</strong><br />

Business Solutions offer are clear.<br />

In the course of the outsourcing<br />

process, <strong>FACC</strong> can effectively and<br />

effi ciently support their suppliers<br />

in improving and maximizing quality,<br />

costs and scheduling within the<br />

shortest time possible. A systematic<br />

supplier development helps<br />

<strong>FACC</strong> to reach its goal of optimizing<br />

the value added chain through<br />

global expansion of the supplier<br />

network and thus increase performance<br />

and competitiveness.<br />

The company places great store<br />

on responsible action in the entire<br />

supply chain, in order to establish<br />

and maintain stable and long term<br />

relations with business partners.<br />

This is the foundation for <strong>FACC</strong>’s<br />

efforts to further expand cooperation<br />

with strategic suppliers in the<br />

future.<br />

<strong>take</strong>off<br />

“We welcome the fact that <strong>FACC</strong> has consented<br />

to actively support EADS in their growth markets.<br />

With their existing competency in the industry of<br />

these markets, <strong>FACC</strong> is contributing to the international<br />

success of the European aerospace industry;<br />

safeguarding jobs in their own company on a long<br />

term basis; and strengthening their partnership with<br />

EADS.<br />

The current success in Abu Dhabi confi rms that<br />

due to <strong>FACC</strong>’s ability to<br />

– plan, defi ne and implement state-of-the-art production<br />

facilities and equipment<br />

– carry out certifi cation of the production facilities<br />

and their equipment<br />

– contribute innovative and state-of-the-art product<br />

and tooling know-how and<br />

– train employees on-site/off-site, i.e. on-site at the<br />

supply chain partner,<br />

the Austrian company is able to and has been able to<br />

make substantial contributions to our endeavours. “<br />

Klaus Kellerhoff<br />

SVP Industrial Globalisation<br />

EADS<br />

9

10<br />

COMAC Board of<br />

Directors representatives<br />

of XAC and <strong>FACC</strong><br />

discussed future<br />

strategic cooperation:<br />

from l. to r. Hang<br />

Huang, Vice Chief<br />

Engineer, Xian Aircraft<br />

International Corporation<br />

and Member of<br />

the Board of <strong>FACC</strong>;<br />

Robert Braunsberger,<br />

VP Engine/Nacelle<br />

<strong>FACC</strong>; Gerhard<br />

Mörtenhuber, VP<br />

Interior; <strong>FACC</strong>, Jian<br />

Meng, Senior VP of<br />

Xian Aircraft International<br />

Corporation and<br />

Member of the Board<br />

of <strong>FACC</strong>; Qingwei<br />

Zhang, Chairman of<br />

the Board, COMAC;<br />

Thomas Pleli, COO<br />

of <strong>FACC</strong> and Xinguo<br />

Zhang, AVIC VP.<br />

<strong>take</strong>off F A C C C U S T O M E R M A G A Z I N E<br />

Chinese VIPs Visit <strong>FACC</strong><br />

For many years <strong>FACC</strong> AG has been cooperating closely with Chinese companies<br />

in the aviation industry. This has been a close cooperation that will be further<br />

expanded under the new majority shareholder XAC. In June two high-ranking<br />

delegations from China came to visit <strong>FACC</strong>.<br />

Chinese Deputy Prime<br />

Minister in Reichersberg<br />

On June 21st the Deputy Prime<br />

Minister of the People’s Republic<br />

of China, Zhang Dejiang, along<br />

with several ministers, high-ranking<br />

politicians and businessmen, visited<br />

the <strong>FACC</strong> facility in Reichersberg.<br />

At the beginning of Decem-<br />

ber 2009 the <strong>take</strong>-over of <strong>FACC</strong> by<br />

the Chinese Xi’an Aircraft Industry<br />

Company (XAC) was completed,<br />

and now the new acquisition was<br />

presented to the highest Chinese<br />

government offi cials. In his speech,<br />

the Deputy Prime Minister assured<br />

the management and employees of<br />

<strong>FACC</strong> that the company location in<br />

Austria was secure: “Even though<br />

<strong>FACC</strong> now in large part belongs to<br />

AVIC concern, <strong>FACC</strong> will always be<br />

an Austrian company.” Lin Zuoming,<br />

Chairman of AVIC, the stateowned<br />

aviation concern and coowner<br />

of XAC, commented on the<br />

future of <strong>FACC</strong> in the large Chinese<br />

enterprise: “The purchase of <strong>FACC</strong><br />

is benefi cial to our fast-growing<br />

Chinese aviation industry. We build<br />

our own aircraft and we are also<br />

suppliers – for Boeing and Airbus.<br />

In the future we will be able to profi t<br />

by giving both many orders on the<br />

Chinese market. The two of us can<br />

only profi t from this.”<br />

COMAC Chairman Visits<br />

<strong>FACC</strong><br />

On July 2nd Zhang Qingwei,<br />

Chairman of the Chinese aviation<br />

company COMAC and leading representative<br />

of XAC visited <strong>FACC</strong>.<br />

The agenda included discussions<br />

about the work that <strong>FACC</strong> is doing<br />

on the ARJ21 program as well as<br />

the future strategic cooperation of<br />

the two companies. The delegation<br />

also inspected each <strong>FACC</strong> facility<br />

in order to get a picture of the advanced<br />

fi ber composite technology<br />

that the aviation supplier uses the<br />

manufacturing of aerostructures,<br />

interiors and engine nacelles.

F A C C C U S T O M E R M A G A Z I N E<br />

Winglets:<br />

Partnership with APB Extended<br />

The successful cooperation between <strong>FACC</strong> AG and Aviation Partners Boeing is<br />

going to continue: A contract extension was recently signed in Seattle that deals<br />

with the delivery of Blended Winglets TM for the Boeing 737 Next Generation as<br />

well as for the Boeing 757. The framework contract is for a volume of over $ 300<br />

million and stipulates delivery for the entire lifetime of the product – prospectively<br />

until into 2019.<br />

<strong>FACC</strong> and Aviation Partners<br />

Boeing (APB), located in Seattle,<br />

USA, started working together in<br />

2002 after signing a production<br />

contract and this cooperation has<br />

developed positively over the past<br />

years. So far <strong>FACC</strong> has equipped<br />

2,820 Boeing airplanes with winglets,<br />

and deliveries of a similar<br />

volume are planned for the next ten<br />

years. “We have had a lot of experience<br />

in the production of Blended<br />

WingletsTM and have been able to<br />

add a number of innovations to the<br />

winglet design, resulting in substantial<br />

weight reduction and costcutting,”<br />

says Martin Bögl, Director<br />

Aerostructures Programs. “The fact<br />

that our long-term partner APB has<br />

decided to continue our cooperation<br />

proves our delivery reliability<br />

and the quality of our services.”<br />

Aviation Partners Boeing is a<br />

joint venture between Aviation Partners,<br />

the inventor of the Blended<br />

WingletTM technology, and the airplane<br />

manufacturer Boeing and is<br />

responsible for marketing the aerodynamic<br />

wing tips. „Aviation Partners<br />

Boeing is delighted to extend<br />

its long-standing relationship with<br />

<strong>FACC</strong> to now include the full life of<br />

both our 737-NG and 757 Blended<br />

Winglet Programs. We have had a<br />

very successful eight-year partnership<br />

and we look forward to its continuation<br />

for many years to come,“<br />

says Dean Poor, Vice President of<br />

Operations, APB.<br />

<strong>FACC</strong> Develops and Manufactures Fuel Saving Winglets<br />

<strong>take</strong>off<br />

<strong>FACC</strong> is a system supplier of Blended Winglets to Aviation Partners Boeing and Boeing<br />

Seattle for the aircraft models Boeing BBJ, Boeing 737-700/-800, Boeing 757-200 and<br />

Boeing 737-900ER and manufactures all production and retrofi t Blended WingletsTM for<br />

these aircraft models. As a subcontractor of Aviation Partners, <strong>FACC</strong> also manufactured<br />

and developed the winglet prototypes for the Airbus A320. The responsibility for the<br />

production of the various winglet systems has allowed <strong>FACC</strong> to develop into a strongperformance<br />

competency center for winglets. The production line was planned to fulfi ll<br />

the requirements of high automatisation and the resulting shorter production time, as<br />

well as the use of the smallest production area. Due to these measures and the constant<br />

improvement of the product by our product technicians, an effi cient product is assured.<br />

11

12<br />

<strong>FACC</strong> CFO Bernhard<br />

Matzner (l) hands over<br />

the 3000th shipset of Ram<br />

Air Inlet for the A320<br />

family to Wilfried Eberhardt,<br />

Airbus Stade (r)<br />

<strong>take</strong>off F A C C C U S T O M E R M A G A Z I N E<br />

3,000 th Ram Air Inlet<br />

Delivered to Airbus<br />

On June 30, 2010 <strong>FACC</strong> AG delivered its 3,000 th shipset of Ram Air Inlets to Airbus<br />

Operations GmbH in Stade, Germany. The milestone Ram Air Inlets will be<br />

incorporated into an aircraft of the A320 family.<br />

Delivery of <strong>FACC</strong>‘s 3,000 th<br />

shipset of Ram Air Inlets, which<br />

marks more than 10 years of the<br />

partnership between Airbus and<br />

<strong>FACC</strong> on this program, occurred<br />

during a ceremony held at <strong>FACC</strong>‘s<br />

manufacturing facility in Ried, Austria.<br />

The system was delivered by<br />

Bernhard Matzner, CFO of <strong>FACC</strong><br />

AG, on behalf of the approximately<br />

40 employees on hand for the festivities<br />

to Wilfried Eberhardt, Manager<br />

Procurement, Airbus Stade.<br />

„We <strong>take</strong> great pride in this milestone,“<br />

noted Bernhard Matzner.<br />

„We value our long standing relationship<br />

with Airbus on this subcontract<br />

program. All <strong>FACC</strong> employees<br />

recognize its importance to the<br />

company and our customer. The<br />

good relationship with Airbus and<br />

the excellent cooperation within the<br />

<strong>FACC</strong> organization are responsible<br />

for ensuring that the project has always<br />

run smoothly over the year.”<br />

The Ram Air Inlet is part of<br />

the environmental control system,<br />

which provides air supply, thermal<br />

control and cabin pressurization for<br />

the passengers. The Ram Air Inlet<br />

is located on the wing-to-body fairing<br />

and controls the air temperature<br />

by providing cold air fl ow from outside<br />

to be mixed with the hot bleed<br />

air <strong>take</strong>n from the engine.<br />

<strong>FACC</strong> is a supplier of the Ram<br />

Air Inlet for the basic A320 model<br />

as well as the A318, A319, and A321<br />

models. In addition to the Ram Air<br />

Inlet, <strong>FACC</strong> also produces various<br />

engine nacelle components and<br />

cabin elements for the A320 family.

The Supplier Excellence Award<br />

was handed over in a ceremony<br />

held by DIEHL Aircabin in Laupheim.<br />

“The award proves that <strong>FACC</strong><br />

is a competent partner. Especially<br />

in diffi cult times, this recognition for<br />

highest quality and reliability confi<br />

rms that we are on the right track”,<br />

said Gerhard Mörtenhuber, Vice<br />

President Interiors of <strong>FACC</strong> AG.<br />

“It will remain our standard to offer<br />

top-performance for our customers<br />

world-wide.”<br />

Gerhard Mörtenhuber received<br />

the award from Laurent Bersot,<br />

Head of Procurement Aerostructures<br />

and Volker R. Schulte, Sen-<br />

F A C C C U S T O M E R M A G A Z I N E<br />

DIEHL Aircabin Supplier Award<br />

Goes to <strong>FACC</strong><br />

<strong>FACC</strong> AG is proud of a further award: DIEHL Aircabin GmbH, the German supplier<br />

for airplane cabin solutions, has awarded <strong>FACC</strong> the Supplier Excellence Award in<br />

the category “Top Performance”. With this award DIEHL Aircabin has recognized<br />

its most reliable suppliers for their above-average performance in the fi elds of<br />

costs, quality, delivery and service.<br />

ior Vice President Procurement of<br />

DIEHL Aircabin GmbH: “With this<br />

award we are showing appreciation<br />

for the successful, long-term cooperation<br />

in partnership with <strong>FACC</strong>.<br />

Due to their exemplary efforts in<br />

meeting the needs of their customer,<br />

<strong>FACC</strong> set an example last year.”<br />

<strong>FACC</strong> has been a supplier for<br />

DIEHL Aircabin for about ten years<br />

and supplies the German interior<br />

specialist with different parts<br />

of luggage compartments for the<br />

Airbus A380 and A320. Years of<br />

experience in development and<br />

production as well as innovations<br />

and fl exibility when confronted with<br />

last-minute changes by customers<br />

have resulted in a stronger cooperation<br />

between DIEHL Aircabin<br />

and <strong>FACC</strong> with an order of the A350<br />

program. The award for “Top Performance”<br />

underscores this decision<br />

and shows appreciation for the<br />

performance of the complete process<br />

chain. The award also refl ects<br />

the effi ciency of an organization.<br />

<strong>take</strong>off<br />

13<br />

With the Supplier<br />

Excellence Award<br />

DIEHL Aircabin recognizes<br />

its supplier<br />

<strong>FACC</strong> for their aboveaverage<br />

performance,<br />

f.r.t.l.: Laurent Bersot,<br />

Head of Procurement<br />

Aerostructures, DIEHL<br />

Aircabin; Volker R.<br />

Schulte, Senior Vice<br />

President Procurement,<br />

DIEHL Aircabin;<br />

Gerhard Mörtenhuber,<br />

Vice President Interiors,<br />

<strong>FACC</strong>; Michael<br />

Steirer, Senior Manager<br />

Interior Programs,<br />

<strong>FACC</strong> and Eveline<br />

Lindorfer, Manager<br />

Interior Programs,<br />

<strong>FACC</strong>

14<br />

<strong>take</strong>off F A C C C U S T O M E R M A G A Z I N E<br />

Supplier Award:<br />

<strong>FACC</strong> FA Honours Their Best Suppliers<br />

A co company relies on its suppliers to ensure quality, competitiveness and customer<br />

satisfaction; satis therefore making a signifi cant contribution to our own business suc-<br />

cess cess. <strong>FACC</strong> AG have honoured three of their suppliers for exceptional commitment<br />

and<br />

exemplary performance with an “Excellent Supplier Award 2009” in Gold, Silver<br />

and<br />

Bronze. In addition, an organisation has also been chosen to receive a “Special<br />

Performance Award” in recognition of their services and total support.<br />

The Excellent Supplier Suppli Awards 2009 go to<br />

the following companies:<br />

Excellent Supplier Award in GOLD:<br />

ISOVOLTA AG<br />

Located in Wiener Neudorf, Austria<br />

Manufacture of high-pressure laminates and fl exible insulating<br />

materials for the electrical industry; technical composites<br />

and semi-fi nished products for aircraft interiors<br />

Excellent Supplier Award in SILVER:<br />

S-FASTENERS GMBH<br />

Located in Baden-Württemberg, Germany<br />

S-Fasteners manufacture the Latch and Hinge system for<br />

the A320 Enhanced Cabin Overhead Storage Compartments<br />

as well as other various fasteners for <strong>FACC</strong> and the<br />

aerospace industry<br />

Excellent Supplier Award in BRONZE:<br />

ENIKON-COMPOSITE<br />

Located in Zagreb, Croatia<br />

Enikon performs preparation work for painting (washing, puttying<br />

and grinding), primer and fi nal coating of aircraft interior<br />

composite, plastic and metal parts for the for the A320<br />

Special Performance Award:<br />

PANALPINA<br />

Located in Linz, Austria<br />

Panalpina is a global forwarding and logistics service<br />

provider who’s dedicated and expert teams help solve<br />

complex logistics tasks. Their global Air Freight network<br />

of hubs and sub-hubs, combined with an integrated Road<br />

Feeder Service or Ocean Freight connections, offers<br />

door-to-door delivery anywhere in the world<br />

The <strong>FACC</strong> Excellent Supplier Award 2009 in Gold goes to Isovolta:<br />

f.l. Andrea Hemetsberger, Procurement, <strong>FACC</strong>; Raimund Fritzl, Head<br />

of Research & Development, Isovolta; Rudolf Leitner, Director of Purchasing,<br />

<strong>FACC</strong>; Kurt Bussecker, Sales & Marketing Director, Isovolta;<br />

Heinz Riedler, Division President, Isovolta; Johann Ondrejas, Technology,<br />

Transportation Prepregs & Laminates, Isovolta; Thomas Bögl, Procurement<br />

Quality Assurance, <strong>FACC</strong> and Stefan Rathwallner, Composite<br />

Buyer, <strong>FACC</strong><br />

The main nomination selection<br />

criterion for an <strong>FACC</strong> “Excellent<br />

Supplier Award” is the continual<br />

provision of both High Quality<br />

products and reliable adherence to<br />

Delivery Requirements. Additional<br />

factors also <strong>take</strong>n into consideration<br />

are: customer service, fl exibility,<br />

co-operation and a willingness<br />

to develop, accept and implement<br />

cost-saving and process-optimising<br />

measures. The “Special Performance<br />

Award“ is presented to<br />

a supplier or organisation whose<br />

performance cannot be measured<br />

by conventional methods, but have<br />

consistently shown outstanding<br />

commitment to both <strong>FACC</strong> and its<br />

customers.<br />

With the annual “Excellent<br />

Supplier Awards”, <strong>FACC</strong> publicly<br />

recognises and rewards optimum<br />

suppliers within its own supply<br />

chain. The Director of Purchasing<br />

Mr. Rudolf Leitner stated: “It is extremely<br />

important to recognise and<br />

reward those suppliers who through<br />

their own diligence and competitive<br />

partnership enable <strong>FACC</strong> to maintain<br />

a ‘spirited edge’ in an on-going<br />

changing and progressive market<br />

environment. These annual awards<br />

and presentations allow <strong>FACC</strong> an<br />

opportunity of showing our gratitude<br />

and appreciation to such suppliers<br />

and organisations who fulfi l<br />

the criteria”.

F A C C C U S T O M E R M A G A Z I N E<br />

Da Blechhauf‘n<br />

Live in Concert<br />

Brass meets composite. For the fi rst time ever,<br />

<strong>FACC</strong> opened its doors for a concert. On Labour Day,<br />

May 1, production shut down in order to make room<br />

for the brass band “da Blechhauf’n”.<br />

“Da Blechhauf’n” is Burgenland’s<br />

most prominent boy brass<br />

band. These seven men, who have<br />

all studied music, offer a wide range<br />

of different types of brass music.<br />

They are musically rooted in polka<br />

rhythms, marches or waltzes.<br />

A Musical Cabaret of a<br />

Different Kind<br />

The group thrilled the audience<br />

in the <strong>FACC</strong> Reichersberg facility<br />

with their concert “In vino veritas”,<br />

a terrifi c balancing act between the<br />

most varied music genres. The entertainers<br />

complemented their music<br />

program with an amazing brass<br />

show. The seven musicians were a<br />

hit – serious as well as ironic and<br />

each one of them a ball of fi re – a<br />

bit off the wall, witty, loud, cynical<br />

and sometimes slightly dubious.<br />

They play the entire range of brass<br />

– high, low and the lowest – and<br />

they also show their fl ippant humor,<br />

recite and dance. They are real pros<br />

and give a wonderful performance.<br />

“Da Blechhauf’n” – much more than<br />

just a concert.<br />

Look for further information and<br />

an audio sample of “da Blechhauf’n”<br />

on their homepage<br />

www.blechhaufn.at<br />

<strong>take</strong>off<br />

15

Lufthansa A380 in Vienna:<br />

<strong>FACC</strong> Components on a Stopover in Austria<br />

On June 2, 2010, the new A380 „Frankfurt am Main“ fi nally landed in Vienna for the fi rst time.<br />

On board the Lufthansa fl agship were various components and systems from <strong>FACC</strong> AG.<br />

<strong>FACC</strong><br />

A-4910 Ried/Austria, Fischerstraße 9<br />

Tel. +43/59/616-0, Fax +43/59/616-81000<br />

e-mail: offi ce@facc.at, www.facc.co.at