Magazin "take off" - Issue 26 - FACC

Magazin "take off" - Issue 26 - FACC

Magazin "take off" - Issue 26 - FACC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

8<br />

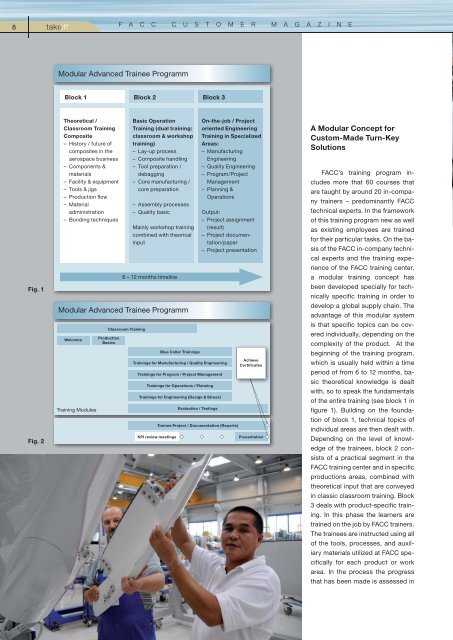

Fig. 1<br />

Fig. 2<br />

<strong>take</strong>off F A C C C U S T O M E R M A G A Z I N E<br />

Modular Advanced Trainee Programm<br />

Block 1 Block 2 Block 3<br />

Theoretical /<br />

Classroom Training<br />

Composite<br />

– History / future of<br />

composites in the<br />

aerospace business<br />

– Components &<br />

materials<br />

– Facility & equipment<br />

– Tools & jigs<br />

– Production fl ow<br />

– Material<br />

administration<br />

– Bonding techniques<br />

Basic Operation<br />

Training (dual training:<br />

classroom & workshop<br />

training)<br />

– Lay-up process<br />

– Composite handling<br />

– Tool preparation /<br />

debagging<br />

– Core manufacturing /<br />

core preparation<br />

– Assembly processes<br />

– Quality basic<br />

Mainly workshop training<br />

combined with theorical<br />

input<br />

6 – 12 months timeline<br />

Modular Advanced Trainee Programm<br />

Welcome<br />

Training Modules<br />

Classroom Training<br />

Production<br />

Basics<br />

Blue Collar Trainings<br />

Trainings for Manufacturing / Quality Engineering<br />

Trainings for Program / Project Management<br />

Trainings for Operations / Planning<br />

Trainings for Engineering (Design & Stress)<br />

Evaluation / Testings<br />

On-the-job / Project<br />

oriented Engineering<br />

Training in Specialized<br />

Areas:<br />

– Manufacturing<br />

Engineering<br />

– Quality Engineering<br />

– Program/Project<br />

Management<br />

– Planning &<br />

Operations<br />

Output:<br />

– Project assignment<br />

(result)<br />

– Project documentation/paper<br />

– Project presentation<br />

Trainee Project / Documentation (Reports)<br />

Achieve<br />

Certifi cates<br />

KPI review meetings Presentation<br />

A Modular Concept for<br />

Custom-Made Turn-Key<br />

Solutions<br />

<strong>FACC</strong>’s training program includes<br />

more that 60 courses that<br />

are taught by around 20 in-company<br />

trainers – predominantly <strong>FACC</strong><br />

technical experts. In the framework<br />

of this training program new as well<br />

as existing employees are trained<br />

for their particular tasks. On the basis<br />

of the <strong>FACC</strong> in-company technical<br />

experts and the training experience<br />

of the <strong>FACC</strong> training center,<br />

a modular training concept has<br />

been developed specially for technically<br />

specifi c training in order to<br />

develop a global supply chain. The<br />

advantage of this modular system<br />

is that specifi c topics can be covered<br />

individually, depending on the<br />

complexity of the product. At the<br />

beginning of the training program,<br />

which is usually held within a time<br />

period of from 6 to 12 months, basic<br />

theoretical knowledge is dealt<br />

with, so to speak the fundamentals<br />

of the entire training (see block 1 in<br />

fi gure 1). Building on the foundation<br />

of block 1, technical topics of<br />

individual areas are then dealt with.<br />

Depending on the level of knowledge<br />

of the trainees, block 2 consists<br />

of a practical segment in the<br />

<strong>FACC</strong> training center and in specifi c<br />

productions areas, combined with<br />

theoretical input that are conveyed<br />

in classic classroom training. Block<br />

3 deals with product-specifi c training.<br />

In this phase the learners are<br />

trained on the job by <strong>FACC</strong> trainers.<br />

The trainees are instructed using all<br />

of the tools, processes, and auxiliary<br />

materials utilized at <strong>FACC</strong> specifi<br />

cally for each product or work<br />

area. In the process the progress<br />

that has been made is assessed in