MU July / August 2016

Machinery Update Issue 4, Volume XXVII, July / August 2016

Machinery Update Issue 4, Volume XXVII, July / August 2016

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

52 MACHINERY UPDATE JULY/AUGUST <strong>2016</strong> www.machineryupdate.co.uk<br />

Feature: Automation, robotics and vision<br />

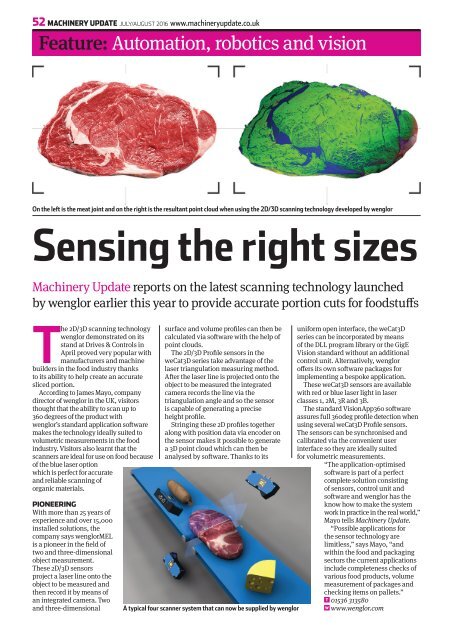

On the left is the meat joint and on the right is the resultant point cloud when using the 2D/3D scanning technology developed by wenglor<br />

Sensing the right sizes<br />

Machinery Update reports on the latest scanning technology launched<br />

by wenglor earlier this year to provide accurate portion cuts for foodstuffs<br />

The 2D/3D scanning technology<br />

wenglor demonstrated on its<br />

stand at Drives & Controls in<br />

April proved very popular with<br />

manufacturers and machine<br />

builders in the food industry thanks<br />

to its ability to help create an accurate<br />

sliced portion.<br />

According to James Mayo, company<br />

director of wenglor in the UK, visitors<br />

thought that the ability to scan up to<br />

360 degrees of the product with<br />

wenglor’s standard application software<br />

makes the technology ideally suited to<br />

volumetric measurements in the food<br />

industry. Visitors also learnt that the<br />

scanners are ideal for use on food because<br />

of the blue laser option<br />

which is perfect for accurate<br />

and reliable scanning of<br />

organic materials.<br />

PIONEERING<br />

With more than 25 years of<br />

experience and over 15,000<br />

installed solutions, the<br />

company says wenglorMEL<br />

is a pioneer in the field of<br />

two and three-dimensional<br />

object measurement.<br />

These 2D/3D sensors<br />

project a laser line onto the<br />

object to be measured and<br />

then record it by means of<br />

an integrated camera. Two<br />

and three-dimensional<br />

surface and volume profiles can then be<br />

calculated via software with the help of<br />

point clouds.<br />

The 2D/3D Profile sensors in the<br />

weCat3D series take advantage of the<br />

laser triangulation measuring method.<br />

After the laser line is projected onto the<br />

object to be measured the integrated<br />

camera records the line via the<br />

triangulation angle and so the sensor<br />

is capable of generating a precise<br />

height profile.<br />

Stringing these 2D profiles together<br />

along with position data via encoder on<br />

the sensor makes it possible to generate<br />

a 3D point cloud which can then be<br />

analysed by software. Thanks to its<br />

A typical four scanner system that can now be supplied by wenglor<br />

uniform open interface, the weCat3D<br />

series can be incorporated by means<br />

of the DLL program library or the GigE<br />

Vision standard without an additional<br />

control unit. Alternatively, wenglor<br />

offers its own software packages for<br />

implementing a bespoke application.<br />

These weCat3D sensors are available<br />

with red or blue laser light in laser<br />

classes 1, 2M, 3R and 3B.<br />

The standard VisionApp360 software<br />

assures full 360deg profile detection when<br />

using several weCat3D Profile sensors.<br />

The sensors can be synchronised and<br />

calibrated via the convenient user<br />

interface so they are ideally suited<br />

for volumetric measurements.<br />

“The application-optimised<br />

software is part of a perfect<br />

complete solution consisting<br />

of sensors, control unit and<br />

software and wenglor has the<br />

know how to make the system<br />

work in practice in the real world,”<br />

Mayo tells Machinery Update.<br />

“Possible applications for<br />

the sensor technology are<br />

limitless,” says Mayo, “and<br />

within the food and packaging<br />

sectors the current applications<br />

include completeness checks of<br />

various food products, volume<br />

measurement of packages and<br />

checking items on pallets.”<br />

T 01536 313580<br />

W www.wenglor.com