PRACTICES

nastt-ne-journal-2016

nastt-ne-journal-2016

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HORIZONTAL<br />

FEET<br />

VERTICAL<br />

FEET<br />

After the land leg tunnel construction is<br />

complete, the contractor will continue with<br />

other work necessary for installation of the<br />

valve chamber structure, connection with<br />

the tunnel, and finishing for LLO mechanical<br />

work within the gate shaft to control the<br />

water release into Schoharie Creek.<br />

MICROTUNNELING CONSTRUCTION<br />

FOR LOW LEVEL OUTLET TUNNELS<br />

Air lock hyperbaric chamber allows safe personnel access to the tunnel face<br />

plished predominantly from the reservoir<br />

surface with a working barge platform. The<br />

finished grades will be verified by sonar.<br />

The Crest of the Gilboa Dam (full pool) is<br />

1130.00 feet while the bottom reservoir sediment<br />

layer at the intake and MTBM receiving<br />

site is recorded at El. 996 feet. As part<br />

of the receiving site and intake structure<br />

foundation preparation, it is required that<br />

the limits of the intake structure foundation<br />

be dredged with hydraulic and mechanical<br />

techniques to remove the sediment and<br />

glacial till respectively.<br />

The dredged limits of the receiving site<br />

are to be replaced with tremie concrete for<br />

75-feet along the tunnel alignment and<br />

around the 30-foot diameter, 26-foot tall<br />

cofferdam built at the center line of the<br />

water leg tunnel to the Jacking Shaft. The<br />

cofferdam will be fitted with a prefabricated<br />

breakout eye for the MTBM reception and<br />

filled with sand pending the arrival of the<br />

MTBM at the completion of the water leg<br />

tunnel mining.<br />

After tunnel construction is complete, a<br />

specialty underwater diving team will install<br />

the intake elbow within the cofferdam and<br />

secure it in place with tremie concrete, the<br />

bulkhead atop the elbow and the intake<br />

structure atop the cofferdam. The bulkhead<br />

atop the elbow will remain in the closed position<br />

until the tunnel is ready to be flooded.<br />

RECEIVING SITE AT<br />

PORTAL/VALVE CHAMBER<br />

The receiving site for the land leg microtunneling<br />

is downstream of the dam at the portal,<br />

along the bank of Schoharie Creek. This portal<br />

will remain as the eastern wall for the opencut<br />

excavation portal housing the bifurcation<br />

piping connection between the tunnel and the<br />

valve chamber, which controls drawdown of<br />

the reservoir. Preparation required to receive<br />

the MTBM includes a 10-foot cube grout plug<br />

installed to stabilize the hole-through area at<br />

the portal face for MTBM break-out upon<br />

completion of the land leg tunnel.<br />

The two tunnel segments are to be constructed<br />

utilizing a 108-inch-diameter MTBM<br />

with slurry pressurized face (AVN2200AB)<br />

manufactured by Herrenknecht. Per contract<br />

requirements, the new MTBM is specifically<br />

designed and fabricated for use on the LLO<br />

project. The MTBM design requirements<br />

include the ability to mine through mixed<br />

ground conditions containing cobbles and<br />

boulders sized up to 30% of the outside diameter<br />

of the MTBM. It is also designed to operate<br />

under external hydrostatic pressure equivalent<br />

to 153 feet of water head, allowing for<br />

underwater retrieval. The MTBM is required<br />

to be equipped with an air lock hyperbaric<br />

chamber which allows safe personnel access to<br />

the tunnel face for obstruction intervention or<br />

disc cutter maintenance under pressures up to<br />

5 bar. An extensive list of additional functionalities<br />

for the MTBM is included in the design<br />

requirement.<br />

The jacking pipe scheduled for use as the<br />

initial and final ground support, for both land<br />

and water leg tunnels, is 108-inch, 1.375-inch<br />

thick Permalok steel pipe with T-7 gasketed<br />

joints. Two intermediate jacking stations are<br />

required for each of the tunnel legs. Utilization<br />

of butt welded steel jacking pipe joints<br />

are not allowed for this project.<br />

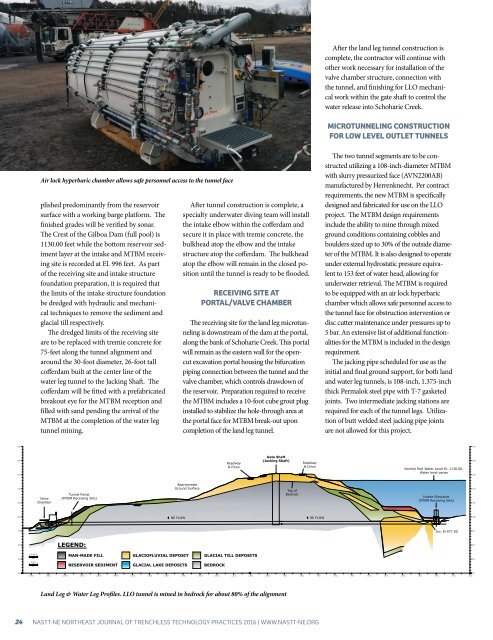

1250<br />

1250<br />

1200<br />

1150<br />

Roadway<br />

& Drive<br />

Gate Shaft<br />

(Jacking Shaft)<br />

Roadway<br />

& Drive<br />

Normal Pool Water Level El. 1130.00.<br />

Water level varies<br />

1200<br />

1150<br />

1100<br />

1050<br />

Valve<br />

Chamber<br />

Tunnel Portal<br />

(MTBM Receiving Site)<br />

Approximate<br />

Ground Surface<br />

Top of<br />

Bedrock<br />

Intake Structure<br />

(MTBM Receiving Site)<br />

1100<br />

1050<br />

1000<br />

NE FLOW<br />

SE FLOW<br />

~<br />

1000<br />

950<br />

Inv. El 977.00<br />

950<br />

900<br />

LEGEND:<br />

900<br />

850<br />

MAN-MADE FILL<br />

GLACIOFLUVIAL DEPOSIT<br />

GLACIAL TILL DEPOSITS<br />

850<br />

RESERVOIR SEDIMENT<br />

GLACIAL LAKE DEPOSITS<br />

BEDROCK<br />

800<br />

800<br />

24+00<br />

23+00 22+00<br />

21+00 20+00 19+00 18+00 17+00 16+00 15+00 14+00 13+00 12+00<br />

11+00<br />

10+00 9+00 8+00 7+00 6+00 5+00 4+00 3+00 2+00 1+00 0+00<br />

-1+00<br />

-2+00<br />

Land Leg & Water Leg Profiles. LLO tunnel is mined in bedrock for about 80% of the alignment<br />

24 NASTT-NE NORTHEAST JOURNAL OF TRENCHLESS TECHNOLOGY <strong>PRACTICES</strong> 2016 | WWW.NASTT-NE.ORG