Copper Alliance HSDG Australia

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

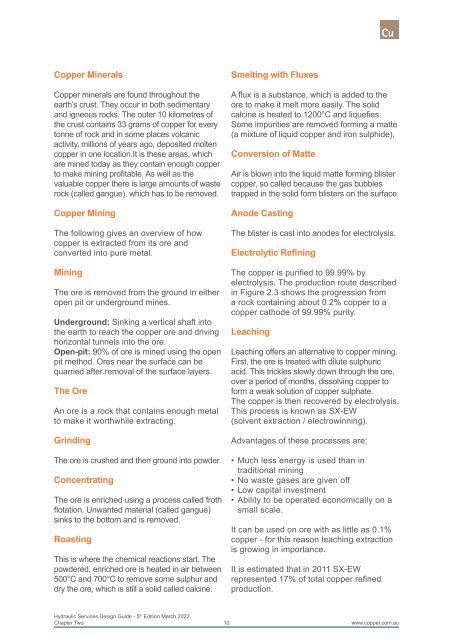

<strong>Copper</strong> Minerals<br />

<strong>Copper</strong> minerals are found throughout the<br />

earth’s crust. They occur in both sedimentary<br />

and igneous rocks. The outer 10 kilometres of<br />

the crust contains 33 grams of copper for every<br />

tonne of rock and in some places volcanic<br />

activity, millions of years ago, deposited molten<br />

copper in one location.It is these areas, which<br />

are mined today as they contain enough copper<br />

to make mining profitable. As well as the<br />

valuable copper there is large amounts of waste<br />

rock (called gangue), which has to be removed.<br />

<strong>Copper</strong> Mining<br />

The following gives an overview of how<br />

copper is extracted from its ore and<br />

converted into pure metal.<br />

Mining<br />

The ore is removed from the ground in either<br />

open pit or underground mines.<br />

Underground: Sinking a vertical shaft into<br />

the earth to reach the copper ore and driving<br />

horizontal tunnels into the ore.<br />

Open-pit: 90% of ore is mined using the open<br />

pit method. Ores near the surface can be<br />

quarried after removal of the surface layers.<br />

The Ore<br />

An ore is a rock that contains enough metal<br />

to make it worthwhile extracting.<br />

Grinding<br />

The ore is crushed and then ground into powder.<br />

Concentrating<br />

The ore is enriched using a process called froth<br />

flotation. Unwanted material (called gangue)<br />

sinks to the bottom and is removed.<br />

Roasting<br />

This is where the chemical reactions start. The<br />

powdered, enriched ore is heated in air between<br />

500°C and 700°C to remove some sulphur and<br />

dry the ore, which is still a solid called calcine.<br />

Smelting with Fluxes<br />

A flux is a substance, which is added to the<br />

ore to make it melt more easily. The solid<br />

calcine is heated to 1200°C and liquefies.<br />

Some impurities are removed forming a matte<br />

(a mixture of liquid copper and iron sulphide).<br />

Conversion of Matte<br />

Air is blown into the liquid matte forming blister<br />

copper, so called because the gas bubbles<br />

trapped in the solid form blisters on the surface.<br />

Anode Casting<br />

The blister is cast into anodes for electrolysis.<br />

Electrolytic Refining<br />

The copper is purified to 99.99% by<br />

electrolysis. The production route described<br />

in Figure 2.3 shows the progression from<br />

a rock containing about 0.2% copper to a<br />

copper cathode of 99.99% purity.<br />

Leaching<br />

Leaching offers an alternative to copper mining.<br />

First, the ore is treated with dilute sulphuric<br />

acid. This trickles slowly down through the ore,<br />

over a period of months, dissolving copper to<br />

form a weak solution of copper sulphate.<br />

The copper is then recovered by electrolysis.<br />

This process is known as SX-EW<br />

(solvent extraction / electrowinning).<br />

Advantages of these processes are:<br />

• Much less energy is used than in<br />

traditional mining<br />

• No waste gases are given off<br />

• Low capital investment<br />

• Ability to be operated economically on a<br />

small scale.<br />

It can be used on ore with as little as 0.1%<br />

copper - for this reason leaching extraction<br />

is growing in importance.<br />

It is estimated that in 2011 SX-EW<br />

represented 17% of total copper refined<br />

production.<br />

Hydraulic Services Design Guide - 5 th Edition March 2022<br />

Chapter Two<br />

10<br />

www.copper.com.au