Copper Alliance HSDG Australia

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Copper</strong> Tube Production<br />

Industry-wide, about 64% of the copper in plumbing tube is derived from recycled scrap.<br />

Raw Materials for Tube Production<br />

The production of copper plumbing tube<br />

begins with raw material: copper, which in<br />

this case may be either copper from scrap,<br />

newly refined copper cathode copper or<br />

copper ingots.<br />

The choice of raw material depends<br />

on economic factors such as cost and<br />

availability, and the technical capabilities of<br />

the plant’s melting furnaces.<br />

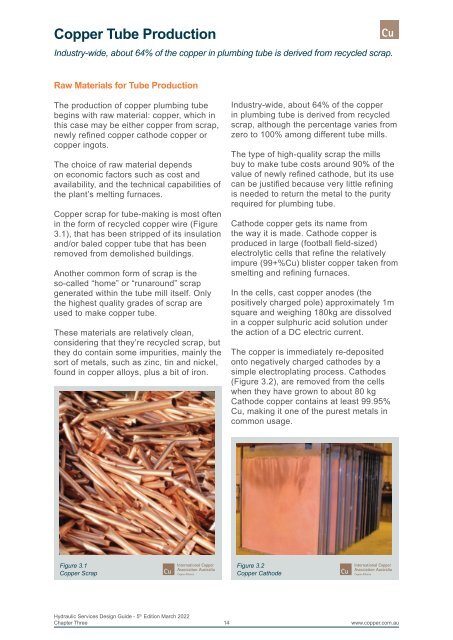

<strong>Copper</strong> scrap for tube-making is most often<br />

in the form of recycled copper wire (Figure<br />

3.1), that has been stripped of its insulation<br />

and/or baled copper tube that has been<br />

removed from demolished buildings.<br />

Another common form of scrap is the<br />

so-called “home” or “runaround” scrap<br />

generated within the tube mill itself. Only<br />

the highest quality grades of scrap are<br />

used to make copper tube.<br />

These materials are relatively clean,<br />

considering that they’re recycled scrap, but<br />

they do contain some impurities, mainly the<br />

sort of metals, such as zinc, tin and nickel,<br />

found in copper alloys, plus a bit of iron.<br />

Industry-wide, about 64% of the copper<br />

in plumbing tube is derived from recycled<br />

scrap, although the percentage varies from<br />

zero to 100% among different tube mills.<br />

The type of high-quality scrap the mills<br />

buy to make tube costs around 90% of the<br />

value of newly refined cathode, but its use<br />

can be justified because very little refining<br />

is needed to return the metal to the purity<br />

required for plumbing tube.<br />

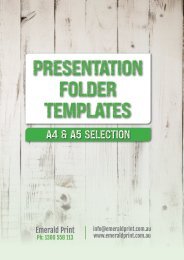

Cathode copper gets its name from<br />

the way it is made. Cathode copper is<br />

produced in large (football field-sized)<br />

electrolytic cells that refine the relatively<br />

impure (99+%Cu) blister copper taken from<br />

smelting and refining furnaces.<br />

In the cells, cast copper anodes (the<br />

positively charged pole) approximately 1m<br />

square and weighing 180kg are dissolved<br />

in a copper sulphuric acid solution under<br />

the action of a DC electric current.<br />

The copper is immediately re-deposited<br />

onto negatively charged cathodes by a<br />

simple electroplating process. Cathodes<br />

(Figure 3.2), are removed from the cells<br />

when they have grown to about 80 kg<br />

Cathode copper contains at least 99.95%<br />

Cu, making it one of the purest metals in<br />

common usage.<br />

Figure 3.1<br />

<strong>Copper</strong> Scrap<br />

Figure 3.2<br />

<strong>Copper</strong> Cathode<br />

Hydraulic Services Design Guide - 5 th Edition March 2022<br />

Chapter Three<br />

14<br />

www.copper.com.au