Copper Alliance HSDG Australia

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Annealing<br />

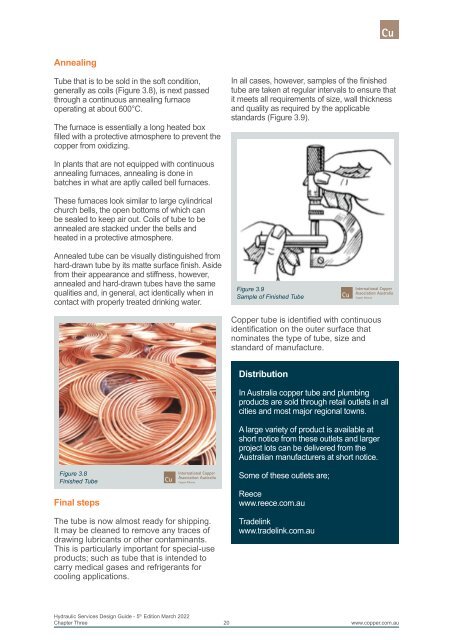

Tube that is to be sold in the soft condition,<br />

generally as coils (Figure 3.8), is next passed<br />

through a continuous annealing furnace<br />

operating at about 600°C.<br />

The furnace is essentially a long heated box<br />

filled with a protective atmosphere to prevent the<br />

copper from oxidizing.<br />

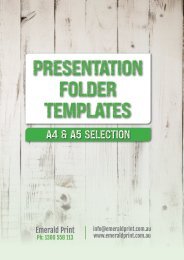

In all cases, however, samples of the finished<br />

tube are taken at regular intervals to ensure that<br />

it meets all requirements of size, wall thickness<br />

and quality as required by the applicable<br />

standards (Figure 3.9).<br />

In plants that are not equipped with continuous<br />

annealing furnaces, annealing is done in<br />

batches in what are aptly called bell furnaces.<br />

These furnaces look similar to large cylindrical<br />

church bells, the open bottoms of which can<br />

be sealed to keep air out. Coils of tube to be<br />

annealed are stacked under the bells and<br />

heated in a protective atmosphere.<br />

Annealed tube can be visually distinguished from<br />

hard-drawn tube by its matte surface finish. Aside<br />

from their appearance and stiffness, however,<br />

annealed and hard-drawn tubes have the same<br />

qualities and, in general, act identically when in<br />

contact with properly treated drinking water.<br />

Figure 3.9<br />

Sample of Finished Tube<br />

<strong>Copper</strong> tube is identified with continuous<br />

identification on the outer surface that<br />

nominates the type of tube, size and<br />

standard of manufacture.<br />

Distribution<br />

In <strong>Australia</strong> copper tube and plumbing<br />

products are sold through retail outlets in all<br />

cities and most major regional towns.<br />

A large variety of product is available at<br />

short notice from these outlets and larger<br />

project lots can be delivered from the<br />

<strong>Australia</strong>n manufacturers at short notice.<br />

Figure 3.8<br />

Finished Tube<br />

Final steps<br />

The tube is now almost ready for shipping.<br />

It may be cleaned to remove any traces of<br />

drawing lubricants or other contaminants.<br />

This is particularly important for special-use<br />

products; such as tube that is intended to<br />

carry medical gases and refrigerants for<br />

cooling applications.<br />

Some of these outlets are;<br />

Reece<br />

www.reece.com.au<br />

Tradelink<br />

www.tradelink.com.au<br />

Hydraulic Services Design Guide - 5 th Edition March 2022<br />

Chapter Three<br />

20<br />

www.copper.com.au