- Page 2:

Computer Testing Supplement for Ins

- Page 6 and 7:

Table of Contents Preface .........

- Page 8 and 9:

• A7S0, Piper PA-34-200 • A11EA

- Page 10 and 11:

Section I: Title 14 of the Code of

- Page 12 and 13:

§ 1.1 General definitions. PART 1

- Page 14 and 15:

Category B, with respect to transpo

- Page 16 and 17:

(1) An ETOPS group 1 Significant Sy

- Page 18 and 19:

Glider means a heavier-than-air air

- Page 20 and 21:

Long-range communication system (LR

- Page 22 and 23:

Overseas air transportation means t

- Page 24 and 25:

Rated maximum continuous augmented

- Page 26 and 27:

(2) With respect to turbine engines

- Page 28 and 29:

ETOPS means extended operations. EW

- Page 30 and 31:

SSALS means simplified short approa

- Page 32 and 33:

(2) May is used in a permissive sen

- Page 34 and 35:

§ 23.1 Applicability. PART 23—AI

- Page 36 and 37:

(i) The highest weight selected by

- Page 38 and 39:

[Doc. No. 4080, 29 FR 17955, Dec. 1

- Page 40 and 41:

significantly reduce the capability

- Page 42 and 43:

(1) The instrument that most effect

- Page 44 and 45:

[Amdt. 23-1, 30 FR 8261, June 29, 1

- Page 46 and 47:

(2) Each exposed sight gauge used a

- Page 48 and 49:

[Doc. No. 4080, 29 FR 17955, Dec. 1

- Page 50 and 51:

(c) Main power cables (including ge

- Page 52 and 53:

(c) Rear position light installatio

- Page 54 and 55:

system is observed from a distance,

- Page 56 and 57:

(c) For those airplanes required to

- Page 58 and 59:

(d) As used in this section: (1) BT

- Page 60 and 61:

§23.1457 Cockpit voice recorders.

- Page 62 and 63:

23.1511 Flap extended speed. (a) Th

- Page 64 and 65:

23.1541 General. (a) The airplane m

- Page 66 and 67:

(1) Each fuel tank selector control

- Page 68 and 69:

(2) Stating that recovery must be i

- Page 70 and 71:

(3) Acrobatic category airplanes. A

- Page 72 and 73:

(4) The effect on landing distances

- Page 74 and 75:

ecommended at these periods. Howeve

- Page 76 and 77:

Subpart A—General §27.1 Applicab

- Page 78 and 79:

(3) The portion of the total weight

- Page 80 and 81:

warn the pilot of the occurrence of

- Page 82 and 83:

(c) Except as provided in paragraph

- Page 84 and 85:

(2) Compliance with paragraph (a)(1

- Page 86 and 87:

§27.1365 Electric cables. (a) Each

- Page 88 and 89:

§27.1391 Minimum intensities in th

- Page 90 and 91:

where: Ie=effective intensity (cand

- Page 92 and 93:

(2) By installing a continually ene

- Page 94 and 95:

§27.1505 Never-exceed speed. (a) T

- Page 96 and 97:

(i) The maximum value determined by

- Page 98 and 99:

(b) Each arc and line must be wide

- Page 100 and 101:

(2) Oil filler openings must be mar

- Page 102 and 103:

(ii) The maximum safe wind for oper

- Page 104 and 105:

PART 39—AIRWORTHINESS DIRECTIVES

- Page 106 and 107:

PART 43—MAINTENANCE, PREVENTIVE M

- Page 108 and 109:

§ 43.5 Approval for return to serv

- Page 110 and 111:

is permanently removed from use on

- Page 112 and 113:

(b) Rotorcraft. Each person perform

- Page 114 and 115:

Appendix A to Part 43—Major Alter

- Page 116 and 117:

(2) Powerplant major repairs. Repai

- Page 118 and 119:

(31) Removing and replacing self-co

- Page 120 and 121:

(3) Internal engine—for cylinder

- Page 122 and 123:

(vi) Barometric scale error. At con

- Page 124 and 125:

Appendix F to Part 43—ATC Transpo

- Page 126 and 127:

§ 45.1 Applicability. This part pr

- Page 128 and 129:

§ 45.14 Identification of critical

- Page 130 and 131:

§ 45.25 Location of marks on fixed

- Page 132 and 133:

§ 91.1 Applicability. PART 91—GE

- Page 134 and 135:

hospital, or doctor, or other perso

- Page 136 and 137:

§§ 91.27-91.99 [Reserved] § 91.2

- Page 138 and 139:

(i) Airplanes with a third attitude

- Page 140 and 141:

(11) On and after January 1, 2004,

- Page 142 and 143:

(iv) Required to be operational by

- Page 144 and 145:

(5) Accept necessary barometric pre

- Page 146 and 147:

§ 91.407 Operation after maintenan

- Page 148 and 149:

(g) Inspection program approved und

- Page 150 and 151:

(iii) The time since last overhaul

- Page 152 and 153:

Section II: Airworthiness Directive

- Page 154 and 155:

MESSERSCHMITT-BOLKOW-BLOHM-GMBH AND

- Page 156 and 157:

AGUSTA, COSTRUZIONI AERONAUTICHE GI

- Page 158 and 159:

BEECH =============================

- Page 160 and 161:

d. Coat entire portion of bolt that

- Page 162 and 163:

AIR TRACTOR, INC. =================

- Page 164 and 165:

BENDIX ============================

- Page 166 and 167:

ENSTROM ===========================

- Page 168 and 169:

BEECH =============================

- Page 170 and 171:

BEECH AIRCRAFT CORPORATION ========

- Page 172 and 173:

PRATT & WITHEY AIRCRAFT OF CANADA,

- Page 174 and 175:

(j) Install a CT stator assembly, a

- Page 176 and 177:

Section III: Exhibits • Exhibit 1

- Page 178 and 179: Rivet identifi cation and part numb

- Page 180 and 181: Aircraft rivet identification. EXHI

- Page 182 and 183: Aircraft rivet identification. (con

- Page 184 and 185: Thickness “t” in inches No. of

- Page 186 and 187: Thickness “t” in inches No. of

- Page 188 and 189: Thickness “t” in inches No. of

- Page 190 and 191: Recommended radii for 90° bends in

- Page 192 and 193: Minimum Bend Radius for Aluminum Al

- Page 194 and 195: 3-19 RADIUS THICKNESS 1/32 .031 1/1

- Page 196 and 197: EXHIBIT 10 K-chart for determining

- Page 198 and 199: . . DATUM D C.G. L . . NOSE WHEEL T

- Page 200 and 201: COMPUTED WEIGHING POINT (C MAIN WHE

- Page 202 and 203: NOSE SCALE 464 LBS. TARE 10 LBS. We

- Page 204 and 205: FULL OIL EXHIBIT 14 Example of chec

- Page 206 and 207: FULL OIL EXHIBIT 15 Example of chec

- Page 208 and 209: 1. GENERAL. The minimum airworthine

- Page 210 and 211: Utility Category Aircraft (FAR 23)

- Page 212 and 213: EXHIBIT 17 Turnbuckle safetying gui

- Page 214 and 215: Straight-shank terminal dimensions

- Page 216 and 217: BEND RADIUS INCHES 3 — 2 — 1

- Page 218 and 219: MINIMUM BEND RADIUS (INCHES) 16 15

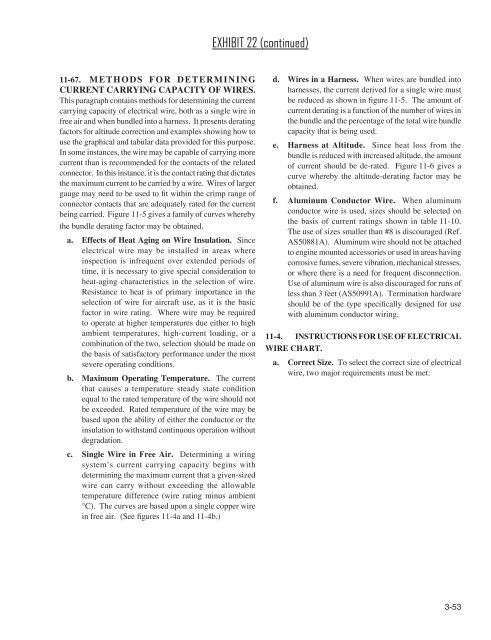

- Page 220 and 221: 211. GENERAL. This chapter contains

- Page 222 and 223: differential of 5.53 in. Hg, i.e.,

- Page 224 and 225: DC wire and circuit protector chart

- Page 226 and 227: Where: T1 T2 TR I2 Imax TABLE 11-9.

- Page 230 and 231: (1) The wire run is 15.5 feet long,

- Page 232 and 233: STEP 1: Refer to the “single wire

- Page 234 and 235: FIGURE 11-3. Conductor chart, inter

- Page 236 and 237: FIGURE 11-4b. Single copper wire in

- Page 238 and 239: FIGURE 11-6. Altitude derating curv

- Page 240 and 241: Minimum Equipment List Page MINIMUM

- Page 242 and 243: EXHIBIT 24 Bend Allowance = 2π (R

- Page 244 and 245: EXHIBIT 25 c = 2π a 2 + b 2 2 Circ

- Page 246 and 247: Section IV: Type Certificate Data S

- Page 248 and 249: TCDS BACKGROUND INFORMATION Type Ce

- Page 250 and 251: Coded Entries Many aircraft and eng

- Page 252 and 253: DEPARTMENT OF TRANSPORTATION FEDERA

- Page 254 and 255: I. Model 208, Caravan (cont’d) 3

- Page 256 and 257: II. - Model 208B, Caravan (cont’d

- Page 258 and 259: Data Pertinent to All Models (cont

- Page 260: Data Pertinent to All Models (cont

- Page 263 and 264: TCDS E4EA PAGE 2 IV. MODEL TYPE (se

- Page 265 and 266: TCDS E4EA PAGE 4 I. MODELS (Cont.))

- Page 267 and 268: TCDS E4EA PAGE 6 I. MODELS (cont.)

- Page 269 and 270: TCDS E4EA PAGE 8 II. MODELS PT6A-45

- Page 271 and 272: TCDS E4EA PAGE 10 III. MODELS (cont

- Page 273 and 274: TCDS E4EA PAGE 12 PT6A-28 PT6A-29 P

- Page 275 and 276: TCDS E4EA PAGE 14 NOTE 1.(continued

- Page 277 and 278: TCDS E4EA PAGE 16 Maximum Continuou

- Page 279 and 280:

TCDS E4EA PAGE 18 Accessory Drive P

- Page 281 and 282:

TCDS E4EA PAGE 20 NOTE 7. The maxim

- Page 283 and 284:

TCDS E4EA PAGE 22 NOTE 13. (Cont'd)

- Page 285 and 286:

P9NE 2 NOTE 2. Blade Model Designat

- Page 287 and 288:

P60GL Page 2 of 3 Certification Bas

- Page 290 and 291:

Page No. 1 2 3 Rev. No. 29 29 29 Re

- Page 292:

E-252 Page 3 The Model 0-200-C is s

- Page 295 and 296:

2A13 Page 2 of 43 Center of Gravity

- Page 297 and 298:

2A13 Page 4 of 43 Propeller Spinner

- Page 299 and 300:

2A13 Page 6 of 43 Propeller Spinner

- Page 301 and 302:

2A13 Page 8 of 43 VI - Model PA-28-

- Page 303 and 304:

2A13 Page 10 of 43 Center of Gravit

- Page 305 and 306:

2A13 Page 12 of 43 Empty Weight C.

- Page 307 and 308:

2A13 Page 14 of 43 X - Model PA-28R

- Page 309 and 310:

2A13 Page 16 of 43 Control Surface

- Page 311 and 312:

2A13 Page 18 of 43 Engine Limits Fo

- Page 313 and 314:

2A13 Page 20 of 43 Manufacturer's S

- Page 315 and 316:

2A13 Page 22 of 43 Center of Gravit

- Page 317 and 318:

2A13 Page 24 of 43 XVI - B. Model P

- Page 319 and 320:

2A13 Page 26 of 43 No. of Seats Nor

- Page 321 and 322:

2A13 Page 28 of 43 Airspeed Limits

- Page 323 and 324:

2A13 Page 30 of 43 Propeller and Pr

- Page 325 and 326:

2A13 Page 32 of 43 Engine Limits Fo

- Page 327 and 328:

2A13 Page 34 of 43 Manufacturer's S

- Page 329 and 330:

2A13 Page 36 of 43 PA-28-236: CAR 3

- Page 331 and 332:

2A13 Page 38 of 43 (Continued) MODE

- Page 333 and 334:

2A13 Page 40 of 43 NOTE 3 The Model

- Page 335 and 336:

2A13 Page 42 of 43 NOTE 20 PA-28-18

- Page 338 and 339:

DEPARTMENT OF TRANSPORTATION FEDERA

- Page 340 and 341:

II - Model 150D, Model 150E, Model

- Page 342 and 343:

IV - Model A150K, Aerobat, 2 PCLM (

- Page 344 and 345:

V - Model 150L (cont’d) Page 7 of

- Page 346 and 347:

VII - Model 150M (cont’d) Page 9

- Page 348 and 349:

IX - Model 152 (cont'd) Page 11 of

- Page 350 and 351:

X - Model A152 (cont’d) Page 13 o

- Page 352 and 353:

Data Pertinent to All Models (cont

- Page 354 and 355:

Page 17 of 19 3A19 Data Pertinent t

- Page 356:

Data Pertinent to All Models (cont

- Page 359 and 360:

E-295 Page 2 of 8 Model Lycoming O-

- Page 361 and 362:

E-295 Page 4 of 8 Certification bas

- Page 363 and 364:

E-295 Page 6 of 8 NOTE 5. These mod

- Page 365 and 366:

E-295 Page 8 of 8 NOTE 12. When equ

- Page 367 and 368:

A7CE Page 2 of 24 Propeller and or

- Page 369 and 370:

A7CE Page 4 of 24 II - Model 401, M

- Page 371 and 372:

A7CE Page 6 of 24 III - Model 402,

- Page 373 and 374:

A7CE Page 8 of 24 IV - Model 421, M

- Page 375 and 376:

A7CE Page 10 of 24 V - Model 414 (N

- Page 377 and 378:

A7CE Page 12 of 24 VI - Model 421B

- Page 379 and 380:

A7CE Page 14 of 24 VII - Model 421C

- Page 381 and 382:

A7CE Page 16 of 24 VIII - Model 414

- Page 383 and 384:

A7CE Page 18 of 24 IX - Model 402C

- Page 385 and 386:

A7CE Page 20 of 24 X - Model 425 (c

- Page 387 and 388:

A7CE Page 22 of 24 X - Model 425 (c

- Page 389 and 390:

A7CE Page 24 of 24 NOTE 3. (cont'd.

- Page 391 and 392:

3A13 Page 2 of 37 Rev. 66 I - Model

- Page 393 and 394:

3A13 Page 4 of 37 Rev. 66 II - Mode

- Page 395 and 396:

3A13 Page 6 of 37 Rev. 66 IV - Mode

- Page 397 and 398:

3A13 Page 8 of 37 Rev. 66 V - Model

- Page 399 and 400:

3A13 Page 10 of 37 Rev. 66 VII - Mo

- Page 401 and 402:

3A13 Page 12 of 37 Rev. 66 VIII - M

- Page 403 and 404:

3A13 Page 14 of 37 Rev. 66 X - Mode

- Page 405 and 406:

3A13 Page 16 of 37 Rev. 66 Model TR

- Page 407 and 408:

3A13 Page 18 of 37 Rev. 66 Model 18

- Page 409 and 410:

3A13 Page 20 of 37 Rev. 66 Data Per

- Page 411 and 412:

3A13 Page 22 of 37 Rev. 66 Data Per

- Page 413 and 414:

3A13 Page 24 of 37 Rev. 66 Data Per

- Page 415 and 416:

3A13 Page 26 of 37 Rev. 66 Long ran

- Page 417 and 418:

3A13 Page 28 of 37 Rev. 66 (3) On t

- Page 419 and 420:

3A13 Page 30 of 37 Rev. 66 Data Per

- Page 421 and 422:

3A13 Page 32 of 37 Rev. 66 XIII - M

- Page 423 and 424:

3A13 Page 34 of 37 Rev. 66 Special

- Page 425 and 426:

3A13 Page 36 of 37 Rev. 66 Oil Capa

- Page 428 and 429:

DEPARTMENT OF TRANSPORTATION FEDERA

- Page 430 and 431:

Maximum Weight S/N 34-7250215 throu

- Page 432 and 433:

5 of 16 A7SO Maximum Weight 4570 lb

- Page 434 and 435:

Maximum Weight 4773 lb. - Ramp 4750

- Page 436 and 437:

Oil Capacity 8 qts. per engine (5 q

- Page 438 and 439:

11 of 16 A7SO Control Surface Movem

- Page 440 and 441:

13 of 16 A7SO Equipment The basic r

- Page 442 and 443:

15 of 16 A7SO The Model PA-34-200T;

- Page 444 and 445:

Page No. 1 2 3 4 5 6 7 8 Rev. No. 1

- Page 446 and 447:

Page 3 A11EA 3. McCauley Model 1A10

- Page 448 and 449:

Oil capacity 6 qt. at (+39) (2 qt.

- Page 450 and 451:

UTILITY CATEGORY AA-1 AA-1A Maximum

- Page 452 and 453:

DEPARTMENT OF TRANSPORTATION FEDERA

- Page 454 and 455:

Page 3 of 15 1A6 Maximum Baggage50

- Page 456 and 457:

Page 5 of 15 1A6 Fuel Capacity 36 g

- Page 458 and 459:

Page 7 of 15 1A6 Fuel Capacity 36 g

- Page 460 and 461:

Page 9 of 15 1A6 Required Equipment

- Page 462 and 463:

Page 11 of 15 1A6 105. Vacuum pump

- Page 464 and 465:

Page 13 of 15 1A6 (w) FAA-DOA appro

- Page 466:

Page 15 of 15 1A6 (3) On left side

- Page 469 and 470:

E-273 Page 2 Model O-470-A O-470-E

- Page 471 and 472:

E-273 Page 4 NOTE 3. The following

- Page 473 and 474:

E-273 Page 6 NOTE 13. The following

- Page 475 and 476:

P57GL Page 2 of 5 Maximum Diameter

- Page 477 and 478:

P57GL Page 4 of 5 NOTE 3. Pitch Con

- Page 480 and 481:

DEPARTMENT OF TRANSPORTATION P-920

- Page 482 and 483:

Page 3 of 12 P-920, Revision 29 Max

- Page 484 and 485:

Note 2: Blade Model Designation (Se

- Page 486 and 487:

Note 9: Special Limits Page 7 of 12

- Page 488 and 489:

Page 9 of 12 P-920, Revision 29 Hub

- Page 490 and 491:

Page 11 of 12 P-920, Revision 29 Hu

- Page 492 and 493:

DEPARTMENT OF TRANSPORTATION FEDERA

- Page 494 and 495:

3 2A4 II. - Model 680-E (cont’d)

- Page 496 and 497:

5 2A4 III. - Model 720 (cont’d) L

- Page 498 and 499:

V - Model 560-F, 7 PCLM (Normal Cat

- Page 500 and 501:

9 2A4 VI - Model 680-FL (cont’d)

- Page 502 and 503:

11 2A4 VII - MODEL 680-FL(P) (cont

- Page 504 and 505:

13 2A4 IX - MODEL 680-V, 11 PCLM (N

- Page 506 and 507:

15 2A4 X - MODEL 680-W (cont’d) D

- Page 508 and 509:

17 2A4 XI - MODEL 681 (cont’d) Se

- Page 510 and 511:

19 2A4 XIII - MODEL 685 (cont’d)

- Page 512 and 513:

XIV - MODEL 690A (cont’d) Maximum

- Page 514 and 515:

23 2A4 XVI - MODEL 690C, 11 PCLM (N

- Page 516 and 517:

25 2A4 XVII - MODEL 695 (cont’d)

- Page 518 and 519:

27 2A4 XVIII - MODEL 695A (cont’d

- Page 520 and 521:

29 2A4 XIX - MODEL 690D (cont’d)

- Page 522 and 523:

31 2A4 Specifications Pertinent to

- Page 524 and 525:

33 2A4 NOTE 6: Model 680FL S/N 1471

- Page 526 and 527:

Page No. 1 2 3 4 Rev. No. 9 9 9 9 R

- Page 528 and 529:

3 E-284 NOTE 4. The "6" in the engi

- Page 530 and 531:

DEPARTMENT OF TRANSPORTATION FEDERA

- Page 532 and 533:

Page 3 of 17 A9CE II. Model A188, A

- Page 534 and 535:

III. Model 188A, AGwagon "A" & "B"

- Page 536 and 537:

V. Model 188B, AGpickup (cont'd) *E

- Page 538 and 539:

Page 9 of 17 A9CE VI. Model A188B (

- Page 540 and 541:

VII. Model T188C (cont'd) Number of

- Page 542 and 543:

Page 13 of 17 A9CE Reference weight

- Page 544 and 545:

Page 15 of 17 A9CE Fuel Flows at Fu

- Page 546:

NOTE 8. 14 volt electrical system 1

- Page 549 and 550:

3A12 2 Rev. 77 I. Model 172 (cont'd

- Page 551 and 552:

3A12 4 Rev. 77 II. Model 172A, Mode

- Page 553 and 554:

3A12 6 Rev. 77 IV. Model 172D, Mode

- Page 555 and 556:

3A12 8 Rev. 77 V. Model 172I, Model

- Page 557 and 558:

3A12 10 Rev. 77 VI. Model 172L (con

- Page 559 and 560:

3A12 12 Rev. 77 VIII. Model 172N (c

- Page 561 and 562:

3A12 14 Rev. 77 IX. Model 172P (con

- Page 563 and 564:

3A12 16 Rev. 77 DATA PERTINENT TO A

- Page 565 and 566:

3A12 18 Rev. 77 DATA PERTINENT TO A

- Page 567 and 568:

3A12 20 Rev. 77 DATA PERTINENT TO A

- Page 569 and 570:

3A12 22 Rev. 77 DATA PERTINENT TO A

- Page 571 and 572:

3A12 24 Rev. 77 DATA PERTINENT TO A

- Page 573 and 574:

3A12 26 Rev. 77 XI - Model 172R (co

- Page 575 and 576:

3A12 28 Rev. 77 Data Pertinent to M

- Page 577 and 578:

3A12 30 Rev. 77 XII - Model 172S (c

- Page 580 and 581:

DEPARTMENT OF TRANSPORTATION FEDERA

- Page 582 and 583:

3 A16CE Control Surface Movements W

- Page 584 and 585:

5 A16CE Data Pertinent to All Model

- Page 586 and 587:

7 A16CE (6) On cargo door: "Baggage

- Page 588 and 589:

9 A16CE (7) Near the manifold press

- Page 590:

11 A16CE NOTE 5. The marking of the

- Page 593 and 594:

Page 2 of 43 3A21 I - Model 210 (co

- Page 595 and 596:

Page 4 of 43 3A21 III - Model 210B,

- Page 597 and 598:

V - Model 210D (cont’d) Empty wt.

- Page 599 and 600:

Page 8 of 43 3A21 VII - Model T210F

- Page 601 and 602:

Page 10 of 43 3A21 IX - Model T210G

- Page 603 and 604:

XI - Model T210J (cont’d) Page 12

- Page 605 and 606:

Page 14 of 43 3A21 XIII Model 210K/

- Page 607 and 608:

Page 16 of 43 3A21 XIV - Model 210M

- Page 609 and 610:

Page 18 of 43 3A21 XV - Model P210N

- Page 611 and 612:

Page 20 of 43 3A21 Model 210N (cont

- Page 613 and 614:

XVII - Model P210R (cont’d) Fuel

- Page 615 and 616:

Model T210R (cont’d) Fuel Capacit

- Page 617 and 618:

Page 26 of 43 3A21 NOTE 2. (cont’

- Page 619 and 620:

Page 28 of 43 3A21 NOTE 2. (4) On f

- Page 621 and 622:

Page 30 of 43 3A21 NOTE 2. (cont’

- Page 623 and 624:

Page 32 of 43 3A21 NOTE 2. (cont’

- Page 625 and 626:

Page 34 of 43 3A21 NOTE 2. (cont’

- Page 627 and 628:

NOTE 2. (cont’d) J. (10) Page 36

- Page 629 and 630:

NOTE 2. (cont’d) J. (21) Near the

- Page 631 and 632:

Page 40 of 43 3A21 NOTE 2. (cont’

- Page 633 and 634:

Page 42 of 43 3A21 NOTE 2. K. (26)

- Page 636 and 637:

DEPARTMENT OF TRANSPORTATION FEDERA

- Page 638 and 639:

A3SO Page 3 of 31 I. - Model PA-32-

- Page 640 and 641:

A3SO Page 5 of 31 II. - Model PA-32

- Page 642 and 643:

A3SO Page 7 of 31 III. - Model PA-3

- Page 644 and 645:

A3SO Page 9 of 31 V. - Model PA-32R

- Page 646 and 647:

A3SO Page 11 of 31 VI. - Model PA-3

- Page 648 and 649:

A3SO Page 13 of 31 VII. - Model PA-

- Page 650 and 651:

A3SO Page 15 of 31 IX. - Model PA-3

- Page 652 and 653:

A3SO Page 17 of 31 X. - Model PA-32

- Page 654 and 655:

A3SO Page 19 of 31 XI. - Model PA-3

- Page 656 and 657:

A3SO Page 21 of 31 XII. - Model PA-

- Page 658 and 659:

A3SO Page 23 of 31 XIV. - Model PA-

- Page 660 and 661:

A3SO Page 25 of 31 PA-32R-301, S/N

- Page 662 and 663:

A3SO Page 27 of 31 23.1329, 23.1351

- Page 664 and 665:

A3SO Page 29 of 31 AFM Supp. VB-357

- Page 666 and 667:

A3SO Page 31 of 31 32R-8029121, 32R

- Page 668 and 669:

Section V FAA FORMS • FAA Form 33

- Page 670 and 671:

5-3 Form Approved Electronic Tracki

- Page 672 and 673:

Paperwork Reduction Act Statement:

- Page 674 and 675:

END OF SECTION 5 5-7