Mono Magazine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

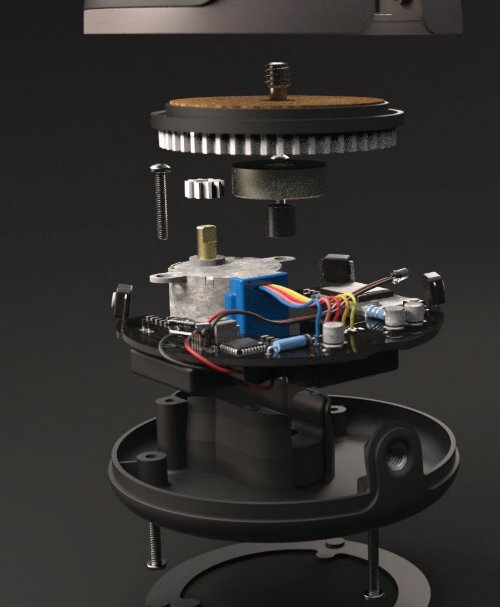

Engineering<br />

A challenge that arose was power consumption and<br />

considerations. The larger form factor of stepper motors provided<br />

them with high torque capability however, has a sub-sequential<br />

high power consumption. To successfully make the <strong>Mono</strong> device<br />

portable, a Lithium-Ion battery was to be integrated within<br />

the small form factor. In considering this, stepper motors were<br />

researched to find a model that had a low profile, high torque and<br />

low power consumption. A five volt stepper motor was found that<br />

used gears effectively to increase the torque whilst remaining<br />

compact and energy efficient. The discovery of this motor and its<br />

power requirements influenced the form factor of the <strong>Mono</strong> device<br />

as the housing had to accommodate this as well as a Lithium-Ion<br />

battery.<br />

To integrate the motor into the housing and effectively use it<br />

to its full potential, a gear ratio scheme was implemented. By<br />

introducing gears into the housing of the <strong>Mono</strong> device, the<br />

torque of the motor could be increased further whilst also<br />

reducing the power draw from the motor. For this to be effective,<br />

experimentation into gear-sets and configurations was undertaken<br />

to find the most suitable option. For this process, engineering<br />

gear generation tools were used to explore gear ratios and tooth<br />

interactions to maximise the efficiency of the system.<br />

Once developed, these were laser cut using acrylic and tested<br />

using a simple jig. A planetary gear-set was explored as the<br />

configuration to provide rotation translation effectively through<br />

the use of multiple gears and ratios. The challenge with using a<br />

planetary gear-set was the driving motor that must be positioned<br />

in the governing axis. In the formation of the <strong>Mono</strong> device, this<br />

was a problem due to the axis being occupied by the mounting<br />

threads and the camera mounting shaft. An alternative solution<br />

saw the employment of a simple 5:1 gear ratio which decentralised<br />

the motor to cater to <strong>Mono</strong>s axis considerations whilst retaining<br />

the advantages of a planetary gear-set.