TIMARIS - Singulus Technologies AG

TIMARIS - Singulus Technologies AG

TIMARIS - Singulus Technologies AG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

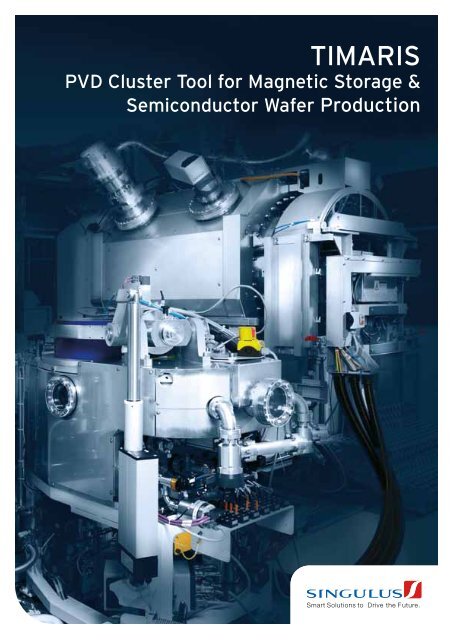

<strong>TIMARIS</strong><br />

PVD Cluster Tool for Magnetic Storage &<br />

Semiconductor Wafer Production<br />

Smart Solutions to Drive the F uture.

2<br />

<strong>TIMARIS</strong> – PVD Cluster Tool from SINGULUS<br />

SINGULUS TECHNOLOGIES<br />

(SINGULUS), founded in 1996,<br />

continues to expand its activities<br />

in the segments Semiconductor,<br />

Solar and Optical Disc.<br />

SINGULUS’ business unit Nano<br />

Deposition <strong>Technologies</strong> is a<br />

renowned manufacturer of advanced<br />

thin-film deposition equipment<br />

for MRAM and Thin-Film Head<br />

production. It is the trusted partner<br />

in the respective industry and<br />

extends its leadership in the<br />

thin-film deposition technology<br />

for Semiconductor applications.<br />

SINGULUS has already established<br />

and qualified the second generation<br />

of the <strong>TIMARIS</strong> PVD Cluster Tool<br />

platform in the market and is offering<br />

a complete portfolio of process<br />

modules for different applications.<br />

As today, seven different process<br />

modules are available to configure<br />

a <strong>TIMARIS</strong> system according to<br />

customer needs. These modules<br />

include the Multi-Target-Module<br />

(MTM), Oxidation-Process-Module<br />

(OPM), Pre-Clean-Module (PCM),<br />

Combi-Process-Module (CPM),<br />

Flexible-Target-Module (FTM) and<br />

Static-PVD-Module (sPVD-M) as<br />

well as the new Rotating-Substrate-<br />

Module (RSM).<br />

The <strong>TIMARIS</strong> PVD modules (MTM,<br />

FTM, RSM, sPVD-M) incorporate the<br />

full scope of sputtering techniques<br />

as: DC magnetron sputtering, pulsed<br />

DC magnetron sputtering and RF<br />

magnetron sputtering as well as<br />

combinations of these modes are<br />

selectable by recipe.

Multi Target Module<br />

Top: Target Drum with<br />

10 rectangular cathodes;<br />

Drum design ensures<br />

easy maintenance;<br />

Bottom: Main part of the<br />

chamber containing LDD<br />

equipment<br />

Oxidation Module<br />

Low Energy Remote<br />

Atomic Plasma Oxidation;<br />

Natural Oxidation;<br />

Soft Energy<br />

Surface Treatment<br />

Thin-Film Heads (TFH)<br />

_ High Moment Material<br />

(Writer Material)<br />

_ TMR (Reader Material)<br />

_ GMR (Reader Material)<br />

_ Deposition of seed and gap layers<br />

Semiconductor<br />

_ MRAM<br />

_ Sensors<br />

_ High-k dielectrics<br />

_ Metal gates<br />

_ Phase-change material deposition<br />

_ SAW/BAW film deposition<br />

_ In-circuit Inductors<br />

Ultra-High-Vacuum Design:<br />

High Throughput (e.g. MRAM):<br />

High Effective Up-time:<br />

Reliability:<br />

All <strong>TIMARIS</strong> applications require<br />

the deposition of ultra-thin metallic<br />

and insulating film stacks down to<br />

a thickness of one (1) nanometer<br />

and below with very precise material<br />

thickness and high uniformity<br />

specifications.<br />

The MTM is the key component<br />

of the <strong>TIMARIS</strong> platform; it<br />

incorporates the Linear Dynamic<br />

Deposition (LDD, US patent US<br />

7,799,179 B2) technology in<br />

combination with ten (10) sputter<br />

targets in one vacuum chamber.<br />

Base Pressure < 5*10-9 Torr<br />

(Deposition Chamber)<br />

up to 18 Wafer/h (see page 11)<br />

Maintenance friendly Design<br />

Solid and well Engineered Design,<br />

no fast moving Parts<br />

3<br />

Cassette Module<br />

(according to Customer<br />

Specification)<br />

Soft-Etch Module<br />

(PreClean, Surface<br />

Treatment)<br />

Transport Module<br />

(UHV wafer handler)<br />

The FTM module uses Linear<br />

Dynamic Deposition in combination<br />

with up to four cathodes. The LDD<br />

technology is especially designed<br />

for deposition of ultra-thin films,<br />

magnetic films, high-quality metallic,<br />

conductive and insulating films and is<br />

the key to deliver world class material<br />

uniformity across large wafer sizes,<br />

combined with an exceptional<br />

precise control of ultra-thin<br />

layer thickness down to 1 % of<br />

a nanometer.

4<br />

Linear Dynamic Deposition (LDD)<br />

Deposition Technique:<br />

Linear PVD Magnetron and<br />

linear movement of wafer<br />

Linear Dynamic Deposition (LDD)⋅<br />

_ Short target-substrate distance:<br />

_ Best coating efficiency<br />

_ Low cost of owner ship<br />

_ Thickness adjusted by wafer speed:<br />

_ Precise thickness control &<br />

repeatability<br />

_ Ultra thin film < 0.1 nm; smallest<br />

thickness step: < 0.01 nm<br />

_ Special LDD capabilities<br />

_ Deposition of thickness wedges<br />

_ Preparation of concentration<br />

gradients<br />

_ Multi-directional coating:<br />

_ Smooth films and interfaces<br />

_ Stationary Aligning Magnetic<br />

Field (AMF):<br />

_ Magnetic pre-alignment of easy<br />

axis direction<br />

_ Leakage field of cathode parallel<br />

to wafer travel direction:<br />

_ Ideal symmetry for magnetic<br />

film applications<br />

_ Robust and reliable design

Multi-Target-Module with<br />

10 DC/RF Cathodes<br />

Multiple film stack deposition, without<br />

the need to break ultra-high vacuum,<br />

is one of the key advantages of the<br />

MTM process module. Additional<br />

features as wafer heating for hot<br />

substrate deposition or a collinear<br />

Aligning Magnetic Field (AMF) can<br />

be activated to align the magnetic<br />

Easy Axis during deposition of<br />

ferromagnetic films.<br />

The Linear Dynamic Deposition (LDD)<br />

technology enables the capability to<br />

deposit wedge films with a different<br />

film thickness across the wafer and<br />

to deposit alloy films with adjustable<br />

concentration gradients across one<br />

wafer. Both features allow a very<br />

cost effective development of film<br />

stacks and accelerate the devices<br />

development.<br />

The LDD technology is the key to<br />

delivering world class material uniformity<br />

across large wafers and exceptional<br />

precise control of ultra thin layer<br />

thickness down to 1 %<br />

of a nanometer.<br />

Details:<br />

_ DC/RF magnetron<br />

_ All sputter deposition modes<br />

selectable by recipe for all<br />

10 cathodes<br />

_ LDD technology<br />

_ RF bias option<br />

_ Ultra-High-Vacuum technology,<br />

base pressure < 5*10 -9 Torr<br />

_ Wafer heating and cooling<br />

5<br />

Multi-Target-Module

6<br />

Flexible-Target-Module (FTM)<br />

Flexible-Target-Module with<br />

4 DC/RF Cathodes<br />

The Flexible-Target-Module (FTM)<br />

incorporates Linear Dynamic<br />

Deposition (LDD) technology in<br />

combination with up to four sputter<br />

targets in one vacuum chamber.<br />

The FTM incorporates the same<br />

functionalities like the Multi-Target-<br />

Module (MTM) as the substrate<br />

heating, the Aligning Magnetic Field<br />

and the capability to deposit wedge<br />

films with a different film thickness<br />

across the wafer and to deposit alloy<br />

films with adjustable concentration<br />

gradients across one wafer. The only<br />

difference of the FTM is the number<br />

of targets.<br />

Details:<br />

_ DC/RF magnetron<br />

_ All sputter deposition modes<br />

selectable by recipe for all<br />

4 cathodes<br />

_ LDD technology<br />

_ RF bias option<br />

_ Ultra-High-Vacuum technology,<br />

base pressure < 5*10 -9 Torr<br />

_ Wafer heating and cooling

Rotating-Substrate-Module<br />

(RSM)<br />

The Rotating-Substrate-Module<br />

(RSM) is a dedicated PVD module<br />

for R&D for different Semiconductors<br />

and other applications.<br />

Rotating-Substrate-Module (RSM)<br />

Essential technical features are:<br />

_ Up to 12 PVD cathodes in one<br />

chamber<br />

_ Rotating substrate deposition<br />

_ Co-sputtering<br />

_ DC-, pulsed DC-, RF-sputtering<br />

_ Wafer heating<br />

_ Base pressure < 10 -8 Torr<br />

_ In-situ aligning magnetic field<br />

_ Alternative equipment<br />

_ Ion source<br />

_ Surface metrology<br />

_ Low R&D costs<br />

7

8<br />

Pre-Clean-Module PCM)<br />

Pre-Clean-Module<br />

The Pre-Clean-Module (PCM) is used<br />

to clean the wafer prior to deposition.<br />

This is a standard technique employing<br />

sputter etch technology by applying<br />

RF power to the wafer. Typically the<br />

process removes residual water<br />

and other molecules and native<br />

oxides by adjusting the etching<br />

process parameters. Optionally,<br />

this module can also be equipped<br />

with an ECWR plasma source.<br />

This additional plasma source<br />

provides a more flexible etching<br />

process (higher etch rates, lower<br />

etching energies). The module<br />

geometry (large plasma source,<br />

rotational symmetric pump system)<br />

ensures a high uniformity of<br />

the etching.<br />

Details:<br />

_ Wafer cleaning, removal of native<br />

oxides by sputter etch<br />

_ ECWR plasma source as option<br />

_ Variable distance between and<br />

ion source<br />

_ Ultra-High-Vacuum technology,<br />

base pressure < 1*10 -8 Torr

Oxidation-Process-Module<br />

The Oxidation-Process-Module<br />

(OPM) is required to oxidize ultra-thin<br />

metallic films into insulating films of<br />

very high quality. Such films are<br />

required in Tunnel Magneto Resistance<br />

layer stacks as tunneling barriers.<br />

The barrier material of choice is<br />

nowadays MgO, but Al 2 O 3 and other<br />

materials have been considered.<br />

The oxidation can be performed by<br />

using a remote plasma provided by<br />

a ECWR plasma source. This source<br />

generates oxygen ions and radicals<br />

of very low adjustable energy.<br />

Alternatively, the oxidation can be<br />

performed by the so-called natural<br />

oxidation by exposing the metal film<br />

Oxidation-Process-Module (OPM)<br />

to pure oxygen of low pressure<br />

(10 Torr down to 0.1 m Torr). The<br />

module geometry (large plasma<br />

source, rotational symmetric pump<br />

system) ensures a high uniformity<br />

of the oxidation. Other applications<br />

for the OM are surface treatment<br />

of wafers by different activated<br />

gases (e.g. N 2 ).<br />

Details:<br />

_ Low energy remote plasma<br />

oxidation<br />

_ Natural oxidation<br />

_ Surface treatment by low<br />

energetic ions<br />

_ Variable distance between<br />

substrate and ion source<br />

_ Ultra-High-Vacuum technology,<br />

base pressure < 1*10 -8 Torr<br />

9

10<br />

Static-PVD-Module (sPVD-M)<br />

Static-PVD-Module<br />

The Static-PVD-Module (sPVD-M)<br />

comprises a standard magnetron<br />

cathode with optimized target<br />

utilization for high rate sputter<br />

deposition of metallic and nonconducting<br />

materials for multiple<br />

applications. DC magnetron as well<br />

as RF magnetron sputter modes are<br />

selectable through a recipe menu.<br />

The module is envisaged to be used<br />

for deposition of films with high<br />

deposition rate that do not require<br />

the extremely high uniformity that can<br />

be achieved by the LDD technology.<br />

Details:<br />

_ DC and RF sputter deposition<br />

selectable by recipe<br />

_ Variable distance between<br />

substrate and sputter target<br />

_ Ultra-High-Vacuum technology,<br />

base pressure < 1*10 -8 Torr

Combination-Process-Module<br />

The Combination-Process-Module<br />

(CPM) comprises both technologies,<br />

of oxidation and pre-clean in one<br />

module. This is a cost-efficient<br />

option, since only one module for<br />

two process steps is required. It is<br />

mainly envisaged for R&D purposes,<br />

where a high throughput is of less<br />

importance. The process performance<br />

is identical with the Oxidation-<br />

Module and the Pre-Clean-Module.<br />

Combi-Process-Module (CPM)<br />

Details:<br />

_ Low energy remote plasma<br />

oxidation<br />

_ Natural oxidation<br />

_ Surface treatment by low<br />

energetic ions<br />

_ Wafer cleaning, removal of native<br />

oxides by sputter etch<br />

_ Variable distance between<br />

substrate and ion source<br />

_ Ultra-High-Vacuum technology,<br />

base pressure < 1*10 -8 Torr<br />

11

Typical <strong>TIMARIS</strong> configuration<br />

for 300 mm MRAM wafer<br />

production with full throughput,<br />

consisting of:<br />

_ 2 Multi-Target-Modules<br />

_ 1 Oxidation-Module<br />

_ 1 Pre-Clean-Module<br />

_ 1 Transport Module (Brooks)<br />

including two FOUP Loadports<br />

_ Multiple wafer handling<br />

_ Throughput: up to 20 Wafer*<br />

_ Software integration:<br />

GEM/SECSII Interface<br />

* standard MRAM layer stack<br />

Typical <strong>TIMARIS</strong> configuration<br />

for 150/200 mm Thin-Film<br />

Head wafer production. The<br />

footprint shown is for a tool for<br />

TMR (GMR) sensor fabrication<br />

and consists of:<br />

_ 1 Multi-Target-Module<br />

_ 1 Oxidation-Module<br />

_ 1 Pre-Clean Module<br />

_ 1 Transport Module (Brooks)<br />

_ Multiple wafer handling<br />

_ Throughput: 9 wafers for a standard<br />

TMR layer stack<br />

_ Software integration:<br />

GEM/SECSII Interface<br />

_ Variants: HMM film deposition<br />

(no oxidation module)<br />

300 mm<br />

Wafer<br />

150 mm<br />

200 mm<br />

Wafer

<strong>TIMARIS</strong> configuration<br />

for 300 mm MRAM and<br />

semiconductor wafer<br />

production, consisting of:<br />

_ 1 Multi-Target-Module<br />

_ 3 Flexible-Target-Modules<br />

_ 1 Pre-Clean-Module<br />

_ 1 Oxidation-Module<br />

_ 1 Transport Module (Brooks)<br />

including three FOUP Loadports<br />

_ Multiple wafer handling<br />

_ Software integration:<br />

GEM/SECSII Interface<br />

Typical <strong>TIMARIS</strong> configuration<br />

for R&D purposes and/or low<br />

volume production. All wafer<br />

up to 300 mm wafer can be<br />

handled. The footprint shown<br />

consists of:<br />

_ 2 Rotating-Substrate-Modules<br />

_ 1 Combi-Process-Module<br />

_ 1 Transport Module<br />

all Wafer<br />

up to<br />

300 mm<br />

all Wafer<br />

up to<br />

300 mm

15<br />

Worldwide Sales & Service Network<br />

SINGULUS Serves Customers Worldwide<br />

SINGULUS Headquarters, Kahl/Main SINGULUS STANGL SOLAR, Fürstenfeldbruck<br />

SINGULUS Headquarters<br />

SINGULUS STANGL SOLAR<br />

Sales & Service Company<br />

Subsidiary

Headquarters<br />

SINGULUS TECHNOLOGIES <strong>AG</strong><br />

Hanauer Landstrasse 103<br />

D-63796 Kahl, Germany<br />

Tel. +49 6188 440-0<br />

Fax +49 6188 440-110<br />

sales@singulus.de<br />

www.singulus.de<br />

Affiliated Companies<br />

China<br />

SINGULUS MANUFACTURING<br />

GUANGZHOU LTD.<br />

Tel. +86 20 34885010<br />

frank@singulus.com.cn<br />

France<br />

SINGULUS TECHNOLOGIES<br />

FRANCE S.A.R.L.<br />

Tel. +33 3 893111-29<br />

singulus@club-internet.fr<br />

Germany<br />

SINGULUS STANGL SOLAR GMBH<br />

Tel. +49 8141 3600-0<br />

stangl@singulus.de<br />

Great Britain<br />

SINGULUS TECHNOLOGIES UK Ltd.<br />

Tel. +44 1793 7842-00<br />

brian.walsh@singulusuk.com<br />

Italy<br />

SINGULUS TECHNOLOGIES ITALIA S.R.L.<br />

Tel. +39 071 79303-12<br />

info@singulus.it<br />

Latin America<br />

SINGULUS TECHNOLOGIES<br />

LATIN AMERICA LTDA.<br />

Tel. +55 1121 6524-10<br />

rodolfo.mignone@singulus.com.br<br />

Netherlands<br />

SINGULUS TECHNOLOGIES <strong>AG</strong><br />

Branch Office Eindhoven<br />

Tel. +31 40 7501-400<br />

mastering@singulus.de<br />

Singapore<br />

SINGULUS TECHNOLOGIES<br />

ASIA PACIFIC PTE LTD.<br />

Tel. +65 674 119-12<br />

sales@singulus.com.sg<br />

Spain<br />

SINGULUS TECHNOLOGIES IBERICA S.L.<br />

Tel. +34 936 7500-25<br />

singulus@singulusib.com<br />

Taiwan<br />

SINGULUS TECHNOLOGIES TAIWAN LTD.<br />

Tel. +886 2 274833-66<br />

sales@singulus.com.tw<br />

United States and Canada<br />

SINGULUS TECHNOLOGIES INC.<br />

Tel. +1 860 68380-00<br />

sales@singulus.com<br />

05/2012 - MetaCom Printed in Germany - Technical alterations reserved