Eastern Automotive Warehousing/Auto Machinery - Autosphere

Eastern Automotive Warehousing/Auto Machinery - Autosphere

Eastern Automotive Warehousing/Auto Machinery - Autosphere

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Pierre Lalonde<br />

www.affi niagroup.com<br />

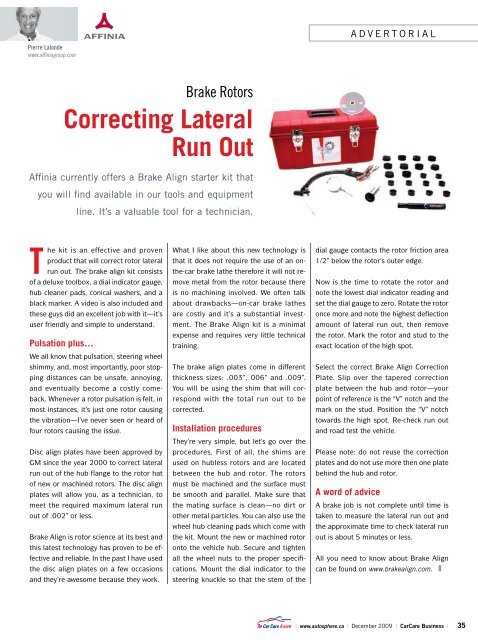

The kit is an effective and proven<br />

product that will correct rotor lateral<br />

run out. The brake align kit consists<br />

of a deluxe toolbox, a dial indicator gauge,<br />

hub cleaner pads, conical washers, and a<br />

black marker. A video is also included and<br />

these guys did an excellent job with it—it’s<br />

user friendly and simple to understand.<br />

Pulsation plus…<br />

Brake Rotors<br />

Correcting Lateral<br />

Run Out<br />

Affi nia currently offers a Brake Align starter kit that<br />

you will fi nd available in our tools and equipment<br />

line. It’s a valuable tool for a technician.<br />

We all know that pulsation, steering wheel<br />

shimmy, and, most importantly, poor stopping<br />

distances can be unsafe, annoying,<br />

and eventually become a costly comeback.<br />

Whenever a rotor pulsation is felt, in<br />

most instances, it’s just one rotor causing<br />

the vibration—I’ve never seen or heard of<br />

four rotors causing the issue.<br />

Disc align plates have been approved by<br />

GM since the year 2000 to correct lateral<br />

run out of the hub fl ange to the rotor hat<br />

of new or machined rotors. The disc align<br />

plates will allow you, as a technician, to<br />

meet the required maximum lateral run<br />

out of .002” or less.<br />

Brake Align is rotor science at its best and<br />

this latest technology has proven to be effective<br />

and reliable. In the past I have used<br />

the disc align plates on a few occasions<br />

and they’re awesome because they work.<br />

What I like about this new technology is<br />

that it does not require the use of an onthe-car<br />

brake lathe therefore it will not remove<br />

metal from the rotor because there<br />

is no machining involved. We often talk<br />

about drawbacks—on-car brake lathes<br />

are costly and it’s a substantial investment.<br />

The Brake Align kit is a minimal<br />

expense and requires very little technical<br />

training.<br />

The brake align plates come in different<br />

thickness sizes: .003”, 006” and .009”.<br />

You will be using the shim that will correspond<br />

with the total run out to be<br />

corrected.<br />

Installation procedures<br />

They’re very simple, but let’s go over the<br />

procedures. First of all, the shims are<br />

used on hubless rotors and are located<br />

between the hub and rotor. The rotors<br />

must be machined and the surface must<br />

be smooth and parallel. Make sure that<br />

the mating surface is clean—no dirt or<br />

other metal particles. You can also use the<br />

wheel hub cleaning pads which come with<br />

the kit. Mount the new or machined rotor<br />

onto the vehicle hub. Secure and tighten<br />

all the wheel nuts to the proper specifi -<br />

cations. Mount the dial indicator to the<br />

steering knuckle so that the stem of the<br />

dial gauge contacts the rotor friction area<br />

1/2” below the rotor’s outer edge.<br />

Now is the time to rotate the rotor and<br />

note the lowest dial indicator reading and<br />

set the dial gauge to zero. Rotate the rotor<br />

once more and note the highest defl ection<br />

amount of lateral run out, then remove<br />

the rotor. Mark the rotor and stud to the<br />

exact location of the high spot.<br />

Select the correct Brake Align Correction<br />

Plate. Slip over the tapered correction<br />

plate between the hub and rotor—your<br />

point of reference is the “V” notch and the<br />

mark on the stud. Position the “V” notch<br />

towards the high spot. Re-check run out<br />

and road test the vehicle.<br />

Please note: do not reuse the correction<br />

plates and do not use more then one plate<br />

behind the hub and rotor.<br />

A word of advice<br />

ADVERTORIAL<br />

A brake job is not complete until time is<br />

taken to measure the lateral run out and<br />

the approximate time to check lateral run<br />

out is about 5 minutes or less.<br />

All you need to know about Brake Align<br />

can be found on www.brakealign.com.<br />

| www.autosphere.ca | December 2009 | CarCare Business | 35