issue 1 2017

Issue 1 2017 of FoodEurope Magazine

Issue 1 2017 of FoodEurope Magazine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

show preview: interpack 39<br />

Milliken: Clear packaging solutions<br />

Leading polyolefins additives supplier Milliken has innovative<br />

solutions to showcase at the upcoming interpack <strong>2017</strong> trade fair<br />

for clear packaging applications in polypropylene and PET. Milliken<br />

will demonstrate why NX UltraClear PP is the optimal, costeffective<br />

option to help brand owners address the growing<br />

packaging trends for both resource efficiency and attentiongrabbing<br />

appeal.<br />

“NX UltraClear PP, which is polypropylene clarified with<br />

Milliken’s Millad ® NX 8000, is the ideal material to bring exceptional clarity,<br />

aesthetics, lightweighting and increased sustainability to a variety of commercial packaging<br />

applications,” according to Sami T.K. Palanisami, Milliken Commercial Manager – EMEA. “It offers<br />

the clarity of materials such as PET, while delivering specific benefits for different processes” – all of<br />

which Milliken will highlight at Interpack <strong>2017</strong> (Hall 10, Booth C32).<br />

Hall 10<br />

Stand C32<br />

Brand owners benefit from thermoformed NX UltraClear PP<br />

When it comes to thermoformed and foldable packaging, NX UltraClear PP delivers a vast range of property<br />

and performance benefits to converters and brand owners, allowing the resin to offer an all-round packaging<br />

solution. These include:<br />

Glass-like transparency – The days of thermoformed polypropylene applications with a milky appearance are<br />

gone. For thermoforming and sheet packaging, NX UltraClear PP rivals the glass-like clarity of commonly used<br />

resins such as A-PET and polystyrene, while also offering a glossier appearance than that normally associated<br />

with standard, nucleated polypropylene.<br />

Lighter weight – NX UltraClear PP has a significantly lower density than other plastic material options,<br />

reducing the weight of a thermoformed part. PP’s density of 0,9kg/m³ compared to PET’s density of<br />

1,37kg/m³ allows converters to produce significantly more trays per kilo of material. n<br />

www.milliken.com<br />

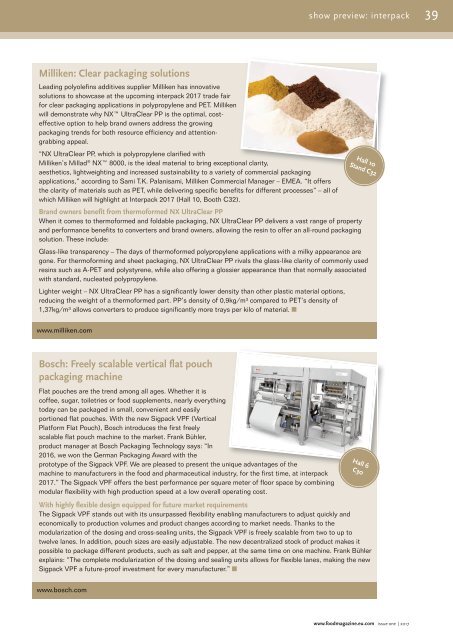

Bosch: Freely scalable vertical flat pouch<br />

packaging machine<br />

Flat pouches are the trend among all ages. Whether it is<br />

coffee, sugar, toiletries or food supplements, nearly everything<br />

today can be packaged in small, convenient and easily<br />

portioned flat pouches. With the new Sigpack VPF (Vertical<br />

Platform Flat Pouch), Bosch introduces the first freely<br />

scalable flat pouch machine to the market. Frank Bühler,<br />

product manager at Bosch Packaging Technology says: “In<br />

2016, we won the German Packaging Award with the<br />

prototype of the Sigpack VPF. We are pleased to present the unique advantages of the<br />

machine to manufacturers in the food and pharmaceutical industry, for the first time, at interpack<br />

<strong>2017</strong>.” The Sigpack VPF offers the best performance per square meter of floor space by combining<br />

modular flexibility with high production speed at a low overall operating cost.<br />

With highly flexible design equipped for future market requirements<br />

The Sigpack VPF stands out with its unsurpassed flexibility enabling manufacturers to adjust quickly and<br />

economically to production volumes and product changes according to market needs. Thanks to the<br />

modularization of the dosing and cross-sealing units, the Sigpack VPF is freely scalable from two to up to<br />

twelve lanes. In addition, pouch sizes are easily adjustable. The new decentralized stock of product makes it<br />

possible to package different products, such as salt and pepper, at the same time on one machine. Frank Bühler<br />

explains: “The complete modularization of the dosing and sealing units allows for flexible lanes, making the new<br />

Sigpack VPF a future-proof investment for every manufacturer.” n<br />

Hall 6<br />

C30<br />

www.bosch.com<br />

www.foodmagazine.eu.com <strong>issue</strong> one | <strong>2017</strong>