Practical Data for Metallurgists - Timken

Practical Data for Metallurgists - Timken

Practical Data for Metallurgists - Timken

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

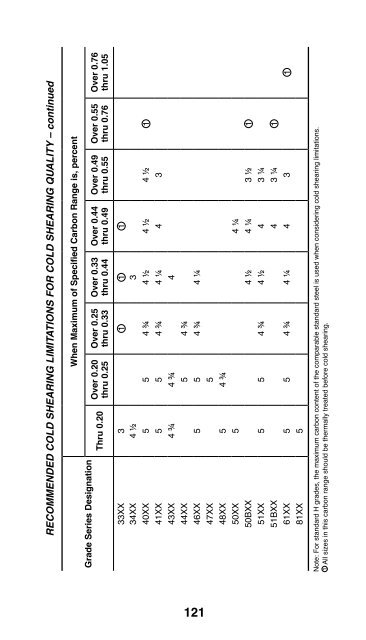

RECOMMENDED COLD SHEARING LIMITATIONS FOR COLD SHEARING QUALITY – continued<br />

When Maximum of Specified Carbon Range is, percent<br />

Over 0.76<br />

thru 1.05<br />

Over 0.55<br />

thru 0.76<br />

Over 0.49<br />

thru 0.55<br />

Over 0.44<br />

thru 0.49<br />

Over 0.33<br />

thru 0.44<br />

Over 0.25<br />

thru 0.33<br />

Over 0.20<br />

thru 0.25<br />

Grade Series Designation<br />

Thru 0.20<br />

33XX 3<br />

34XX 4 ½ 3<br />

40XX 5 5 4 ¾ 4 ½ 4 ½ 4 ½<br />

41XX 5 5 4 ¾ 4 ¼ 4 3<br />

43XX 4 ¾ 4 ¾ 4<br />

44XX 5 4 ¾<br />

46XX 5 5 4 ¾ 4 ¼<br />

47XX 5<br />

48XX 5 4 ¾<br />

50XX 5 4 ¼<br />

50BXX 4 ½ 4 ¼ 3 ½<br />

51XX 5 5 4 ¾ 4 ½ 4 3 ¼<br />

51BXX 4 3 ¼<br />

61XX 5 5 4 ¾ 4 ¼ 4 3<br />

81XX 5<br />

121<br />

Note: For standard H grades, the maximum carbon content of the comparable standard steel is used when considering cold shearing limitations.<br />

All sizes in this carbon range should be thermally treated be<strong>for</strong>e cold shearing.