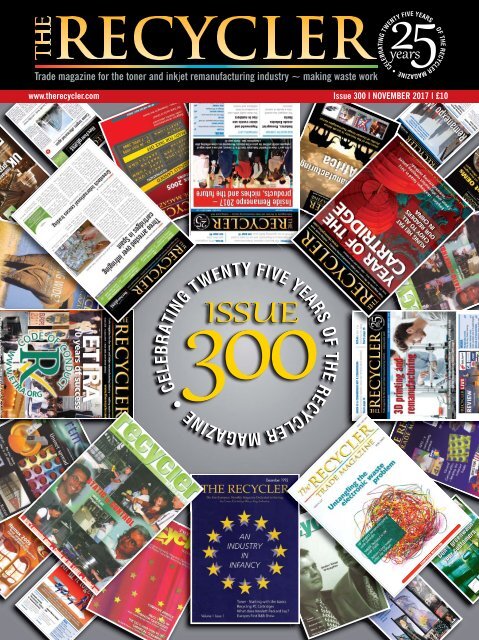

The Recycler Issue 300

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

years<br />

CELEBRATING TWENTY FIVE YEARS<br />

OF THE RECYCLER MAGAZINE<br />

•<br />

www.therecycler.com <strong>Issue</strong> <strong>300</strong> l NOVEMBER 2017 l £10<br />

CELEBRATING<br />

•<br />

•<br />

C<strong>300</strong><br />

ISSUE<br />

ELEBRATING<br />

TWENTY<br />

TWENTY<br />

FIVE YEARS OF<br />

FIVE YEARS OF<br />

THE RECYCLER MAGAZINE<br />

THE RECYCLER MAGAZINE

27.–30.1.2018, Frankfurt am Main<br />

paperworld.messefrankfurt.com<br />

Paperworld 2018 –<br />

Business matchmaking<br />

• Reach your target prospects<br />

• Maintain your customer<br />

relationships<br />

• Increase your brand awareness<br />

• Showcase your new capabilities<br />

• Paperworld – connecting your<br />

business world to people around<br />

the world<br />

Powered by<br />

Visit www.therecycler.com/live for more information

•<br />

<strong>300</strong><br />

<strong>300</strong><br />

ISSUE<br />

CELEBRATING TWENTY FIVE YEARS OF<br />

THE RECYCLER MAGAZINE<br />

Remanufacturing –<br />

<strong>The</strong> last twenty-five years<br />

I remanufactured my first cartridge in 1989<br />

having been introduced to remanufacturing<br />

by a HP sales engineer. I had<br />

bought the HP IIP printer in the US and<br />

imported it into the Middle East where I<br />

was working at the time. So I couldn’t wait<br />

to for it to empty so I could remanufacture<br />

and prove my business concept. As soon<br />

as the toner low came up, I took the<br />

cartridge apart, cleaned and refilled it and<br />

put it back together and it worked.<br />

<strong>The</strong>re were a few teething problems like the toner particles<br />

going through the vacuum cleaner and clinging to the walls<br />

of my home office. <strong>The</strong> 40 minutes it took to remanufacture<br />

the cartridge were a lot less than the time it took to clean the<br />

room and vacuum cleaner. Early days and indeed a steep<br />

learning curve.<br />

<strong>The</strong> early years<br />

In 1992 when <strong>The</strong> <strong>Recycler</strong> was first published there were<br />

about three hundred companies in the UK and another<br />

eighteen hundred or so in the rest of the European Union<br />

(EU) that were actively remanufacturing. At the time, the EU<br />

consisted of twelve member states and accessing Eastern<br />

European countries was still a challenge.<br />

<strong>The</strong> remanufacturing businesses were mostly small and<br />

employing three or four people and remanufacturing<br />

mainly CX/SX/ LX cartridges, some IBM 4019’s and Kyocera<br />

DK3 and DK5 drum units and less than a thousand<br />

cartridges a month.<br />

<strong>The</strong> market was small, but growing. A new laser printer<br />

David Connett<br />

Creative Partner at Connett and Unland<br />

GbR<br />

was a significant investment and not every<br />

business had one. Typewriters, dot matrix<br />

and golf ball printers were very much the<br />

mainstay office printer and the ribbon<br />

companies had the advantage. <strong>The</strong>y knew<br />

the market and quickly added remanufactured<br />

laser cartridges to their catalogues.<br />

<strong>The</strong> challenge was finding customers that<br />

used laser printers, and this invariably<br />

meant picking up the phone book and<br />

calling each company and asking the<br />

question “do you have a laser printer?” If they had, you knew,<br />

if they didn’t, you might end up explaining what they were<br />

and how they worked.<br />

<strong>The</strong> sales strategy was simple. <strong>The</strong> cartridges are<br />

expensive and can be refilled, and you save money, it’s good<br />

for the environment, and you could tailor the cartridge to suit<br />

a particular requirement. For instance, graphic designers<br />

wanted a very dark print for producing camera-ready copy<br />

for advertising etc. and would pay a premium.<br />

It was a regular practice to buy a new OEM cartridge,<br />

remove the OEM OPC and replace it with a Dainippon OPC<br />

that gave a dark print. Ideal for graphic designers and<br />

profitable for remanufacturers. <strong>The</strong> OEM cartridge was £70<br />

($92/ €78), and the Dainippon drum was £20 ($26/ €22),<br />

labour and packaging was another £8 ($10/ €9). A £98<br />

($129/ €109) cartridge that you could sell on for £140 ($184/<br />

€156). You made a good profit, and you had a new OEM<br />

OPC as a spare.<br />

Apart from Lexmark, the OEMs didn’t remanufacture<br />

cartridges although HP did dip their toe in the water with a<br />

THE RECYCLER • ISSUE <strong>300</strong> • NOVEMBER 2017<br />

3

FEATURE: Remanufacturing – <strong>The</strong> last twenty-five years<br />

remanufactured SX cartridge. Thankfully it was poorly made,<br />

and it never took off! Later a few OEMs introduced a<br />

“compatible” range of cartridges for HP printers.<br />

Enter inkjet<br />

Inkjet emerged into the market a few years after laser and<br />

soon became to the home solution of choice because it was<br />

cheaper to buy an inkjet printer even though the cost per<br />

page was significantly higher. <strong>The</strong> ubiquitous 26A cartridge<br />

was the money maker. I recall receiving a request from a<br />

major brand to source ten thousand OEM 26A cartridges. At<br />

the time, you could buy them at about $10.50 (€8.88) each in<br />

the USA, but I didn’t have a spare $105,000 (€88,000) in the<br />

bank. So, I did what every good salesperson does, I<br />

increased the price to $12.95 (€10.95) each and said it was<br />

payment with order, thinking they wouldn’t go for it. I faxed<br />

over the quote and thought I would hear no more, but three<br />

days later my bank manager phones and tells me that I have<br />

just received $129,500 (€109,600) in my bank account. So, I<br />

bought the cartridges and shipped them to the customer<br />

along with the invoice to reconcile the transaction. Ten days<br />

later I received another $129,500 (€109,600). Yes, they paid<br />

twice, and it took almost a year for them to accept that they<br />

had made a mistake and take the money back. This doesn’t<br />

happen anymore!<br />

Empties and IP<br />

Sourcing empties was a challenge, and it was common to<br />

have a two-price strategy depending on whether there was a<br />

cartridge supplied to remanufacture, or one needed to be<br />

sourced. Deposits were charged on cartridges to offset the<br />

cost of the OPC and cartridge.<br />

Empties were, are and always will be a challenge, but it<br />

was possible to make substantial returns on dealing in<br />

empties. Most remanufacturers had their in-house collection<br />

programmes, but the problem was always to have the<br />

empties you need when you need them. This is where the<br />

brokers were able to fill gaps in the market, and you could<br />

barter your surplus cartridges for the ones you needed.<br />

<strong>The</strong> industry was, and is, incredibly successful at collecting<br />

empties, and by the late nineties more cartridges were being<br />

collected than were needed for remanufacturing and the bulk<br />

shipping of empties to Asia and North America was standard<br />

practice.<br />

From an IP point of view remanufacturing someone’s<br />

cartridge for them was IP risk-free because of the first sale<br />

doctrine. Buying, remanufacturing and selling a cartridge<br />

carried more IP risk, but it was a known and manageable risk.<br />

Enter the new built<br />

In 2001 the Basel Action Network did a huge expose on the<br />

illegal trade in e-waste that was ending up in China for<br />

processing. In 2006 and based on a story first published in<br />

the South China Morning Post, <strong>The</strong> <strong>Recycler</strong> published an<br />

article about the dumping of waste in Guiyu, China. <strong>The</strong><br />

iconic picture of a child sat on a pile of e-waste went global.<br />

<strong>The</strong> Chinese government were quick to act and banned the<br />

import of e-waste cartridges, and they established a<br />

licensing system that is still in effect today that carefully<br />

controls the importation of cartridges. <strong>The</strong> licensing<br />

programme was limited to established companies, and the<br />

effect was to limit the growth of remanufacturing in China.<br />

For Chinese companies that couldn’t source enough<br />

empties for remanufacturing a new source of newly made<br />

empties appeared on the market. <strong>The</strong>se newly built empties<br />

were sold on the Chinese domestic market and found their<br />

way into the Middle East, African and Eastern European<br />

markets and were quickly converted into new cartridges. But<br />

as replica cartridges, they clearly breached at least one or<br />

more of over seven thousand patents.<br />

Today new-build cartridges are part of the market mix, but<br />

the argument continues as to whether they infringe IP or not.<br />

<strong>The</strong> market today<br />

© 2006 Basel Action Network (BAN)<br />

<strong>The</strong> office print market is changing, and we are all printing<br />

less. <strong>The</strong> main reasons for the reduction in print are the<br />

increasing use of connected technology, but we still need to<br />

print, and the paperless office is still a long way down the<br />

road.<br />

<strong>The</strong> overall market has contracted by around 8 percent<br />

between 2014 and 2016. Within that global market<br />

contraction, the demand for OEM supplies has increased by<br />

five percent to sixty-six percent. This can be attributed to the<br />

growth of MPS and Instant Ink programmes that have grown<br />

faster than the decline in traditional transactional sales of<br />

OEM products.<br />

4 THE RECYCLER • ISSUE <strong>300</strong> • NOVEMBER 2017

“<br />

<strong>The</strong> market will continue to change, and printing<br />

won’t disappear, but some of the big brands will.<br />

“<br />

New<br />

Build<br />

12%<br />

Reman 12%<br />

Counterfeit 2%<br />

OEM 73%<br />

<strong>The</strong> next five years<br />

<strong>The</strong> market will continue to change, and printing<br />

won’t disappear, but some of the big brands will.<br />

A couple of informal surveys conducted by <strong>The</strong><br />

<strong>Recycler</strong> this year indicates that the market<br />

expects the number of major OEM brands to<br />

shrink from around twenty to around ten.<br />

[visit therecycler.com/brands/ to vote on<br />

which brands you think will disappear]<br />

<strong>The</strong> most significant change will be how you<br />

market your products. By 2020 more than half the<br />

working population will be under forty and<br />

businesses need to consider new ways of<br />

communicating to an audience where media<br />

consumption is rapid, multitasking is the norm<br />

and filtering information quickly is a necessity.<br />

Counterfeit<br />

10%<br />

2016 Market share laser<br />

<strong>The</strong> market for remanufactured products has<br />

contracted from around twenty-five percent in 2014<br />

to about eighteen percent today. While the volumes<br />

are down, there is a trend away from producing high<br />

volume, low margin cartridges to more high value,<br />

fast moving niche products. <strong>The</strong> challenge for<br />

remanufacturers is adapting to a more contractual<br />

sales model (MPS / Instant Ink) rather than the<br />

traditional transactional model.<br />

Technology is at the more prevalent than ever. In<br />

2016 HP launched a firmware upgrade that locked<br />

out most aftermarket cartridges. After a tremendous<br />

amount of media pressure, they relented and<br />

provided a rollback. Interestingly my source at HP<br />

said the upgrade had been successful and about 70 percent<br />

of printer users did not take advantage of the rollback.<br />

All of the OEMs have the technology to lock out the<br />

aftermarket, and in a declining market must be tempted to do<br />

so. <strong>The</strong> time is probably right to engage with OEMs and<br />

governments to establish a licensing system, like the auto<br />

industry, where technology can be licensed to ensure a fair<br />

and even market for all products that benefit the consumers.<br />

New<br />

Build<br />

25%<br />

Reman 7%<br />

2016 Market share Inkjet<br />

<strong>The</strong> next twenty-five years<br />

OEM 59%<br />

I hope to be around and hopefully will have got a book or two<br />

published and written my memoirs. As an industry<br />

remanufacturing is, in its broadest sense, a twenty-firstcentury<br />

core activity because societal and political pressures<br />

will ensure that everything we buy and consume can be<br />

remanufactured or reused. No-fill to landfill.<br />

R<br />

THE RECYCLER • ISSUE <strong>300</strong> • NOVEMBER 2017<br />

5

IN THIS ISSUE<br />

In this <strong>Issue</strong><br />

Remanufacturing<br />

<strong>The</strong> last twentyfive<br />

years<br />

David Connett looks back on the<br />

last twenty-five years to see how<br />

the industry has changed and<br />

where it will be going in the next<br />

twenty-five years.<br />

Starts page 3<br />

IR Italiana<br />

Riprografia 25 years<br />

in the industry<br />

IR Italiana Riprografia was<br />

founded in 1992, read about<br />

their history.<br />

Page 44<br />

3: FEATURE:<br />

Remanufacturing – <strong>The</strong> last twenty-five<br />

years<br />

World Focus<br />

8: EU confirms guidelines on remanufactured<br />

products; WISeKey prevents ink cartridge<br />

counterfeiting<br />

10: Another September 13th update disaster;<br />

Printer manufacturers face French lawsuit<br />

11: Canon settles with Amazon reseller; HP’s<br />

UAE customers still falling victim to<br />

counterfeit products<br />

12: Italian remanufacturer locked in legal battle<br />

14: Troubled Xerox faces federal lawsuit and job<br />

losses; JSC Skorpiono Takas hosts two<br />

industry seminars<br />

16: Pelikan team jets off to China in Print-Rite<br />

visit; Tesco awards DCI Blue Rating<br />

17: Inkjet Printing Bounces Back; 2018 WEEE<br />

open scope consequences<br />

City News<br />

18: Nu-Tone announces acquisition of Densi;<br />

Staples sale completed<br />

19: Restore PLC reveals half-year results;<br />

Toshiba’s struggles with chip unit sale<br />

Around the Industry<br />

20: 2017 is a fruitful year for CET Group; ITDL<br />

merges companies<br />

21: Honest Inks added to UK parliament<br />

supplier list; Microsoft Office 2007<br />

discontinued<br />

22: Italian study explores sustainable future;<br />

Armor Group uses sports to bring<br />

employees together<br />

24: Brückmann-Turbon will join the board at<br />

Turbon AG; Emery Van Donzel joins<br />

2Service; GIT achieves ISO standard<br />

26: Recycling cartridges: the privacy issue;<br />

EMEA printer shipments on the rise<br />

28: FEATURE:<br />

Twenty-five years and <strong>300</strong> editions<br />

30: FEATURE:<br />

<strong>The</strong> following story took place in 2006 and<br />

is entirely true!<br />

32: FEATURE:<br />

<strong>300</strong> issues and a reflection on the industry<br />

34: FEATURE:<br />

In the beginning… or ‘Tales of the<br />

unexpected’<br />

40: FEATURE:<br />

<strong>The</strong> <strong>Recycler</strong>: A solid rock in high seas<br />

42: FEATURE:<br />

Stranger in a strange land<br />

44: FEATURE:<br />

IR Italiana Riprografia 25 years in the<br />

industry<br />

46: FEATURE:<br />

Nubeprint - MPS is our mission<br />

48: FEATURE:<br />

wtas Carsten Weser 20 years in<br />

remanufacturing<br />

Products & Technology<br />

50: IR Italiana Riprografia announces<br />

compatible toners for Kyocera-Mita with<br />

chips; UniNet releases whole range of new<br />

products<br />

52: Aster releases Kyocera replacement toner<br />

kits; New releases from Embatex and<br />

Turbon; Mito releases new toner kits for<br />

Oki printers<br />

54: Apex releases replacement chips; Cross<br />

Imaging releases new ranges of toner<br />

6 THE RECYCLER • ISSUE <strong>300</strong> • NOVEMBER 2017

page 7<br />

AD

WORLD FOCUS<br />

visit www.therecycler.com for all the breaking news<br />

EUROPE EU Commission, Guidelines, Remanufactured Products<br />

EU confirms guidelines on remanufactured products<br />

In a letter seen by <strong>The</strong> <strong>Recycler</strong>, the EU Commission confirmed the obligations of producers of remanufactured products under<br />

Directive 2012/19/EU on waste electrical and electronic equipment (WEEE Directive).<br />

<strong>The</strong> letter states that producers of<br />

remanufactured/refilled cartridges can turn to<br />

the EU’s Blue Guide, which gives information<br />

on the implementation of the Union’s 2016<br />

EU product rules, to discover whether or not<br />

what they have manufactured is regarded as<br />

being a new product or not.<br />

According to paragraph 1.4 of the Guide, a<br />

producer is deemed to be “either a<br />

manufacturer of a finished product or a<br />

component part of a finished product,<br />

producer of any raw material, or any person<br />

who presents himself as a manufacturer (for<br />

example by affixing a trademark).”<br />

As for the products themselves, paragraph<br />

2.1 of the Guide states that “a modified<br />

product sold under the name or trademark of<br />

a natural or legal person different from the<br />

original manufacturer, should be considered<br />

as new” and goes on to say that “<strong>The</strong> person<br />

who carries out important changes to the<br />

product carries the responsibility for verifying<br />

whether or not it should be considered as a<br />

GLOBAL WISeKey, New Technology, Counterfeiting<br />

Swiss IoT and cybersecurity company,<br />

WISeKey, has announced the launch of its<br />

new WISePrint solution, “the first fully<br />

integrated platform for printing cartridges<br />

protection and anti-counterfeiting.”<br />

WISePrint, a technology developed after<br />

years of working with well-established<br />

industry companies, “takes full advantage of<br />

WISeKey’s recognised know-how and<br />

experience” and has been designed to allow<br />

printer makers to both “secure their<br />

revenue” and keep their consumers<br />

protected from counterfeit cartridges. Such<br />

counterfeit ink and toner cartridges can<br />

have severe knock-on effects, including “bad<br />

user experience, potential health issues and<br />

damaged printers”, as well as having a<br />

significant impact both on the environment<br />

and on the global printer market, with<br />

an estimated annual loss of $3 billion<br />

(€2.5 billion).<br />

Now WISeKey’s revolutionary technology<br />

will help “reduce the risk of fraud and help<br />

printer manufacturers to protect their<br />

genuine cartridges”, thanks to such features<br />

as “a cryptographic hardware secure<br />

new product in relation to the relevant Union<br />

harmonisation legislation. If the product is to<br />

be considered as new, this person becomes<br />

the manufacturer with the corresponding<br />

obligations.”<br />

If the remanufactured/refilled cartridges<br />

are judged to be new “the product has to<br />

undergo a full conformity assessment before<br />

it is made available on the market”. However,<br />

“It is up to the natural or legal person who<br />

carries out changes or has changes carried<br />

out to the product to demonstrate that not<br />

all elements of the technical documentation<br />

need to be updated. Products which have<br />

been repaired or exchanged (for example<br />

element (WISeKey’s VaultIC) placed on the<br />

container” and a “turnkey high security<br />

Public Key Infrastructure solution”, which is<br />

currently used in e-passport applications. In<br />

addition the platform comes with “options<br />

and features built to provide easy<br />

deployment of any device/printer from the<br />

plant to the field.<br />

WISePrint’s VaultIC element features “a<br />

Near Field Communication (NFC)<br />

contactless interface or an industry standard<br />

wired connection to the printer main<br />

processor”, depending on printer<br />

integration, and WISeKey’s Certificate<br />

Management System “ensures the<br />

authentication of the cartridges”. In addition<br />

users will benefit from “smart refill<br />

management and high-speed patented<br />

multi-cartridges authentication.”<br />

“We are excited to be introducing<br />

WISePrint at the right time while printer<br />

makers are looking for more efficient<br />

solutions to protect their assets,” said Carlos<br />

Moreira, Founder and CEO of WISeKey.<br />

“This solution inherits a strong track record<br />

of WISeKey as a proven provider of managed<br />

following a defect), without changing the<br />

original performance, purpose or type, are<br />

not to be considered as new”. As a result they<br />

do not “need to undergo conformity<br />

assessment again”.<br />

As to the legality of being deemed a<br />

manufacturer, in paragraph 3.1 of the Guide it<br />

says “the responsibility of the manufacturer is<br />

placed on any person who changes the<br />

intended use of a product in such a way that<br />

different essential or other legal requirements<br />

will become applicable, or substantially<br />

modifies or re-builds a product (thus creating<br />

a new product), with a view to placing it on<br />

the market or for putting it into service”.<br />

As a result of these rules, anyone who<br />

places their remanufactured or refilled<br />

cartridges on the market, using their own<br />

trademark (providing said cartridges meet<br />

the EEE definition stated in Article 3(1)(a)<br />

of the WEEE directive), are considered as<br />

EEE producers and are bound by the<br />

relevant obligations.<br />

WISeKey prevents ink cartridge counterfeiting<br />

<strong>The</strong> Swiss-based company has unveiled new WISePrint solution designed to protect ink cartridges against counterfeiting.<br />

PKI services and the Company’s award<br />

winning WISeAuthentic platform for digital<br />

brand protection. For an efficient<br />

deployment of the WISePrint solution,<br />

WISeKey also offers extensive services such<br />

as provisioning, setup in premises and<br />

consultancy.”<br />

“WISePrint offers a significant technology<br />

breakthrough compared to other anticounterfeiting<br />

solutions on the market,” said<br />

Olivier Debelleix, Director of Brand<br />

Protection & Wearable Security Business<br />

Unit for WISeKey. “<strong>The</strong> alliance of a robust<br />

hardware security expertise demonstrated<br />

by WISeKey in many government and<br />

banking success stories, and the Company’s<br />

managed PKI platform that permits a real<br />

time tracking of the fraud, makes WISePrint<br />

‘<strong>The</strong> Solution’ to protect printer makers’<br />

from counterfeiting.”<br />

8 THE RECYCLER • ISSUE <strong>300</strong> • NOVEMBER 2017

WORLD FOCUS<br />

visit www.therecycler.com for all the breaking news<br />

GLOBAL HP, Firmware Update<br />

Another September 13th update disaster<br />

HP’s latest security update is preventing third-party cartridges from functioning, prompting a slew of ‘Cartridge Problem’ errors.<br />

This new release from HP is the latest in a<br />

series of firmware-related issues reported on<br />

by <strong>The</strong> <strong>Recycler</strong>, such as the security update<br />

in 2016 which prompted widespread<br />

criticism and complaints from customers. In<br />

the wake of this technical debacle, HP<br />

apologised to its consumers but confirmed<br />

that it “will block non-HP cartridges again in<br />

the future”.<br />

Now history seems to be repeating itself<br />

with HP’s release of a new security update on<br />

13 September 2017, exactly a year since the<br />

previous one which caused such uproar.<br />

This new security update, which is an<br />

update for HP’s Officejet printers, “appears<br />

to block third-party ink from functioning<br />

correctly” according to an article by Martin<br />

Brinkman on ghacks.net. As a result, while<br />

some cartridges may still be accepted, many<br />

consumers are being faced with the following<br />

message on their printers:<br />

‘One or more cartridges appear to be<br />

damaged. Remove them and replace with<br />

new cartridges.’<br />

Some of the printer models that are being<br />

affected include the HP Officejet Pro 6200<br />

Series, the HP Officejet 6800 series and the<br />

HP Officejet Pro 8600 series, to name a few.<br />

Different from the last security update,<br />

which locked out third-party consumables,<br />

this time consumers who are encountering<br />

difficulties with their remanufactured<br />

cartridges can resolve the issue by<br />

downloading the new firmware from HP’s<br />

support page.<br />

EUROPE France, OEMs, Legal<br />

Printer manufacturers face French lawsuit<br />

Executives from HP, Canon, Epson and Brother could be handed a prison sentence and all companies face hefty fines if found guilty.<br />

Environmental association, Halte à<br />

l’Obsolescence Programmée (Stop Planned<br />

Obsolescence) announced this week that<br />

four global printing manufacturers face a<br />

criminal lawsuit in France over claims that<br />

they deliberately limit the lifespan of<br />

their machines.<br />

<strong>The</strong> association brought the lawsuit to the<br />

Court of the Republic of Nanterre, in<br />

accordance with new legislation that was<br />

introduced by France to ensure that<br />

household appliances are more durable and<br />

long-lasting. It is the first case to arise as a<br />

result of the 2015 legislation.<br />

As a result of the new law, executives from<br />

the four printer manufacturers face a<br />

maximum sentence of two years in prison<br />

and will also be handed a maximum fine of<br />

€<strong>300</strong>,000 ($354,414) if found guilty. In<br />

addition, the companies could be fined five<br />

percent of the average annual revenue they<br />

have received over the previous three years.<br />

<strong>The</strong> French environmental association<br />

says that HP, Canon, Epson and Brother<br />

“have all broken the law by<br />

encouraging consumers to<br />

buy new printers instead of<br />

prolonging the lives of their<br />

old ones.”<br />

Laetitia Vasseur, founder of<br />

the association, stated, “<strong>The</strong><br />

association was alerted by<br />

numerous people scandalised<br />

by the short lifespan of printers and<br />

ink cartridges. We have reason to believe<br />

there is truly a problem.” <strong>The</strong> association’s<br />

lawyer, Emile Meunier, said, “Millions of<br />

French print owners could be wronged.”<br />

Epson is a particular focus of the lawsuit,<br />

with the association claiming that its ink<br />

cartridges had been programmed to stop<br />

working when 20 percent of the ink still<br />

remained. <strong>The</strong> lawsuit also alleges a similar<br />

issue with the company’s ink pads,<br />

declaring, “<strong>The</strong> price of repairing or<br />

changing the ink pad (is) roughly the same<br />

as the price of buying a new printer.”<br />

Stop Planned Obsolescence has also<br />

denounced a continuous<br />

increase in the price of<br />

cartridges, with the ink costing<br />

twice as much as Chanel<br />

No 5 perfume, as well as<br />

denouncing the willingness of<br />

manufacturers to hinder the<br />

use of generic cartridges that<br />

are most cost effective for<br />

consumers.<br />

To date, Epson has offered no comment<br />

in response to the claims, and Brother<br />

and HP have also declined to comment on<br />

the lawsuit.<br />

Canon has stated to <strong>The</strong> Times that it<br />

would “co-operate with the authorities and<br />

that it was committed to sustainable<br />

economic growth.”<br />

Stop Planned Obsolescence has declared<br />

that it is now up to the Prosecutor to decide<br />

what action to take. If there is no<br />

prosecution, the association plans to file a<br />

civil action directly with the examining<br />

magistrate.<br />

27.–30.1.2018, Frankfurt am Main<br />

paperworld.messefrankfurt.com<br />

Remanexpo: Product Group<br />

Connecting people and businesses<br />

<strong>The</strong> dedicated part of the event focused on reuse and<br />

remanufacturing of printer cartridges<br />

Powered by<br />

To find out more, visit www.therecycler.com/live<br />

10 THE RECYCLER • ISSUE <strong>300</strong> • NOVEMBER 2017

You can contact <strong>The</strong> <strong>Recycler</strong> via Twitter at @<strong>Recycler</strong>Media<br />

WORLD FOCUS<br />

EUROPE Canon, Legal, IP, Germany<br />

Canon settles with Amazon reseller<br />

<strong>The</strong> OEM announced the conclusion of its dispute with Jakubowski und Gert GbR (trading as DISA SHOP24).<br />

Canon Inc. announced that the Amazon<br />

reseller Jakubowski und Gert GbR, doing<br />

business under “DISA-SHOP24” or “DiSa<br />

GbR,” signed a cease-and-desist declaration<br />

regarding the offering and distribution of the<br />

laser toner cartridge models “DISA<br />

CE505X/CF280X” and “DISA CE505A/CF280A”.<br />

<strong>The</strong> offered cartridges of the above<br />

mentioned types allegedly were completely<br />

new cartridges without any OEM<br />

components.<br />

Canon said that the cease-and-desist<br />

declaration was signed based on the<br />

assumption of the use of the German portion<br />

of Canon’s European patent EP 2 087 407<br />

relating to a drum unit and a process<br />

IMEA HP Inc, Counterfeit, UAE<br />

cartridge. <strong>The</strong> cartridges concerned were<br />

offered via Amazon under the ASIN<br />

(Amazon Standard Identification Number)<br />

B06X3QTWNN and B01NA0BF42 and replace<br />

the cartridge models CE505X, CF280X,<br />

CE505A and CF280A compatible with HP laser<br />

beam printers.<br />

With the cease-and-desist declaration the<br />

reseller is obligated to refrain from offering<br />

and distributing the above mentioned laser<br />

toner cartridges and to render information<br />

and accounting about the offer and<br />

distribution of said laser toner cartridges.<br />

Furthermore, the reseller has accepted to<br />

pay damages to Canon and to destroy any of<br />

the above mentioned products in its<br />

possession or property. Canon confirmed<br />

Jakubowski und Gert GbR has already ceased<br />

offering the cartridge models via Amazon.<br />

HP’s UAE customers still falling victim to counterfeit products<br />

While searching for the cheapest print cartridges and toners, many people are being duped into purchasing fake print supplies.<br />

<strong>The</strong> global counterfeit market is vast and<br />

multi-faceted, dealing in everything from<br />

DVDs and fake designer handbags through<br />

to pharmaceuticals, cosmetics and various<br />

electronics.<br />

Print cartridges in particular are regularly<br />

produced by counterfeiters, due to the<br />

high demand from both individual<br />

consumers and businesses. In the UAE the<br />

prevalence of fake cartridges and toners is<br />

very high, with millions being seized over<br />

the last few years by law enforcement<br />

agencies.<br />

<strong>The</strong> OEM HP has an unfortunate history<br />

of being plagued by the sales of counterfeit<br />

products in the country, with <strong>The</strong> <strong>Recycler</strong><br />

reporting back in May 2012 that HP had<br />

been forced to conduct anti-counterfeit<br />

raids in collaboration with the country’s law<br />

enforcement agencies.<br />

However despite the OEM’s best efforts<br />

and a stringent law enforcement campaign,<br />

<strong>The</strong> Khaleej Times reported in August 2017<br />

that many UAE consumers were still being<br />

duped into purchasing fake products. An<br />

article penned by Mathew Thomas, HP’s<br />

Managing Director for the Middle East,<br />

Turkey and East Africa, examined the<br />

ramifications of purchasing fake print<br />

supplies for your machine.<br />

In the piece, Thomas pondered why<br />

people tend to take a blasé attitude toward<br />

purchasing their cartridges and toner,<br />

particularly when the effects can be so<br />

damaging. <strong>The</strong> knock-on effects of using<br />

counterfeits can be very severe, ranging<br />

from expensive re-prints, poor colour<br />

quality, toner splatter and leaking cartridges<br />

all the way through to contaminated key<br />

parts and even irreparable damage to<br />

consumer’s printer which renders its<br />

warranty void.<br />

So why do people purchase these<br />

counterfeits, and where do they find them?<br />

As Thomas reports, many counterfeits are<br />

dispensed by “dubious online sales sites<br />

and unapproved stores” and their allure<br />

arises through their cheaper price. <strong>The</strong>y<br />

can also be very difficult to spot, with many<br />

products closely resembling the genuine<br />

item, even down to specific details of<br />

packaging.<br />

Adding to the problem, the money which<br />

duped consumers spend on these<br />

counterfeit printing supplies is funnelled<br />

directly back into illegal activities and the<br />

world of organised crime, creating a<br />

vicious cycle.<br />

With counterfeit cartridges and toner<br />

being produced in such quantities, HP and<br />

the region’s law enforcement agencies have<br />

elected to take a hard line, working in close<br />

collaboration to both investigate and<br />

confiscate these fake products in a series of<br />

raids and seizures.<br />

<strong>The</strong> <strong>Recycler</strong> cited an article from <strong>The</strong><br />

Gulf News in June 2012 in which HP warned<br />

that counterfeit manufacturers could<br />

expect “relentless” action, and there is no<br />

sign of the OEM’s campaign against<br />

their stream of fake products letting up<br />

anytime soon.<br />

27.–30.1.2018, Frankfurt am Main<br />

paperworld.messefrankfurt.com<br />

Remanexpo: Business Matchmaking<br />

Connecting people and businesses<br />

<strong>The</strong> service allows you to meet new customers and<br />

suppliers at Paperworld 2017<br />

Powered by<br />

To find out more, visit www.therecycler.com/live<br />

THE RECYCLER • ISSUE <strong>300</strong> • NOVEMBER 2017<br />

11

WORLD FOCUS<br />

visit www.therecycler.com for all the breaking news<br />

EUROPE Ecoservice di Santirelli Paolo, Legal, Italy<br />

Italian remanufacturer locked in legal battle<br />

Earlier this year, PACTO, the Italian Association of Remanufacturers brought a legal action against remanufacturer Ecoservice; now<br />

Ecoservice is fighting back in the courts.<br />

In September 2017, <strong>The</strong> <strong>Recycler</strong> covered the<br />

court case that raged between PACTO, the<br />

Italian Association of Remanufacturers, and<br />

cartridge remanufacturer Ecoservice di<br />

Santarelli Paolo. PACTO had filed a complaint<br />

against Ecoservice three years previously in<br />

September 2014 at the court in Macerata,<br />

citing that, on two separate occasions in<br />

March 2014, Ecoservice had been found to be<br />

selling new cartridges as remanufactured.<br />

This was discovered when a professional<br />

investigator working with PACTO made two<br />

test cartridge purchases from Ecoservice; on<br />

both occasions, when inspected, the<br />

supposedly remanufactured cartridges were<br />

found to be new. <strong>The</strong> court was also shown<br />

sales and purchase invoices, as well as<br />

delivery notes, supporting PACTO’s claim<br />

against the remanufacturer.<br />

In translated court papers seen by <strong>The</strong><br />

<strong>Recycler</strong>, the court found in favour of the<br />

plaintiffs, and confirmed that on at least two<br />

occasions new toners that had not been<br />

remanufactured were “made to pass” for<br />

regenerated and were sold at a lower price<br />

than the price of a remanufactured toner.<br />

An act that can qualify as unfair<br />

competition conduct is one that “directly or<br />

indirectly of any other means not complying<br />

with the principles of professional and<br />

appropriate fairness to hurt the other<br />

company. “<br />

<strong>The</strong> Judge in Macerata subsequently found<br />

in favour of PACTO and awarded the<br />

association damages of €5000 ($5979). <strong>The</strong><br />

court also awarded PACTO €6569 ($7855) for<br />

costs and disbursements.<br />

PACTO, which was established in 2009 and<br />

includes Sapi, Eco–Recuperi and Microlaser<br />

Italia, aims to promote any initiative that<br />

helps to support the development and<br />

progress of the Italian remanufacturing<br />

industry. According to the association,<br />

genuine remanufacturers currently hold a 10<br />

percent share of the Italian toner cartridge<br />

market, which is currently estimated to be<br />

around nine million cartridges per year. <strong>The</strong><br />

Italian government accounts for around three<br />

million of the total market sales.<br />

Ecoservice di Santarelli Paolo was first<br />

started back in 1996 and now has a staff of<br />

over 60 employees. In 2016 the company<br />

produced 40, 000 cartridges per month, 50<br />

per cent of which were for the export market.<br />

Now, in response to the court findings,<br />

Ecoservice is launching an appeal and is also<br />

issuing a cease and desist order against<br />

PACTO and its members.<br />

In an email sent to <strong>The</strong> <strong>Recycler</strong> regarding<br />

the case, Ecoservice’s owner, Santarelli Paolo<br />

accuses PACTO and their members of<br />

“disseminating false and incorrect<br />

information about Ecoservice, based on a<br />

sentence issued by a nonprofessional judge”<br />

who “…has made grave mistakes.”<br />

Paulo also states that his company is<br />

not only a remanufacturer of printing<br />

consumables but also distributes compatible<br />

consumables and explains that in Italy the<br />

word “compatible” is used for the “new and<br />

non-original” cartridges. His email goes on to<br />

say that PACTO is an Association representing<br />

five Italian companies that produce and sell<br />

printing consumables that are both<br />

remanufactured and compatible.<br />

<strong>The</strong>se are companies in competition with<br />

Ecoservice and, according to Paolo, they have<br />

a marginal share in the Italian market of nonoriginal<br />

printing consumables. <strong>The</strong>y are also<br />

all of smaller dimensions than Ecoservice in<br />

terms of turnover, number of employees,<br />

production and commercial spaces and Paolo<br />

explained that, in the past, PACTO has moved<br />

other actions against Ecoservice, both in civil<br />

and penal law. <strong>The</strong>se have been definitively<br />

rejected by Italian judges.<br />

Regarding the specific complaint which led<br />

to the judgement and penalty, Paulo states<br />

“…that PACTO, in 2014, held out a civil suit<br />

against Ecoservice and hired a private<br />

investigator for purchasing from our<br />

production headquarter, at two occasions, nr.<br />

6 cartridges, without specifying, at the<br />

moment of the purchase, the intention to buy<br />

a “compatible” or “remanufactured” (this can<br />

be deducted by the investigators’ statements<br />

and by the investigative report, which is<br />

attached to the proceedings of PACTO). In<br />

the transport document which Pacto itself has<br />

attached in the proceeding, it is clear that the<br />

delivered cartridges were actually<br />

“compatible” and that these were not passed<br />

off as “remanufactured”, even though the<br />

cartridges were packed in non-coherent<br />

boxes (as in that moment the proper boxes<br />

were not available).”<br />

According to Paolo “<strong>The</strong> first instance<br />

judge has incredibly accepted the requests of<br />

PACTO, only the basis of the witness proof<br />

requested by the complaining party,<br />

considering it reliable despite its general<br />

nature at the time of examination by the<br />

judge and the paper documents produced by<br />

PACTO itself. That [according to Paolo]<br />

contradict their own witness and the evident<br />

contradiction between the investigative<br />

report and what has been reconstructed by<br />

Pacto during the proceedings and that the<br />

witness proofs of Ecoservice that are<br />

coherent with all objective probative<br />

elements reported as well by PACTO.”<br />

Paolo also states “A further mistake of the<br />

Judge consists in having believed in a damage<br />

based on the fact that cartridges had been<br />

sold at an anti-competitive price, lower than<br />

its market value. This is pure judiciary fantasy,<br />

since PACTO has not mentioned about nor<br />

the market prices of remanufactured nor the<br />

prices of the compatible ones in the process.<br />

<strong>The</strong>refore, the judge could not know the<br />

market price of the cartridges, object of the<br />

process matter; yet he accepted the request<br />

of PACTO.”<br />

In closing his email Paolo says, “For all<br />

these reasons, and as Ecoservice has already<br />

appealed to the Italian Justice, we believe that<br />

the statements that appeared on “<strong>The</strong><br />

<strong>Recycler</strong>”, that describe the event as an “An<br />

act that can qualify as unfair competition<br />

conduct that directly or indirectly of any<br />

other means not complying with the<br />

principles of professional and appropriate<br />

fairness to hurt the other company” are<br />

absolutely unfounded, incorrect and not<br />

permanently proven.<br />

According to Paolo, Ecoservice has issued<br />

the cease and desist order to the association<br />

PACTO alleging that their behaviour “is<br />

exceeding the limits of correctness between<br />

the competing companies.”<br />

Editor’s note: <strong>The</strong> above story is based on Mr<br />

Santarelli Paolo’s email in response to our<br />

story published on 13th September 2017 as,<br />

following our editorial guidelines, he is<br />

allowed a right of response.<br />

<strong>The</strong> <strong>Recycler</strong> editorial guidelines offer a right<br />

of reply where there is significant criticism or<br />

allegations of wrongdoing because it can help<br />

achieve accuracy in our news output.<br />

12 THE RECYCLER • ISSUE <strong>300</strong> • NOVEMBER 2017

Break through the “Wall” and get to 92%<br />

of colour users that are still buying OEM<br />

By using Hubei Dinglong<br />

toner you can give OEM<br />

quality to your customers<br />

WE OFFER<br />

• 17 Years toner Industry experience<br />

• Investment in Chemical Colour Toner<br />

Production, Q/C and R&D $50m<br />

• Equal to OEM performance in Yield<br />

and Colour Match<br />

• Total Sales in 2016 - 2000 MT Tns<br />

Available now<br />

Toner for use in:<br />

Printer Series<br />

HP1025/1215/2025<br />

HP<strong>300</strong>0/3600/3800<br />

HP3535/4025/5225<br />

HP4700/5550, HP6015<br />

Samsung CLP 326/366/430W/415N/680ND<br />

KM1600W/3730/4750/5550<br />

Dell 3110CN/3115CN<br />

Dell 2660/3760/5130/H825/3840<br />

Fuji-Xerox CP105b<br />

Xerox 6180/6280/6700<br />

Xerox WorkCentre 5605/6605<br />

Copier toner for<br />

KONICA<br />

FUJI-XEROX<br />

RICOH<br />

Call for details<br />

NEW<br />

Toner for use in<br />

Brother 8360,<br />

3170, 9200<br />

Hubei DingLong Co., Ltd<br />

Contact us: Tel: +86-27-59596631 Tel: +44 1293 783904 Fax: +86-27-59881614<br />

e-mail: yxd@dl-kg.com ianc@dl-kg.com<br />

No1 Dongjing-River Road WETDZ, Wuhan China4<strong>300</strong>57<br />

www.dinglongchem.com

WORLD FOCUS<br />

visit www.therecycler.com for all the breaking news<br />

NORTH AMERICA Business, Jobs, USA<br />

Troubled Xerox faces federal lawsuit and job losses<br />

It is a turbulent year for Xerox, as the corporation’s American unit is slapped with a federal lawsuit and is forced to cut jobs across<br />

three US states.<br />

Earlier this month, the company became the<br />

subject of a federal lawsuit filed by Californiabased<br />

avocado-grower Eco Farms, which<br />

consisted of a 22-page complaint accusing<br />

Xerox of “demanding extreme and illegal fees<br />

on its products and services.”<br />

<strong>The</strong> suit, which was filed at the U.S. District<br />

Court in Rochester, claimed Xerox had not<br />

adhered to the June 2013 agreement which<br />

was reached between the two companies, with<br />

Xerox frequently charging higher rates than<br />

those set out in the agreement.<br />

It was also alleged that Xerox “induces<br />

individuals and entities to contract for<br />

equipment and supply services without<br />

disclosing the true cost of such services” and<br />

the company was accused of burying<br />

“unconscionable and self-serving contractual<br />

provisions in its fine print”.<br />

Eco Farms concluded its contract with the<br />

corporation by paying out $24,609 (€29,073)<br />

and removed the Xerox equipment it had been<br />

using off-site with the intention that Xerox<br />

would come and collect it. However Xerox did<br />

not pick up the equipment and handed Eco<br />

Farms a bill of $11, 575 (€9,797) “for the cost of<br />

its machine”, which Eco Farms refused to pay.<br />

It was asserted by the Rochester Business<br />

Journal, which reported on the lawsuit, that<br />

the net cost of the claim could be as high<br />

as $5 million (€4.82 million), because the<br />

“requested class includes all Xerox customers<br />

in the United States that paid a fee that was not<br />

authorised in their lease agreements since 2011<br />

and all Xerox customers that paid a termination<br />

fee penalty in violation of their lease<br />

agreements since 2011.”<br />

<strong>The</strong> impact on staff<br />

Shortly after news of the lawsuit broke, Xerox<br />

announced that it would be cutting 100 jobs,<br />

with the losses affecting the company’s<br />

branches in the Rochester locale as well as in<br />

Oregon, Texas and as far afield as the United<br />

Kingdom.<br />

<strong>The</strong> company’s reason for the job losses was<br />

its implementation of an initiative to become<br />

“more efficient and responsive to our markets”.<br />

<strong>The</strong> Democrat & Chronicle revealed that the<br />

cuts had primarily been made from Xerox’s<br />

“Information Management and Finance<br />

groups”. A spokesman from Xerox, Bill McKee,<br />

stated that although some employees had had<br />

to leave their roles right away, others were able<br />

to stay on for a limited time before giving up<br />

their position.<br />

Further cuts<br />

Not long after these 100 job losses had been<br />

announced, Xerox went public once again to<br />

announce that even more employees would be<br />

stripped of their jobs, as the corporation had<br />

decided to shut down a unit at its Webster<br />

facility in New York.<br />

A local media outlet, Morningside<br />

Maryland, revealed that Xerox would be laying<br />

off 115 staff and reported that the scandalwracked<br />

corporation had “filed a Workers<br />

Adjustment and Retraining Notification”.<br />

Xerox revealed that the reason for these<br />

further cuts was “economic”.<br />

EUROPE JSC Skorpiono Takas, OOO Infotronic, Events<br />

JSC Skorpiono Takas hosts two industry seminars<br />

In partnership with its subsidiary, OOO Infotronic, the company has hosted two remanufacturing seminars, one in Lithuania and one in Belarus.<br />

Lithuanian wholesale printing consumables<br />

distributor, JSC Skorpiono Takas, along with its<br />

Belarus-based subsidiary company, OOO<br />

Infotronic, held two remanufacturing<br />

seminars last week, one in Panevezys and one<br />

in Minsk.<br />

27 companies were in attendance at the<br />

Lithuanian seminar and 42 attended the event<br />

in Minsk. During the seminars attendees were<br />

given detailed technical information about<br />

brands, and there was an in-depth discussion<br />

of IP patents and their influence in Europe.<br />

<strong>The</strong> main purpose of both seminars was to<br />

give companies a fresh insight into cartridge<br />

refilling and the advantages of remanufactured<br />

cartridges, as opposed to the distribution of<br />

cheap compatibles.<br />

Prominent seminar guests included Print-<br />

Rite, represented by Seashell Caixinmiao and<br />

Frank Fan; Imex, represented by Miguel<br />

Garcia; and Goldengreen, represented by<br />

Andrejus Jeršovas.<br />

JSC Skorpiono Takas has a long history as a<br />

seller of printing consumables, serving as a<br />

distributor in the Baltic States for 25 years and<br />

offering the “largest regional assortment of<br />

consumables from one warehouse”. Its<br />

subsidiary, OOO Infotronic, has been<br />

operating almost as long in Minsk, with a total<br />

of 23 years under its belt.<br />

27.–30.1.2018, Frankfurt am Main<br />

paperworld.messefrankfurt.com<br />

Remanexpo: Product Group<br />

Connecting people and businesses<br />

<strong>The</strong> dedicated part of the event focused on reuse and<br />

remanufacturing of printer cartridges<br />

Powered by<br />

To find out more, visit www.therecycler.com/live<br />

14 THE RECYCLER • ISSUE <strong>300</strong> • NOVEMBER 2017

WORLD FOCUS<br />

visit www.therecycler.com for all the breaking news<br />

NORTH AMERICA Print-Rite, Pelikan, Business<br />

Pelikan team jets off to China in Print-Rite visit<br />

Two months after the announcement Pelikan’s team toured the Print-Rite facilities in China to discuss and progress the<br />

integration process of the two companies.<br />

<strong>The</strong> <strong>Recycler</strong> reported earlier this year that<br />

the Chinese Print-Rite Group had acquired<br />

the assets of Pelikan Hardcopy, giving them<br />

exclusive rights to manufacture unique, highquality<br />

cartridges, using Pelikan’s brand,<br />

under a 30-year licensing agreement.<br />

<strong>The</strong> RM30 million ($6.9 million/ €6.1<br />

million) sale of Pelikan’s hardcopy supplies<br />

business included manufacturing, sales and<br />

distribution subsidiaries. Pelikan, which has<br />

built up a strong reputation in the European<br />

market, selected Print-Rite, with its 2,600<br />

patents, as the most fitting choice of partner<br />

in a move which Print-Rite’s founding<br />

chairman described as “an important<br />

strategic collaboration for the two highly<br />

reputable companies.”<br />

Now, two months after the announcement<br />

of their alliance, the two companies have<br />

begun the process of unifying their<br />

businesses, with management teams from<br />

Print-Rite and Pelikan getting the feel for<br />

each other’s facilities and new colleagues.<br />

Most recently, a press release from PRP<br />

Solutions reported that a team from Pelikan<br />

had jetted off to China to tour Print-Rite’s<br />

offices and production facilities in order to<br />

“trust each other personally and to work<br />

together as one team.”<br />

During the visit, Print-Rite’s technical<br />

experts explained their production processes<br />

and quality control measures. Print-Rite’s<br />

strategy is to invest heavily in “developing<br />

products that respect the IP of the original<br />

printer manufacturer”, a strategy approved<br />

by Pelikan.<br />

With all current trading having been<br />

transferred to two new companies, based in<br />

France and Germany, both trading under the<br />

name PRP Solutions, the union of traditional<br />

European company Pelikan and China’s<br />

Print-Rite arises from a desire to produce<br />

“more superior and reliable products”.<br />

EUROPE DCI, Tesco, Blue Rating<br />

Tesco awards DCI Blue Rating<br />

Dynamic Cassette International has recently achieved the highest audit rating from UK supermarket giant Tesco.<br />

DCI, the inkjet and toner cartridge<br />

remanufacturer, has announced that it has<br />

been awarded a blue rating from Tesco, the<br />

highest audit rating that can be achieved.<br />

<strong>The</strong> Blue Rating, which is internationally<br />

recognised, was awarded to DCI after an<br />

audit carried out by an approved Tesco<br />

auditor. During this process “everything<br />

from products, processes, materials and<br />

cleanliness is scrutinised to ensure that a<br />

supplier meets a strict criteria in order to<br />

supply Tesco stores.”<br />

DCI’s Health and Safety Manager, Sean<br />

Hill, said in response to the rating, “This<br />

rating is an amazing achievement for us,<br />

and we are really proud to obtain a<br />

standard that is only awarded to a handful<br />

of suppliers. Our partnership with Tesco<br />

has spanned more than a decade, supplying<br />

remanufactured inkjet cartridges, and we<br />

are so pleased to continue to be a supplier<br />

of the highest class.”<br />

Now that DCI has been awarded a blue<br />

rating, the company will no longer need to<br />

undergo “the more rigorous annual audit<br />

process”, instead only needing to be<br />

audited once every two years. However DCI<br />

is keen to assure consumers that it will not<br />

become complacent as a result, with Hill<br />

commenting, “Although we have always<br />

been confident in our products and<br />

processes, we know how much hard work<br />

goes into maintaining such high standards,<br />

and the rating is truly testament to the way<br />

in which we operate, and the commitment<br />

of our staff.”<br />

27.–30.1.2018, Frankfurt am Main<br />

paperworld.messefrankfurt.com<br />

Remanexpo: Product Group<br />

Connecting people and businesses<br />

<strong>The</strong> dedicated part of the event focused on reuse and<br />

remanufacturing of printer cartridges<br />

Powered by<br />

To find out more, visit www.therecycler.com/live<br />

16 THE RECYCLER • ISSUE <strong>300</strong> • NOVEMBER 2017

You can contact <strong>The</strong> <strong>Recycler</strong> via Twitter at @<strong>Recycler</strong>Media<br />

WORLD FOCUS<br />

GLOBAL Ninestar, Inkjet, Business<br />

Inkjet Printing Bounces Back<br />

After experiencing a downturn ten years ago inkjet printing has been rejuvenated and is now going from strength to strength.<br />

Ninestar’s Senior Product Manager, Jarek<br />

Yang, examines the boom to bust – and back<br />

again – projectile of inkjet printing.<br />

Charting the industry’s early successes,<br />

Yang writes, “From ancient China’s movable<br />

type printing and 1950’s modern inkjet printer<br />

prototype to 1970’s rapid development of<br />

inkjet printing, we can see that inkjet printing<br />

was booming.”<br />

However, the global financial crash of 2008<br />

dealt the industry a withering blow and for a<br />

while it seemed that inkjet printing was on its<br />

way out. But over time, as economies across<br />

the world began to right themselves and<br />

innovations in various sectors were made,<br />

new technological developments rejuvenated<br />

inkjet printing and now, as Yang explains, the<br />

industry “is entering a new age.”<br />

Part of this success is due to the<br />

improvement of manufacturing capacity and<br />

an increase in inkjet printing speed,<br />

innovations which have enabled OEMs such as<br />

Epson and HP to enter “a new profitable<br />

market.”<br />

Analysis of industry data indicates that total<br />

inkjet cartridge revenue is on the rise and that<br />

cartridges take up 58 percent of worldwide<br />

office printing revenue, leading to<br />

expectations that the business inkjet industry<br />

will continue to expand.<br />

Yang believes that business office users are<br />

looking for the following qualities in the ink<br />

they use on a daily basis:<br />

1. Fast-drying<br />

2. Water-proof<br />

3. Reliable and stable ink, to reduce<br />

maintenance costs<br />

4. Inks that can preserve office<br />

documentation<br />

Bearing these factors in mind, over the last<br />

17 years Ninestar has developed Everbrite<br />

Office, “a professional ink solution for<br />

business and office users”.<br />

Everbrite Office has been specially designed to:<br />

1. Ensure reliable printing without clogging,<br />

and provide virtually maintenance-free<br />

operation<br />

2. Be water and scratch resistant<br />

3. Be fadeless for 100 years under normal<br />

atmospheric conditions<br />

4. Offer high-quality colour performance<br />

EUROPE WEEE, Regulations<br />

2018 WEEE open scope consequences<br />

From August 2018 the EU has decided that the ten WEEE categories are to be replaced by six new categories and the scope will be<br />

expanded.<br />

<strong>The</strong> Waste Electrical and Electronic<br />

Equipment Directive, which was made an<br />

EU law in February 2003, was instituted to<br />

set collection, recycling and recovery targets<br />

for electrical goods, with the overall aim of<br />

recycling “at least 2% of electrical and<br />

electronics waste equipment by 2016”.<br />

Over the years the directive has<br />

undergone a number of revisions. Until<br />

recently it had consisted of 10 categories,<br />

including large household appliances,<br />

lighting equipment, consumer equipment<br />

and medical devices. But this is now set to<br />

change, with the EU replacing them with 6<br />

new categories:<br />

1. Temperature exchange equipment:<br />

fridges, freezers, air conditioning, etc.<br />

2. Screens, monitors, and equipment<br />

containing screens having a<br />

surface greater than 100cm²: TVs,<br />

computer monitors, etc.<br />

3. Lamps<br />

4. Large equipment (any external<br />

dimension more than 50cm):<br />

washing machines, dish washers,<br />

cooking stoge and hoven,<br />

cookers, luminaires, large<br />

printers, copying equipment, large<br />

equipment in general, etc.<br />

5. Small equipment (no external dimension<br />

more than 50cm): vacuum cleaners,<br />

calculators, video cameras, cameras, hifi<br />

equipment, watches and clocks, smoke<br />

detectors, payment systems, etc.<br />

6. Small IT and telecommunication<br />

equipment (no external dimension more<br />

than 50cm): mobile phones,<br />

tablets, routers, laptops, GPS,<br />

printers, etc<br />

As a result of these new<br />

categories, according to<br />

WEEELogic, national<br />

compliance schemes “across<br />

Europe […] are currently<br />

working on a new structure<br />

that finally allows them to report back to<br />

their national Ministry the total EEE put on<br />

the market by producers as well as WEEE<br />

collected, treated etc. according to the six<br />

new categories. <strong>The</strong>refore over the coming<br />

months we expect most national WEEE<br />

schemes to provide new price lists as well as<br />

new declaration categories and subcategories<br />

for producers.”<br />

27.–30.1.2018, Frankfurt am Main<br />

paperworld.messefrankfurt.com<br />

Remanexpo: Business Matchmaking<br />

Connecting people and businesses<br />

<strong>The</strong> service allows you to meet new customers and<br />

suppliers at Paperworld 2017<br />

Powered by<br />

To find out more, visit www.therecycler.com/live<br />

THE RECYCLER • ISSUE <strong>300</strong> • NOVEMBER 2017<br />

17

CITY NEWS<br />

OEM share prices<br />

Ocotber 2017<br />

Prices correct as of 1st October 2017<br />

COMPANY SEPT OCT<br />

Brother Industries (Yen) ¥ 2494 2608<br />

Canon (Yen) ¥ 3793 3957<br />

Dainippon Ink & (Yen) ¥ 3790 4130<br />

Chemicals<br />

Sun Chemicals parent company<br />

HP Inc. (US$) $ 19.39 17.38<br />

Hubei Dinglong (RMB) ¥ 10.17 9.93<br />

Jadi (MYR) M 0.06 0.06<br />

LG Chem (S Korean Won) W 372k 385k<br />

Matsushita Electric (Yen) ¥ 1462 1652<br />

Industrial Co.<br />

Panasonic parent company<br />

Mitsubishi Chemicals (Yen) ¥ 1007 1110<br />

Ninestar Corporation (RMB) ¥ 26.88 29.36<br />

Formerly Apex Microelectronics<br />

Oki (Yen) ¥ 1459 1497<br />

Samsung (S Korean Won) W2350k 2732k<br />

Seiko Epson (Yen) ¥ 2737 2682<br />

Turbon AG (Euro) € 10.56 11.00<br />

Xerox (US$) $ 32.21 32.71<br />

UK Waste Prices<br />

price per tonne<br />

Aluminium €10.39 8.41<br />

Plastic €68.16 71.53<br />

Paper € 1.03 1.30<br />

Currency<br />

€/US$ 1.19 1.18<br />

€/£ 0.91 0.90<br />

£/US$ 1.31 1.12<br />

Oil Price<br />

Crude oil - (US$) 54.07 56.95<br />

‘Brent Crude futures,<br />

1-Pos IPE close’ per barrel<br />

Shipping Prices<br />

Europe (Hamburg/Antwerp/ 886 714<br />

Felixstowe/Le Havre)<br />

Mediterranean (Barcelona/ 791 692<br />

Valencia/Genoa/Naples<br />

USWC (Los Angeles/ 1661 1414<br />

Long Beach/Oakland)<br />

USEC (New York/Savannah 2661 1991<br />

Norfolk/Charleston)<br />

Sources: HMRC, FT.com, krx.co.kr, tse.or.jp,<br />

Environment Exchange, packagingnews.co.uk<br />

*Brent Crude price is for October 2017<br />

Find out more about our Weekly Newsletter at www.therecycler.com/newsletters<br />

NORTH AMERICA Nu-tone, Densi, Acquisition<br />

Nu-Tone announces<br />

acquisition of Densi<br />

Nu-Tone revealed that it has now completed the acquisition of Densi’s assets.<br />

Earlier this year the news was broken that<br />

Densi, a distributor of imaging supplies and<br />

parts, had been forced to file a notice of<br />

intention due to “a downturn in the imaging<br />

aftermarket”, particular in Canada. This<br />

downturn was caused by several factors,<br />

including an increase in foreign<br />

competition, and three years of currency<br />

variations between the Canadian and<br />

US dollars.<br />

Densi had also revealed that a rebranding<br />

process which had taken place in 2015 had<br />

been “unprofitable”, despite the company<br />

devoting a significant amount of money.<br />

Finally, towards the end of May 2017<br />

<strong>The</strong> <strong>Recycler</strong> reported on the sale of<br />

Densi’s assets to four companies, among<br />

them Nu-Tone, a Quebec-based office<br />

imaging supplies business, which acquired<br />

Densi’s stock “and certain intellectual<br />

property assets.”<br />

NORTH AMERICA Staples, Sycamore Partners, Acquisition<br />

Staples sale completed<br />

“We are pleased to have completed this<br />

transaction and look forward to partnering<br />

with CEO Shira Goodman and the Staples<br />

management team as we seek to increase<br />

long-term profitability,” said Stefan Kaluzny,<br />

Managing Director of Sycamore Partners.<br />

“With the support of its dedicated associates,<br />

Staples is well-positioned to leverage its iconic<br />

brand and leading competitive position to<br />

drive even greater value for its business-tobusiness<br />

and retail customers in the U.S.<br />

and Canada.”<br />

In recent developments, Nu-Tone has<br />

formally announced its acquisition of Densi,<br />

stating that its commitment to its customers<br />

“is to ensure a smooth transition, while<br />

offering increased benefits.”<br />

Densi’s original website, www.densi.com,<br />

remains temporarily operational but the<br />

company has also developed a new website<br />

for its customers, www.nutone-densi.com,<br />

where consumers can learn all about the<br />

company’s latest products.<br />

In addition, Nu-Tone has also revealed that<br />

it has become an exclusive supplier of CET<br />

Group products in Canada. CET has an<br />

inventory of 5,000 “compatible quality<br />

products” designed for use in printers and<br />

photocopiers, including “a full range of inks”.<br />

“Nu-Tone itself is known for making and<br />

distributing high-quality remanufactured<br />

products, including EcoTone toner<br />

cartridges and Premium Toner cartridges”.<br />

Sycamore Partners announced it has completed the acquisition of Staples, Inc., which<br />

means Staples is now in private ownership.<br />

“We are excited about the tremendous<br />

opportunities ahead for the Company and our<br />

talented associates,” said Shira Goodman,<br />

Chief Executive Officer and President, Staples,<br />

Inc. “We look forward to benefitting from<br />

Sycamore Partners’ retail and wholesale<br />

experience as we work together to deliver<br />

exceptional products, services and expertise<br />

that enable businesses to work better.”<br />

As a result of the completion of the merger,<br />

the common stock of Staples will no longer be<br />

listed for trading on Nasdaq.<br />

18 THE RECYCLER • ISSUE <strong>300</strong> • NOVEMBER 2017

You can contact <strong>The</strong> <strong>Recycler</strong> via Twitter at @<strong>Recycler</strong>Media<br />

CITY NEWS<br />

EUROPE Restore PLC, Acquisitions, Financials<br />

Restore PLC reveals half-year results<br />

<strong>The</strong> UK office services provider has unveiled its unaudited results as well as news of its acquisition of two shredding businesses<br />

A summary’s of the company’s half-year<br />

achievements revealed the following changes:<br />

• Group revenue up 57 percent to £86.9<br />

million ($114.7 million/ €95.7 million)<br />

• Document Management revenue up 74<br />

percent; operating profit up 63 percent<br />

• Relocations revenue up 21 percent;<br />

operating profit up 18 percent<br />

• Group adjusted profit before tax up 59<br />

percent to £15.3 million ($20.2 million/<br />

€16.8 million)<br />

• Adjusted earnings per share up 38 percent<br />

to £0.109 ($0.143/ €0.120)<br />

• Good organic growth across both divisions<br />

• PHS Data Solutions successfully integrated<br />

• Restore Datashred performance ahead of<br />

expectations<br />

• 7 acquisitions completed since the start of<br />

the year<br />

• Interim dividend per share up 26 percent to<br />

£0.167 ($0.220/ €0.184)<br />

• Banking facilities increased and extended<br />

Charles Skinner, Chief Executive of Restore<br />

PLC, commented that, “We continued to make<br />

good operational and financial progress in the<br />

first half. In particular we delivered strong<br />

organic growth across the Group and our<br />

shredding business, which was significantly<br />

enlarged by a major acquisition in 2016,<br />

performed better than expected.<br />

“We will continue to pursue our strategy of<br />

organic and acquisitive growth and we are<br />

well positioned to gain further market share<br />

across all of our businesses.<br />

“<strong>The</strong> second half has started well and the<br />

Board expects to deliver a full year<br />

performance slightly ahead of its previous<br />

expectations.”<br />

<strong>The</strong> company’s strategy of acquisitive<br />

growth has already been put into effect this<br />

year with Restore simultaneously releasing<br />

news of its latest acquisitions along with the<br />

half-year report – the businesses involved are<br />

Lombard Recycling Limited and Data Shred<br />

Limited, two related secure shredding<br />

businesses that are located in London,<br />

grouped under the name ‘Lombard’.<br />

Describing this latest acquisition, Skinner<br />

said, “Lombard is the fifth secure shredding<br />

acquisition we have made since we acquired<br />

the Datashred business as part of our<br />

acquisition of PHS Data Solutions a year ago.<br />

It provides us with further economies of scale<br />

and extends our position as the UK’s second<br />

largest provider of secure shredding services.”<br />

Toshiba’s struggles with chip unit sale<br />

NORTH AMERICA Toshiba, Western Digital, Business<br />

<strong>The</strong> company’s plans to sell off its multi-billion dollar computer chip business have been plagued with last-minute difficulties.<br />

<strong>The</strong> Hi-Tech Facts reported last week that,<br />

while “Toshiba’s board signed off<br />

Wednesday” on selling the business to “a<br />

group led by Bain Capital Private Equity”,<br />

the deal has been complicated by the fact<br />

that Western Digital, Toshiba USA’s joint<br />

venture partner, has opposed it.<br />

Toshiba’s attempts to sell the business<br />

have been well-publicised ever since the<br />

international company first began seeking a<br />

buyer in January this year. Auditors “finally<br />

signed off in August after an investigation<br />

that centred on whether Toshiba had<br />

known in advance about the losses that<br />

emerged related to Westinghouse’s<br />

acquisition of CB&I Stone & Webster, a<br />

nuclear construction and services<br />

business.”<br />

Toshiba’s decision to sell its $18 billion<br />

(€15.1 billion) NAND memory chips<br />

business was taken at a company board<br />

meeting last Wednesday. <strong>The</strong> consortium<br />

“includes South Korea’s SK Hynix and other<br />

Japanese and foreign companies” and<br />

Toshiba released a statement saying that $3.2<br />

billion (€2.6 billion) “will be invested to<br />

stabilise the chip business operations”.<br />

Now it is reported that Bain, which has<br />

partnered with SK Hynix and “brought in<br />

deep-pocketed USA buyers of Toshiba chips<br />

such as Apple Inc. and Dell Inc. to bolster its<br />

bid” nevertheless faces last-minute problems<br />

in clinching the deal due to the opposition<br />

of Western Digital.<br />

Akira Minamikawa, principal analyst at<br />

HIS Markit, commented, “It’s clear to<br />

everyone that this Bain deal will have<br />

difficulty succeeding,” adding, “And strong<br />

players there are Samsung and Western<br />

Digital, not SK Hynix.” Only a few days later<br />

Reuters reported that Western Digital seeks<br />

injunction to block Toshiba sale.<br />

Western Digital, a US firm “which jointly<br />

invests in Toshiba’s main chip plant”, made<br />

the announcement of its pending<br />

injunction. This legal action is the latest<br />

chapter in the long tale of Toshiba’s<br />