XtraBlatt Issue 02-2017

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MENSCHEN INFORMATION<br />

2<br />

1<br />

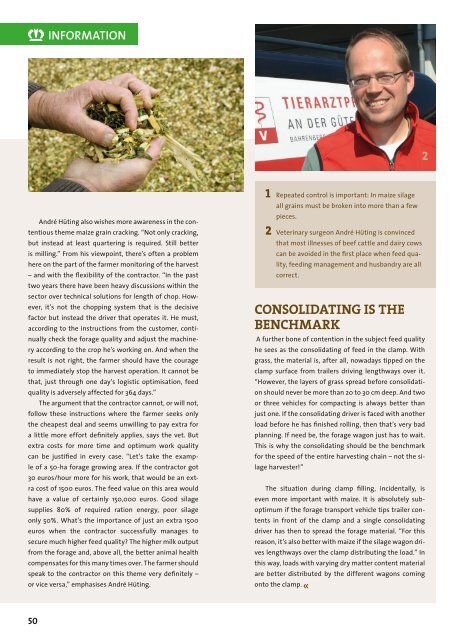

1 Repeated control is important: In maize silage<br />

all grains must be broken into more than a few<br />

André Hüting also wishes more awareness in the contentious<br />

theme maize grain cracking. “Not only cracking,<br />

but instead at least quartering is required. Still better<br />

is milling.” From his viewpoint, there’s often a problem<br />

here on the part of the farmer monitoring of the harvest<br />

– and with the flexibility of the contractor. “In the past<br />

two years there have been heavy discussions within the<br />

sector over technical solutions for length of chop. However,<br />

it’s not the chopping system that is the decisive<br />

factor but instead the driver that operates it. He must,<br />

according to the instructions from the customer, continually<br />

check the forage quality and adjust the machinery<br />

according to the crop he’s working on. And when the<br />

result is not right, the farmer should have the courage<br />

to immediately stop the harvest operation. It cannot be<br />

that, just through one day’s logistic optimisation, feed<br />

quality is adversely affected for 364 days.”<br />

The argument that the contractor cannot, or will not,<br />

follow these instructions where the farmer seeks only<br />

the cheapest deal and seems unwilling to pay extra for<br />

a little more effort definitely applies, says the vet. But<br />

extra costs for more time and optimum work quality<br />

can be justified in every case. “Let’s take the example<br />

of a 50-ha forage growing area. If the contractor got<br />

30 euros/hour more for his work, that would be an extra<br />

cost of 1500 euros. The feed value on this area would<br />

have a value of certainly 150,000 euros. Good silage<br />

supplies 80% of required ration energy, poor silage<br />

only 50%. What’s the importance of just an extra 1500<br />

euros when the contractor successfully manages to<br />

secure much higher feed quality? The higher milk output<br />

from the forage and, above all, the better animal health<br />

compensates for this many times over. The farmer should<br />

speak to the contractor on this theme very definitely –<br />

or vice versa,” emphasises André Hüting.<br />

pieces.<br />

2 Veterinary surgeon André Hüting is convinced<br />

that most illnesses of beef cattle and dairy cows<br />

can be avoided in the first place when feed quality,<br />

feeding management and husbandry are all<br />

correct.<br />

CONSOLIDATING IS THE<br />

BENCHMARK<br />

A further bone of contention in the subject feed quality<br />

he sees as the consolidating of feed in the clamp. With<br />

grass, the material is, after all, nowadays tipped on the<br />

clamp surface from trailers driving lengthways over it.<br />

“However, the layers of grass spread before consolidation<br />

should never be more than 20 to 30 cm deep. And two<br />

or three vehicles for compacting is always better than<br />

just one. If the consolidating driver is faced with another<br />

load before he has finished rolling, then that’s very bad<br />

planning. If need be, the forage wagon just has to wait.<br />

This is why the consolidating should be the benchmark<br />

for the speed of the entire harvesting chain – not the silage<br />

harvester!”<br />

The situation during clamp filling, incidentally, is<br />

even more important with maize. It is absolutely suboptimum<br />

if the forage transport vehicle tips trailer contents<br />

in front of the clamp and a single consolidating<br />

driver has then to spread the forage material. “For this<br />

reason, it’s also better with maize if the silage wagon drives<br />

lengthways over the clamp distributing the load.” In<br />

this way, loads with varying dry matter content material<br />

are better distributed by the different wagons coming<br />

onto the clamp.<br />

50