American Iron Magazine December 2017

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TECHLINE • BY DONNY PETERSEN<br />

<br />

<br />

Part II: Powertrain rigidity 1929-2018<br />

<br />

as power surges through the<br />

powertrain. Handling and vibration<br />

may seem like separate<br />

subjects, but both intertwine with the<br />

<br />

From 1929–64, classic V-twin Harley<br />

engines and transmissions bolted<br />

separately and independently to the<br />

head<br />

engine introduced in 1929, the<br />

Knuckle in 1936, and the Panhead in<br />

nents<br />

depended on correctly machined<br />

bers.<br />

All I have to say is “good luck.”<br />

Each engine and transmission with the<br />

heavy rotating clutch pack vibrated<br />

<br />

<br />

they did.<br />

A thin, stamped sheet metal chaincase<br />

shielded the primary chain, engine<br />

<br />

connecting the engine and transmis-<br />

-<br />

<br />

grating through the churning internal<br />

chain and assemblies.<br />

-<br />

<br />

<br />

comes handling impediments.<br />

In 1965, the last-year Panhead<br />

engine and transmission morphed into<br />

<br />

changes and improvements. One was<br />

<br />

cast inner and outer aluminum primary<br />

<br />

<br />

derby was incorporated to allow easy<br />

access to the clutch. Oil-impregnated<br />

-<br />

<br />

<br />

removal was necessary to service these<br />

<br />

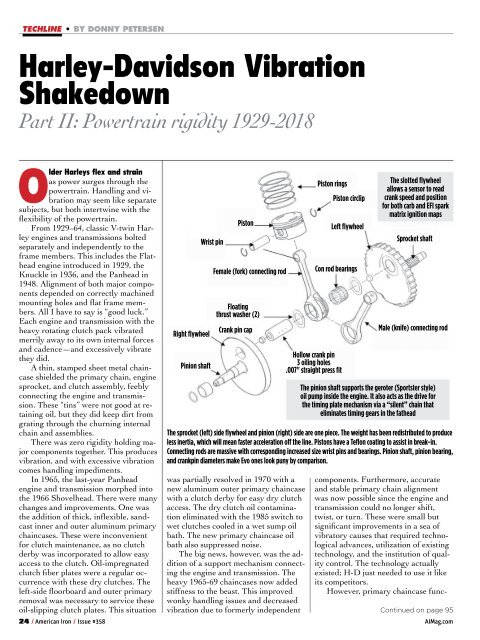

Right flywheel<br />

Pinion shaft<br />

Wrist pin<br />

The sprocket (left) side flywheel and pinion (right) side are one piece. The weight has been redistributed to produce<br />

less inertia, which will mean faster acceleration off the line. Pistons have a Teflon coating to assist in break-in.<br />

Connecting rods are massive with corresponding increased size wrist pins and bearings. Pinion shaft, pinion bearing,<br />

and crankpin diameters make Evo ones look puny by comparison.<br />

was partially resolved in 1970 with a<br />

new aluminum outer primary chaincase<br />

<br />

tion<br />

eliminated with the 1985 switch to<br />

wet clutches cooled in a wet sump oil<br />

<br />

bath also suppressed noise.<br />

-<br />

-<br />

<br />

heavy 1965-69 chaincases now added<br />

<br />

wonky handling issues and decreased<br />

<br />

Piston rings<br />

Piston circlip<br />

Left flywheel<br />

components. Furthermore, accurate<br />

and stable primary chain alignment<br />

was now possible since the engine and<br />

<br />

<br />

<br />

vibratory causes that required techno-<br />

<br />

-<br />

<br />

<br />

its competitors.<br />

-<br />

Continued on page 95<br />

24 / <strong>American</strong> <strong>Iron</strong> / Issue #358 AIMag.com<br />

Piston<br />

Female (fork) connecting rod<br />

Floating<br />

thrust washer (2)<br />

Crank pin cap<br />

Con rod bearings<br />

Hollow crank pin<br />

3 oiling holes<br />

.007" straight press fit<br />

The slotted flywheel<br />

allows a sensor to read<br />

crank speed and position<br />

for both carb and EFI spark<br />

matrix ignition maps<br />

Sprocket shaft<br />

Male (knife) connecting rod<br />

The pinion shaft supports the geroter (Sportster style)<br />

oil pump inside the engine. It also acts as the drive for<br />

the timing plate mechanism via a “silent” chain that<br />

eliminates timing gears in the fathead